Professional Documents

Culture Documents

Conmix Utg 2011

Uploaded by

Fredj Ben SalemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conmix Utg 2011

Uploaded by

Fredj Ben SalemCopyright:

Available Formats

CONMIX LTD.

UNIVERSAL TILE GLUE - UTG

Top grade tile adhesive...

UTG is a dry pre mix, waterproof, cement-based tile glue for thin-bed fixing of ceramic tiles on walls and floors. Long open time and excellent workability ensure the fixing of even heavy tiles. Available in grey and white colour.

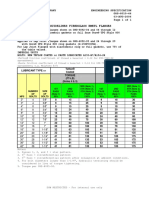

TECHNICAL DATA

Composition : Ordinary Portland Cement, oven dried, processed sand and chemical additives. Binder Aggregate Size Appearance Mixing Ratio : : : : Portland Cement 0-0.6 mm Granular powder available in Grey &White colours

APPLICATION METHOD

BACKGROUND UTG is a thin bed mortar suitable for fixing a wide variety of wall and floor tiles onto backgrounds such as: Portland Cement based

renders, floor screeds, concrete 7.5 ltrs of water per 25 kg bag Water/Powder ratio = 0.30 Approx. Yield/Coverage * : 18 ltrs per 25 kg bag; 6m2 per 25 kg bag at 3mm thickness Density * Compressive Strength * Flexural Strength * Pack Size Shelf Life : : : : : Wet : 1.8 kg/ltr 20 N/mm2 @ 28 days 3.0 N/mm2 @ 28 days 25 kg paper bags The suction in the background 12 months from date of production when stored under dry conditions Working Time Specification : : Approx. 45 minutes ANSI, BS5385, BSEN12004, DIN:18156-2 should be neutralized by applying potable water. Free water on the surface should be allowed to disperse before applying UTG. Dry : 1.7 kg/ltr and gypsum boards. UTG should not be applied onto wood, metal sheets or painted surfaces. The background and tile must be clean, free of dust deposits, sinter skin, formwork oil and other contamination, which may affect the adhesion.

* Typical results under laboratory condition Cont...

Application tools

1/2

PMP/UTG/ Ver2/04/10

Pre-treatment, ie. wetting of tiles is essential. However, due to the wide variety of tiles available, it is advisable to consult the tile manufacturer for recommendations. MIXING UTG supplied in 25 kg bags has to be mixed with potable water only, in a clean plastic bucket or a clean, non-corrosive uncontaminated metal tub. To ensure a homogeneous and uniform mix, an electric agitator must be used. The amount of water to be added is approximately 7.5 ltrs per 25 kg bag (i.e. 30% by weight). Add UTG to water, turn the contents of the bag carefully and stir frequently. Once mixed, allow to stand for 5 minutes and mix again before applying. No further water should be added to the mix. The mixed mortar must be used within 45 minutes. Hard and set mortar should not be re-mixed or used. APPLICATION UTG is applied in one coat, having a thickness of 3-5 mm. To achieve a uniform thickness the mortar is levelled with a serrated trowel. The thickness of the ribs will depend on the size and type of the tile. Do not spread more than 1m2 at a a time, spreading larger areas may result in the mortar drying out before tiles can be pressed home, resulting in poor adhesion. Once the mortar has been applied, the working time will vary according to the porosity of the surface and ambient conditions. While tiling in wet areas, i.e. swimming pools, shower rooms etc, ensure solid bedding, no voids or air pockets behind the tiles. Do not apply the mortar sparingly. Buttering the mortar onto the back of the tile is not recommended; but if essential it should be spread over the entire back of the tile to an even depth. Conmix demonstration team will assist in these procedures upon request. SPECIAL NOTES UTG has to be protected from direct exposure to sun, wind and rain during application. Ceramic tiles should never be fixed with tight joints. Leave a minimum space of 2 mm around every tile. Tiling in newly constructed buildings should not commence until all shrinkage movement and creeping has taken place. Cement based mortars, plasters, renders and floor screeds must be allowed to harden before tiling commences. Grouting should not be carried out for at least 48 hours after the completion of tiling. STORAGE Conmix UTG must be stored in a dry place, off the ground and well covered. Hard or lumpy material must be rejected.

PMP/UTG/ Ver2/04/10

2/2

It is the customers responsibility to satisfy themselves by checking with the company that the information is still current at the time of use. The customer must be satisfied that the product is suitable for the use intended. All products comply with the properties shown on current data sheets.Conmix however do not warrant or guarantee the installation of the products as it does not have any control over installation or end use of product. All information and in particular the recommendations relating to application and end use are given in good faith. The products are guaranteed against any defect and are manufactured and sold to Conmix standard terms and conditions of sale.

You might also like

- Products: CatalogueDocument43 pagesProducts: CatalogueEngChuan LimNo ratings yet

- Concrete Placement (Spec)Document18 pagesConcrete Placement (Spec)Vetrivel MuruganNo ratings yet

- Jet Fuel Sealant CEMTEC 200Document2 pagesJet Fuel Sealant CEMTEC 200pravi3434No ratings yet

- Polyseal 1PU: One Part Polyurethane Joint SealantDocument2 pagesPolyseal 1PU: One Part Polyurethane Joint SealantVaittianathan MahavapillaiNo ratings yet

- TDS Renderoc RGM IndiaDocument4 pagesTDS Renderoc RGM IndiaKishore Nayak kNo ratings yet

- Working Method Statement of PLASTERINGDocument4 pagesWorking Method Statement of PLASTERINGfranklin mertoNo ratings yet

- Masterflex 700 GGDocument3 pagesMasterflex 700 GGHaresh BhavnaniNo ratings yet

- Qcs 2010 Part 24.05 TilesDocument6 pagesQcs 2010 Part 24.05 TilesRotsapNayrb100% (1)

- Jotashield exterior paint work methodDocument2 pagesJotashield exterior paint work methodSetyawanNo ratings yet

- PDS - SikaSeal-402 Fillerboard MYDocument2 pagesPDS - SikaSeal-402 Fillerboard MYSiji OktoberNo ratings yet

- Epoxy Painting Method GuideDocument3 pagesEpoxy Painting Method GuideKaram MoatasemNo ratings yet

- Mastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentDocument3 pagesMastertop 528: Commercial Grade Self-Levelling Cementitious Floor UnderlaymentFrancois-No ratings yet

- Cmci Cmci: Epoxy Grout System For Equipment BasesDocument2 pagesCmci Cmci: Epoxy Grout System For Equipment Basespravi3434No ratings yet

- Repairing of Plaster WallsDocument4 pagesRepairing of Plaster WallsSayan GharNo ratings yet

- CMCI Aliphatic PU coating applicationDocument3 pagesCMCI Aliphatic PU coating applicationPageduesca RouelNo ratings yet

- Micrasil TDSDocument2 pagesMicrasil TDSAmmarNo ratings yet

- Renderoc TGDocument4 pagesRenderoc TGBalasubramanian Ananth100% (1)

- Gabion Wall Installation GuideDocument5 pagesGabion Wall Installation GuideJoel KomaNo ratings yet

- Vetonit Spatter Dash-MC SDM212Document2 pagesVetonit Spatter Dash-MC SDM212toni mujiyonoNo ratings yet

- METHOD OF STATEMENT - ALKHOMRA PROJECT - MarbleDocument9 pagesMETHOD OF STATEMENT - ALKHOMRA PROJECT - Marbleahmed samirNo ratings yet

- MS Brickwork Manhole and In-Situ Cast Manhole Top SlabDocument4 pagesMS Brickwork Manhole and In-Situ Cast Manhole Top SlabCameron MayNo ratings yet

- Tds Al Jazeera Green SilkDocument1 pageTds Al Jazeera Green SilknanoNo ratings yet

- MOS of Installation Rise FloorDocument13 pagesMOS of Installation Rise FloorHussam WaleedNo ratings yet

- Waterproof Planiseal 288Document3 pagesWaterproof Planiseal 288Chezy629No ratings yet

- Method Statement For Roof Water ProofingDocument6 pagesMethod Statement For Roof Water ProofingSagar ParabNo ratings yet

- How To Install D400 Manhole Covers: Technical GuideDocument12 pagesHow To Install D400 Manhole Covers: Technical GuideBalaji Naik100% (1)

- AIPL WMS Granite Flooring MethodDocument3 pagesAIPL WMS Granite Flooring MethodDeepak PatilNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Method Statement Asphalt PavingDocument3 pagesMethod Statement Asphalt PavingHussam WaleedNo ratings yet

- Technical Data - Light Emperador MarbleDocument1 pageTechnical Data - Light Emperador MarbleGlexer Dazo Corrales0% (1)

- Epoxy Bedding SystemDocument2 pagesEpoxy Bedding Systempravi34340% (1)

- Fenomastic Pure Colours Enamel MattDocument4 pagesFenomastic Pure Colours Enamel MattAslam KhanNo ratings yet

- Plastering Method StatementDocument5 pagesPlastering Method StatementChezy629No ratings yet

- Technical Data Sheet for Emulsified Bituminous PrimerDocument2 pagesTechnical Data Sheet for Emulsified Bituminous Primerhandhammer qatarNo ratings yet

- Method Statement For In-Situ Pull Off Test On MarbleDocument15 pagesMethod Statement For In-Situ Pull Off Test On MarbleGary Lo67% (3)

- Silver Schmidt ManualDocument47 pagesSilver Schmidt ManualEl LlacunaNo ratings yet

- MS - CHRYSO Tapelastic Premia (Kalpitiya)Document3 pagesMS - CHRYSO Tapelastic Premia (Kalpitiya)Kasun HewagamaNo ratings yet

- Epoxy Grouting Application Work ProcedureDocument14 pagesEpoxy Grouting Application Work Proceduremanoj thakkarNo ratings yet

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972No ratings yet

- Instruction Manual for Hilman Roller SystemsDocument22 pagesInstruction Manual for Hilman Roller SystemsMohd Fadli0% (1)

- Al-Jazeera Epo-Rich Primer12 PDFDocument2 pagesAl-Jazeera Epo-Rich Primer12 PDFAmer Y K100% (1)

- Al Jazeera Rawa15Document1 pageAl Jazeera Rawa15hemajsuryaNo ratings yet

- Quality Assurance ManualDocument6 pagesQuality Assurance ManualEdgarDavidDiazCamposNo ratings yet

- Method Statement For Backfilling and Compaction ProcedureDocument22 pagesMethod Statement For Backfilling and Compaction ProcedureAlbertyNo ratings yet

- Cem Tec White PuDocument2 pagesCem Tec White Pupravi3434No ratings yet

- Method of Statement PCDocument8 pagesMethod of Statement PCAbada SaadNo ratings yet

- Torque Guidelines Fiberglass Emetl FlangesDocument1 pageTorque Guidelines Fiberglass Emetl FlangesvesselyNo ratings yet

- MS For Wet TradeDocument11 pagesMS For Wet TradeGary LoNo ratings yet

- ASTM D2397-05 Cationic EmulsionsDocument11 pagesASTM D2397-05 Cationic EmulsionsRicardoNo ratings yet

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For ScaffoldingDouglas JambaNo ratings yet

- Method Statement: Emergency Contact DetailsDocument9 pagesMethod Statement: Emergency Contact DetailsShazwaniNo ratings yet

- UltraTech FixoBlock Thin Joint MortarDocument2 pagesUltraTech FixoBlock Thin Joint MortarRohan BagadiyaNo ratings yet

- Autoclaved Aerated Concrete Blocks (Acc Blocks)Document3 pagesAutoclaved Aerated Concrete Blocks (Acc Blocks)Omar DaghistaniNo ratings yet

- Majestic True Beauty Matt: Technical Data SheetDocument3 pagesMajestic True Beauty Matt: Technical Data SheetBilher SihombingNo ratings yet

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Document8 pagesVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- Apron Concrete Repair Method R01Document19 pagesApron Concrete Repair Method R01ayhanarmanNo ratings yet

- Renderoc FC (1) Fairing Coat PDFDocument4 pagesRenderoc FC (1) Fairing Coat PDFPrashant MankarNo ratings yet

- Method Statement For Brickworks: Pembinaan Infra E&J SDN BHDDocument5 pagesMethod Statement For Brickworks: Pembinaan Infra E&J SDN BHDChezy629No ratings yet

- Conmix C800 2011Document2 pagesConmix C800 2011Fredj Ben Salem50% (4)

- Adhesive InstructionsDocument3 pagesAdhesive Instructionsyiel2003No ratings yet

- Cpupec Dec SolDocument1 pageCpupec Dec SolFredj Ben SalemNo ratings yet

- Conmix C800 2011Document2 pagesConmix C800 2011Fredj Ben Salem50% (4)

- Salem Halila ModelDocument1 pageSalem Halila ModelFredj Ben SalemNo ratings yet

- Ligne D'influence de Poutre de RiveDocument4 pagesLigne D'influence de Poutre de RiveFredj Ben SalemNo ratings yet

- Autodesk 2012 Product Key Stingy - The Right To (April 28, 2011)Document6 pagesAutodesk 2012 Product Key Stingy - The Right To (April 28, 2011)Fredj Ben SalemNo ratings yet

- Final Bill (Submitted)Document16 pagesFinal Bill (Submitted)Tariq MahmoodNo ratings yet

- Sealand-A Maersk Company - BrandBooklet - vs01Document3 pagesSealand-A Maersk Company - BrandBooklet - vs01MT JasonNo ratings yet

- Baselitz - Exhibition CatalogueDocument5 pagesBaselitz - Exhibition CatalogueArtdataNo ratings yet

- Training & Certification UpdatesDocument64 pagesTraining & Certification UpdatesRoger MachaNo ratings yet

- Quality Management Project On Quality Tools of "Ford Motors"Document6 pagesQuality Management Project On Quality Tools of "Ford Motors"Anuj SharmaNo ratings yet

- Psykter by DourisDocument1 pagePsykter by DourisGayatri GogoiNo ratings yet

- Chinese pagodas and the Chicago Tribune TowerDocument8 pagesChinese pagodas and the Chicago Tribune TowerJehan Mohamad100% (1)

- Squisito 2020 - Company Profile PDFDocument16 pagesSquisito 2020 - Company Profile PDFSquisito LLCNo ratings yet

- Door and Frame - Technical Manual PDFDocument384 pagesDoor and Frame - Technical Manual PDFRichard Oon100% (1)

- Increte Clear SealDocument2 pagesIncrete Clear SealBrembertNo ratings yet

- Catalog WID - Automotive 240718 REV04 OKTDocument111 pagesCatalog WID - Automotive 240718 REV04 OKTlukman al hakimNo ratings yet

- Song Words For Yr 6 7 BookletsDocument7 pagesSong Words For Yr 6 7 Bookletsadalcayde2514No ratings yet

- Puducherry Artwork.Document14 pagesPuducherry Artwork.Yukta SainiNo ratings yet

- The Great Beauty of BogotaDocument3 pagesThe Great Beauty of BogotaDwightDemar DemarNo ratings yet

- Pigment DispersionsDocument4 pagesPigment DispersionsRatih AriyaniNo ratings yet

- KLEEMANN Design - New Catalog For Lift Cabins, Cops-Lops and DoorsDocument77 pagesKLEEMANN Design - New Catalog For Lift Cabins, Cops-Lops and DoorsKleemmann Hellas SANo ratings yet

- Florentine Baroque Art American CollectionsDocument1 pageFlorentine Baroque Art American Collectionsthot777No ratings yet

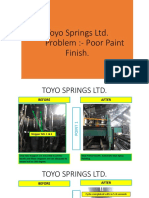

- Toyo Springs LTD (Action Plan Lucknow)Document9 pagesToyo Springs LTD (Action Plan Lucknow)Abhishek ChauhanNo ratings yet

- Restoration Dolly Project DetailsDocument1 pageRestoration Dolly Project DetailsLizar YusNo ratings yet

- The Workshop - A Tale of Edible Delights by Danieller123Document2,390 pagesThe Workshop - A Tale of Edible Delights by Danieller123rosebard22100% (1)

- Scope of Work Required For HDB RenovationDocument1 pageScope of Work Required For HDB RenovationgalacinNo ratings yet

- Proof Reading (Genesis)Document270 pagesProof Reading (Genesis)Mariappan EddiahNo ratings yet

- g30 Brochure Dec04Document12 pagesg30 Brochure Dec04Igor SimunovicNo ratings yet

- Thesis Report AshishDocument53 pagesThesis Report AshishSonu Sharma100% (1)

- Cactus Crochet Pattern: Size: 14 CM (5.5 Inch) Tall MaterialsDocument5 pagesCactus Crochet Pattern: Size: 14 CM (5.5 Inch) Tall MaterialsHien Tran100% (1)

- Jan Svankmajer: A Mannerist SurrealistDocument14 pagesJan Svankmajer: A Mannerist SurrealistCaio Cesar100% (1)

- (October Books) Denis Hollier, Betsy Wing-Against Architecture - The Writings of Georges Bataille-The MIT Press (1992) PDFDocument226 pages(October Books) Denis Hollier, Betsy Wing-Against Architecture - The Writings of Georges Bataille-The MIT Press (1992) PDFJanaína NagataNo ratings yet

- Starfall Kindergarten Lesson Plans Week5Document26 pagesStarfall Kindergarten Lesson Plans Week5Ashley YinNo ratings yet

- Epoxy Coating Method for Protecting Steel Pipes from CorrosionDocument5 pagesEpoxy Coating Method for Protecting Steel Pipes from Corrosionrahmed7862580% (5)

- Advertisng Design & PrinciplesDocument48 pagesAdvertisng Design & PrinciplesDiana Burns100% (11)