Professional Documents

Culture Documents

3 - Preliminary Design

Uploaded by

eyerusalemhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 - Preliminary Design

Uploaded by

eyerusalemhCopyright:

Available Formats

Site Investigation Manual - 2002

Chapter 3 Preliminary Design

3.

3.1

PRELIMINARY DESIGN

Preliminary Design Sampling and Testing

Investigations for design are often conducted in two stages (preliminary stage, and final stage), depending on the terms of reference. Where two stages are chosen or specified, the frequency of sampling and testing during the preliminary stage is significantly less that that for the final design. See Figure 1-2 for a representation of the flow chart for sampling and testing. The field exploration in the preliminary stage (in either case) should be of such extent as to have sufficient data for preliminary design. The explorations and testing, which are costly and time-consuming, should serve the obvious needs of civil and structural design. The preliminary design phase data must have sufficient accuracy, coverage and applicability to support design analysis and decisions. It should also permit reasonably accurate preliminary estimates of material quantities and construction costs. The field reconnaissance portion of the preliminary design includes the conduct in indicator tests on materials. These are the same tests as those conducted during the final design, and as indicated in both Chapter 4: Final Design and in Appendix B: Laboratory Testing. However, these tests are usually but not always conducted at a lower sampling frequency than that required during the final design process. See Figure 4-1 for a sampling frequency for common investigations for preliminary design. 3.2 General

The preliminary design requires the following geotechnical studies: Soils and rock conditions as they pertain to earthworks operations and subgrade conditions as pavement support. As far as possible, the interface between soil (or rippable rock) and unweathered rock should be identified in order to optimize the alignment and profile. Also, an assessment of the subgrade strength is required at this stage to conduct the pavement design, together with a definition of the conditions of compaction and reuse of excavated materials into embankments. Materials search. Although a precise estimate of the volumes may not be warranted during preliminary design, it is important to verify the existence of sources of materials at desirable intervals for all types of materials. A verification of the quality and suitability of the materials is essential at this stage. If problems become apparent with the availability of certain materials, then a more precise determination of the quantities is warranted. In certain areas, water may be scarce for construction purposes and in particular for providing proper moisture content during compaction of the soils and pavement layers materials. Since this problem can have significant financial consequences, it is important to investigate the resources and to compile the sources of water and their respective yields and distances from the construction operations. Depending on the seriousness of the problem, hydrogeological studies may be warranted.

Ethiopian Roads Authority

Page 3-1

Chapter 3 Preliminary Design

Site Investigation Manual - 2002

Preliminary pavement design. This is required to compare the availability of materials with the needs for pavement construction. Alternate solutions may need to be evaluated if a scarcity of materials becomes apparent. Slopes of the cut sections in particular should be estimated as a function of height, with consideration given to prior local experience and to geological and pedological formations. The influence of potential erosion and local resurgence should also be investigated and taken into consideration. The side slopes to adopt for the embankments should also be verified. This is important to assess mass diagrams of earthworks. Other problem areas. Embankment stability, as well as a potential for excessive settlements, may occasionally become problematic if soft and compressible deposits are encountered. It is at this stage of preliminary design that the magnitude and rate of anticipated settlements should be estimated, together with the potential for embankment failure, in order to select remedial solutions and determine the possible need for further investigations and studies. Significant problems regarding expansive soils should also be identified and solutions proposed. Soils and foundation conditions at stream crossings or other bridge locations. The goal is to define the soil characteristics in the vicinity of the crossings in order to optimize the location of the structures, prior to the final foundation design. Sampling Program: Earthworks and Subgrade Soils

3.3

Common investigations include (in-situ) test pits and hand auger probes, and occasionally borings. It is sometimes impossible to dig trial pits to the depth of the anticipated formation level. It is then recommended to use a hand or power auger to drill holes to the depth required. Common investigations also include, in particular for existing roads, DCP testing. Data regarding in-situ moisture content and strength (via DCP testing) are collected. Logs of field investigations are established. In the laboratory, moisture-density-CBR correlations are established. The use of excavated materials for embankments is assessed and the need for side borrow materials established. Estimating the subgrade nature, moisture at equilibrium and strength is of primary importance. Adequate sampling is required, i.e. representative sampling of subgrade materials for visual and later further laboratory classification. This paragraph regarding sampling (primarily in proposed cut areas) deals with the assessment of the subgrade strength at the finished subgrade level in cuts and of the suitability of the excavated materials as embankment materials. Further considerations regarding specific problems in cut (e.g. rock excavation, side slopes) are mentioned in Chapter 5 (Special Investigations). Further considerations regarding investigations of additional search for borrow materials are given in Section 4.6 (Soil and Gravel Borrow Pits). Test pits should be dug through the pavement layers in the case of an existing road, or from the existing ground level in the case of a new road. The frequency and spacing of the test pits should depend on sound engineering judgement and be guided by a prior review of all possible documents as well as a preliminary visual survey of the entire road alignment and the results of the investigations during preliminary design. Although it is

Page 3-2 Ethiopian Roads Authority

Site Investigation Manual - 2002

Chapter 3 Preliminary Design

neither possible nor desirable to specify rigid rules for spacing, it is necessary to set adequate average guidelines for homogeneity of design and reliability. As a standard guideline, at least one sample should be taken per kilometer of anticipated alignment as an average, with more frequent samples where there are significant changes in soil type. Significant changes are those which affect the general classification of the soils, as well as, perhaps more importantly, their bearing strength (CBR). The average frequency of one sample per kilometer applies to identification tests. Representative samples for compaction and CBR testing (which are necessarily larger) should be taken at an average of at least one large sample every 10 kilometers (preferably every 5 kilometers). Note: The recommended approximate quantity (mass) of sample required may be determined by verifying the tests required (see subchapters 3.4 and 3.5) and referring to Table 4-2. It is simpler and generally preferable to retrieve in the field each sample large enough to conduct all required tests (i.e. identification tests as well as compaction and CBR tests) in the lab. This allows for a better selection of representative samples in the laboratory prior to compaction and CBR testing. If logistics preclude the taking and transportation of large quantities of samples, careful examination of the soils in the field must be conducted and judgment must be exercised to select truly representative samples for compaction and CBR testing. For the purpose of taking representative samples, pits shall be dug mostly in anticipated cut areas (since these cuts will expose the subgrade support of the future pavement and provide embankment materials), if possible down to at least 30 cm below the expected subgrade level. Further, in the case of a new alignment, the depth of any pit should in no case be less than 1.5m unless rock or other material impossible to excavate by hand is encountered. The engineer in charge of planning the investigations should make every effort to locate the test pits (along the alignment as well as within the lateral extent of the anticipated excavation) in order to optimize the representativity of the material excavated from the test pit. If deep cuts are proposed through materials indicated to be variable by test pits and a study of the geological maps, consideration is to be given to drilling the cuts at the final design stage when the potential hard stone sources are being investigated. The position (in plan and elevation) of each test pit must be accurately determined and recorded. This implies that geotechnical and topographical tasks must be coordinated in the field. In every test pit, all layers, including topsoil, shall be accurately described and their thicknesses measured. All layers of more than 30 cm (except topsoil) shall be sampled. This will promote a proper assessment of the bulk of the materials excavated in cuts and to be used in embankments. The sample shall be taken over the full depth of the layer by taking a vertical slice of material. The log of each test pit shall be accurately drawn and included in the Soils and Materials Report. The field sequence of operations should be as follows: Excavation to finished subgrade level and below Logging of the test pit, Determination of the in-situ density as appropriate Sampling Backfilling (using left over excavation materials and/or side borrow materials)

Page 3-3

Ethiopian Roads Authority

Chapter 3 Preliminary Design

Site Investigation Manual - 2002

Care shall be taken, when retrieving samples, to secure and preserve a small but sufficient quantity of soil for the purpose of measuring the moisture content in the laboratory, unless provisions are made to measure the moisture content in the field. Measuring the in-situ moisture content is particularly desirable at the anticipated finished grade level. Photographs should also be taken of the test pit location, as well of the soils horizons in the test pit. This will help both the engineers in charge of reporting the investigations and in charge of interpreting the results. Selected, representative photographs should also be included in the Soils and Materials Report. 3.4 Testing of Soils on New Alignments

The size of the samples (see Table 4-2) should be sufficient for the following tests to be carried out: 1. Grading to 0.075 mm sieve (ASTM C 136). However, if a large proportion of finegrained soils (having more than 50% by weight of their particles passing a 0.075 mm sieve) are present along the alignment, it is advisable to schedule a few tests with a hydrometer analysis (ASTM D 422). 2. Atterberg Limits (ASTM D 4318) if required for classification Note: The soils should be classified in accordance with ASTM D 2487. The above two tests are usually sufficient for this purpose. Measuring the in-situ moisture content on the small samples secured in the field for this purpose should be done concurrently. 3. Compaction Test (Standard Compaction with 2.5 kg rammer, ASTM D 698) 4. CBR and swell on sample(s) molded at 100% maximum dry density (Standard Compaction) and optimum moisture content (Standard Compaction) Notes: 1. It is to be noted that the above procedure for compaction and CBR aims at a preliminary assessment of the compaction and strength characteristics of the subgrade soils along the alignment. A complete testing procedure of the representative soil categories, once these have been identified, is given in Chapter 4: Final Design. The above procedure (tests (3) and (4)) requires the preparation of at least 4 (preferably 5) molds for compaction and at least one mold for CBR. 2. The CBR shall normally be measured after 4 days soak, except in arid areas (annual rainfall less than 500 mm). In those areas, they may be measured at OMC or after a reduced soaking period, depending on the equilibrium moisture content predicted under the pavement in the area (see ERA Pavement Design Manual - 2002). The moisture contents after soaking shall be measured, both on the whole CBR specimen (by weighing it after soaking) and on a sample taken from beneath the plunger, after testing. 3.5 Testing of Subgrade on Alignments of Existing Roads

This paragraph applies to sections of existing gravel roads that are to be upgraded, the geometric standards of which are good enough to maintain the existing alignment. It also

Page 3-4 Ethiopian Roads Authority

Site Investigation Manual - 2002

Chapter 3 Preliminary Design

applies to existing paved roads when testing of the subgrade under existing pavements is valuable in assessing subgrade conditions under future pavements, and in particular subgrade moisture content. Where more than 10 cm of existing gravel wearing course is in place on the road and where the shape is adequate, samples of subgrade are to be submitted to tests (1), (2) and (3) described above (i.e. identification and standard compaction test). In addition, the Field Moisture Content and Field Dry Density of each sample shall be measured; this is to decide whether to leave the subgrade undisturbed or to recompact it. Several methods are suggested for the purpose of these measurements in Appendix B of this manual. An entire project should not rely entirely on nuclear methods, and verification of the results should be made using in particular the Sand-Cone Method for in-situ density and ASTM D 2216 for moisture content. If the degree of field compaction is found to be consistently satisfactory (preferably at least 100% of the maximum dry density achieved by ASTM D 698), then CBRs shall be measured in the laboratory at Field Dry Density on representative samples of the subgrade. These measurements may be supplemented by direct measurements of the subgrade strength using DCP testing (see ERA Pavement Design Manual - 2002). If the degree of compaction is not satisfactory, the subgrade will need recompaction and the CBRs shall then be measured at 100% M.D.D. (Standard Compaction). Measurement of the moisture content in the subgrade below existing pavements is helpful in determining the design moisture content to adopt in the design of new pavements in the same vicinity. Further details are given in the ERA Pavement Design Manual - 2002. Direct measurements of the subgrade strength may also be taken under existing pavements, as indicated in the ERA Pavement Design Manual - 2002. 3.6 Existing Gravel Wearing Course

Where a gravel road is to be upgraded on the same alignment, the existing gravel wearing course may provide extra material either for subbase, or for improved subgrade. Measurements of thickness and width of gravel wearing course shall then be recorded every 100m. One sample per kilometer of existing gravel wearing course shall be taken, where the gravel layer is at least 15 cm thick. Each sample shall be submitted to tests (1), (2), (3) and (4) described in subchapter 3.3 for the testing of the subgrade, i.e. identification, compaction and CBR tests. 3.7 3.7.1 Soil and Gravel Borrow Pits GENERAL

Soil and gravel borrow pits are to be located at intervals in order to provide construction materials for the pavement layers. These construction materials, using a terminology consistent with ERA's Pavement Design Manual - 2002, may consist of:

Ethiopian Roads Authority Page 3-5

Chapter 3 Preliminary Design

Site Investigation Manual - 2002

Unbound pavement materials (refer to Section 6 of the ERA Pavement Design Manual - 2002) - Base course materials GB2 (natural materials to be used after crushing) or GB3 (natural gravels and weathered rock). Note: Usually, it will be preferable to use crushed aggregate quarry materials (GB1) as base course materials when available. Nevertheless, GB2 and GB3 materials may be considered in areas of scarcity of such preferred materials. Subbase materials GS (natural gravels). Materials for selected subgrade and capping layers GC. Gravel wearing course materials

Cement- and lime-stabilized materials CB1, CB2 and CS (refer to Section 7 of the ERA Pavement Design Manual - 2002) Note: Limited use is generally being made of such stabilized materials, and consideration should be given to their use only in case of scarcity of otherwise economically available materials.

Coarse aggregate for bitumen-bound materials (to be used after crushing), since specifications for these materials are similar to those for granular base course (refer to Section 8 of the ERA Pavement Design Manual - 2002). It should however be kept in mind during the investigations that crushed rock will generally be preferable for this purpose if economically available.

Where feasible, borrow pits should be spaced so as to obtain the most economic use or materials. What represents an economical spacing between borrow pits will evidently depend on the conditions of exploitation and the quantities required per kilometer of construction. Nevertheless, it is worth indicating a desirable interval between borrow pits on the order of 10 km as a general guideline. The minimum thickness of deposit normally considered workable is on the order of one meter. However, there may be instances when thinner horizons have to be exploited, as no suitable alternative exists. The absolute minimum depends on the area of the deposit and the thickness of overburden (if there is no overburden as may be the case in arid areas, horizons as thin as 30 cm may be workable). 3.7.2 FIELD INVESTIGATIONS AND SAMPLING PROCEDURE

Test pits should be dug approximately on a 50 m grid, through the full depth of the layer(s) proposed for use. A minimum of 5 test pits is required for each borrow pit ultimately proposed after analysis of the results. These guidelines may be modified to conform to local conditions and in particular to the apparent thickness of usable materials. However, the frequency of sampling (i.e. the number of cubic meters of materials represented by each sample) as indicated further below in paragraph 3.7.3 must be satisfied.

Page 3-6

Ethiopian Roads Authority

Site Investigation Manual - 2002

Chapter 3 Preliminary Design

The location of each proposed borrow pit shall be indicated on a key plan. A site plan of each proposed borrow pit shall be prepared, showing the position of each test pit, the characteristic features of the site and the means of access and location. In every test pit, all layers, including top soil and overburden, shall be accurately described and their thicknesses measured. All layers visually considered as suitable for use shall be sampled. The sample shall be taken over the full depth of the layer proposed, by taking a vertical slice of material. The quantity (mass) of material in each sample must be sufficient to carry out the testing described in paragraph 3.7.3 below. The required quantity may be assessed from Table 4-5. The log of each test pit shall be accurately drawn and included in the Soils and Materials Report. The Report shall also include the site plan of each borrow pit. 3.7.3 FREQUENCY OF SAMPLING AND TESTING

A sufficient number of samples, each of sufficient quantity, are to be taken to carry out tests to determine the main materials, processes and additives to be used, the approximate borrow pit locations and hauls and the approximate pavement thicknesses and percentages of additives required. Samples for Identification Tests Sampling shall be carried out so as to obtain at least one sample per 4,000 m3 of material proposed for use. At least one sample shall be taken from each positive test pit, even if the volume represented is small. Each sample shall be submitted to the following tests: (1) (2) Grading to 0.075 mm sieve (ASTM C 136) Atterberg Limits (ASTM D 4318) if required for classification

Note: The soils should be classified in accordance with ASTM D 2487. The above two tests are usually sufficient for this purpose. Large Samples for Compaction and CBR Tests Large samples for Compaction and CBR tests (see Table 4-2 for required quantity) shall be obtained as required for testing as defined further below. In consideration of the above identification results, large samples may be obtained by re-sampling from typical existing test pits which are representative of the various categories of material found within the potential borrow pit area, or by sampling additional quantities at the time of the initial investigation. Alternatively, large samples may be obtained by mixing "small" identification samples. A mix must be representative of a workable area. All the "small" samples to be incorporated in a mix must be of the same type of material and must have fairly consistent identification characteristics (grading and Atterberg Limits). Within each borrow pit, the mixes shall be chosen in order to cover adequately the range of materials proposed for use.

Ethiopian Roads Authority Page 3-7

Chapter 3 Preliminary Design

Site Investigation Manual - 2002

At least one large sample, whether re-sampled or mixed, is required per 15,000 m3 of material proposed for use. Each large sample shall be submitted to the following tests: (1) (2) (3) (4) Grading to 0.075 mm sieve (ASTM C 136) Atterberg Limits (ASTM D 4318). Compaction test (Heavy Compaction with 4.5 kg rammer, ASTM D 1557) CBR and swell at 4 days soak, on specimens molded at OMC (Heavy Compaction) at 3 levels of compaction, normally around 90, 95 and 100% MDD (Heavy compaction).

The moisture contents after soaking shall be measured, both on the whole CBR specimen (by weighing it after soaking) and on a sample taken from beneath the plunger, after testing. Notes: 1. For the types of gravel susceptible to crushing during compaction, the grading of the specimen compacted closest to 95% MDD shall be determined after compaction and CBR testing and compared with the grading before compaction of the specimen prepared for CBR. 2. To assess the suitability of the materials as base course material GB2, other tests than those listed above are necessary. Refer to Chapter 6 of the ERA Pavement Design Manual - 2002. 3. To assess the suitability of the materials as base course material GB3, it will be first necessary to compare the gradation of the natural materials with the gradations recommended in Chapter 6 of the ERA Pavement Design Manual - 2002. This may indicate the need for mechanical improvement by screening and crushing. Additional requirements regarding the percentage of particles with angular, irregular or crushed faces are given in Chapter 6 of the ERA Pavement Design Manual - 2002. Additional tests may be required as per the same paragraph. The CBR requirement is also detailed in the same paragraph. 4. To assess the suitability of the materials as subbase material GS, refer to Chapter 6 of the ERA Pavement Design Manual - 2002. Testing for CBR under unsaturated conditions may be advisable. 5. The requirements for naturally occurring materials to be suitable as subgrade materials and capping layers (GC) are given in Chapter 6 of the ERA Pavement Design Manual - 2002 and should be referred to. However, it should be noted that the above tests are normally sufficient to assess the suitability of the materials, unless testing for CBR under unsaturated conditions are deemed necessary. 6. Requirements for materials to be suitable as gravel wearing courses are detailed in Chapter 6 of the ERA Pavement Design Manual - 2002 and should be referred to. Of particular importance are the combined gradation and plasticity characteristics. The above results should indicate the possible need for crushing and/or screening of the natural materials. Other needs may consist of screening-off oversize material or mixing in crushed stone to improve gradation and angularity of particles.

Page 3-8

Ethiopian Roads Authority

Site Investigation Manual - 2002

Chapter 3 Preliminary Design

7. Coarse aggregate for bitumen-bound materials, which can be obtained from crushing natural gravels, will not be judged on the results of the above tests, but on results of tests similar to those detailed for crushed stone (see further below and Chapter 8 of ERA Pavement Design Manual - 2002). Treatment Tests (when appropriate) If the above Compaction and CBR tests (tests (3) and (4)) show that the available natural materials do not meet the quantity or quality requirements, treatment tests shall be carried out on the relevant large samples. Treatment may be considered to use the materials, with cement or lime, as base course materials (CB1, CB2), subbase (CS), or capping or selected fill layers. The selection of the type of treatment (cement or lime) is based on the plasticity and particle size distribution of the material to be treated, and is described in Chapter 7 of the ERA Pavement Design Manual - 2002. The laboratory testing procedure to assess the suitability of the materials after cement stabilization is detailed in Chapter 7 of the ERA Pavement Design Manual - 2002 and should be referred to. The procedure includes the initial consumption of lime test (ICL), British Standard 1924, and the ASTM Test Method D 1557 Heavy Compaction test. The strength of the material after treatment is assessed by crushing cube or cylinder specimens, or alternatively by CBR testing after moist curing and soaking. Similarly, the lime stabilization is discussed in Chapter 7 of the ERA Pavement Design Manual - 2002, which should be referred to, and the procedure for selecting the lime content should be carried out in accordance with British Standard 1924. At least one large sample per 15,000 m3 of material proposed for treatment should be submitted to the treatment tests. 3.8 3.8.1 Crushed Stone Aggregates (Quarry Materials) GENERAL

Potential sources of stone should be identified, initially as indicated for the feasibility study (Chapter 2). Those visually considered suitable, in terms of stone quality and quantity should then be further investigated. Approximate quantity estimates should be made based on visual observations. However, more detailed quantity estimates should be taken up during the final design stage as described in Chapter 4. Practical considerations concerning the exploitation of the potential quarries, such as access, ease of working, overburden, etc. should be noted. The location of each potential source of stone shall be indicated on a key plan. A site plan of each potential quarry shall be prepared, showing the characteristic features of the site (including outcrops) and the means of access and location. As for the investigations for earthworks and subgrade soils, coordination with topographical work is desirable in order in particular to better assess quantities of rock material with a potential for exploitation.

Ethiopian Roads Authority

Page 3-9

Chapter 3 Preliminary Design

Site Investigation Manual - 2002

3.8.2

SAMPLING

Hand sampling from existing faces or outcrops shall be carried out. At least 3 samples shall be taken from each potential source. The position of each sampling point or group of sub-sampling points shall be accurately determined and reported on the site plan. Each sample shall be accurately described, from a geological and mineralogical viewpoint. Great care shall be taken to ensure that the samples are obtained from sound rock and not from a superficial horizon of weathered rock. Each sample shall contain sufficient material to carry out the tests indicated in paragraph 3.8.3 below. The quantity of material required is on the order of 50 Kg. 3.8.3 TESTING

Testing is aimed at verifying the suitability of the rock to produce: Unbound base course materials GB1 (or GB2): see ERA Pavement Design Manual 2002 Chapter 6. Aggregates for bitumen-bound premixes (see ERA Pavement Design Manual - 2002 Chapter 8) and chippings for surface treatments (see ERA Pavement Design Manual 2002 Chapter 9)

Each sample shall be subjected to the following tests: (1) (2) (3) (4) (5) Los Angeles Abrasion (ASTM C131 or C 535) Aggregate Crushing Value (BS 812, Part 110) Sodium Sulphate or Magnesium Sulphate Soundness (ASTM C 88) Plasticity Index on fines from the Los Angeles Abrasion test (ASTM D 4318) Mineralogical analysis It may be noted that the above tests cover the testing required to assess the suitability of the rock to produce aggregates for unbound base course materials using in particular the Aggregate Crushing Value as a criterion (alternative tests such as the Ten Per Cent Fines Value and the Aggregate Impact Test are also suggested in the ERA Pavement Design Manual - 2002). It should also be noted that considerations related to gradation and flakiness are governed to a large extent by the crushing process and may generally be left for verification during final design. Compaction and CBR tests may also be omitted during preliminary design. The above tests (with the inclusion of the Los Angeles Abrasion test) are also considered appropriate at the preliminary design stage to assess the potential of the quarry material for producing coarse and fine aggregates for bituminous mixes. Such characteristics as flakiness, resistance to polishing, water absorption, bitumen affinity, sand equivalent and plasticity index of material passing the 0.425 mm sieve are usually reserved for verification during final design. The suitability of the rock to produce chippings for surface treatments will be verified against the requirements of British Standards 63, Part 2. Further design considerations, such as selection of chipping sizes, are based on flakiness and chipping sizes, and may be addressed during final design.

Ethiopian Roads Authority

Page 3-10

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Depreciation Faqs v2Document6 pagesDepreciation Faqs v2eyerusalemhNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Request For Interpretation: Enhri Training Center Building ProjectDocument1 pageRequest For Interpretation: Enhri Training Center Building ProjecteyerusalemhNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Ebcs-5 18Document4 pagesEbcs-5 18eyerusalemh100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 3xusrvh: Site Investigation Manual - 2002Document4 pages3xusrvh: Site Investigation Manual - 2002eyerusalemhNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

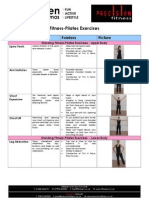

- Fitness Pilates ExercisesDocument4 pagesFitness Pilates ExercisesMohamrd FashithNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 4.5 Procedures For Diaphragms: CommentaryDocument10 pages4.5 Procedures For Diaphragms: CommentaryeyerusalemhNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Cranes and DerricksDocument15 pagesCranes and DerricksAl Hamra AyashofiyaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Conoco Phillips - Engineering Numbering Systems (COPENS) - Document No. 2169 Rev9Document236 pagesConoco Phillips - Engineering Numbering Systems (COPENS) - Document No. 2169 Rev9Javeed A. Khan50% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Ford Manual Police PackageDocument76 pagesFord Manual Police PackageKevin TimmonsNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Gradeability/Speed/Rimpull: Gross WeightDocument1 pageGradeability/Speed/Rimpull: Gross WeightPedroNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Brochure Renault BVA DP2Document4 pagesBrochure Renault BVA DP2ossoski50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Diagnostic Manual (EMS) : Cruise ControlDocument4 pagesDiagnostic Manual (EMS) : Cruise ControlZacklift Para Gruas Y CamionesNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Annexure B - Standard Technical SpecificationDocument157 pagesAnnexure B - Standard Technical SpecificationYohannes GirmaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Jaguar XE Brochure 1X7601804SSSBGBEN01P - tcm76 386866 PDFDocument32 pagesJaguar XE Brochure 1X7601804SSSBGBEN01P - tcm76 386866 PDFjohnleeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Legend of King Kong - Bo GoldmanDocument133 pagesThe Legend of King Kong - Bo GoldmanEusebio García RojasNo ratings yet

- CAR Daily Vehicle Pre Checks InformationDocument6 pagesCAR Daily Vehicle Pre Checks InformationKhalid AhmedNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CASE-1 Hindustan MotorsDocument3 pagesCASE-1 Hindustan MotorsSiddhartha DeshmukhNo ratings yet

- FR Error MercyDocument5 pagesFR Error MercyNoeRtjahya Ahmad100% (1)

- Caterpillar 3412 Marine Engine Details, Specs, Features & ExtrasDocument5 pagesCaterpillar 3412 Marine Engine Details, Specs, Features & ExtrasTobias Bengtsen100% (1)

- Exhaust System Removal and Installation PDFDocument4 pagesExhaust System Removal and Installation PDFMichael Hernandez100% (1)

- Transport PolicyDocument7 pagesTransport PolicyandeepthiNo ratings yet

- Market Study FormDocument6 pagesMarket Study FormJc IbarraNo ratings yet

- Study of A Single Effect EvaporatorDocument11 pagesStudy of A Single Effect Evaporatormahbub133267% (6)

- Fuel System Safety: Presented By: Tony HeatherDocument40 pagesFuel System Safety: Presented By: Tony HeatherABDELRHMAN ALINo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Ancheta: Jose Arnel L. Quebal Punong BarangayDocument2 pagesAncheta: Jose Arnel L. Quebal Punong BarangayLenin TolentinoNo ratings yet

- 2016 BMW R 1200 GS Adventure - Owner's ManualDocument213 pages2016 BMW R 1200 GS Adventure - Owner's ManualIvan Gavrilovic67% (3)

- 6681 Book Resized PDFDocument345 pages6681 Book Resized PDFhhsNo ratings yet

- Unit 4 General Test: Listen To The Conversations. Then Choose The Word or Phrase That Correctly Completes Each SentenceDocument5 pagesUnit 4 General Test: Listen To The Conversations. Then Choose The Word or Phrase That Correctly Completes Each SentenceAngel Cardenas100% (5)

- Scroll Down To Read The ArticleDocument23 pagesScroll Down To Read The ArticlerickNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Padernal-BSA-1A-SW-Accounts ReceivableDocument4 pagesPadernal-BSA-1A-SW-Accounts ReceivableFly ThoughtsNo ratings yet

- Ilternary Ke Perth AustraliaDocument7 pagesIlternary Ke Perth AustraliaAhmad AuzanNo ratings yet

- Dual Ignitors and Continuos Ignition in Jet EnginesDocument5 pagesDual Ignitors and Continuos Ignition in Jet Enginesa_sharafieh100% (1)

- Maximum Specific Gravity of Bituminous Mixtures (GMM) : Employer: Engineer: Ethiopia Road Authority (ERA)Document14 pagesMaximum Specific Gravity of Bituminous Mixtures (GMM) : Employer: Engineer: Ethiopia Road Authority (ERA)Guda GudetaNo ratings yet

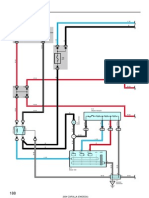

- 2004 Corolla Air Conditioning Wiring DiagramDocument4 pages2004 Corolla Air Conditioning Wiring Diagramjldamasceno100% (2)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Owning and Operating Cost BulldozerDocument3 pagesOwning and Operating Cost BulldozerReynaldoNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)