Professional Documents

Culture Documents

Spools Cops Bobbin SewingThread Reels of Wood

Uploaded by

big johnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spools Cops Bobbin SewingThread Reels of Wood

Uploaded by

big johnCopyright:

Available Formats

56.

PROFILE ON PRODUCTION OF SPOOLS, COPS, BOBBINS & SEWING THREAD REELS, OF WOOD

56- 2

TABLE OF CONTENTS

PAGE

I.

SUMMARY

56-3

II.

PRODUCT DESCRIPTION & APPLICATION

56-3

III.

MARKET STUDY AND PLANT CAPACITY A. MARKET STUDY B. PLANT CAPACITY & PRODUCTION PROGRAMME

56-3 56-3 56-6

IV.

MATERIALS AND INPUTS A. RAW & AUXILIARY MATERIALS B. UTILITIES

56-7 56-7 56-8

V.

TECHNOLOGY & ENGINEERING A. TECHNOLOGY B. ENGINEERING

56-8 56-8 56-9

VI.

MANPOWER & TRAINING REQUIREMENT A. MANPOWER REQUIREMENT B. TRAINING REQUIREMENT

56-10 56-10 56-10

VII.

FINANCIAL ANALYSIS A. TOTAL INITIAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEFITS

56-11 56-11 56-12 56-13 56-14

56- 3 I. SUMMARY

This profile envisages the establishment of a plant for the production of spools, cops, bobbins and reels of wood with a capacity of 5,000 kg per annum.

The present demand for the proposed product is estimated at 4,500 kg per annum. The demand is expected to reach at 11,672 kg by the year 2017 .

The plant will create employment opportunities for 12

persons.

The total investment requirement is estimated at Birr 881,600, out of which Birr 239,000 is required for plant and machinery.

The project is financially viable with an internal rate of return (IRR) of 18% and a net present value (NPV) of Birr 288,220, discounted at 8.5%.

II

PRODUCT DESCRIPTION AND APPLICATION

These products are essential accessories of textile & handloom industries. With the development of textile industries, these products are in good demand which is expected to increase. The demand is currently met through imports, except some local producers.

III.

MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past Supply and Present Demand

The textile manufacturing sector requires various types of spools, cops, bobbins and sewing thread reels made of plastic, paper or paperboard and wood. The demand for

56- 4 these items is mainly met through import. Import of the products made of wood

(excluding plastic and paper) is presented in Table 3.1

Table 3.1 IMPORT OF SPOOLS, COPS, BOBBINS AND SEWING THREAD REELS OF WOOD

Year 2002 2003 2004 2005 2006 Total Average

Import (Kg) 3,457 13,271 3,880 2,126 22,734 4547

Source: - Ethiopian Customs Authority.

As shown in Table 3.1, import of spols, cops, bobbins and sewing thread reels of wood exhibits year-to-year fluctuation with out any discernible trend. The highest import was in 2003, i.e., about 13.3 tonnes. In 2005, the country did not import the product while in the remaining three years the amount imported ranged from 2,126kg to 3,457 kg. The reason for such huge difference from year to year is due to a stock carry over from periods in which import was very high. In the absence of a trend in the import data, it is considered as reasonable to assume that the average of the past five years to reflect the present demand. Hence, the present demand for the product would be in the order of 4,500kg.

2.

Projected Demand

Demand for the products is directly related with the development of the textile industries in the country. Due to the good opportunities created for textile products in the U.S.A

56- 5 and Europe, the government is taking various measures for the development of the sector. As a result, a number of textile projects in the country are under implementation. Considering this situation, demand for the products is assumed to grow by 10% per annum. The projected demand is shown in Table 3.2.

Table 3.2 PROJECT DEMAND FOR SPOOLS, COPS, BOBBINS AND SEWING THREAD REELS OF WOOD (KG)

Year 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017

Projected Demand 4,950 5,445 5,990 6,588 7,247 7,972 8,769 9,646 10,611 11,672

Demand for the product is projected to be 5,990 kg by the year 2010. By the year 2013 and 2017, the demand will grow to 7,972 kg and 11,672kg, respectively.

3.

Pricing and Distribution

Based on the average price of import, a factory-gate price of Birr 75 per kg is recommended. The products can be sold directly to the end-users, i.e., textile mills.

56- 6 B. PLANT CAPACITY AND PRODUCTION PROGRAMME

1.

Plant Capacity

According to demand projection indicated in Table 3.2 of the market study, the demand for spools, cops, bobbins and sewing thread reels of wood in year 2008 will be 4,950 kilogrammes, while this figure will grow to 9,646 kilogrammes by the year 2015. It is, therefore, proposed that the envisaged plant will have an annual production capacity of 5,000 kg of the assorted products of wood. The plant will operate single shift of 8 hours a day and for 300 days a year. Production can be doubled if the market warrants by operating the plant 16 hours a day without making any change in investment on machinery and building.

2.

Production Programme

A gradual production build-up is proposed for the plant so as to allow skill development and for establishment of sufficient market outlets. The plant, hence, will commence production at 65% of full capacity at the first year of operation. Production will then grow to 75% and 85% in the second and third year, respectively.

Full capacity production shall be attained in the fourth year and then after. Table 3.3 below indicates the details of the proposed production programme.

Table 3.3 PRODUCTION PROGRAMME

Year Capacity utilization (%) Production (kgs) (Assorted

1 65 3,250

2 75 3,750

3 85 4,250

4 and above 100 5,000

Wood Products)

56- 7 IV. MATERIALS AND INPUTS

A.

RAW AND AUXILIARY MATERIALS

The major raw material required for the production of spools, cops, bobbins and reels is wood. Some times wooden waste pieces can be used as long as the size and quality of the waste wood meets the requirement. The raw material can be obtained from sawing mills in SNNPRS, or from sawing mills of other regions. Soft wood from pines, oak, etc., are best suited for manufacturing of assorted products.

Production of the assorted wood products require auxiliary materials such as varnish, polishing materials, etc. Annual requirement of raw and auxiliary materials at full

capacity production is shown in Table 4.1 below.

Table 4.1 RAW AND AUXILIARY MATERIALS REQUIREMENT AND COST AT FULL CAPACITY

Sr. No.

Description

Qty

Cost (000 Birr)

A. Raw Material 1 Soft wood (kg) (wooden waste pieces) Sub-total B. Auxiliary Materials 1 2 Wood varnish Polishing materials, labels, etc. Sub-total Total Reqd Reqd 5.0 5.0 10.0 35.05 25.05 5,010 25.05

56- 8

B.

UTILITIES

Electricity and water are utilities required for the plant. A total of 10kWh of electricity and 50 m3 of water are required. At the rate of Birr 0.474 per kWh for electricity and Birr 10 per m3 for water, the annual expenditure on utilities is estimated at Birr 11,876.

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

1.

Production Process

It would be preferable for the wood products to be manufactured from sizable waste pieces of woodware manufacturing factory or soft wood available from pine tree, oak tree, etc. The major operations involved in the production process are:Selection and preparation of wood Sizing of the pieces according to the type of product Preparation of holes and grooves /slots Planing wood surfaces and producing shapes for spools/bobbins, cops, or reels, depending on the type of product Polishing and varnishing for finished products Packing and labeling.

2.

Source of Technology

Address of supplier for word working equipment for the manufacture of the assorted products is given below.

56- 9 Naohing zi Hamlet, Dalianwan Town, Ganjingzi District Dalian, CHINA Tel. 86411 8133 5615 Fax: 86 411 8711 2012 E-mail: yedwood 125@ 163.com

B.

ENGINEERING

1.

Machinery and Equipment

Table 5.1 below indicates machinery and equipment required for the envisaged plant and cost. Table 5.1 MACHINERY AND EQUIPMENT REQUIREMENT AND COST Sr. No. 1 2 3 4 5 6 Description Power saw Planning machine Wood rather machine Wood drilling machine Surface grinder Miscellaneous (Hammer, 1 1 2 1 1 knives, Reqd Qty LC Cost (000 Birr) FC 35 34 50 15 25 30

TC 35 34 50 15 25 30

tools, work benches, FOB price Freight, Bank and Insurance 50 189 189 50

charges, materials handling. CIF Landed Cost 50 189 239

56- 10 2. Land, Building and Civil Works

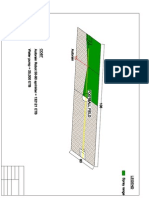

Land is required to accommodate buildings for production and administration, for storage of materials, and for future expansion. In view of these factors, the total and requirement is estimated to be 1,000 m2. Of this the built-up area will be 200 m2. At the rate of Birr 1.0 per m2 for land leasing for a period of 80 years, and Birr 1,500 per m2 for building and construction work, the total investment on land , building and civil works will be Birr 380,000.

3.

Proposed Location

Location of a plant is determined on the basis or proximity to raw materials, availability of infrastructure and distrance to potential market areas, woreda identified are Bonga zuria, yeki, mizan Teferi zuria and Dita. Considering fair distribution of projects, Dita woreda is selected. It is, therefore, suggested that the envisaged plant be established in Zada town.

VI.

MANPOWER AND TRAINING REQUIREMENT

A.

Manpower Requirement

The envisaged project requires 12 work force. The list of manpower and annual labour cost is given in Table 6.1.

B.

TRAINING REQUIREMENT

As indicated above operators of production equipment, including the production foreman will be trained to attain the required wood working skill., A two- weeks training

program will be sufficient. Training program can be carried out in one of the wood working enterprises in Addis Ababa. The total cost of such training is estimaied at Birr 50,000.

56- 11 Table 6.1 MANPOWER REQUIREMENT AND LABOUR COST (BIRR) (Birr) Sr. No. A. Administration 1 2 3 4 5 6 Plant manager Secretary Cashier Store man Clerk General services Sub-total B. Production 1 2 Skilled operators Laborer Sub-total Workers benefit (25% BS) Total 2 2 4 12 14,400 6,000 20,400 18,600 93,000 1 1 1 1 1 2 8 1,800 600 600 600 400 250 21,600 7,200 7,200 7,200 4,800 6,000 54,000 Job Title Req. No. Monthly Salary Annual Wages

56- 12 VII. FINANCIAL ANALYSIS

The

financial

analysis

of

the

spools,

cops,

bobbins

and

reels

of

wood

project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

1 year 30 % equity 70 % loan

Tax holidays Bank interest Discount cash flow Accounts receivable Raw material local Work in progress Finished products Cash in hand Accounts payable

3 years 8.5 % 8.5 % 30 days 30 days 2 days 30 days 10 days 30 days

A.

TOTAL INITIAL INVESTMENT COST

The total investment cost of the project including working capital is estimated at 881,600, of which 13 per cent will be required in foreign currency.

The major breakdown of the total initial investment cost is shown in Table 7.1.

56- 13 Table 7.1 INITIAL INVESTMENT COST

Sr. No. 1 2 3 4 5 6 7 Cost Items Land lease value Building and Civil Work Plant Machinery and Equipment Office Furniture and Equipment Vehicle Pre-production Expenditure* Working Capital Total Investment cost Foreign Share

Total Cost (000 Birr) 80.0 300.0 239.0 50.0 201.9 10.7 881.6 13

* N.B Pre-production expenditure includes interest during construction ( Birr 51.87 thousand ) training (Birr 50 thousand ) and Birr 100 thousand costs of registration, licensing and formation of the company including legal fees, commissioning expenses, etc.

B.

PRODUCTION COST

The annual production cost at full operation capacity is estimated at Birr

268,320

(see Table 7.2). The material and utility cost accounts for 17.49 per cent, while repair and maintenance take 7.45 per cent of the production cost.

56- 14 Table 7.2 ANNUAL PRODUCTION COST AT FULL CAPACITY ('000 BIRR)

Items Raw Material and Inputs Utilities Maintenance and repair Labour direct Administration Costs Total Operating Costs Depreciation Cost of Finance Total Production Cost

Cost 35.05 11.88 20 39 54 159.93 73.9 34.49 268.32

% 13.06 4.43 7.45 14.53 20.13 59.60 27.54 12.85 100

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the first year of operation. Important ratios such as profit to total sales, net profit to equity (Return on equity) and net profit plus interest on total investment (return on total investment) show an increasing trend during the life-time of the project.

The income statement and the other indicators of profitability show that the project is viable.

56- 15

2.

Break-even Analysis

The break-even point of the project including cost of finance when it starts to operate at full capacity ( year ) is estimated by using income statement projection.

BE =

Fixed Cost Sales Variable Cost

= 40 %

3.

Pay Back Period

The investment cost and income statement projection are used to project the pay-back period. The projects initial investment will be fully recovered within 5 years.

4.

Internal Rate of Return and Net Present Value

Based on the cash flow statement, the calculated IRR of the project is 18 % and the net present value at 8.5 % discount rate is Birr 280,220.

D.

ECONOMIC BENEFITS

The project can create employment for 12 persons. In addition to supply of the domestic needs, the project will generate Birr 209,830 in terms of tax revenue. The establishment of such factory will have a foreign exchange saving effect to the country by substituting the current imports.

You might also like

- Tea and IrrigationDocument14 pagesTea and Irrigationbig johnNo ratings yet

- BS Year1 No14 - Apr.02 1925Document4 pagesBS Year1 No14 - Apr.02 1925big johnNo ratings yet

- Nursery Manual For Native Plants PDFDocument309 pagesNursery Manual For Native Plants PDFbig john100% (1)

- The Date Palm Journal PDFDocument240 pagesThe Date Palm Journal PDFbig johnNo ratings yet

- Commodity TeaDocument4 pagesCommodity Teabig johnNo ratings yet

- Jam and JellyDocument28 pagesJam and Jellybig johnNo ratings yet

- Herb Production OrganicDocument20 pagesHerb Production OrganicShoshannah33% (3)

- Lowland OilcropsDocument14 pagesLowland Oilcropsbig johnNo ratings yet

- Co-Op Bulk Spice List in Order by Alphabetic Spice NameDocument3 pagesCo-Op Bulk Spice List in Order by Alphabetic Spice Namebig johnNo ratings yet

- OrangeDocument23 pagesOrangebig john100% (1)

- PomegranatesDocument5 pagesPomegranatesbig johnNo ratings yet

- CIB, ContractDocument89 pagesCIB, Contractbig johnNo ratings yet

- Football Field Layout1Document1 pageFootball Field Layout1big johnNo ratings yet

- Tea and IrrigationDocument14 pagesTea and Irrigationbig johnNo ratings yet

- Grape JuiceDocument16 pagesGrape Juicebig johnNo ratings yet

- Chewaka Store ModelDocument1 pageChewaka Store Modelbig johnNo ratings yet

- Tuta AbsolutaDocument25 pagesTuta Absolutabig johnNo ratings yet

- Horticulture Report FinalDocument57 pagesHorticulture Report Finalbig john100% (1)

- Ethiopia Irrigation Diagnostic July 2010 2Document59 pagesEthiopia Irrigation Diagnostic July 2010 2big john100% (1)

- Tomato MarketingDocument8 pagesTomato Marketingbig johnNo ratings yet

- FCKupload File FAO Syria Crisis Report enDocument106 pagesFCKupload File FAO Syria Crisis Report enbig johnNo ratings yet

- CIB, ContractDocument89 pagesCIB, Contractbig johnNo ratings yet

- Final EgyptDocument258 pagesFinal Egyptbig johnNo ratings yet

- 36 Tomato Sauce, Ketchup and PureesDocument9 pages36 Tomato Sauce, Ketchup and Pureesbig johnNo ratings yet

- Tomato Paste and JuiceDocument14 pagesTomato Paste and JuiceRamanathan Meyyappan100% (1)

- Participatory Irrigation Management in AlbaniaDocument25 pagesParticipatory Irrigation Management in Albaniabig johnNo ratings yet

- Unu Strategic Plan 2011-2014 enDocument20 pagesUnu Strategic Plan 2011-2014 enbig johnNo ratings yet

- Agribusiness Organization and Management SeminarDocument24 pagesAgribusiness Organization and Management Seminarbig john100% (2)

- Dried Spray FruitDocument130 pagesDried Spray Fruitbig john100% (2)

- 101 Iced Tea RecipesDocument109 pages101 Iced Tea RecipesNessa Santiago100% (3)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Basis Technical AnalysisDocument92 pagesBasis Technical Analysisrahulsheth_cal2159No ratings yet

- Ic 38 - Rnis Mock Test Paper 2017Document46 pagesIc 38 - Rnis Mock Test Paper 2017Rekha GuptaNo ratings yet

- Multiple Choice Questions Chapter 11 Perfect CompetitionDocument26 pagesMultiple Choice Questions Chapter 11 Perfect CompetitionAfrose KhanNo ratings yet

- MCQ of Financial Statement AnalysisDocument8 pagesMCQ of Financial Statement AnalysisRahul Ghosale100% (11)

- Depreciation Provisions and Reserves Class 11 NotesDocument48 pagesDepreciation Provisions and Reserves Class 11 Notesjainayan8190No ratings yet

- 3.zara Home Product Assorment. Final EssayDocument9 pages3.zara Home Product Assorment. Final EssayEugenio Pavon GutierrezNo ratings yet

- Order 2 Packing SlipDocument2 pagesOrder 2 Packing SlipArnav JoshiNo ratings yet

- Cost of Preferred Stock and Common StockDocument20 pagesCost of Preferred Stock and Common StockPrincess Marie BaldoNo ratings yet

- Western India Plywood LTDDocument14 pagesWestern India Plywood LTDRafshad mahamood100% (1)

- Securities Analysis & Portfolio Management For BSEC Investor EducationDocument37 pagesSecurities Analysis & Portfolio Management For BSEC Investor EducationHole StudioNo ratings yet

- MNP Transfer PricingDocument2 pagesMNP Transfer PricingNational PostNo ratings yet

- Retail MerchandisingDocument27 pagesRetail MerchandisingKiran TikuNo ratings yet

- Case: Triumph Tours: November 13, 2010Document7 pagesCase: Triumph Tours: November 13, 2010RoseAnnGatuzNicolas0% (1)

- Writ of Acquisition: X Orbon Binbrow XDocument5 pagesWrit of Acquisition: X Orbon Binbrow XAnonymous ZpsGbeZQWNo ratings yet

- International Transfer PricingDocument26 pagesInternational Transfer Pricingmessi1986No ratings yet

- AMAZON.COM - Inc. 2004 overview and analysisDocument45 pagesAMAZON.COM - Inc. 2004 overview and analysisAjay KumarNo ratings yet

- T8 W9: CAPACITY & PRIVITY OF CONTRACT CASE SUMMARYDocument4 pagesT8 W9: CAPACITY & PRIVITY OF CONTRACT CASE SUMMARYalibabaNo ratings yet

- Foundation Course in Managerial Economics: DR Barnali Nag IIT Kharagpur Lecture 25: MonopolyDocument19 pagesFoundation Course in Managerial Economics: DR Barnali Nag IIT Kharagpur Lecture 25: MonopolyDebesh GhoshNo ratings yet

- Earnings Management Are View of LiteratureDocument13 pagesEarnings Management Are View of LiteratureLujin MukdadNo ratings yet

- Qatar Review Q1 2016 enDocument6 pagesQatar Review Q1 2016 enahmedh_98No ratings yet

- PEST Analysis of IOCDocument4 pagesPEST Analysis of IOCArpkin_love100% (3)

- Steven Belkin Case AnalysisDocument7 pagesSteven Belkin Case AnalysisDiva PatriciaNo ratings yet

- Progress and Potential of Mango Pulp Industry in India: P. A. Lakshmi Prasanna Sant KumarDocument26 pagesProgress and Potential of Mango Pulp Industry in India: P. A. Lakshmi Prasanna Sant KumarKashmira SawantNo ratings yet

- 6 Marlin Pring On Market MomentumDocument1 page6 Marlin Pring On Market MomentumTUAN NGUYỄNNo ratings yet

- Mcdonald 2016Document10 pagesMcdonald 2016Andrika SaputraNo ratings yet

- The Bullwhip Effect in HPs Supply ChainDocument9 pagesThe Bullwhip Effect in HPs Supply Chainsoulhudson100% (1)

- Cupping According QDocument25 pagesCupping According QGiorgos AlaniadisNo ratings yet

- Textbook Buyers Browse OptionsDocument1 pageTextbook Buyers Browse OptionsAndrew Flohr-SpenceNo ratings yet

- Chapter 10 - Facility LocationDocument48 pagesChapter 10 - Facility LocationTrey Holton100% (1)

- 04 Mrudula Ice Cream ParlourDocument14 pages04 Mrudula Ice Cream ParlourAnil Joshi100% (1)