Professional Documents

Culture Documents

Quality Evaluation Standard

Uploaded by

satish_trivediOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

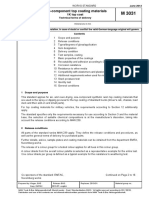

Quality Evaluation Standard

Uploaded by

satish_trivediCopyright:

Available Formats

TITLE:

QUALITY EVALUATION STANDARD OF STEEL, ALUMINUM AND ALUMINUM ALLOY SHEETS AND COILS FOR AUTOMOBILE

1. APPLICABLE MATERIALS This Standard applies to steel sheets and steel strips for automobiles (NES M2000 series) as well as cold-rolled aluminum alloy plates for automobiles (automobile bodies) (NES M4000 series) used in Nissan Subsidiaries.

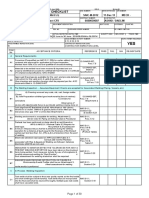

2. CLASSIFICATION OF QUALITY PROBLEMS (1) Classification of problems A summary of the steel sheet and aluminum sheet quality problems covered in this Standard is provided below. Classification 1. Packing style 2. Dimensions 3. Surface 4. Mechanical test values 5. Internal defects 6. Plating properties 7. Others Summary Packing style of coil and sheet material Coil width and sheet thickness of delivered coils and sheet material Surface quality of delivered coils and sheet material Mechanical characteristic values of delivered coil and sheet material Internal defects Plating properties Others Table 1 (2) Summary of quality problem evaluation and judgement criteria A summary of the problem classifications is provided below. Problem Rank A (Serious claim) Description Safety problem or serious accident occurred. - An accident or hazardous work occurred because of this problem. - A subsequent process (such as the vehicle body) stopped because of this problem. - A die or piece of equipment was damaged because of this problem. Safety problem, serious accident, or stoppage of subsequent process might occur; or occurrence criteria described below are met. <Surface defect control purposes> The quantity of said coils, blank materials, or products that contain defects is at least 1% (cold-rolled) or 3% (hot-rolled acid-cleaned or equivalent) per bundle or steel strip. <General purposes> - For strict-appearance materials, the quantity of said coils, blank materials, or products that contain defects is at least 3% (cold-rolled) or 5% (hot-rolled acid-cleaned or equivalent) per bundle or steel strip. - For normal-appearance materials, the quantity of said coils, blank materials, or products that contain defects is at least 5% per bundle or steel strip. - Item that does not correspond to problem rank A or B mentioned above, but is considered to include potential manufacturer-related problems. Table 2 Specific standards (criteria) are indicated in the following pages.

-1-

B (Claim)

C (Quality information)

1. Packing style Classification

Problem

Measurement Method

Rank A

Rank B Rank C

Reference

1 Abnormal outer diameter of coil 2 Abnormal inner diameter of coil 3 Collapsed coil

Measurement with steel tape measure, etc. Measurement with steel tape measure, etc. Visual and measurement with steel tape measure, etc. Visual

Based on Table 2.

Based on Table 2.

Based on Table 2.

4 Winding defect - Bamboo shoot - Partial projection

Based on Table 2.

5 Dents

Visual

Based on Table 2.

Size delivered is not the one agreed upon with the plant. Size delivered is not the one agreed upon with the plant. Coil cannot be set in line because of coil collapse. Person in charge of blank line and the supervisor confirm that unpacking or operation is impossible due to poor winding. Based on Table 2.

Each plant blank line machine performance table Each plant blank line machine performance table Although collapse occurs, production is possible. Although winding defects occur, production is possible.

Used for general purpose and there is no problem as product. At time of delivery, band specifications (number and width) differ from normal, and there is risk of breakage. Markings are difficult to see.

6 Band defect - Circumferential longitudinal band

Visual

Based on Table 2. Production is not possible because band is not used or is broken at the time of delivery. Based on Table 2.

At time of delivery, band is not securely fixed or is starting to break, and it is handled by Nissan.

7 Identification tag defect 8 Others

Visual

Based on Table 2.

There are no marking items specified by NES. Individual handling (according to agreement between the parties concerned)

NES M 2020, etc.

-2-

2. Dimensions Classification

Problem

Measurement Method

Rank A

Rank B

Rank C

Reference

1 Sheet thickness

Measurement with micrometer, etc. Measurement with steel tape measure, etc.

Based on Table 2.

2 Coil width - Includes length of sheet material

Based on Table 2.

3 Flatness - Wave - Edge wave - Center buckle 4 Camber

Visual and measurement as required

Based on Table 2.

Measurement based on NES

Based on Table 2.

5 Others 1 Flaws - Roll marks - Drawing marks - Seizure marks - Chatter marks - Scale (steel only) - Scratches - Scab - Others Based on visual/tactile standards and limit samples established ahead of time through separate agreement specifications. For all other cases, the following shall be regarded as defects: <Strict-appearance material> - Flaws that catch on fingernails - Flaws/patterns that can be confirmed with normal oilstone after pressing <Normal-appearance material> - Cracks and other flaws that become forming defects

Based on Table 2. Based on Table 2.

Indicated sheet thickStandard is met, but NES M 2020, etc. ness does not meet problem has occurred. NES standard. Does not meet NES Standard is met, but NES M 2020, etc., agreement document standard or agreement manufacturers volunin writing between the tary control target is not parties concerned. met, and problem has (Based on Table 2.) occurred. Does not meet NES Can visually confirm, NES M 2020, etc., agreement document standard or agreement but level permits proin writing between the duction. parties concerned. (Based on Table 2.) Does not meet NES Can visually confirm, NES M 2020, etc. standard. (Based on but level permits proTable 2.) duction. Individual handling (according to agreement between the parties concerned) Based on Table 2. There are many flaws that are not the target of the surface defect control leading to a risk of problems in forming process. NES M 2020, etc.

3. Surface

-3-

Classification

Problem

Measurement Method

Rank A

Rank B

Rank C

Reference

2 Grime (after unpacking) - Oil smear - Oil stains - Foreign material - Contaminants - Others 3 Rust - Rust spots - Rusty edges - White rust (aluminum only) 4 Discoloration

Visual, tactile

Based on Table 2.

Based on Table 2.

Based on Table 2. - There are stains that are no problem as a product.

NES M 2020, etc.

Visual, tactile (focusing on coils that are cut within one week after coil delivery)

Based on Table 2.

Based on Table 2.

Based on Table 2. - There is rust that is no problem as a product.

NES M 2020, etc.

Visual <Strict-appearance material> Visual confirmation must be possible. <Other> For said part, discoloration must not cause forming defect.

Based on Table 2.

Based on Table 2.

Based on Table 2.

5 Surface roughness

Based on Table 2.

Does not meet NES standard with respect to high image clarity specification. (Based on Table 2.)

6 Oil application

Based on Table 2.

7 Others

Based on Table 2.

Type of rust-preventive oil or quantity of oil was changed without prior written notification and consent from Nissan, causing vehicle production problems. Individual handling (according to agreement between the parties concerned)

- Normal finish with strict purpose: Ra > 1.5 - Normal finish with general purpose: Does not meet NES reference value. Production problems have not occurred, but quantity of oil was changed; thus, future problems are expected.

NES M 2020, etc.

-4-

4. Mechanical Classification test values

Problem

Measurement Method

Rank A

Rank B

Rank C

Reference

1 Abnormal mechanical test value - Cracks - Wrinkles - Dents Other 1 Stretcher strain 2 Structural defects 3 Internal segregation 4 Others - Rough surface - Cracks - Streaks - Bands - Unevenness Other 1 Plating defects - Abnormal amount of plating deposit - Abnormal plating composition - Nonuniformity of GI material plating 2 Peeling of plating or organic coating - Power rings - Flaking - Dross 3 Others Different from the designated organic film, etc.

JIS Z 2241/other

Based on Table 2.

Does not meet NES standard.

Based on Table 2. - Standard is met, but cracks or other problems have occurred.

NES M 2020, etc.

5. Internal defects

After press forming, determination by visual/tactile means

Based on Table 2.

Based on Table 2.

Based on Table 2.

NES M 2020, etc. (particularly aging characteristics)

6. Plating properties (steel only)

NES M 2036, etc.

Based on Table 2.

Does not meet NES standard. (Based on Table 2.)

Based on Table 2.

NES M 2036, etc.

Based on Table 2.

Based on Table 2.

Handled by Nissan (according to agreement between the parties concerned)

-5-

Classification

Problem

Measurement Method

Rank A

Rank B

Rank C

Reference

1 Erroneous coil delivery

Based on Table 2.

Does not meet NES standard. Based on Table 2. Based on Table 2.

Others

2 Edge burring 3 Others

Based on Table 2. Based on Table 2.

Individual handling (according to agreement between the parties concerned)

-6-

3. APPLICATION PRECAUTIONS This section describes precautionary points to remember when applying this Standard. (1) Troubleshooting Troubleshooting basically consists of the actions described below. As a practical matter, actions are determined through agreement between the parties concerned, based on the conditions of occurrence. Problem Handling Count Remarks Level Rank A Discuss between the parties concerned Implement Set target for as a matter involving a warranty (supplenumber of inmentation or compensation for loss) cidents. and/or serious claim. Rank B Request improvement as a matter involv- Implement Set target for ing a warranty (supplementation or comnumber of inpensation for loss) and/or claim. cidents. Rank C Submit information as quality information. Implement Submit results. (2) Counting the number of problem incidents In principle, incidents shall be counted as 1 incident/coil (sheet = 1 incident/bundle). (3) Problem ranks, in principle, shall be determined in the presence of the manufacturer. Also, the actual determination shall be made by the plant's Material Quality Service Section (Quality Assurance Section or Stamping Section). (4) The material quality service section shall set targets, tabulate the number of problem incidents, and issue improvement requests to manufacturers. Also, yearly summaries of the status of problems at each plant shall be prepared once a year by the Production Engineering Department. 4. APPLICATION DATE: The revision of this matter shall be applied starting on December 2, 2005. 3 5. NORMATIVE REFERENCES (1) NES M2020 (2) NES M2021 (3) NES M2027 (4) NES M2028 ; Cold Rolled Carbon Steel Sheets and Strips ; Hot Rolled Steel Plates, Sheets and Strip for Automobiles ; Zinc Coating (Hot-Dipped) on Steel Plates and Steel Strips for Automobiles 3 ; Electrogalvanized, and Zn-Ni-Electroplated Steel Sheets and Steel Strips for Automobiles (5) NES M2029 ; Hot Dipped Aluminum Coated Steel Sheets and Strips for Automobiles (6) NES M2030 ; Terne Coated and Nickel/Terne Coated Steel Sheets and Strips for Automobiles (7) NES M2032 ; High Tensile Strength Cold Rolled Carbon Steel Sheets and Strips for Automobiles (8) NES M2036 ; Durasteel Corrosion Control Coated Steel Sheets and Strips - Automobile (9) NES M2037 ; Aluminum Coated Hot-Dipped Stainless Steel Sheets for Automobiles (10) NES M4064 ; Cold Rolled Aluminum Alloy Sheets for Automobiles (for Bodies) (11) JIS Z2241 ; Method of tensile test for metallic materials

-7-

You might also like

- E M0140 2009-N PDFDocument11 pagesE M0140 2009-N PDFAna Georgina Vidrio Longoria75% (4)

- Esbm5a-B 1n261-s Aa RSWDocument37 pagesEsbm5a-B 1n261-s Aa RSWChandrajeet Shelke50% (2)

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocument9 pagesFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNo ratings yet

- VW 011 03Document22 pagesVW 011 03Alexandre UrquizaNo ratings yet

- Paint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2020-N Nissan Engineering StandardDocument14 pagesPaint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2020-N Nissan Engineering StandardCARLOS A.N. LANZILLOTTO100% (1)

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDocument7 pagesAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzNo ratings yet

- ISO-n Exponent PDFDocument12 pagesISO-n Exponent PDFjavidokNo ratings yet

- TSB1503G 9 P 1Document18 pagesTSB1503G 9 P 1kk_pammu_915176926No ratings yet

- PPAP 4th EdDocument11 pagesPPAP 4th EdEd Ri0% (1)

- GMW3001Document1 pageGMW3001skgolban0% (1)

- M0140 (2014-N) NES: Salt Spray TestingDocument11 pagesM0140 (2014-N) NES: Salt Spray TestingBea RiveraNo ratings yet

- GMW16536 Sealer-In Welded Struct Aug2011Document9 pagesGMW16536 Sealer-In Welded Struct Aug2011Taofiq AbiolaNo ratings yet

- b53 3271 Emboutillage para Argentina y BrasilDocument9 pagesb53 3271 Emboutillage para Argentina y BrasilGT-LUCAS BARCINo ratings yet

- WSS-M1A346-A - Calidad de ChapaDocument12 pagesWSS-M1A346-A - Calidad de ChapaDANIEL DIAZNo ratings yet

- CS-11000Document17 pagesCS-11000Engenharia APedro100% (1)

- M0132 2007 (N)Document8 pagesM0132 2007 (N)jenwitbunjongsatNo ratings yet

- Weld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelDocument8 pagesWeld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelMuhammad AliNo ratings yet

- D0031 (2012-N) NES: Marking of Polymeric PartsDocument16 pagesD0031 (2012-N) NES: Marking of Polymeric PartsDiego CamargoNo ratings yet

- Ford We 910 - 2001Document6 pagesFord We 910 - 2001Jason-chungNo ratings yet

- FCA - PS.50009 (2014) - Ex PS.5570Document7 pagesFCA - PS.50009 (2014) - Ex PS.5570FeliceNo ratings yet

- Mpaps G-20Document6 pagesMpaps G-20PANKAJ CHAUHANNo ratings yet

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- TL 256 en 2022Document8 pagesTL 256 en 2022Michal BílekNo ratings yet

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocument5 pagesCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- D271389 F' PDFDocument13 pagesD271389 F' PDFReza AbdolahiNo ratings yet

- TSH5603G - 8 - P - 1 Arc WeldingDocument14 pagesTSH5603G - 8 - P - 1 Arc Weldinggüray bağdatlı100% (1)

- Hes d2003 05 - Galvanoplastia (Para A Corrosão Prevenção, A OxidaçãoDocument14 pagesHes d2003 05 - Galvanoplastia (Para A Corrosão Prevenção, A Oxidaçãohkatzer100% (1)

- M 3031 (2013-06)Document16 pagesM 3031 (2013-06)Hatada FelipeNo ratings yet

- GMW PQ140-250 PF144x72Document4 pagesGMW PQ140-250 PF144x72seriousguy2No ratings yet

- TSZ2207G: Toyota Engineering StandardDocument6 pagesTSZ2207G: Toyota Engineering StandardGuilherme DurãesNo ratings yet

- Sae J82-2013Document6 pagesSae J82-2013Marcos RosenbergNo ratings yet

- PWPT001 H Interior-Exterior Plastic Parts For DecorationDocument28 pagesPWPT001 H Interior-Exterior Plastic Parts For Decorationmohammad yazdanpanahNo ratings yet

- TL245 English 2004Document8 pagesTL245 English 2004Elliott RussellNo ratings yet

- Fiat52605 02Document6 pagesFiat52605 02LucaNo ratings yet

- Engineering Material SpecificationDocument10 pagesEngineering Material SpecificationMike FiorenNo ratings yet

- 013 Determination of Degree of Rusting of Coatings: C/CTNDocument5 pages013 Determination of Degree of Rusting of Coatings: C/CTNjoaopedrosousa50% (2)

- STJLR.50.5058 Issue 2 20190805Document6 pagesSTJLR.50.5058 Issue 2 20190805Shu FuNo ratings yet

- VW 13750 Englisch Superficial TratamentDocument16 pagesVW 13750 Englisch Superficial Tratamentrgi178No ratings yet

- Guia de Materiales - MatricesDocument11 pagesGuia de Materiales - MatricesGracielaNo ratings yet

- John Deere Design, Process, and Assembly ReviewDocument33 pagesJohn Deere Design, Process, and Assembly ReviewcucuNo ratings yet

- ASTM E 505 Cast DefectsDocument3 pagesASTM E 505 Cast DefectsMario Moura JrNo ratings yet

- Astm B765Document4 pagesAstm B765Purushottam Sutar100% (2)

- GMW14400 May2007 PDFDocument9 pagesGMW14400 May2007 PDFAkmal NizametdinovNo ratings yet

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Document13 pagesNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNo ratings yet

- BMS 0000147Document15 pagesBMS 0000147方綵樺No ratings yet

- GMW 1Document3 pagesGMW 1nirav87404No ratings yet

- Is 1079 - 2009Document10 pagesIs 1079 - 2009Shradha SinghaniaNo ratings yet

- Worldwide Engineering Standards: Low Carbon Sheet SteelDocument13 pagesWorldwide Engineering Standards: Low Carbon Sheet SteelaldairlopesNo ratings yet

- Astm D 7087 - 2010Document4 pagesAstm D 7087 - 2010Emmanuel BoquetNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Coating Systems For Customised, Special Versions: January 2004Document14 pagesCoating Systems For Customised, Special Versions: January 2004Akmal NizametdinovNo ratings yet

- Cs 9003Document22 pagesCs 9003ibrahime mohammed100% (1)

- WSS M1a347 (Hsla)Document14 pagesWSS M1a347 (Hsla)Enrique Maya VisuetNo ratings yet

- Title: Cover-Fr Under No. 75892 NDS01Document7 pagesTitle: Cover-Fr Under No. 75892 NDS01Diego Camargo100% (1)

- Astm A 653 PDFDocument9 pagesAstm A 653 PDFAdán Vera GoNo ratings yet

- Updated: 05/02/2007: IMO PSPC - IACS Interpretations IMO PSPC Topic Approved Clarification Items InterpretationsDocument7 pagesUpdated: 05/02/2007: IMO PSPC - IACS Interpretations IMO PSPC Topic Approved Clarification Items InterpretationsLinnie McleodNo ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- Astm D2563-94Document24 pagesAstm D2563-94Santiago AngelNo ratings yet

- Saep 306Document13 pagesSaep 306brecht1980No ratings yet

- Gujarat PDFDocument1 pageGujarat PDFsatish_trivediNo ratings yet

- Gujarat PDFDocument1 pageGujarat PDFsatish_trivediNo ratings yet

- GL SpecialtyDocument32 pagesGL Specialtysatish_trivediNo ratings yet

- Nagaland PDFDocument1 pageNagaland PDFsatish_trivediNo ratings yet

- Westbengal Road Map: Close WindowDocument2 pagesWestbengal Road Map: Close Windowsatish_trivediNo ratings yet

- Tripura Road Map: Close WindowDocument2 pagesTripura Road Map: Close Windowsatish_trivediNo ratings yet

- Manipur Road Map: Close WindowDocument1 pageManipur Road Map: Close Windowsatish_trivediNo ratings yet

- Assam Road Map: Close WindowDocument1 pageAssam Road Map: Close Windowsatish_trivediNo ratings yet

- Jharkhandroads: Close WindowDocument1 pageJharkhandroads: Close Windowsatish_trivediNo ratings yet

- Bihar Road Map: Close WindowDocument1 pageBihar Road Map: Close Windowsatish_trivediNo ratings yet

- Arunachal Pradesh Road Map: Close WindowDocument1 pageArunachal Pradesh Road Map: Close Windowsatish_trivediNo ratings yet

- Jan 15 PDFDocument72 pagesJan 15 PDFsatish_trivediNo ratings yet

- Feb 2014 PDFDocument72 pagesFeb 2014 PDFsatish_trivediNo ratings yet

- SKF Shaft SealDocument379 pagesSKF Shaft Sealsatish_trivediNo ratings yet

- SDMSLite Install GuideDocument15 pagesSDMSLite Install Guidesatish_trivediNo ratings yet

- Chapter 3 Structures of Metal ComplexesDocument25 pagesChapter 3 Structures of Metal ComplexesRaheem SimsNo ratings yet

- Compabloc 207-235Document248 pagesCompabloc 207-235Anie EkpenyongNo ratings yet

- 2 - Properties of Oil and Natural Gas - 2007 - Petroleum Production EngineeringDocument9 pages2 - Properties of Oil and Natural Gas - 2007 - Petroleum Production EngineeringHaziq YussofNo ratings yet

- Cooling Tower. Merkel Theory - TreybalDocument39 pagesCooling Tower. Merkel Theory - TreybalMarx CesarNo ratings yet

- Extrusion Press PDFDocument2 pagesExtrusion Press PDFRobert25% (4)

- Urinary Organic Acids DR BralleyDocument5 pagesUrinary Organic Acids DR BralleyMetametrixNo ratings yet

- Publication 10 11891 250 UV-Vis2Document12 pagesPublication 10 11891 250 UV-Vis2abhinavNo ratings yet

- Microreactors (General) PDFDocument1 pageMicroreactors (General) PDFAnonymous Ksq1dyPRhNo ratings yet

- Experiment 2: Analysis of Carbohydrates: Learning ObjectivesDocument7 pagesExperiment 2: Analysis of Carbohydrates: Learning ObjectivesJerico NaveraNo ratings yet

- Characterization of Turkey Berry (Solanum Torvum) - Fresh, Dry & PowderDocument7 pagesCharacterization of Turkey Berry (Solanum Torvum) - Fresh, Dry & Powderw vanayaNo ratings yet

- Ijpdt 8 (2) 2018 12-36Document25 pagesIjpdt 8 (2) 2018 12-36wlNo ratings yet

- Pipe FittingsDocument63 pagesPipe FittingsAdriana LimaNo ratings yet

- Concrete Recyclicling AggDocument11 pagesConcrete Recyclicling AggBesmir BeqiriNo ratings yet

- Coach Ally Open School Physics Paper 1 Form FourDocument5 pagesCoach Ally Open School Physics Paper 1 Form FourJuma BwaiNo ratings yet

- Bull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault SynthesisDocument3 pagesBull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault Synthesisjanina_nazarskaNo ratings yet

- CHE F312 Chemical Engineering Laboratory-I: BITS PilaniDocument16 pagesCHE F312 Chemical Engineering Laboratory-I: BITS PilaniHritik LalNo ratings yet

- Air Pollution Lesson PlanDocument11 pagesAir Pollution Lesson PlanThe Service Dog LifeNo ratings yet

- RRSMDocument14 pagesRRSMfitrie dwi lestariNo ratings yet

- Hipol 18 LV TDSDocument2 pagesHipol 18 LV TDSAbhineet ShrivastavaNo ratings yet

- Cindye DNK 1Document3 pagesCindye DNK 1jose iniestaNo ratings yet

- SADASDocument6 pagesSADASJORGE TADDANo ratings yet

- CHEMANOL Product1Document21 pagesCHEMANOL Product1M A JADOON100% (1)

- Ureal: GLDH 4 2Document8 pagesUreal: GLDH 4 2CarinaVillasantiNo ratings yet

- Test-2Topics Y8: Senior SchoolDocument5 pagesTest-2Topics Y8: Senior SchoolMadiha ShakilNo ratings yet

- Parenteral S RonaDocument14 pagesParenteral S RonalanDraynNo ratings yet

- B.tech. Biotechnology NotesDocument14 pagesB.tech. Biotechnology NotesMudit MisraNo ratings yet

- Kunkle Models 910, 911, 916, 917, 920, 921 and 927Document24 pagesKunkle Models 910, 911, 916, 917, 920, 921 and 927Alexsandro TorezinNo ratings yet

- Different Types of Aluminium Windows: Aluminium Bi Fold (Sliding & Folding) Windows - These Type of Windows Are VeryDocument4 pagesDifferent Types of Aluminium Windows: Aluminium Bi Fold (Sliding & Folding) Windows - These Type of Windows Are Veryvaishnavi karvekarNo ratings yet

- INDEX 10G2 SI 02 815 10 Fault Code 74 PDFDocument6 pagesINDEX 10G2 SI 02 815 10 Fault Code 74 PDFGarcia CruzNo ratings yet

- Iest-Rp-Cc0021,3 Testing Hepa and Ulpa Filter Media PDFDocument29 pagesIest-Rp-Cc0021,3 Testing Hepa and Ulpa Filter Media PDFAdrian ZamoraNo ratings yet

- 2016 - Environmental Comparison-Biochar and AC - 3rd TreatmentDocument27 pages2016 - Environmental Comparison-Biochar and AC - 3rd TreatmentMinh MacNo ratings yet