Professional Documents

Culture Documents

DSS Nosecone - Design, Study and Construction

Uploaded by

Vicente Alvero ZambranoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DSS Nosecone - Design, Study and Construction

Uploaded by

Vicente Alvero ZambranoCopyright:

Available Formats

DOUBLE SUGAR SHOT NOSECONE DESIGN,STUDY AND CONSTRUCTION

REV. 2013/01/28

Author: Vicente Alvero

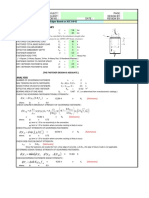

Mass and materials. As the SStS project generally uses low impuls rocket propellant, this fact implicates extremely high requirements on mass ratio of the whole vehicle. If propellants of higher specific impulse would be used, there would be no such critical need. Therefore, mass of all fairings and covers should be held as low as possible. Some mass calculated were provided, but there is always a lot of unconsidered bolts, nuts, wires, holders and brackets. Theirs mass may increase the final checksum significantly. Based on the DSS Mass Target, iteration #1 should be total mass of the NC kept below of 1.156 kg. For first approximation, the shape of the NC is considered to be true cone length of 0.93 m and 169 mm diameter at the base. NC surface is calculated to be: S = *r *s , where 2 = 2 + 2 When h>>r then h s and S = *0.169*0.93 = 0.496 0.5 [m, m, m2] Then outer surface of the NC (approximation for the true cone) is 0.496 sqm. If usual fiber glass cloth 160 g/ m2 ( thickness about 0.16mm) would be used, one full dry ply covering the whole surface of the NC weighs 160*0.496= 79,4 80 [g/m2, m2 , g] If resin/fiber glass mass ratio about 1:1 would be considered, one full ply including resin would take about 160g. If overlaps are considered, lets increase this mass for 15%, 160*1.15 = 184 [g, %, g] for full cured ply ( what is lot more realistic number). If kevlar (170 gr/2 , thickness 1.7mm) would be used, the entire covering ply of the NC would weigh 170*0.496 = 84.32 [gr/m2, m2, gr] If resin/kevlar mass ratio about 1:1 would be considered, one full ply including resin would take about 170g. If overlaps are considered, lets increase this mass for 15%, 170*1.15 = 195 [g, %, g] Our main requirements for the monocoque are that no more than 1.5 mm thick and weighing no more than 1156 grams.

Author: Vicente Alvero

If entire NC structure doesn't have to be heavier than 1156 g at maximum, mass margin for the nylon tip should be at least 5%, this leaves 1156*0.95 = 1098.2 [g, %, g] (approx 1098g) As we can see, if monocoque design would be proposed, it could consist from 1098 : 195 = 5.63 6 [gr ,gr , -] That means 6 full plies of 160 g/ m2 fiber glass cloth (well saturated, because 50:50 cloth/resin ratio is usually considered for free hand-layup technologies). Therefore, the total number of folds that it used is 6. In which case the thickness is equal to: 6 * 0.2 = 1.2 [- ,mm , mm] Rigidity. In this particular situation, as much as we can for the NC, means to keep all structures as thick, as possible. As calculated above, small increasing of the kevlar thickness doesn't change mass fraction too much, but the gain of final rigidity is extreme. Remember that the value of the modulus of elasticity at room temperature is around 80 GPa (Kevlar29) and 120 (Kevlar49) . The value of a typical steel is 200 GPa. Higher rigidity also moves selfresonance frequencies higher and simultaneously decreases their maximum amplitude. However,increased rigidity of structural components imposes higher requirements on manufacturing tolerances. Unidirectional plies embeded into the NC structure may change the final stiffness significantly; using of the IM (Intermediate Modulus) kevlar/fiber glass filaments also provides higher strength than usual HT (High Tenacity) filament type. When line of bolts or rivets is considered as a part of structure, a softening strips may be used to keep local stresses under control and displaced over larger areas. There was a finite element study on the final design of the nose cone and requirements have been met, because the weakest area of the nose cone, the base can withstand loads of 220 N (50 lbf).

Author: Vicente Alvero

Deformations of the NC. Basically, the NC may be considered a long tube (his length >> his diameter) his aspect ratio is about 5.5. Exactly, this is valid only for total length and full diameter of the NC at the root; his structure however, may be considered also as a tube of smaller diameters of the extended length, as we travel from the root to the tip. In case of wobbling, the structure in fairing-NC adjacent areas is extremely stressed. Under extreme conditions, root of NC or upper part of adjacent fairing may crack, especially when vehicle moves by transsonic velocities. As result from experience, confirmed by calculations of pressure fields in Partial Heating Study (pressure fields and streamlines are by products of temperature results) values of local overpressures combined with interference and movements of shock waves may exceed steady conditions several times. Therefore, all joints and all weak points of the structure should be carefully tested and overrated as we are not capable to determine such a loads exactly. Flattening of the NC (change of round cross-section of the into the ellipse) may happened when structure of the tube in considered section is too thin and flexible and not rigid enough - as tube changes into the ellipse, it loses stability and may bend, subsequently crack. This sequence may be dangerous in highly stressed area. Therefore, the structure should so stiff as possible. Uncertainty here may be considered so high and dangerous, that adjacent fairing could be proposed and designed with the NC as a monocoque structure. Therefore, the structure should be designed and manufactured very carefully.

Author: Vicente Alvero

Construction Mold The first step in building the nosecone was making the mold. We used two panels of Galician oak with dimensions of 1 meter long, 20 cm wide and 10 in thickness, which were joined together by epoxy resin.

Once they were bonded, was given pressure and the resin was allowed to dry for one week.

Once dry, we draw the outline of the nosecone on the surface of the wood and cut everything out of the trace of the pencil, so that the lathe need to work least possible.

Author: Vicente Alvero

Df Df

Once the mold has been finished with the lathe, sanding and is used to get the surface as smooth and uniform as possible.

And thereby the mold is finished.

Author: Vicente Alvero

Nosecone Once the mold is ready to start with the fiberglass, you need to apply a few layers of primer to cover his posilbes pores, layers of wax release agent and polyvinyl alcohol.

Applies 4 layers of primer drying time between coats 1 hour and thoroughly sanded between coats with 600 grit sandpaper. Also applied 6 layers of wax release agent with a drying time between layers 1 hour. Once the wax 6 layers have dried properly apply 4 layers of polyvinyl alcohol, waiting 3 hours between layers for its proper drying. Once everything is dry, we cut the layers of fiberglass and Kevlar, we can begin. For the nosecone ,we determined the following configuration with layers: two layers of 200 gr/sqm fiberglass, two layers of 170 gr/sqm kevlar and two layers of 160 gr/sqm fiberglass. All dried in a room at a constant temperature of 30 C for 24 hours.

Author: Vicente Alvero

Once the resin is completely dry, we proceed to sanding. For this process, we use the lathe in which the mold we had made previously. This ensures uniform sanding the entire surface. To sandig, we use different sandpaper with different grains, to finish with a 800 grit sandpaper.

Once the nosecone is sanded, and the edges are cut, we proceed to demoulding. The weight of the nose cone, the absence of the tip, is 581 gr. An improvement of 47% with respect to calculated. Finally, once the tip made of nylon, the overall weight of the nosecone is 639 gr, 45% improvement with respect to the top marked.

Author: Vicente Alvero

Author: Vicente Alvero

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Single Tension Fastener Away From Edges Based On ACI 318-02Document2 pagesSingle Tension Fastener Away From Edges Based On ACI 318-02civixxNo ratings yet

- Astm e 90Document15 pagesAstm e 90Ginneth_Millan_0No ratings yet

- Jack Sarfatti - Hologram UniverseDocument9 pagesJack Sarfatti - Hologram UniverseFrankOfTomorrowNo ratings yet

- Merchant's Circle NotsDocument5 pagesMerchant's Circle NotsSaravanan MathiNo ratings yet

- Chemistry Final Exam Review KEY: Practice ProblemsDocument7 pagesChemistry Final Exam Review KEY: Practice ProblemsZetrix JensenNo ratings yet

- Preliminary Steel Composite Bridge Design ExampleDocument11 pagesPreliminary Steel Composite Bridge Design Examplemamad66No ratings yet

- Ch2QM PDFDocument26 pagesCh2QM PDFfractalgeoNo ratings yet

- Formwork DesignDocument2 pagesFormwork DesignBilal Ahmed Barbhuiya67% (3)

- Ejercicios Calor ExamenDocument4 pagesEjercicios Calor ExamenAlexander Yauri Gomez50% (2)

- 09 Science Notes Ch10 GravitationDocument4 pages09 Science Notes Ch10 Gravitationdvrao_chowdaryNo ratings yet

- 151 0548 FS2017 K3 Introduction To Polymer MaterialsDocument49 pages151 0548 FS2017 K3 Introduction To Polymer MaterialsLu HkarrNo ratings yet

- Coupled PendulumDocument5 pagesCoupled PendulumSubhasis PandaNo ratings yet

- Photolysis Study by FtirDocument8 pagesPhotolysis Study by FtirrakibhossainNo ratings yet

- Strength of Materials (S.O.M.) Model Question Paper (Q.P.) SolutionDocument16 pagesStrength of Materials (S.O.M.) Model Question Paper (Q.P.) SolutionProf. P. H. Jain92% (13)

- Hubungan Antara Ilmu Dan TeknologiDocument38 pagesHubungan Antara Ilmu Dan Teknologiyoga prasetyaNo ratings yet

- Chapter 3c X Ray DiffractionDocument51 pagesChapter 3c X Ray DiffractionDeependra Kumar Ban100% (1)

- 4e3 A Maths Prelim Exam Paper 2Document4 pages4e3 A Maths Prelim Exam Paper 2ahmedzaki1234No ratings yet

- AmpereDocument28 pagesAmpereJaneth de JuanNo ratings yet

- Radial Equation For Spherically Symmetric PotentialDocument7 pagesRadial Equation For Spherically Symmetric PotentialOliver58No ratings yet

- Inverted Pendulum ControlDocument2 pagesInverted Pendulum ControlShwethaNo ratings yet

- Laboratory Manual: FOR Physics Laboratory - IDocument71 pagesLaboratory Manual: FOR Physics Laboratory - IAmy PetersNo ratings yet

- Chem ch3Document20 pagesChem ch3ChandlerNo ratings yet

- BD 2101Document77 pagesBD 2101babarkhattakNo ratings yet

- Chapter 2Document40 pagesChapter 2IntanLeeyanaNo ratings yet

- Crushed Ore Agglomeration and Its Control For Heap Leach OperationsDocument18 pagesCrushed Ore Agglomeration and Its Control For Heap Leach Operationsmehra222100% (3)

- 1525950185module-2 Unit5 COM-IDocument8 pages1525950185module-2 Unit5 COM-ISimranNo ratings yet

- Class 11 Chemistry Chapter 2 Atomic StructureDocument44 pagesClass 11 Chemistry Chapter 2 Atomic StructureamirbadshahNo ratings yet

- Uganda Advanced Certificate of Education Resource Mock X Physics Paper 1 2 Hours 30 MinutesDocument9 pagesUganda Advanced Certificate of Education Resource Mock X Physics Paper 1 2 Hours 30 Minutesssempijja jamesNo ratings yet

- Physics NotesDocument10 pagesPhysics NotesWavyBaconNo ratings yet

- Optimizing Materials Cost and MechanicalDocument8 pagesOptimizing Materials Cost and MechanicalKaleem UllahNo ratings yet