Professional Documents

Culture Documents

Comparision Between NDCT and IDCT PDF

Uploaded by

kichasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparision Between NDCT and IDCT PDF

Uploaded by

kichasCopyright:

Available Formats

Comparison between Natural Draft Cooling Tower and Induced Draft Cooling Tower S.

No Natural Draft Cooling Tower 1 Works on the principle of chimney effect. Air flow is natural and based on exit and inlet conditions of air. No power required apart from pumping of water to the tower Maintenance free as far as rotary equipment are concerned Induced Draft Cooling Tower Cooling is accomplished by draught of air created by a fan. Power for fan operation is additional requirement. Regular maintenance of rotary equipment required

2 3 4

Generally operates on very low water load- Can operate at very high water loading upto 25 m3/hr/m2 for film and 19m3/hr/m2 for ing about 7.5 m3/hr/m2 max for film fill and generally upto 6 0 m3/hr/m2 for splash film. splash fills. As generally applicable to tropical conditions. Low operating fill velocities Generally operates where the load available is very near to the design heat load since at low loads the density difference becomes very low Since there is only one enclosure and number of risers are generally two with one or two main ducts, the possibility of part shut down operation of water is not logical. Higher operating fill velocities. Can operate at various load conditions.

5 6

Since there are individual risers to each cell, each cell can be considered as independent of the others. Towers with number of pumps can be operated at optimum pumping cost by shutting down pumps and cells when atmospheric conditions are suitable for the same Tower requires smaller area due to higher water loading

8 9

Tower requires greater area due to lower water loading

Larger pumping head is required to cater to Requires smaller pumping head for the large diameters at the bottom to enable same application proper air flow through the system Generally suitable for large water flows Generally suitable for larger ranges and bigger approaches than IDCT. Generally greater than 4.5 deg c Longer construction period Suitable for all water flows Suitable for lower approaches also

10 11

12

Much shorter construction period especially since work can be carried out simultaneously on 2 or more towers. FRP Pultruded, Timber, Steel and Concrete can be used as construction material Additional cells can be added or fan can be operated at higher pitch to increase capacity

13 14

Mainly built of concrete Capacity cannot be enhanced once the tower is built.

S. No Natural Draft Cooling Tower 15 Natural draught towers performance are affected greatly by wind both at discharge and inlet. Tower sizing is directly affected by relative humidity of the inlet air

Induced Draft Cooling Tower Effect of wind is far less than that of NDCT

16

RH of inlet air has very negligible effect on the tower performance once the inlet WBT is taken into consideration.

17

Difficult to dismantle due to the large size of Easier to dismantle than an NDCT the tower and affect on the nearest structures. Difficult to repair concrete at great heights Easier to repair concrete due to lower due access related issues and safety aspects heights. Possibility of unequal water and air loadings Generally 20 to 22m dimensions are largest due to very large size and huge diameter of in a IDCT and hence the tower (eg. towers are being built with unequal water distribution is not a problem diameters upto 130m or higher). Such towers could malfunction because of unequal air and water loadings due to large path of the air from periphery upto the centre of the tower Necessity for providing unequal fill distribu- Not necessary as above tion or unequal water distribution to try and ensure uniformity in air and water loadings There is requirement of major equipment like tower cranes and jump form which are expensive Cleaning and Maintenance of water distribution system is quite difficult due to the size of the structure NDCTs are not affected by recirculation and less effected by drift losses Project can be carried out with minimal equipment since it is a column / beam structure encased with walls. Comparatively easier especially if envisaged properly during engineering stage. IDCT need to be oriented correctly, designed suitably to minimize the recirculation and need to provide proper drift eliminators to avoid drift. Initial cost is much lower although cost of power needs to be considered as of today and forecast for the future for evaluation of the total cost. Suitable for all weather conditions

18

19

20

21

22

23

24

With increasing cost of construction the NDCT is at least 1.6-1.8 times in construction cost and operating cost due to higher pump head could also be substantial depending upon the design of the tower. Not very suitable for very dry climates with high dry bulb and low relative humidity since tower becomes extremely large with decreasing RH.

25

You might also like

- VRF, MPLS and MP-BGP FundamentalsDocument55 pagesVRF, MPLS and MP-BGP FundamentalsIVAN TANEV100% (2)

- 300 Excel TipsDocument5 pages300 Excel TipsGlenn96% (23)

- Health and Safety Plan TranslationDocument17 pagesHealth and Safety Plan TranslationEvaristo MudenderNo ratings yet

- AMECO Catalog For Stacker Reclaimer and ScrapperDocument33 pagesAMECO Catalog For Stacker Reclaimer and Scrapperkichas100% (3)

- TM 5-805-7 - Welding Technical Manual (US Army 1985)Document96 pagesTM 5-805-7 - Welding Technical Manual (US Army 1985)Ahmed FarazNo ratings yet

- Npti 210 MW Power Plant ManualDocument6 pagesNpti 210 MW Power Plant ManualSaiNo ratings yet

- Working Principle of Hydroelectric Power PlantDocument4 pagesWorking Principle of Hydroelectric Power PlantGummadi AmarNo ratings yet

- Generator & Exciter BasicDocument8 pagesGenerator & Exciter Basictowfiqeee100% (1)

- Abdominal Exam Guide: Palpation, Inspection & Surface MarkingsDocument4 pagesAbdominal Exam Guide: Palpation, Inspection & Surface MarkingsPhysician AssociateNo ratings yet

- Back Pressure TurbinesDocument4 pagesBack Pressure TurbinesSharath Kota100% (1)

- Knowing God Intimately Joyce Meyer Christiandiet - Com .NGDocument343 pagesKnowing God Intimately Joyce Meyer Christiandiet - Com .NGadriana mariaNo ratings yet

- Auxiliary Power Consumption Reduction in Thermal Power StationsDocument3 pagesAuxiliary Power Consumption Reduction in Thermal Power StationsbarunNo ratings yet

- Turbine Startup Modes and Initial Cold Startup ProcedureDocument15 pagesTurbine Startup Modes and Initial Cold Startup ProcedurerobiansahNo ratings yet

- Chapter 14 Governing SystemDocument7 pagesChapter 14 Governing Systemsambhu100% (1)

- Generator Capability CurveDocument18 pagesGenerator Capability Curvenamgyel30No ratings yet

- Handling of Turbine During EmergencyDocument17 pagesHandling of Turbine During EmergencyManohar TatwawadiNo ratings yet

- Digital Electro Hydraulic Governing System PresentationDocument38 pagesDigital Electro Hydraulic Governing System PresentationNaveenNo ratings yet

- STEAG Energy Services India - Profile References-Rev 5 10 15Document43 pagesSTEAG Energy Services India - Profile References-Rev 5 10 15Prasad Rajendra100% (1)

- Cooling Tower DesignDocument11 pagesCooling Tower DesignSmrutiNo ratings yet

- 660MW Turbo Generator & Its AuxiliariesDocument88 pages660MW Turbo Generator & Its AuxiliariesAshvani ShuklaNo ratings yet

- MAXScript EssentialsDocument20 pagesMAXScript EssentialsSebastián Díaz CastroNo ratings yet

- Thermal Power Plant GuideDocument33 pagesThermal Power Plant GuideManoj KumarNo ratings yet

- Technical Feedback on Horn Drop TestingDocument4 pagesTechnical Feedback on Horn Drop Testingarindam misra8No ratings yet

- Generator EdcDocument77 pagesGenerator EdcAJAY KUMAR100% (1)

- Monitoring Stator Water Systems for Large Turbine GeneratorsDocument12 pagesMonitoring Stator Water Systems for Large Turbine GeneratorsUmesh HadiyaNo ratings yet

- STEAG Training Calendar 2019-2020Document33 pagesSTEAG Training Calendar 2019-2020sourav mahapatraNo ratings yet

- Instrument Symbols and Flow Measurement GuideDocument85 pagesInstrument Symbols and Flow Measurement GuidekichasNo ratings yet

- Hydraulic turning gear operation and logicsDocument5 pagesHydraulic turning gear operation and logicsSai Swaroop50% (2)

- 660MW Emergency Operating ProcedureDocument117 pages660MW Emergency Operating ProceduregARRYNo ratings yet

- Auxiliary Power ConsumptionDocument27 pagesAuxiliary Power ConsumptionAbdulyunus AmirNo ratings yet

- RGMO SynopsisDocument2 pagesRGMO Synopsismahima sharmaNo ratings yet

- L-03 Spring Loaded Foundation-PresentationDocument34 pagesL-03 Spring Loaded Foundation-PresentationSam100% (1)

- Generator ProtectionDocument24 pagesGenerator ProtectionSantoshkumar Gupta100% (1)

- Automatic Turbine Run-Up SystemDocument22 pagesAutomatic Turbine Run-Up SystemSam100% (1)

- Roof Drains Tech DataDocument19 pagesRoof Drains Tech DataperezismaelNo ratings yet

- Thermal power plant engineering thermodynamics syllabusDocument51 pagesThermal power plant engineering thermodynamics syllabuseddula ganeshNo ratings yet

- Electrical Interview Questions & Answers - Hydro Power PlantDocument2 pagesElectrical Interview Questions & Answers - Hydro Power PlantLaxman Naidu NNo ratings yet

- Calculation of The Net Head and Power GenerationDocument15 pagesCalculation of The Net Head and Power GenerationUdara PriyankaraNo ratings yet

- Cooling Towers: Design of Tall Structures Me Structural Engineering DrspdalalDocument21 pagesCooling Towers: Design of Tall Structures Me Structural Engineering DrspdalalMegha LakhaniNo ratings yet

- Gen-Seal&cool-New - 500 MWDocument98 pagesGen-Seal&cool-New - 500 MWharisankar100% (2)

- Philo Q1module 4Document18 pagesPhilo Q1module 4Abygiel Salas100% (1)

- SWITCHYARDDocument30 pagesSWITCHYARDKaran TripathiNo ratings yet

- Cold Startup Procedure 250 MWDocument7 pagesCold Startup Procedure 250 MWPrudhvi RajNo ratings yet

- Turbine Rolling-Tiroda PDFDocument11 pagesTurbine Rolling-Tiroda PDFs91No ratings yet

- Stator Water Sys.Document29 pagesStator Water Sys.cyyguy3kNo ratings yet

- A ProjectDocument26 pagesA ProjectSumit ChauhanNo ratings yet

- Mechanical - Pumps KSB Centrifugal Pump DesignDocument44 pagesMechanical - Pumps KSB Centrifugal Pump DesignkichasNo ratings yet

- NTPC Training ReportDocument49 pagesNTPC Training Reportpusd_90100% (1)

- Thermal Power Plant GuideDocument14 pagesThermal Power Plant GuideDev KumarNo ratings yet

- NK Bansal BHEL Experience Sharing On Spring Loaded PaperDocument4 pagesNK Bansal BHEL Experience Sharing On Spring Loaded PaperelrajilNo ratings yet

- WHR APT AspectsDocument28 pagesWHR APT AspectsUdhayakumar VenkataramanNo ratings yet

- ABB 500 MW Steam TurbineDocument11 pagesABB 500 MW Steam TurbineRama Ranjan Samantaray100% (1)

- OPM-07 Rev.000, Resubmitted On 20.03.13 - NIGRIEDocument113 pagesOPM-07 Rev.000, Resubmitted On 20.03.13 - NIGRIESakthi MuruganNo ratings yet

- Lalitpur Superthermal Power Project - 3 X 660 MWDocument10 pagesLalitpur Superthermal Power Project - 3 X 660 MWpramod_nandaNo ratings yet

- BasicsDocument23 pagesBasicsSam100% (1)

- Procedure To Apply Jharkhand BOE-2016 ExaminationDocument2 pagesProcedure To Apply Jharkhand BOE-2016 Examinationpothan100% (1)

- Different Soot Blower: Their Working PrincipleDocument16 pagesDifferent Soot Blower: Their Working PrincipleMY NAME IS NEERAJ..:):)No ratings yet

- Thermal Power Station ReportDocument51 pagesThermal Power Station ReportChinni BandaruNo ratings yet

- LP Turbine Assembly ProcedureDocument8 pagesLP Turbine Assembly Procedurebhushanbharat_843298No ratings yet

- Rafako CFBC Boiler PDFDocument13 pagesRafako CFBC Boiler PDFadehriya100% (1)

- Steam TurbineDocument27 pagesSteam TurbinePrakashKr100% (1)

- Advantages of hydrogen cooling in large generatorsDocument5 pagesAdvantages of hydrogen cooling in large generatorsUsMan ZaFarNo ratings yet

- Summer Training Report On NTPC Tanda Ambedkar NagarDocument9 pagesSummer Training Report On NTPC Tanda Ambedkar NagarNaman ShahNo ratings yet

- NTPC Vindhyachal ReportDocument13 pagesNTPC Vindhyachal Reportblackswan_07No ratings yet

- Understanding Steam Turbines: Types, Components & Working PrinciplesDocument46 pagesUnderstanding Steam Turbines: Types, Components & Working PrinciplesIbrahim Mostafa50% (2)

- Dcs SystemDocument7 pagesDcs SystemJeya Kannan100% (1)

- Cooling Towers: Definition: # in Power Plants The Hot Water From Condenser IsDocument27 pagesCooling Towers: Definition: # in Power Plants The Hot Water From Condenser IsUsman SheriffNo ratings yet

- COOLING TOWERS EXPLAINEDDocument19 pagesCOOLING TOWERS EXPLAINEDVitthal s kandeNo ratings yet

- Industrial Plant Cooling EquipmentDocument15 pagesIndustrial Plant Cooling EquipmentkennnNo ratings yet

- Rubble Trench Foundation3Document6 pagesRubble Trench Foundation3Vicces P. EstradaNo ratings yet

- Cooling Towers: Operation and MaintenanceDocument26 pagesCooling Towers: Operation and MaintenanceMandeep MalikNo ratings yet

- Cooling Tower BasicDocument6 pagesCooling Tower Basicsininarayanan50% (2)

- Guía de Ingeniería EclipseDocument121 pagesGuía de Ingeniería Eclipsegiovanny1136No ratings yet

- OPEC April Report 2016Document96 pagesOPEC April Report 2016Amos DesmondNo ratings yet

- OPEC Annual Statistical Bulletin - 50th Edition - 2015Document120 pagesOPEC Annual Statistical Bulletin - 50th Edition - 2015studyendlessNo ratings yet

- Calculate N.P.S.H.ADocument9 pagesCalculate N.P.S.H.AkichasNo ratings yet

- Casing & Drill Pipe DataDocument1 pageCasing & Drill Pipe DatakichasNo ratings yet

- DOT Pipeline SpecificationsDocument20 pagesDOT Pipeline Specificationssect349No ratings yet

- BFBC or StrokerDocument6 pagesBFBC or StrokerkichasNo ratings yet

- Understanding The Basics of Packaged Steam GeneratorsDocument5 pagesUnderstanding The Basics of Packaged Steam Generatorskichas100% (1)

- Calculate N.P.S.H.ADocument9 pagesCalculate N.P.S.H.AkichasNo ratings yet

- Dry Screw Vs Oil Flooded ScrewDocument2 pagesDry Screw Vs Oil Flooded Screwkichas100% (1)

- Air Receiver SizingDocument2 pagesAir Receiver SizingkichasNo ratings yet

- CT Fill SelectionDocument4 pagesCT Fill SelectionkichasNo ratings yet

- A Practical Approach To Predicting Ash DepositionDocument13 pagesA Practical Approach To Predicting Ash DepositionkichasNo ratings yet

- BC CEMA Power ConsumptionDocument2 pagesBC CEMA Power ConsumptionkichasNo ratings yet

- 16 20Document5 pages16 20kichasNo ratings yet

- Materials For Steam SuperheatersDocument9 pagesMaterials For Steam Superheatersjyoti swaroop repaka50% (2)

- Cooling Water TreatmentDocument2 pagesCooling Water TreatmentkichasNo ratings yet

- 16 20Document5 pages16 20kichasNo ratings yet

- 2013 Course Structure BTech CSEDocument32 pages2013 Course Structure BTech CSEMankush JainNo ratings yet

- A Meta Analysis of Effectiveness of Interventions To I - 2018 - International JoDocument12 pagesA Meta Analysis of Effectiveness of Interventions To I - 2018 - International JoSansa LauraNo ratings yet

- Cazul Cyril Burt 3Document3 pagesCazul Cyril Burt 3Cosmina MihaelaNo ratings yet

- Generator Honda EP2500CX1Document50 pagesGenerator Honda EP2500CX1Syamsul Bahry HarahapNo ratings yet

- The dangers of electrostatic phenomenaDocument14 pagesThe dangers of electrostatic phenomenaYaminNo ratings yet

- 302340KWDocument22 pages302340KWValarmathiNo ratings yet

- BTechSyllabus EC PDFDocument140 pagesBTechSyllabus EC PDFHHNo ratings yet

- Why We Can't Stop Obsessing Over CelebritiesDocument2 pagesWhy We Can't Stop Obsessing Over CelebritiesJoseMa AralNo ratings yet

- Xist PDFDocument2 pagesXist PDFAgustin Gago LopezNo ratings yet

- 9 - The Relationship Between CEO Characteristics and Leverage - The Role of Independent CommissionersDocument10 pages9 - The Relationship Between CEO Characteristics and Leverage - The Role of Independent Commissionerscristina.llaneza02100% (1)

- CH - 3 Class XII Physics (E-Notes)Document9 pagesCH - 3 Class XII Physics (E-Notes)tejasNo ratings yet

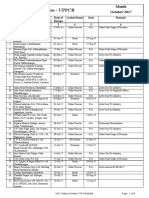

- NOC Status for UPPCB in October 2017Document6 pagesNOC Status for UPPCB in October 2017Jeevan jyoti vnsNo ratings yet

- Guided Reading Activity: The Reach of ImperialismDocument2 pagesGuided Reading Activity: The Reach of ImperialismevertNo ratings yet

- Product Brand Management 427 v1Document484 pagesProduct Brand Management 427 v1Adii AdityaNo ratings yet

- Cengage Advantage Books Essentials of Business Law 5th Edition Beatty Solutions ManualDocument16 pagesCengage Advantage Books Essentials of Business Law 5th Edition Beatty Solutions Manualladonnaaidanm5s100% (28)

- VE With CLE 10-Module 22-4th Quarter - CASTRODocument5 pagesVE With CLE 10-Module 22-4th Quarter - CASTRORojan ClarkNo ratings yet

- Sri Bhavishya Educational AcademyDocument4 pagesSri Bhavishya Educational AcademyAnonymous A6Jnef04No ratings yet

- Faith Surah RefutationDocument9 pagesFaith Surah RefutationKhairul Anuar Mohd IsaNo ratings yet

- Shwebo District ADocument280 pagesShwebo District AKyaw MaungNo ratings yet

- En Eco-Drive Panel ConnectionDocument4 pagesEn Eco-Drive Panel ConnectionElectroventica ElectroventicaNo ratings yet

- HamletDocument44 pagesHamletMonica AnechiteiNo ratings yet

- India's Fertilizer IndustryDocument15 pagesIndia's Fertilizer Industrydevika20No ratings yet

- Grand Caravan Couch BedDocument8 pagesGrand Caravan Couch BedfraniviajeraNo ratings yet

- RuelliaDocument21 pagesRuelliabioandreyNo ratings yet