Professional Documents

Culture Documents

Cooling Tower: Asst - Prof.Dr - Sirirat Wacharawichanant

Uploaded by

Anonymous PkeI8e84RsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling Tower: Asst - Prof.Dr - Sirirat Wacharawichanant

Uploaded by

Anonymous PkeI8e84RsCopyright:

Available Formats

Heat Transfer Operations

Introduction

Cooling towers are heat rejection devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to reject process heat and cool the working fluid to near the wet-bulb air temperature or rely solely on air to cool the working fluid to near the drybulb air temperature. Common applications include cooling the circulating water used in oil refineries, chemical plants, power plants and building cooling. The towers vary in size from small roof-top units to very large hyperboloid structures.

Cooling Tower

Asst.Prof.Dr.Sirirat Wacharawichanant

Department of Chemical Engineering Silpakorn University

Introduction

(continue)

Introduction

(continue)

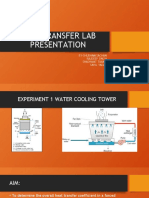

In a typical water-cooling tower, warm water flows countercurrent to an air stream. Typically, the warm water enters the top of a packed tower and cascades down through the packing, leaving at the bottom. Air enters at the bottom of the tower and flows upward through the descending water. The tower packing often consists of slats of plastic or a packed bed. The water is distributed by troughs and overflows to cascade over slat gratings or packing that provides large interfacial areas of contact between the water and air in the form of droplets and films of water.

The flow of air upward through the tower can be induced by the buoyancy of the warm air in the tower or by the action of a fan. The water cannot be cooled below the wet bulb temperature. The driving force for the evaporation of the water is approximately the vapor pressure of the water less the vapor pressure it would have at the wet bulb temperature . The water can be cooled only to the wet bulb temperature, and in practice it is cooled to about 3 K or more above this.

Introduction

(continue)

Categorization by air-to-water flow

Crossflow

Crossflow is a design in which the air flow is directed perpendicular to the water flow (see diagram below). Air flow enters one or more vertical faces of the cooling tower to meet the fill material.

Figure 1 Crossflow.

Only amount of water is lost by evaporation in cooling water. Since the latent heat of vaporization of water is about 2300 kJ/kg, typical change of about 8 K in water temperature corresponds to an evaporation loss of about 1.5%. Hence, the total flow of water is usually assumed to be constant in calculations of tower size.

Categorization by air-to-water flow

Crossflow

(continue)

Categorization by air-to-water flow

Counterflow

(continue)

Water flows (perpendicular to the air) through the fill by gravity. The air continues through the fill and thus past the water flow into an open plenum area. A distribution or hot water basin consisting of a deep pan with holes or nozzles in the bottom is utilized in a crossflow tower. Gravity distributes the water through the nozzles uniformly across the fill material.

Figure 2 Counterflow.

In a counterflow design the air flow is directly opposite of the water flow. Air flow first enters an open area beneath the fill media and is then drawn up vertically. The water is sprayed through pressurized nozzles and flows downward through the fill, opposite to the air flow.

Theory and Calculations for Water-Cooling Towers

Temperature and concentration profiles at interface

In Fig. (10.5-1) the temperature profile and concentration profile in terms of humidity are shown at the water-gas interface. Water vapor diffuses from the interface to the bulk gas phase with a driving force in the gas phase of (Hi-HG) kg H2O/kg dry air. There is no driving force for mass transfer in the liquid phase, since water is a pure liquid. The temperature driving force is TL-Ti in the liquid phase and Ti-TG K or C in the gas phase.

Theory and Calculations for Water-Cooling Towers

Temperature and concentration profiles at interface

(continue)

Figure 10.5-1 Temperature and conversion profiles in vapor part of cooling tower.

Theory and Calculations for Water-Cooling Towers

Temperature and concentration profiles at interface

(continue)

Theory and Calculations for Water-Cooling Towers

Temperature and concentration profiles at interface

(continue)

Sensible heat flows from the bulk liquid to the interface in the liquid. Sensible heat also flows from the interface to the gas phase. Latter heat also leaves the interface in the water vapor, diffusing to the gas phase. The sensible heat flow from the liquid to the interface equals the sensible heat flow in the gas plus the latent heat flow in the gas.

The conditions in Fig. 10.5-1 occur at the upper part of the cooling tower. In the lower part of the cooling tower, the temperature of the bulk water is higher than the wet bulb temperature of the air but may be below the dry bulb temperature. Then the direction of the sensible heat flow in Fig. (10.5-1) is reversed.

Theory and Calculations for Water-Cooling Towers

Rate equations for heat and mass transfer

(continue)

Theory and Calculations for Water-Cooling Towers

Rate equations for heat and mass transfer

(continue)

We shall consider a packed water-cooling tower with air flowing upward and water countercurrently downward in the tower. The total interfacial area between the air and water phases is unknown, since the surface area of the packing is not equal to the interfacial area between the water droplets and the air. Hence, we define a quantity a, defined as m2 of interfacial area per m3 volume of packed section or m2/m3.

This is combined with the gas-phase mass-transfer coefficient kG in kg mol/sm2Pa or kg mol/sm2atm to give a volumetric coefficient kGa in kg mol/sm3 volumePa or kg mol/sm3 atm. This process is carried out adiabatically; the various streams and conditions are shown in Fig. (10.5-2).

Theory and Calculations for Water-Cooling Towers

Rate equations for heat and mass transfer

(continue)

L = water flow, kg water/sm2 TL = temperature of water, C or K G = dry air flow, kg/sm2 TG = temperature of air, C or K H = humidity of air, kg water/kg dry air Hy = enthalpy of air-water vapor mixture, J/kg dry air

Figure 10.5-2 Continuous countercurrent adiabatic water cooling.

You might also like

- Psychometric Success Numerical Ability - Reasoning Practice Test 1Document7 pagesPsychometric Success Numerical Ability - Reasoning Practice Test 1mita000No ratings yet

- Psychometric Success Concentration Practice Test 1 PDFDocument0 pagesPsychometric Success Concentration Practice Test 1 PDFEfran Ocehb100% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Water Energy Generator US20060180473A1Document26 pagesWater Energy Generator US20060180473A1JohnNo ratings yet

- EKC316 - HUMIDIFICATION AND COOLING TOWER DESIGNDocument92 pagesEKC316 - HUMIDIFICATION AND COOLING TOWER DESIGNfadilo_93100% (1)

- Cooling Towers Design TrainingDocument57 pagesCooling Towers Design TrainingKagira Drawing Soltuion100% (1)

- Psychometric Success Mechanical Reasoning - Practice Test 1 PDFDocument12 pagesPsychometric Success Mechanical Reasoning - Practice Test 1 PDFKonul AlizadehNo ratings yet

- Muammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesDocument29 pagesMuammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesMohd FakhriNo ratings yet

- Psychometric Success Verbal Ability - Spelling Practice Test 1Document9 pagesPsychometric Success Verbal Ability - Spelling Practice Test 1Dewinta Sari Pratiwi100% (1)

- Psychometric Success Verbal Ability - Spelling Practice Test 1Document9 pagesPsychometric Success Verbal Ability - Spelling Practice Test 1Dewinta Sari Pratiwi100% (1)

- Psychometric Success Numerical Ability - Computation Practice Test 1 PDFDocument7 pagesPsychometric Success Numerical Ability - Computation Practice Test 1 PDFMudiare UjeNo ratings yet

- Cooling TowersDocument11 pagesCooling TowersSlim Kat Nkosi0% (2)

- Cooling Tower AshraeDocument18 pagesCooling Tower AshraeMAITREE JHANo ratings yet

- 12.0 Cooling Towers and LightingDocument55 pages12.0 Cooling Towers and LightingNesarkiran BagadeNo ratings yet

- Cooling Towers Design Feb12 - CHENG PDFDocument6 pagesCooling Towers Design Feb12 - CHENG PDFisosicaNo ratings yet

- Boiling and Condensation 1Document48 pagesBoiling and Condensation 1hasan bish100% (1)

- Cooling Tower Deign Guidelines and ProcedureDocument6 pagesCooling Tower Deign Guidelines and ProcedureVikas Dadhich100% (4)

- CONDENSER PERFORMANCE: Factors Affecting Heat Transfer & VacuumDocument26 pagesCONDENSER PERFORMANCE: Factors Affecting Heat Transfer & VacuumFranz MonsantoNo ratings yet

- Identify The Choice That Best Completes The Statement or Answers The QuestionDocument5 pagesIdentify The Choice That Best Completes The Statement or Answers The Questiontwinckel mae bienesNo ratings yet

- Cooling TowerDocument32 pagesCooling TowerPrasoon ChaturvediNo ratings yet

- Cooling SystemsDocument30 pagesCooling SystemsTa Den AprilNo ratings yet

- Report Cooling TowerDocument15 pagesReport Cooling TowerAnonymous HikwNM092% (13)

- Cooling TowerDocument28 pagesCooling TowerKangae Ilham100% (4)

- Effective Thermal Design of Cooling TowersDocument11 pagesEffective Thermal Design of Cooling Towershamid vahedil larijaniNo ratings yet

- COOLING TOWER THEORY AND TYPESDocument28 pagesCOOLING TOWER THEORY AND TYPESPriyank kanjariyaNo ratings yet

- Cooling Tower Water CalculationsDocument11 pagesCooling Tower Water CalculationsShesadri ChakrabartyNo ratings yet

- Cooling TowerDocument8 pagesCooling TowerMohammed IhsanNo ratings yet

- Cooling Tower PDFDocument30 pagesCooling Tower PDFcynaidu100% (1)

- Nptel ReboilerDocument8 pagesNptel ReboilerGurubasavaraju T MNo ratings yet

- Boiler Maintenance and Safety Study GuideDocument10 pagesBoiler Maintenance and Safety Study GuideKapila2zNo ratings yet

- Effective Thermal Design of Cooling TowersDocument13 pagesEffective Thermal Design of Cooling TowersKarthick VelayuthamNo ratings yet

- Cooling TowersDocument16 pagesCooling TowersAhmed GadNo ratings yet

- Cooling TowersDocument35 pagesCooling TowersSingaravelu MariappanNo ratings yet

- EKC316 - Humidification Process Design and Psychrometric AnalysisDocument95 pagesEKC316 - Humidification Process Design and Psychrometric AnalysisSathiswaran SelvamNo ratings yet

- Residual Life Assessment of 110 KV XLPE CableDocument9 pagesResidual Life Assessment of 110 KV XLPE CableJesúsNo ratings yet

- Con Cent Eric Tube Heat ExchangerDocument15 pagesCon Cent Eric Tube Heat ExchangerAmr BanawanNo ratings yet

- Kuliah 9Document46 pagesKuliah 9Zulfansyah MuchtarNo ratings yet

- Cycles of ConcentrationDocument2 pagesCycles of ConcentrationSagar PatilNo ratings yet

- UOFE AssignmentDocument4 pagesUOFE AssignmentSahar Batool QaziNo ratings yet

- Koeltorenboekje Engels Zonder LogoDocument32 pagesKoeltorenboekje Engels Zonder Logoanup_nairNo ratings yet

- Overall Heat Transfer Coefficient 2Document37 pagesOverall Heat Transfer Coefficient 2John Harold CuaresmaNo ratings yet

- 2 2C TowerDocument13 pages2 2C TowerAhmed GadNo ratings yet

- Cooling Tower 2020 SPLM1B2 Notes 13 - 14 AugustDocument23 pagesCooling Tower 2020 SPLM1B2 Notes 13 - 14 AugustThabangNo ratings yet

- Week 3 - Continuous Humidification ProcessesDocument46 pagesWeek 3 - Continuous Humidification ProcessesLAU POEY YEE STUDENTNo ratings yet

- Refrigeration HandbookDocument223 pagesRefrigeration Handbookmonil panchalNo ratings yet

- Heat Exchanger2Document33 pagesHeat Exchanger2Saloni.Dhawale Btech2018No ratings yet

- Heat Transfer and CombustionDocument9 pagesHeat Transfer and CombustionmihailmiNo ratings yet

- Second: Heat Transfer Correlations For Flow Boiling Heat TransferDocument9 pagesSecond: Heat Transfer Correlations For Flow Boiling Heat Transfermalek mustafaNo ratings yet

- Mass Transfer Lab Presentation: By-Shubham Sachan Rajdeep Singh Shashwat Tiwari Sahil YadavDocument21 pagesMass Transfer Lab Presentation: By-Shubham Sachan Rajdeep Singh Shashwat Tiwari Sahil Yadavbadshah sharmaNo ratings yet

- Cooling Tower: Bangladesh University of Engineering and TechnologyDocument15 pagesCooling Tower: Bangladesh University of Engineering and TechnologyMarsya MaysitaNo ratings yet

- Cooling TowerDocument8 pagesCooling TowerHemant PatilNo ratings yet

- Condenser PerformanceDocument23 pagesCondenser PerformanceSatyam KumarNo ratings yet

- An Exergy Analysis On The Performance of ADocument13 pagesAn Exergy Analysis On The Performance of ASaurav SumanNo ratings yet

- MECH3423 Building Services Engineering II Experiment 1: Basic Water Cooling TowerDocument6 pagesMECH3423 Building Services Engineering II Experiment 1: Basic Water Cooling TowerMahleh Thabe'khuluNo ratings yet

- Full ReportDocument16 pagesFull ReportafiqahanuwarNo ratings yet

- Comparative Study of The Packing Design (Comparative Study of The Packing Design)Document14 pagesComparative Study of The Packing Design (Comparative Study of The Packing Design)Johnathan Ortega MenesesNo ratings yet

- Experiment 3 - CH142LDocument15 pagesExperiment 3 - CH142LAllyssa BadilloNo ratings yet

- Power Lab #3 (Surface Condenser)Document4 pagesPower Lab #3 (Surface Condenser)Mahmud L. MusaNo ratings yet

- Boiling Heat Transfer Positioning Evaporator PipeDocument28 pagesBoiling Heat Transfer Positioning Evaporator PipeJoão PeixotoNo ratings yet

- Thermal Analysis Formulas STHXDocument23 pagesThermal Analysis Formulas STHXFaheem Fiaz ChohanNo ratings yet

- Convection&RadiationDocument40 pagesConvection&RadiationdesdainedmanNo ratings yet

- TurnitinDocument8 pagesTurnitinirfan hilmanNo ratings yet

- Heuristics for Engineering Problem SolvingDocument42 pagesHeuristics for Engineering Problem SolvingDEV RAJNo ratings yet

- Analysis of Evaporative Cooling TowersDocument11 pagesAnalysis of Evaporative Cooling TowersAnonymous YcAZv5qF67No ratings yet

- Natural ConvectionDocument28 pagesNatural ConvectionGülgün YenigünNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Busty Mature Lady Smokes A CigaretteDocument1 pageBusty Mature Lady Smokes A CigaretteAnonymous PkeI8e84Rs0% (2)

- Ss 1Document2 pagesSs 1Anonymous PkeI8e84RsNo ratings yet

- SmokingFetish 1000 p101 198Document98 pagesSmokingFetish 1000 p101 198Anonymous PkeI8e84Rs50% (4)

- What Are The Pressure Requirements For Pipe Testing?Document1 pageWhat Are The Pressure Requirements For Pipe Testing?Anonymous PkeI8e84RsNo ratings yet

- Álvarez ATE 2016Document16 pagesÁlvarez ATE 2016Anonymous PkeI8e84RsNo ratings yet

- Sample of WorkDocument21 pagesSample of WorkAnonymous PkeI8e84RsNo ratings yet

- CHP 11Document62 pagesCHP 11Anonymous PkeI8e84RsNo ratings yet

- Item 2U Staff ReportDocument22 pagesItem 2U Staff ReportAnonymous PkeI8e84RsNo ratings yet

- Hillary Has Fun2Document1 pageHillary Has Fun2Anonymous PkeI8e84RsNo ratings yet

- SmokingFetish 1000 p1-100Document100 pagesSmokingFetish 1000 p1-100Anonymous PkeI8e84Rs63% (8)

- Test Doc 001Document1 pageTest Doc 001Anonymous PkeI8e84RsNo ratings yet

- Valuation Cogeneration Plants Things To ConsiderDocument8 pagesValuation Cogeneration Plants Things To ConsiderAnonymous PkeI8e84Rs100% (1)

- Test 003Document1 pageTest 003Anonymous PkeI8e84RsNo ratings yet

- 88 999 ji iuy f iyta 8889 987Document1 page88 999 ji iuy f iyta 8889 987Anonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ kkfkdf90595lllkkkkkkkkDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ kkfkdf90595lllkkkkkkkkAnonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJ JJ JJJ LLL LLDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJ JJ JJJ LLL LLAnonymous PkeI8e84RsNo ratings yet

- Smoking BabeDocument3 pagesSmoking BabeAnonymous PkeI8e84RsNo ratings yet

- Math GamesDocument27 pagesMath GamesAnonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDFDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDFAnonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJAnonymous PkeI8e84RsNo ratings yet

- Psychometric Success Fault Diagnosis - Practice Test 1Document12 pagesPsychometric Success Fault Diagnosis - Practice Test 1emmaclick100% (1)

- Sit Down, Stand UpDocument1 pageSit Down, Stand UpAnonymous PkeI8e84RsNo ratings yet

- Properties of Fluids: Sample Problems BDocument4 pagesProperties of Fluids: Sample Problems BFronda Jerome BlasNo ratings yet

- Aircraft Dynamics Equations DerivationDocument55 pagesAircraft Dynamics Equations DerivationCadey TsaNo ratings yet

- 120 Rad/sDocument35 pages120 Rad/sEzra Orita CeletariaNo ratings yet

- Class 2 Certificate Syllabus For Hong Kong Marine Engg, CertificateDocument14 pagesClass 2 Certificate Syllabus For Hong Kong Marine Engg, Certificatedannynoronha755271100% (6)

- Thermodynamics 1 Basic Principles, Concepts and DefinitionDocument8 pagesThermodynamics 1 Basic Principles, Concepts and DefinitionHENRICK IGLENo ratings yet

- Triboelectric Nanogenerator Built Inside Shoe Insole For Harvesting Walking EnergyDocument7 pagesTriboelectric Nanogenerator Built Inside Shoe Insole For Harvesting Walking EnergyQuốc TínNo ratings yet

- Remote Sensing Session 2 Modern Surveying - 20Ce32P: Study MaterialDocument14 pagesRemote Sensing Session 2 Modern Surveying - 20Ce32P: Study Materialshashi kumarNo ratings yet

- Grillage Analysis SampleDocument6 pagesGrillage Analysis SamplerenandNo ratings yet

- Protections of Devices and CircuitsDocument69 pagesProtections of Devices and CircuitsAtiq Ur RehmanNo ratings yet

- Technical Solutions for Estimating Induction in Telecom FacilitiesDocument4 pagesTechnical Solutions for Estimating Induction in Telecom FacilitiesReza AfarandNo ratings yet

- Seismic Performance of Timber StructuresDocument3 pagesSeismic Performance of Timber StructuresAllan MarbaniangNo ratings yet

- Tension and Compression TestDocument37 pagesTension and Compression TestLydiaNo ratings yet

- Application of 1st Order ODEDocument8 pagesApplication of 1st Order ODEafiqah_507No ratings yet

- Diagramme LogP-H - T-S À ImprimerDocument2 pagesDiagramme LogP-H - T-S À ImprimerRiad OualiNo ratings yet

- Newtons Laws ApplicationsDocument17 pagesNewtons Laws ApplicationsFernando AvenirNo ratings yet

- Finite Element MethodsDocument2 pagesFinite Element MethodsRadha KrishnaNo ratings yet

- Physics XII CH 8 Physics Assertion Reasoning Electromagnetic WavesDocument4 pagesPhysics XII CH 8 Physics Assertion Reasoning Electromagnetic WavesNjan KL16么PorottaNo ratings yet

- Chemical Kinetics - DPP 09 - Lakshya JEE 2024Document2 pagesChemical Kinetics - DPP 09 - Lakshya JEE 2024Hrishith SavirNo ratings yet

- EN200 Naval Engineering Chapter 1 PDFDocument33 pagesEN200 Naval Engineering Chapter 1 PDFanusha_wiproNo ratings yet

- F. Reif - Statistical Physics - Chapter 1 PDFDocument51 pagesF. Reif - Statistical Physics - Chapter 1 PDFIndrawati WilujengNo ratings yet

- Class 9 Maths Olympiad Achievers Section Practice PapersDocument2 pagesClass 9 Maths Olympiad Achievers Section Practice Paperslokesh kumarNo ratings yet

- Techno-Economic Analysis of Air Humidification DesalinationDocument5 pagesTechno-Economic Analysis of Air Humidification DesalinationIbrahim Al-MutazNo ratings yet

- Ch-1 - The World of MechanismsDocument62 pagesCh-1 - The World of MechanismsAdil Ali ShahNo ratings yet

- Chem 1301 - 2021 MidtermDocument14 pagesChem 1301 - 2021 MidtermRandom PersonNo ratings yet

- Liquefied Strength Ratio From Liquefaction Flow PDFDocument19 pagesLiquefied Strength Ratio From Liquefaction Flow PDFAlcides Cordova MateoNo ratings yet

- TRB PG Syllabus For All Subjects WDocument41 pagesTRB PG Syllabus For All Subjects WBOSS BOSSNo ratings yet