Professional Documents

Culture Documents

Experimental Work On Cold-Formed Steel Elements For Earthquake Resilient Moment Frame Buildings

Uploaded by

Ovunc TezerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Work On Cold-Formed Steel Elements For Earthquake Resilient Moment Frame Buildings

Uploaded by

Ovunc TezerCopyright:

Available Formats

Engineering Structures 42 (2012) 371386

Contents lists available at SciVerse ScienceDirect

Engineering Structures

journal homepage: www.elsevier.com/locate/engstruct

Experimental work on cold-formed steel elements for earthquake resilient moment frame buildings

Alireza Bagheri Sabbagh a,, Mihail Petkovski a, Kypros Pilakoutas a, Rasoul Mirghaderi b

a b

Department of Civil and Structural Engineering, University of Shefeld, Shefeld, UK School of Civil Engineering, College of Engineering, University of Tehran, Tehran, Iran

a r t i c l e

i n f o

a b s t r a c t

This paper presents an experimental investigation on the use of thin-walled cold-formed steel (CFS) sections as energy dissipative elements for earthquake resistant moment frame multi-storey buildings. The tests were performed on six bolted beam-to-column connections, using through plates and curved ange beams with different types of out-of-plane stiffeners in the connection region. The hysteretic behaviour of the CFS connections shows high seismic energy dissipation capacity and sufcient ductility to satisfy code requirements for seismic design. The use of out-of-plane stiffeners inside the beams in the connection region results in improvement of the momentrotation behaviour of the connection by up to 35% in strength and 75% in ductility. Mobilising connection slip after the elastic cycles provides highly stable hysteretic behaviour and an increase of up to 240% in energy dissipation capacity. The tested connections can be classied as rigid with partial or full strength depending on the connection stiffeners. 2012 Elsevier Ltd. All rights reserved.

Article history: Received 23 November 2011 Revised 17 April 2012 Accepted 26 April 2012 Available online 7 June 2012 Keywords: Cold-formed steel sections Beam-column connections Moment-resisting frames Seismic behaviour

1. Introduction Experimental work on monotonic and cyclic behaviour of components and elements of CFS moment-resisting frames (MRFs) is very limited [14]. Premature local failures are prevalent in common CFS sections because of their thin-walled elements. One solution to avoid premature local failures and to provide ductility in bolted CFS connections is to mobilise slip and bearing action of bolts while beams and columns remain elastic [1]. This limited source of ductility restricts such structures to one-storey dwellings [1]. For seismic design of multi-storey buildings, there is a need to dissipate large amount of energy through plasticity in the beams rather than just yielding the material around the bolt holes. There are research studies [2,3] showing that by using appropriate connection details for CFS beam-column connections, such as gusset plates, relatively high moment resistance can be developed in CFS double back-to-back channel sections. In this type of beamto-column connection however, no ductile capacity was achieved after reaching the peak bending moment. The general assumption is that CFS beams with thin-walled elements cannot develop plastic hinges, thus cannot be used for high seismicity areas [57]. In a recent study by the authors [4] conventional double backto-back channel beam sections integrated within topping concrete were shown to possess a degree of ductile capacity in dissipating

Corresponding author. Address: Department of Civil and Structural Engineering, University of Shefeld, Sir Frederick Mappin Building, Mappin Street, Shefeld S1 3JD, UK. Tel.: +44 (0)114 222 5724; fax: +44 (0)114 222 5700. E-mail address: alireza_bghs@yahoo.com (A. Bagheri Sabbagh).

0141-0296/$ - see front matter 2012 Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.engstruct.2012.04.025

seismic energy by achieving rotations larger than 0.04 rad; satisfying the requirements for special moment frames [7]. However, they did not satisfy the required width/thickness limits of design codes [57] which aim to delay the local buckling after yielding. This research also showed encouraging results for through plate type of CFS beam-to-column connections [4]. If CFS beams are designed as the main energy dissipation components in seismic resistant MRFs, the ductility capacity of the beams with thin-walled elements must be improved. The rst step is to delay local buckling as much as possible to enable plastic deformations. Curved ange beam sections were developed by the authors [810] by introducing more bends in the anges (Fig. 1a), a stepby-step process that ultimately led to signicant increase in moment resistance, stiffness and ductility, compared with at ange beams. In this study a web bolted moment resistant type of connection is used for CFS beam-column connections. This type of connection has already been examined as lapped connections in portal frames [11,12]. The main components of the beam-column MR connection are welded cross through-plates which can be bolted to separate beam and column sections, as shown in Fig. 1b. Previous research [810] has shown that web bolted through-plate beam-to-column connection produced a lower level of ductility and strength than that of a theoretical xed-end beam. Web buckling adjacent to the rst line of bolts at the beam-through plate connection was identied as the main reason for premature loss of strength [810]. An optimum combination of vertical and horizontal out-ofplane stiffeners has been identied for the web bolted CFS connec-

372

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

(a)

(b)

Fig. 1. (a) Step-by-step development of curved ange sections and (b) CFS beam-column connections: diamond column, cross through-plates and curved ange beam [810].

tions to increase both the strength and ductility [810]. Minimum number of vertical stiffeners has also been identied for easier implementation and for connections where ductility demand can be met by a reduced number of stiffeners rather than a full (optimum) set of stiffeners [9,10]. The experimental study presented in this paper investigates the concept of CFS thin-walled curved ange sections as seismic energy dissipative elements for moment frame buildings using full and minimum sets of out-of-plane stiffeners. It also aims to examine if curved ange CFS sections can produce full plastic moment (Mp) sustained at large rotations similar to Class 1 cross sections in Eurocode 3 [6] and larger than 0.04 rad required for special moment frames in AISC Seismic Provisions [7].

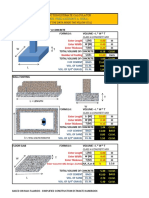

2. Testing arrangement and specimen details Two specimen types with different thickness (A) 3 mm, and (B) 4 mm, with three different out-of-plane stiffener congurations (A1, A2, A3, and B1, B2, B3) were used in the experimental investigation (Table 1). The nominal dimensions of the components of the test specimens are shown in Fig. 2. According to the FE analysis presented previously by the authors [810], the connections with full stiffeners (used for Specimens A3 and B3) produce a signicant increase in both strength ($40%) and ductility ($100%) in comparison with the connections without stiffeners (Specimens A1 and B1) which were used for bench marking and comparison purposes. The difference between the boundary conditions of FE models and the test specimens is that hot-rolled back-to-back channels were used in the tests instead of CFS columns. This was easier to manufacture and install into the testing rig. This change was supported by the results of

the FE analyses, which showed no yielding or large deformation in the CFS columns [9,10]. For all specimens, the connections were designed using the requirements for slip-critical joints given in AISC Specication for Structural Joints [13]. The design slip resistances of the farthest bolts (Rn) in the connections were calculated by assuming slip coefcient of l = 0.5 for uncoated blast-cleaned steel [13] and applying a pretension force Tm = 67 kN for the beam-to-through plate (BT) and Tm = 53 kN for the through plate-to-column (TC) connections, approximately equal to 42% of the tensile strength of the bolts (60% of the 70% tensile strength, given in the Specication [13]). This resulted in design resistance (Rn), higher than the required resistances (Rreq) for specimens type A, but just below the required resistances (Rreq) for specimens type B. Therefore, it was expected that if the beam plastic moment was mobilised in the tests of specimens type B, slipping at the connections would be triggered. 2.1. Test set-up Fig. 3 shows a drawing and a photo of the test set-up. A brief description of the design specications for the test set-up components are given in Appendix A. 2.2. Instrumentation Strain gauges (SGs), inclinometers and LVDTs were placed at different locations of the through plates, beams and columns as

Table 1 The specimens congurations. Specimens A1 A2 A3 B1 B2 B3 Beam thickness (mm) 3 3 3 4 4 4 Connection stiffeners No stiffeners Partial (minimum) stiffeners Full (optimum) stiffeners No stiffeners Partial (minimum) stiffeners Full (optimum) stiffeners Connection type Slip-critical Slip-critical Slip-critical Slip-critical Slip-critical Slip-critical Fig. 2. Dimensions and conguration of the test specimens.

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

373

shown in Fig. 4 to measure stresses and deformations at all the critical parts of the specimens. 2.3. Loading protocol Cyclic loading was applied through a hinge connection at the end of the beam (Fig. 3) using a loading protocol (Fig. 5) given in section S6.2 of AISC Seismic Provisions [7] for qualifying beam-column moment connections in special and intermediate moment frames. The centre of the plastic hinge region, used for calculating the bending moment, M, and the rotation, h of the beams, is assumed to be at the end of the through plate (Fig. 5). The distance between this section and the loading point (1811 mm) was used to determine the displacement of the actuator (Fig. 5) for a given value of h. 3. Test results The momentrotation (Mh) behaviour, connection rigidity and strain distribution results for all the specimens are presented in the following subsections. The normalised moment (M/Mp) is shown against the applied h. Mp is the nominal plastic moment of the

beam sections: 67 kN m for Specimens A and 90 kN m for Specimens B, all assumed with nominal yield stress fy = 275 MPa. The actual yielding stresses of the beams based on the tensile test results for Specimens A and B were 310 MPa and 320 MPa, respectively. Therefore, the actual plastic moment strength of the beams is expected to be 75 kN m for Specimens A and 105 kN m for Specimens B. It should be noted that in the design of beam-column connections this difference is accounted for by using an overstrength factor [7].

3.1. Specimens A13 and B1: connections dominated by rotation in the beams In Specimens A13 and B1 the rotation behaviour is dominated by exural and local buckling deformation in the beams. From the M/Mph curves (Fig. 6), different regions corresponding to different aspects of behaviour can be identied: (i) Elastic region (AB): Points B and B correspond to the beginning of the inelastic region, (ii) Inelastic region (BC): Points C and C correspond to the maximum bending moments in the beam, (iii) Postbuckling region (CD): Points D and D correspond to 80% of the maximum moment and (iv) Failure region (DE): Points E and E correspond to connection failure as

Fig. 3. Test set-up.

374

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

Fig. 4. Instrumentation sketches of the specimens.

Fig. 5. Loading cycles.

seen in Fig. 7. For a better understanding of the rotational behaviour of the connections of the specimens, videos of the connections (Videos 14) that were made by framing the photos at every 60 s are also presented. The ductility factors based on the rotation ratios at points B and D are 2.7, 4.0, 4.7 and 4.7 for Specimens A13 and B1, respectively. The beams sustained 80% of the nominal plastic moment at a rotation (at Point D) larger than 0.04 rad (for Specimens A23 and B1) which is the rotation required for special moment frames (SMFs) [7]. 3.1.1. Hysteretic momentrotation behaviour of Specimen A1 The web buckling in Specimen A1 beam was initiated at h = 0.03 rad rotation at the end of the through plate and extended to the ange at h = 0.04 rad (see Video 1). This web buckling was also identied by the authors through a set of FE analyses [9] as the main reason for an abrupt loss of strength. This conrms that vertical stiffeners at this location should be used (similar to Specimens A2 and B2). In the failure region (DE) the web and ange buckling progressed further and the anges at the end of the beam opened up as seen in Fig. 7. The large failure deformation of the beam anges and webs highlights the need for vertical stiffeners.

The local rotations and deformations at the connection region versus the actuator load (F) are shown in Fig. 8. The total rotation of the beam at the connection region was very small, as shown in Fig. 8a. This was veried by measuring the deformations at the top and bottom of the through plate (horizontal transducers 11 and 12 in Fig. 8b). Slight slip in the through plate-to-column (TC) connection during the last cycles (see Fig. 8b) can be due to out-of-plane bending of the through plate (this is veried by strain measurements shown later, in Section 3.4.1). A small vertical deformation of the column was also recorded (Fig. 8c) and this is attributed to shear deformation of the column web. It can be concluded that the rotation recorded at the end of the beam (Fig. 6A1) represents the beam rotation capacity, without signicant contributions from the connection elements. 3.1.2. Hysteretic momentrotation behaviour of Specimen A2 In the test of Specimen A2, the connection slipped at Point C, in the reverse loading cycle of h = 0.03 rad, dropping from M/ Mp = 1.03 to M/Mp = 0.81 (Fig. 6A2). In the loading cycle of h = 0.04 rad, the connection slipped at M/Mp = +0.54. By repeating this cycle, the web buckling was triggered outside the connection adjacent to the vertical stiffener and the ange buckling was initiated between the vertical stiffener and the lateral bracing (see Vi-

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

375

Fig. 6. Momentrotation curves of Specimens A13 and B1.

Fig. 7. Failure deformations of Specimens A13 and B1 correspond to Point E.

deo 2). The maximum loads were slightly reduced due to the initiation of local buckling in this cycle. In the repeating cycle of 0.06 rad, the maximum load was reduced to M/Mp = 0.81, corresponding to Points D and D in Fig. 6. Points E and E correspond to the rotation of 0.07 rad. In this region the web and ange buckling deformation extended at both sides of the vertical stiffener at the through plate end as shown in Video 2 and Fig. 7. The local rotations and deformations in the connection region versus the applied load (F) are shown in Fig. 9. As expected, the rotation at the column side of the connection was very small (Fig. 9a). This conrms that the xing of the specimens to the reaction frame worked well.

The total rotation of the beam-to-through plate (BT) and the through plate-to-column (TC) connections (identifying the rst slip and maximum points corresponding to those in Fig. 6A2) is shown in Fig. 9b. The rotation of the TC connection was also measured by the horizontal transducers 11 and 12 (Fig. 9c). These measurements show that the TC connection contributed substantially in the total rotation of the connection. The total rotation showed elastic cycles up to Point C where the rst slip occurred. The total rotation of the connection elements (Fig. 9b) shows a signicant contribution (0.0173 rad) to the global beam-end rotations (Fig. 6A2). Most of the slip occurred at the stabilised slip load, Fs, at around 20 kN (corresponding to M/Mp = 0.54).

376

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

Fig. 8. Specimen A1: local deformations in elements of connection.

Fig. 9. Specimen A2: local deformations in elements of connection.

The maximum total rotation of the connection (h6 = 0.0173 rad) and the maximum rotation of the TC connection, 0.0135 rad, were close to the value of 0.0167 rad, calculated as rotation due to clearance. This value was calculated by assuming a uniform rotation and 2 mm clearance for the bolt holes divided by the farthest distances at each of the connections (2 mm/300 mm BT connection + 2 mm/200 mm TC connection = 0.0167 rad). This shows that very little bearing action was activated in the connections.

The slip of the bolts is not symmetric as can be seen in Fig. 9b. This leads to different maximum strain values at the top and bottom anges.

3.1.3. Hysteretic momentrotation behaviour of Specimen A3 The ange buckling of Specimen A3 was initiated in the h = 0.05 rad cycle, at the edge of the anges between the 2nd, 3rd

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

377

and the 4th vertical stiffeners, and extended in the subsequent cycles (see Video 3). At h = 0.07 rad, the maximum load dropped to M/Mp = +0.84 and 0.86 corresponding to Points D and D, respectively. At Points E and E, corresponding to rotation of h = 0.08 rad, the specimen failed due to rupture of the anges following large beam deformation (see Video 3 and Fig. 7). During the test, the vertical stiffeners were deformed out-ofplane due to restraining forces from the horizontal stiffeners. Therefore, both the vertical and horizontal stiffeners were effective in restraining the web and ange buckling and resisted the local buckling deformations. The total rotation of the BT and the TC connections, measured by inclinometer 6 is shown in Fig. 10a. The maximum total rotation was 0.005 rad, part of which was due to the rotation in the TC connection (shown in Fig. 10b). The other part was the rotation in the BT connection. The rotation measured for the TC connection by the horizontal LVDTs 11 and 12 can be due to both slip of the bolts and out-of-plane bending of the through plate (especially towards the end of the test). No sudden slip was observed in the connection (see Video 3), but clicking sounds were heard during the test due to local slip of the bolts. This slip was mainly in the rst and last line of bolts of the BT connection. In this test, the slip deformation was not sudden or signicant. Therefore, the slip affected neither the global behaviour (Fig. 6A3), nor the overall connection behaviour (Fig. 10a). 3.1.4. Hysteretic momentrotation behaviour of Specimen B1 The web buckling in Specimen B1 was initiated in the beam at h = 0.05 rad, at the critical section at the through plate end and extended in the subsequent cycles (see Video 4). At rotation of h = 0.07 rad the maximum load dropped to M/Mp = 0.76 corresponding to Points D and D (Fig. 6). During this cycle the web buckling was intensied and it interacted with the ange buckling. The specimen failed at Points E and E corresponding to rotation of h = 0.08 rad (Fig. 6) due to extensive web and ange buckling accompanied by a large deformation of the beam (Fig. 7). The total connection rotation measured by inclinometer 6 is shown in Fig. 11a. The rotation of the TC connection (measured by the horizontal transducers 11 and 12, Fig. 11b), was small. During the last cycles signicant deformation occurred in the TC connection mainly due to the out-of-plane deformation of the through plate. The total rotation of the connection was mainly due to the contribution of the BT connection. Most of the slip of the BT connection occurred in the last cycles after the peak moment was reached (Point C) and after the development of web buckling. This may be a result of reduction of the frictional contact surfaces of the rst line of bolts due to the adjacent web buckling. Therefore, vertical stiffeners at this location (similar to Specimens A2 and B2)

should be used to protect the frictional contact surfaces of the rst line of bolts which are the farthest from the centre of rotation and more susceptible to slip. Relatively small slip of the bolts was due to the fact that the deformation demand was mostly met by the beam. The rotation of the connection elements (Fig. 11) shows that their maximum contribution to the beam-end rotation (Fig. 6B1) was only 0.015 rad. 3.2. Specimens B2 and B3: Connections dominated by rotational behaviour produced by connection slip From the momentrotation (M-h) curves (Fig. 12B2 and B3), different regions corresponding to different aspects of behaviour can be identied: (i) Elastic region (AB), (ii) Prebuckling-slip region (BC) and (iii) Postbuckling region (CD). The ductility factors, based on the deformations at Point D (Specimen B2) or Point C (Specimen B3) relative to Point B are 6.0 and 6.7, respectively, although the load has not degraded at the end of the tests. The beams sustained maximum strength up to a rotation signicantly higher than the rotation of 0.04 rad required for special moment frames (SMFs) [7]. At that stage of these tests, since a high ductility factor had already been achieved, before doing further damage to the beam, it was decided to unload and stop the test and to increase the pretension forces of the connection bolts in order to limit the deformations due to slip. The pretension forces were increased from 42% of the tensile strength of bolts to 68% and 56% (0.95 and 0.80 of 70% tensile strength) for BT connections of Specimens B2 and B3, respectively, and to 60% (0.85 of 70% tensile strength) for TC connections of both specimens. In the retest of these specimens, only the inelastic cycles from 0.03 rad onward were applied (Fig. 12B2 (retest) and B3 (retest)). The behaviour patterns for the retests are similar to those of the specimens dominated by rotation in the beams (Section 3.1). The cyclic behaviour indicating connection slip and progressive failure (Videos 58 and Fig. 13) for each of these tests and retests is discussed below. 3.2.1. Hysteretic momentrotation behaviour of Specimen B2 The rst slip at the through plate-to-column connection of Specimen B2 occurred at the reverse cycle of h = 0.02 rad (see Video 5) when the load dropped from M/Mp = 0.8 (at h = 0.015 rad, Point B) to M/Mp = 0.56 (Fig. 12). During the second cycle of 0.02 rad rotation, the connection slip load was reduced to M/Mp = +0.48 at the positive direction. The slip load levels for all subsequent rotations remained around M/Mp = 0.4. The edges of the anges between the vertical stiffener at the through plate end and the lateral brace were slightly deformed at h = 0.07 rad (see Video 5). This may be due to the initiation of lateraltorsional buckling of the beam which, however, was prevented by the lateral braces.

Fig. 10. Specimen A3: local deformations in elements of connection.

378

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

Fig. 11. Specimen B1: local deformations in elements of connection.

Fig. 12. Momentrotation hysteretic curves of Specimens B2 and B3.

At h = 0.08 rad, the maximum loads were M/Mp = 1.07 (Points C and C, Fig. 12). At the end of this cycle web buckling was initiated beyond the vertical stiffeners inside the beam. At h = 0.09 rad the maximum moment was M/Mp = +1.0 (Point D, Fig. 12). The ange buckling that was initiated in the previous cycles was more noticeable (Fig. 13) and accompanied by large connection slip and beam deformation. The total rotation of the BT and the TC connections measured by inclinometer 6 is shown in Fig. 14a. Both the TC connection (Fig. 14b) and the BT connection (Fig. 14c and d) contributed to the total rotation of the connection. The start of the slip is identied by Point B on the connection rotation curves (Fig. 14a and b). This point indicates that the slip of the connection started at the TC connection (see Video 5). BT slip was activated from the cycle at h = 0.05 rad (see Video 5 and Fig. 14c and d). Most slip occurred at the stabilised slip load, Fs, at around 20 kN (corresponding to M/Mp = 0.40). The maximum rotation value of the connection (h6 = 0.055 rad) was higher than 0.0167 rad calculated by assuming 2 mm bolt holes clearance, suggesting that elongation of the bolt holes. It can be concluded that the local rotations of the connection elements (Fig. 14) made a large contribution (maximum

h = 0.055 rad) to the global rotation of 0.09 rad at the beam-end (Fig. 12B2).

3.2.2. Hysteretic momentrotation behaviour of Specimen B2 during retest The torque on the bolts of the beam-to-through plate (BT) and the through plate-to-column (TC) connections was increased from 240 N m to 380 N m and from 170 N m to 240 N m, respectively. The new increased pretension forces were calculated such that the resistance of the farthest bolts was greater than the largest applied forces (Rreq/Rn = 0.71 and 0.8 for the BT and the TC connections, respectively). It should be noted that both curved anges of the beam were already slightly buckled from the previous test. The specimen failed at Points E and E at a rotation of 0.08 rad (see Fig. 12 and Video 6). Rupture in the bottom ange took place at the bottom of the rst bolt line of the BT connection following large web and ange buckling in the beam (shown in Fig. 13). The total rotation of the BT and the TC connections measured by inclinometer 6 (Fig. 15a) and the rotation of the TC connection (Fig. 15b) conrm that the connection slip was minimised by the increase in the pretension force of the bolts. Therefore, the slip of

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

379

Fig. 13. Connection slip and failure deformations of Specimens B2 and B3 at the last cycle.

Fig. 14. Specimen B2: local deformations in elements of connection.

the connection elements (Fig. 15) made only a small contribution to the global rotation at the beam end (Fig. 12). 3.2.3. Hysteretic momentrotation behaviour of Specimen B3 In the test of Specimen B3, the rst slip was triggered at h = 0.03 rad, in the BT connection (see Video 7) at the load of M/

Mp = 0.76 (Fig. 12). At h = 0.05 rad rotation, the slip load level reduced to M/Mp = 0.58. The reduction in slip loads indicates either loss of friction or pretension force in the bolts (or both). The slip load levels for all the subsequent rotations remained around M/ Mp = 0.4 which corresponds to the same load level as for Specimen B2. The maximum loads increased to M/Mp = 1.19 at Points

380

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

Fig. 15. Specimen B2 (retest): local deformations in elements of connection.

Fig. 16. Specimen B3: elongation of the material around the bolt holes in the BT connection after the test.

C and C corresponding to h = 0.1 rad (Fig. 12). This conrms that bolt slip eventually leads to signicant bearing action, enough to develop the full plastic moment capacity of the beam section. The slip and elongation of the material around the bolt holes (see Fig. 16) show that the rst line of bolts in the BT connection experienced the largest deformation. The last line of bolts (near the face of column) and the second line of bolts also experienced some slip and bearing action. This indicates that the centre of BT rotation was not at the centre of the bolt group contrary to what was assumed in its design. The total rotation of the BT and the TC connections measured by inclinometer 6 is shown in Fig. 17a. The rotation of the TC connection (Fig. 17b) shows that a part of the total rotation was provided by the TC connection. The other part of the connection rotation was provided by the BT connection (Fig. 17c and d). The initial connection rotation was mainly provided by the BT connection (see Video 6). The rst line of bolts of the BT connection slipped rst (as expected) as the rotation of the last line of bolts was not initially signicant (Fig. 17d). The slip of the TC connection was mainly activated from the 0.06 rad cycle onwards (see Video 6 and Fig. 17b). It can be concluded that the local rotation of the connection elements (Fig. 17) made a large contribution (maximum h = 0.053 rad) to the global rotation of 0.1 rad at the beam end (Fig. 12B3). 3.2.4. Hysteretic momentrotation behaviour of Specimen B3 during retest For the retest of Specimen B3 the torque on the beam-tothrough plate and the through plate-to-column connections bolts

was increased from 240 N m to 320 N m and from 170 N m to 240 N m, respectively. The new increased pretension forces were calculated such that the resistance of the farthest bolts was greater than the largest applied forces (Rreq/Rn = 0.83 and 0.8 for the BT and the TC connections, respectively). It should be noted that both curved anges of beam already experienced massive plastic strains (in excess of 35,000 le) from the previous test. Slip of the connections was triggered at h = 0.03 rad cycle (see Video 8) at the load of M/Mp = 0.89 which was higher than the M/Mp = 0.76 from the rst test (Fig. 12). In the second cycle of this rotation, the slip load dropped to M/Mp = +0.78 and 0.72. At h = 0.06 rad cycle, ange local buckling was initiated between the 2nd and 3rd vertical stiffeners (see Video 8). At h = 0.07 rad cycle, the slip loads occurred at M/Mp = +0.78 and 0.7 and the maximum loads reached M/Mp = 1.09 (Points C and C, Fig. 12). At h = 0.09 rad, at the second cycle the maximum loads dropped to M/Mp = +0.83 and 0.91 (Points D and D). At h = 0.1 rad cycle, the load dropped signicantly to Point E due to rupture in the anges which extended vertically through the bolt holes in the webs, as shown in Figs. 13 and 18. The total rotation of the BT and the TC connections (Fig. 19a) shows that connection slip was reduced in comparison with the rst test (Fig. 17). The slip of the TC connection (Fig. 19b) was activated from the rst cycle (see Video 8). By increasing the pretension forces, most of the deformation was provided in exure by the beam and this led to very large plastic strains on top of the plastic strains already developed during the rst test. The fracture was a result of low cycle fatigue.

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

381

Fig. 17. Specimen B3: local deformations in elements of connection.

Fig. 18. Specimen B3 (retest): Rupture at h = 0.1 rad cycle (Point E).

Fig. 19. Specimen B3 (retest): local deformations in elements of connection.

382

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

values remained steady without noticeable change at large rotations (Fig. 22). 3.4.2. Strain distribution in beam anges The typical normalised strains at the crest of the anges (SG6171) for different cycles and for both loading directions are shown in Fig. 23a and b for Specimen A1. The strain values show that e/ey = 1 occurred in the critical sections (SG63-69) immediately after 0.015 rad corresponding to Point B in Fig. 6. At h = 0.03 rad0.04 rad rotations, the strain values in the critical sections increased signicantly due to buckling in compression (region CD in Fig. 6). Due to extensive ange buckling after 0.04 rad, the strain values in the critical sections increased massively and plastic strains were locked in such a way that the local strains remained compressive even when the ange was in tension (region DE in Fig. 6). For the specimens in which the deformations were dominated by connection slip (Specimens B2 and B3) the strain increased in a symmetric and gradual manner both on the tension and compression anges up to the last cycle of 0.1 rad rotation (Fig. 24 for Specimen B3) without any evidence of signicant local buckling (contrary to what was seen in the previous type of specimens). 4. General discussion Based on the test results, this section presents a summary and discussion on ductility, strength, energy, slip-bearing action and design of the web bolted connections. 4.1. Ductility and strength The use of the two stiffener congurations in the connections (minimum: 2 pairs of vertical stiffeners, full: four pairs of vertical and two pairs of horizontal stiffeners) resulted in a signicant increase in ductility for Specimens A2 and A3 by 50% and 75% and for Specimens B2 and B3 by 28% and 43%, respectively, relative to the specimens without stiffeners (A1 and B1; see Fig. 25a). Correspondingly, the moment strength increased for Specimens A2 and A3 by 29% and 35% and for Specimens B2 and B3 by 10% and 23% (see Fig. 25b), respectively. The stiffeners constrained both the anges and the webs and increased the buckling resistance of the elements. 4.2. Energy dissipation The cumulative energy dissipation (E) derived from the hysteretic curves (at each rotation level) for all the specimens is shown in Fig. 26.

Fig. 20. Specimen A1: connection rigidity Sj,ini = Mc/(h6 h5).

3.3. Connection rigidity The initial stiffness value of Sj,ini = KbLb/EIb proposed in Eurocode 3 part 18 [14] was used to classify the rigidity of the beam-tocolumn connections: Sj,ini < 0.5Lb/EIb for simple connections and Sj,ini > 25Lb/EIb for rigid connections, where Lb and EIb are the length and bending rigidity of the beam, respectively. For all the specimens, the connections can be placed in the category of rigid connections. The initial slope of the curves, Mc / (h6 h5), is larger than 25Lb/EIb as shown in Fig. 20 for Specimen A1, where Mc is the bending moment at the column face and the relative beam-column rotation (h6 h5) was taken as the difference of the values measured by inclinometers 5 and 6.

3.4. Strain distributions This section presents the maximum strain values at the critical sections of the through plate and the beam anges normalised by the proof strain, ey = 0.2%.

3.4.1. Strain distribution in through plates The normalised strains for different cycles at the face of the column and at the middle of the inclined edges of the through plate are shown in Fig. 21a and b, respectively for Specimen A1 typical of specimens dominated by exural and local buckling deformation in the beams (Specimens A13 and B1). At rotations exceeding 0.03 rad, following buckling initiation, the strain values begin to drop. It is clear from Fig. 21 that, as desired, the through plate did not yield. The unsymmetrical results can be due to out-of-plane bending of the through plate, which means there is a potential for lateral failure mode if the beam is not braced properly. For the specimens in which the deformations were dominated by connection slip (Specimens B2 and B3), the through plate strain

(a)

(b)

Fig. 21. Specimen A1: maximum through plate normalised strains (ey = 0.2%) (a) at the face of the column (b) at the middle of the inclined edges.

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

383

(a)

(b)

Fig. 22. Specimen B2: maximum through plate normalised strains (ey = 0.2%) (a) at the face of the column (b) at the middle of the inclined edges.

Fig. 23. Specimen A1: maximum normalised strains (ey = 0.2%) at the crest of the anges.

Fig. 24. Specimen B3: maximum normalised strains (ey = 0.2%) at the crest of the anges.

384

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

Fig. 25. (a) Ductility factors and (b) normalised bending moment strength of all specimens.

(a)

Specimen A1 (3 mm beam thickness) without any stiffeners dissipated the lowest amount of energy (Fig. 26a). The use of partial stiffeners for Specimen A2 increased the hysteretic energy by $30%. The use of full stiffeners for Specimen A3 increased the hysteretic energy further by $90% and allowed the specimen to reach larger rotation cycles (Fig. 26a). By increasing the beam thickness to 4 mm in Specimen B1, the hysteretic energy increased by $122% compared to Specimen A1 (Fig. 26a). In specimens B2 and B3, the use of partial or full stiffeners in conjunction with connection slip enabled the development of both the nominal plastic moment capacity and stable hysteretic cycles at large rotations. This led to a signicant increase of the hysteretic energy (e.g. 73% for B3 in Fig. 26b relative to B1). By limiting the connection slip in the retest of specimens B2 and B3, the cumulative hysteretic energy increased even further (240% for B3-retest in Fig. 2.26b relative to B1) until the eventual failure due to ange rupture. Connection slip can be benecial in severe earthquakes by delaying failures in beams and thus producing highly stable energy dissipating elements.

(b)

experience higher frictional resistance which lead to higher loads. On the other hand the position of the bolts relative to the plate holes is not known. Therefore, the bolt shafts may come in contact with the plate at any stage after slip. This contact can be in any direction and it can be a full contact or just partial contact. Hence, at the beginning of bolt slip the bearing contribution is not easily determined. However, eventually at large rotations bearing action will be fully mobilised. The connection slip-bearing actions at high levels of load and deformation (without any local buckling) were reached in Specimens B2 and B3 (as expected). When bearing action was activated after slip of the bolts, the bending moment in the beam increased to values greater than the nominal Mp. Therefore, after reaching large deformations in the connections, the deformation demand was again shifted to the beam. This allowed the beams to sustain their bending moment resistance at very large deformations without any local buckling. The contribution of the connections in dissipating seismic energy by slip-bearing actions can be utilised to reduce the damage on the main structural members during severe earthquakes. 4.3.1. Stabilised slip resistance load After the initial slip cycles, the contact area within the slip zone becomes smoother, thus leading to a reduction of the slip resistance load at subsequent cycles, as shown in Fig. 27 for Specimens B2 and B3. Another reason for this reduction may be the loss of pretension forces in the bolts. In the case of specimens B2 and B3 the slip load stabilised at around M/Mp = 0.4. These results can be used in updated FE models to simulate the slip resistance [15]. Simple experiments can also be devised to determine the cyclic slip force. 4.3.2. Design implications of slip-bearing actions In Specimens A13 the required resistance of the farthest bolts was lower than the design resistance [13] (Rreq/Rn = 0.83 for BT connection and Rreq/Rn = 0.85 for TC connection). In Specimens

Fig. 26. Hysteretic energy dissipation curves of all specimens.

4.3. Slip-bearing action Slip-bearing at the connections can be a highly nonlinear action especially under cyclic loads. The observed slip of the bolts is characterised by sudden changes (jumpinggripping), thus hardening in the Mh curve could be either due to friction (gripping) or bearing of the bolts. This depends on the frictional resistance between bolts and plates and the contact resistance between bolts and the material around the bolt holes. In the tested specimens the plate surfaces were shot blasted to increase the roughness and slip resistance. The applied pretension forces were expected to somewhat atten the surface and reduce the roughness of the area of the plates in contact with the bolt washers. Once the slip resistance of the bolts was reached, the slipping bolts (and washers) had to atten the rough surface of the adjacent area and as a result

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386

385

(ii) moment capacity (up to 35%) and (iii) hysteretic energy dissipation capacity (up to 240%) also due to the activation of connection slip.

Acknowledgements The authors would like to express their gratitude to the Earthquake Research Group in the Department of Civil and Structural Engineering at The University of Shefeld and Corus Research, Development & Technology for their nancial support.

Fig. 27. Slip resistance at the loading cycles of Specimens B2 and B3.

Appendix A The design specications of the auxiliary (test set-up) components are the following: Connections: The force distribution in the beam-to-through plate and through plate-to-column connections was based on the assumption of uniform rotation in the connections. The column-to-reaction frame connection was designed by assuming coupling forces such that to provide overstrength in this connection. Reaction frame: This comprised two very large (and stiff) columns seated on a large bottom beam and a supporting top beam. The test column was connected to the lower part of one of the reaction frame columns. Lateral restraints were connected to the bottom beam and the loading actuator was hanged from the top beam of the reaction frame. Column: Back-to-back hot-rolled channels were used with ange width of 150 mm, thickness of 16 mm, and web depth of 300 mm and thickness of 10 mm. Lateral restraints: Two lateral brace frames were used to avoid premature global instability. According to the AISC Seismic Provisions [7], both beam anges should be laterally braced near plastic hinges and regions with concentrated forces. Four brackets and PTFE sheets were used between the bracing frames and the beam at both sides to minimise friction. Loading plates: A loading plate connected by 6M16 was placed between the webs of the beam sections. This plate was connected to the head of the actuator by the detail shown in Fig. 3. The reason of using this complicated detail was the height limitation of the supporting frame that lowered the actuator head below the beam. Stiffeners: The end of the beams at the loading point was stiffened to avoid premature local failure. For this purpose, three pairs of stiffeners were welded inside the beams near the load application point (Fig. 3). Four pairs of stiffeners and continuity plates were welded inside the webs of the column and the reaction frame (Fig. 3), to avoid any premature local failure in the connection between the column and reaction frame. Filler plates: To protect the strain gauges in the connection panel zone area and to simulate the actual boundary conditions of the through plate in tube columns (without restraint inside the column), two ller plates were placed on each side of the through plate at the locations of the through plate-to-column connection bolts (Fig. 3).

B13 the required resistance of the farthest bolts was higher than the design resistance [13] (Rreq/Rn = 1.11 for BT connection and Rreq/Rn = 1.13 for TC connection). Therefore, no connection slip was expected in Specimens A1- 3. However, the test results showed that slip was not completely absent in Specimens type A, with noticeable slip in Specimen A2. The main reason for this is the assumption of uniform rotation in connection design, which was found not to be valid in these experiments as the rst line of bolts was more susceptible to slip than the other bolt lines. A thorough investigation is needed to determine the precise location of the centre of rotation. Specimen B1 showed no noticeable connection slip contrary to what was expected from the design calculations. The reason was that only 0.97Mp was mobilised at the critical section of the beam instead of the full design moment of 1.21Mp. Therefore, the required/available slip resistance ratio was reduced to 0.97/ 1.21 1.13 = 0.91. In Specimens B2 and B3 the mobilised moments were 1.065Mp and 1.19Mp, respectively, so the required/available slip resistance ratios were reduced to 1.065/1.21 1.13 = 1.0 and 1.19/1.21 1.13 = 1.11, respectively. For Specimens B2 and B3 a large part of the deformation demand was met by slip and bearing actions in the connection prior to the occurrence of any local buckling in the beams. To achieve this behaviour, it is recommended to design the slip of the connection at the level of nominal bending strength of the beam without accounting for the strain hardening and material overstrength and by applying a modication factor if the full moment strength cannot be activated. 5. Conclusions This study has shown that CFS curved ange beams cannot only exceed the nominal plastic moment capacity (Mp), but also sustain this capacity at large rotations similar to Class 1 cross sections in Eurocode 3 part 1-1 [6] and larger than 0.04 rad required for special moment frames in AISC Seismic Provisions [7]. The tested connections can be classied as rigid, and either partial strength with M/Mp < 1 (Specimens A1 and B1) or full strength with M/Mp > 1 (Specimens A23 and B23) according to Eurocode 3 part 18 [14]. In the beams of Specimens B2 and B3, large plastic strains were delayed and occurred at very large rotations after mobilisation of the bearing action in the connections. This enabled the CFS bolted connections to produce highly stable hysteretic behaviour which can be utilised to improve the seismic performance of buildings. The use of a minimum conguration (for Specimens A2 and B2) and a full conguration (for Specimens A3 and B3) of connection stiffeners resulted in a signicant increase (relative to Specimens A1 and B1 without stiffeners) in (i) ductility (up to 75%),

Appendix B. Supplementary material Supplementary data associated with this article can be found, in the online version, at http://dx.doi.org/10.1016/j.engstruct.2012. 04.025.

386

A. Bagheri Sabbagh et al. / Engineering Structures 42 (2012) 371386 [8] Bagheri Sabbagh A, Petkovski M, Pilakoutas K, Mirghaderi R. Ductile momentresisting frames using cold-formed steel sections: an analytical investigation. J Constr Steel Res 2011;67:63446. [9] Bagheri Sabbagh A, Petkovski M, Pilakoutas K, Mirghaderi R. Development of cold-formed steel elements for earthquake resistant moment frame buildings. Thin-Wall Struct 2012;53:99108. [10] Bagheri Sabbagh A. Cold-formed steel elements for earthquake resistant moment frame buildings, PhD thesis, University of Shefeld; 2011. [11] Lim JBP, Nethercot DA. Ultimate strength of bolted moment-connections between cold-formed steel members. Thin-Wall Struct 2003;41:101939. [12] Ho HC, Chung KF. Experimental investigation into the structural behaviour of lapped connections between cold-formed steel Z sections. Thin-Wall Struct 2004;42:101333. [13] Specication for structural joints using ASTM A325 or A490 bolts. American Institute of Steel Construction, Chicago, Illinois; 2004. [14] Eurocode 3: design of steel structures: Part 1.8: Design of joints, EN 1993-1-8; 2005. [15] Bagheri Sabbagh A, Petkovski M, Pilakoutas K, Mirghaderi R. Cyclic behaviour of bolted cold-formed steel moment connections; FE modeling including slip. J Constr Steel Res, submitted for publication.

References

[1] Uang C-M, ASCE M, Sato A, Hong J-K, Wood K. Cyclic testing and modeling of cold-formed steel special bolted moment frame connections. J Struct Eng 2010;136(8). [2] Chung KF, Lau L. Experimental investigation on bolted moment connections among cold formed steel members. Eng Struct 1999;21:898911. [3] Wong MF, Chung KF. Structural behaviour of bolted moment connections in cold-formed steel beam-column sub-frames. J Constr Steel Res 2002;58:25374. [4] Bagheri Sabbagh A, Mirghaderi R, Petkovski M, Pilakoutas K. An integrated thin-walled steel skeleton structure (two full scale tests). J Constr Steel Res 2010;66:4709. [5] ANSI/AISC 360-05, Specication for structural steel buildings, american institute of steel construction, Illinois; 2005. [6] Eurocode 3: design of steel structures: Part 1.1: General rules and rules for buildings, EN 1993-1-1; 2005. [7] ANSI/AISC 341-05, Seismic provisions for structural steel buildings, american institute of steel construction (AISC), Illinois; 2005.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Estimating Calculator Based On Max PajardoDocument26 pagesEstimating Calculator Based On Max Pajardofred anthony UeraNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Multistoreyed Building 2Document40 pagesMultistoreyed Building 2V.m. Rajan100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Brief History of Beam-Column DesignDocument11 pagesA Brief History of Beam-Column DesigntaosyeNo ratings yet

- Bruhn + Supplement PDFDocument1,128 pagesBruhn + Supplement PDFCraig Swenson100% (4)

- Designers' Guide To EN1991-1-2, EN1992-1-2, EN1993-1-2 and EN1994-1-2Document136 pagesDesigners' Guide To EN1991-1-2, EN1992-1-2, EN1993-1-2 and EN1994-1-2Ahmed Ewis100% (2)

- Column Design As Per BS 8110-1:1997: PHK/JSNDocument16 pagesColumn Design As Per BS 8110-1:1997: PHK/JSNJennifer Tang100% (2)

- Quantity SurveyingDocument34 pagesQuantity SurveyingVaruni_Gunawardana100% (2)

- Industrial Training ReportDocument63 pagesIndustrial Training ReportMohamed Shamal77% (13)

- Slimdek Pattern BookDocument40 pagesSlimdek Pattern BookBabak WSP GroupNo ratings yet

- STRUCTURAL DESIGN REPORTDocument24 pagesSTRUCTURAL DESIGN REPORTJaydeep PatelNo ratings yet

- JDE 12 - Design of ColumnsDocument47 pagesJDE 12 - Design of Columnsyedida viswanadhNo ratings yet

- Design of structural elements according to EurocodesDocument8 pagesDesign of structural elements according to EurocodesIMJ JNo ratings yet

- Concept and Development of A Steel - Bamboo SI (Skeleton-Infill) System: Experimental and Theoretical AnalysisDocument12 pagesConcept and Development of A Steel - Bamboo SI (Skeleton-Infill) System: Experimental and Theoretical AnalysislaythsalmsnNo ratings yet

- Column (1) SRCDocument17 pagesColumn (1) SRCpratik ranaNo ratings yet

- Two Way SlabDocument19 pagesTwo Way SlabAllysa Joy MoralesNo ratings yet

- Ip 21151006Document15 pagesIp 21151006Abuturab SharikmaslatNo ratings yet

- BibliografiaDocument14 pagesBibliografiaAndrésNo ratings yet

- Behavior of Q690 High-Strength Steel Columns - Part 2 - Can - Be - UsedDocument16 pagesBehavior of Q690 High-Strength Steel Columns - Part 2 - Can - Be - UsedSeymur AkbarovNo ratings yet

- Env PDFDocument164 pagesEnv PDFHarsh GuptaNo ratings yet

- 3b. Column Base Plate Ce134p Escruz LRFDDocument17 pages3b. Column Base Plate Ce134p Escruz LRFDjohn devonNo ratings yet

- Basic Components of A BuildingDocument7 pagesBasic Components of A Buildingrahimmulla100% (3)

- Calatrava 1 PDFDocument100 pagesCalatrava 1 PDFKawaii Sherly-Shop0% (1)

- 1001bit Pro User GuideDocument87 pages1001bit Pro User GuideArthur ChavesNo ratings yet

- 1569 ch31Document58 pages1569 ch31Karthik KrishNo ratings yet

- Statically Inderterminate MembersDocument143 pagesStatically Inderterminate MembersKai de LeonNo ratings yet

- Designing slim concrete columns for fire resistanceDocument25 pagesDesigning slim concrete columns for fire resistancealberto5791No ratings yet

- Deflection - Ontario Building CodeDocument2 pagesDeflection - Ontario Building CodechidsalazarNo ratings yet

- Laced and Battened ColumnsDocument24 pagesLaced and Battened ColumnsAbdullahi Dirie AbdiNo ratings yet

- Bi-Axial PM InteractionDocument368 pagesBi-Axial PM InteractionSTRUCTURE -STRUCTURENo ratings yet

- Anchor Bolts and Baseplate DesignDocument10 pagesAnchor Bolts and Baseplate DesignochukoikoghoNo ratings yet