Professional Documents

Culture Documents

Tooling Approval Checklist For Plastic Moulds0

Uploaded by

Herman HutabaratOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tooling Approval Checklist For Plastic Moulds0

Uploaded by

Herman HutabaratCopyright:

Available Formats

TOOLING APPROVAL CHECK LIST FOR PLASTIC MOULDS

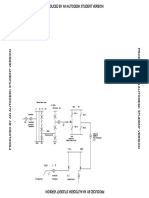

Part Name: Customer Part No.: Your Company's Part No.: Customer drawing No.: Revision: Date of Review: Mould maker's Mould no.: Your Company's mould no.: Mould drawing No.: Revision level: Hot runner details: Mould Size: Mould Weight: No. of cavities: Remark / Deviation

S.No 1 2 3 4 5 6 7 8 9 10 11 12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

Check points OK/ NOK/ NA All the Notes written on part drawing are accomplished Core and Cavity material test certificate is ready Final mould inspection report Blue matching of cavity, core, side core and other matching areas Flash observed on the part Is there buckling on core, cavity and ejector plates No. of fasteners is sufficient for core and cavity inserts Lifting holes provided for heavier core and cavity inserts Dismantling and assembly of moulds is easy All parts of the mould are identified for easy assembly All necessary parts are heat treated Is the core surface Free from polishing line Free from EDM or milling marks Free from waviness Draft angle is sufficient Mould dimensions produce components within component tolerances Mouldings remain on ejector side when the mould opens Ejector stroke clears components Component is free from catching, cracking and warpage Is the texture according to standard and is uniform Free movement of ejector system Adopter is suitable to the machine selected Ejector return mechanism is acceptable Main guide pillars enter before any other part of the mould Is there scoring on any parts Cavity and Core inserts properly located Electrical wires on the mould is properly clamped All electrical connections, wiring are checked Water channel inlet and outlet are according to drawings and stamped for IN , OUT and thread size Water lines are completely checked for leaks at 5 bar pressure Are Water and hydraulic hoses, conectors interfering during mould loading and during moulding Locating ring is matching to the machine selected Sprue bush nozzle seating radius matching with planned machine Is Sprue bush draft sufficient and polished Is Sprue puller proper Runners are of sufficient size Runners are polished and free from burrs Gate to be checked for size and burrs Mould is sufficiently vented Opening and closing is acceptable Mould lifting eye bolts are sufficient Eye bolt size, mould weight, mould no. and part no. punched Lifting Strap, if any does not project beyond plates and foul with other parts Special instructions are punched on the mould Check for doweling of all guide rails Check for cracks on mould parts Circuit diagram for heaters to be provided on the mould towards the operator side All catalogues in original Process sheet for Mould Setting Side cores are removable while the mould is in the machine All cavities are numbered Check for split line burrs Moulds to be provided with Hasco water nipples The mould should not have any brazed part Mould part drawings Crictical spares are identified and provided Side core movement controlled by Ball catch or stopper plates Top plate cooling on hot runner mould Tool Approved YES / NO

Other Comments

Signature and Name of the Tool maker with Seal

Signatute and Name of Your Company representatives (Production, Quality, Engineering)

Tooling Approval Checklist for Plastic Moulds.xls

Page 1 of 1

You might also like

- Mould Trial ReportDocument5 pagesMould Trial ReportSUBODHH0% (1)

- Mold Design Spec SheetDocument1 pageMold Design Spec Sheetomerscheen0% (1)

- Mold Design ChecklistDocument10 pagesMold Design ChecklistRamesh RaoNo ratings yet

- Die Design ChecklistDocument3 pagesDie Design ChecklistLương TuấnNo ratings yet

- Mould Change, Storage and Maintenance ProcedureDocument10 pagesMould Change, Storage and Maintenance ProcedureTechnicians SIM100% (1)

- 1362-Mould Design Verification ChecklistDocument6 pages1362-Mould Design Verification Checklistrajesh100% (1)

- Job Startup Checklist Format No: P3/00 Part Name: Date Part Number: Shift Check Points: Yes No NADocument1 pageJob Startup Checklist Format No: P3/00 Part Name: Date Part Number: Shift Check Points: Yes No NAubraghuNo ratings yet

- Mould MaintenanceDocument13 pagesMould Maintenancebest4rever100% (2)

- Mold Maintenance StepDocument0 pagesMold Maintenance StepMonica JoynerNo ratings yet

- Mold and Die - PPTDocument110 pagesMold and Die - PPTThaloengsak Kucharoenpaisan100% (2)

- Theory of Moulds - ContentsDocument9 pagesTheory of Moulds - Contentsnagesh_sprao19275% (4)

- Paulson Training - Injection MoldingDocument25 pagesPaulson Training - Injection MoldingSyed Mujtaba Ali BukhariNo ratings yet

- Mold Maintenance ProgramDocument14 pagesMold Maintenance ProgramLordsonNo ratings yet

- Molding Defects.Document13 pagesMolding Defects.jineshdmehta100% (1)

- P&ID Check ListDocument6 pagesP&ID Check ListSrihari Kodimela0% (1)

- Mold Design ChecklistDocument2 pagesMold Design ChecklistWerner SchrammelNo ratings yet

- Mold Spec SheetDocument1 pageMold Spec SheetRakesh Junnur100% (1)

- Mold Spec Guidelines Jun 08revisedDocument27 pagesMold Spec Guidelines Jun 08revisedDirk HenningNo ratings yet

- Plastic Injection Mold Design ChecklistDocument2 pagesPlastic Injection Mold Design ChecklistSelvaraj Balasundram100% (1)

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Mold Check ListDocument10 pagesMold Check Listapk11No ratings yet

- IMM Process SetupsDocument25 pagesIMM Process Setupslam nguyen100% (1)

- Molding Parameter Record RevDocument26 pagesMolding Parameter Record Revapi-37326090% (1)

- Moulding TroubleshootingDocument22 pagesMoulding TroubleshootingPiousPatialaNo ratings yet

- Injection Mold Design ChecklistDocument4 pagesInjection Mold Design Checklistctansari0% (1)

- Moulding Check ListDocument2 pagesMoulding Check Listapi-3732609No ratings yet

- Mould Maintenance A.kumarDocument40 pagesMould Maintenance A.kumarShankar Hindgavkar100% (2)

- Mould Starndard Parts PDFDocument13 pagesMould Starndard Parts PDFMohd Nazri SalimNo ratings yet

- Defects of PlasticsDocument12 pagesDefects of PlasticsVenkata Chakradhar100% (1)

- Mold Check ListDocument4 pagesMold Check Listctansari100% (1)

- The Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SDocument6 pagesThe Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SSanjay KumarNo ratings yet

- Minsa Trial Report Molde SC194Document2 pagesMinsa Trial Report Molde SC194daniel ortiz fuentesNo ratings yet

- Process Parameter SheetDocument1 pageProcess Parameter SheetNur AmiraNo ratings yet

- Mold Cost EstimationDocument5 pagesMold Cost EstimationPenjahit TedyNo ratings yet

- Injection Molding Part CostingDocument4 pagesInjection Molding Part CostingfantinnoNo ratings yet

- Injection Moulding - Quality Molded PartsDocument28 pagesInjection Moulding - Quality Molded PartsQuản Lê Đình100% (3)

- Injection Molding Defect OzDocument12 pagesInjection Molding Defect Oztopkaya100% (1)

- Injection Mold Design DetailsDocument43 pagesInjection Mold Design DetailsKen100% (1)

- Injctmld F03Document2 pagesInjctmld F03prasad_kcpNo ratings yet

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocument2 pagesNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNo ratings yet

- Fmea For Injection MoldingDocument53 pagesFmea For Injection MoldingQuality teamNo ratings yet

- Clamping Force & Tonnage CalculationDocument3 pagesClamping Force & Tonnage CalculationJyoti KaleNo ratings yet

- CV Cipet Production NewDocument4 pagesCV Cipet Production NewKamlesh KumarNo ratings yet

- 2.describe Mould Parts and ConstructionDocument49 pages2.describe Mould Parts and ConstructionNazri100% (4)

- Moulding Technology: by Balraj TanwarDocument37 pagesMoulding Technology: by Balraj TanwarVinod KumarNo ratings yet

- Mould Theory PDFDocument35 pagesMould Theory PDFArunava Bala75% (4)

- Mold Spec GuideDocument25 pagesMold Spec Guidemrj27050% (2)

- Injection Molding Troubleshooting Flash BurnmarksDocument60 pagesInjection Molding Troubleshooting Flash Burnmarkswawawa1100% (1)

- Injection Molding Process & Machine SelectionDocument72 pagesInjection Molding Process & Machine SelectionShubham ChaudharyNo ratings yet

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHHNo ratings yet

- Injection Molding: Part Cost EstimatorDocument3 pagesInjection Molding: Part Cost EstimatorpchakkrapaniNo ratings yet

- Mold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationDocument3 pagesMold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationUmang Srivastava100% (1)

- DFM Injection Molding Analysis 0614Document9 pagesDFM Injection Molding Analysis 0614anjal22No ratings yet

- Mold Design Fundamental Calculation BATTERY COVERDocument7 pagesMold Design Fundamental Calculation BATTERY COVERrgrao85No ratings yet

- Setting Molding ConditionsDocument21 pagesSetting Molding Conditionssuwithy04No ratings yet

- Mold Standards & ClassificationsDocument3 pagesMold Standards & ClassificationsKamleshVasavaNo ratings yet

- P&Id Related: Sr. No. Check Points DoneDocument5 pagesP&Id Related: Sr. No. Check Points DoneSwapna Priya VattemNo ratings yet

- Detailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer ChecklistDocument3 pagesDetailed Engineering Drawings, Codes and Standards: Piping & Instrumentation Diagram - Designer ChecklistSuresh RamakrishnanNo ratings yet

- Mold Design Review Checklist: Part InformationDocument5 pagesMold Design Review Checklist: Part InformationAbdul BasitNo ratings yet

- Dove Holy Spirit PowerPoint TemplatesDocument48 pagesDove Holy Spirit PowerPoint TemplatesChittaNo ratings yet

- Work Sequence: Coating Application 36 Inch Cgs 5 Duri To Dumai Area Package 2 - 2019Document1 pageWork Sequence: Coating Application 36 Inch Cgs 5 Duri To Dumai Area Package 2 - 2019Herman HutabaratNo ratings yet

- Duration 4 Days Fee Rp. 4.500.000: ObjectiveDocument1 pageDuration 4 Days Fee Rp. 4.500.000: ObjectiveHerman HutabaratNo ratings yet

- Herman Pardamean Hutabarat: Mechanical EngineerDocument3 pagesHerman Pardamean Hutabarat: Mechanical EngineerHerman HutabaratNo ratings yet

- Form Request Man PowerDocument1 pageForm Request Man PowerHerman HutabaratNo ratings yet

- Tips and Trick To Avoid Fake Recruitment On Behalf of PERTAMINADocument14 pagesTips and Trick To Avoid Fake Recruitment On Behalf of PERTAMINAHerman HutabaratNo ratings yet

- Load Chart FT 5 TonDocument1 pageLoad Chart FT 5 TonHerman HutabaratNo ratings yet

- Ceklist Rev 1Document1 pageCeklist Rev 1Herman HutabaratNo ratings yet

- Ceklist Rev 1Document1 pageCeklist Rev 1Herman HutabaratNo ratings yet

- Accident PreventionDocument11 pagesAccident PreventionHerman HutabaratNo ratings yet

- FormcompDocument1 pageFormcomp123456mkNo ratings yet

- Form Pendaftaran.1Document2 pagesForm Pendaftaran.1Veronika ChaidirNo ratings yet

- Accident Reporting & InvestigationDocument26 pagesAccident Reporting & InvestigationHerman HutabaratNo ratings yet

- 1-7 - Ornamental Designs ModelDocument1 page1-7 - Ornamental Designs ModelHerman HutabaratNo ratings yet

- NI Tutorial 5097Document2 pagesNI Tutorial 5097Herman HutabaratNo ratings yet

- Book SetDocument1 pageBook SetHerman HutabaratNo ratings yet

- Warning:: - This Is An Automated Message. Please Do Not ReplyDocument1 pageWarning:: - This Is An Automated Message. Please Do Not ReplyHerman HutabaratNo ratings yet

- WG's Process Engineers' Codes & StandardsDocument7 pagesWG's Process Engineers' Codes & StandardsHerman HutabaratNo ratings yet

- Baca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveDocument1 pageBaca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveHerman HutabaratNo ratings yet

- MalDocument1 pageMalHerman HutabaratNo ratings yet

- Baca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveDocument1 pageBaca Buku Wajib: Chapter 1 of Electronic Commerce 2004: A Managerial PerspectiveHerman HutabaratNo ratings yet

- Beam & Column Selection CalculatorDocument63 pagesBeam & Column Selection CalculatorVivek Prajapati100% (1)

- Danareksa Management Trainee Application Form: Personal InformationDocument1 pageDanareksa Management Trainee Application Form: Personal InformationHerman HutabaratNo ratings yet

- SymbolsDocument1 pageSymbolsbarmarwanNo ratings yet

- SymbolsDocument1 pageSymbolsbarmarwanNo ratings yet

- FormcompDocument1 pageFormcomp123456mkNo ratings yet

- Friction FactorDocument6 pagesFriction Factorrajeshsapkota123No ratings yet

- 1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsDocument2 pages1BFF68 Pipe-Flow Friction-Factor Calcns Head-Loss Si UnitsTKASHIQUE100% (1)

- Calculation of Water Flow Rates For Different Pipe Sizes - US UnitsDocument4 pagesCalculation of Water Flow Rates For Different Pipe Sizes - US UnitsRyan KaneNo ratings yet

- Grade 7 and 8 November NewsletterDocument1 pageGrade 7 and 8 November Newsletterapi-296332562No ratings yet

- Johannes Gensfleisch Zur Laden Zum GutenbergDocument2 pagesJohannes Gensfleisch Zur Laden Zum GutenbergNathan SidabutarNo ratings yet

- Don't Just Lead, Govern: Implementing Effective IT GovernanceDocument20 pagesDon't Just Lead, Govern: Implementing Effective IT GovernanceWahyu Astri Kurniasari100% (1)

- ¿Cómo Se Utilizan Las Partituras en La Enseñanza y El Aprendizaje de La Música?Document15 pages¿Cómo Se Utilizan Las Partituras en La Enseñanza y El Aprendizaje de La Música?manaimanaNo ratings yet

- Mahindra08 Tractor 2Document5 pagesMahindra08 Tractor 2Pawan SinghNo ratings yet

- H S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolDocument58 pagesH S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolCRISTIANNo ratings yet

- XJ3 PDFDocument2 pagesXJ3 PDFEvert Chavez TapiaNo ratings yet

- TCE BE EEE RulesandRegulationsDocument509 pagesTCE BE EEE RulesandRegulationsAplieNo ratings yet

- Eurotherm 2604 PDFDocument2 pagesEurotherm 2604 PDFLorena100% (1)

- 11kv BB1Document1 page11kv BB1Hammadiqbal12No ratings yet

- S9300&S9300E V200R001C00 Hardware Description 05 PDFDocument282 pagesS9300&S9300E V200R001C00 Hardware Description 05 PDFmike_mnleeNo ratings yet

- Poiseuille Lab ExperimentDocument7 pagesPoiseuille Lab ExperimentArjun SinghNo ratings yet

- Case StudyDocument80 pagesCase Studybravo deltafoxNo ratings yet

- New Microsoft Office Power Point PresentationDocument21 pagesNew Microsoft Office Power Point PresentationSai DhanushNo ratings yet

- Experiment No.7 Study of Disc Pelletizer: ObjectivesDocument4 pagesExperiment No.7 Study of Disc Pelletizer: ObjectivesPrafulla Subhash SarodeNo ratings yet

- Characteristics of Supercritical Flow in Rectangular ChannelDocument10 pagesCharacteristics of Supercritical Flow in Rectangular ChannelFatihNo ratings yet

- Toshiba NB520 Compal LA-6859PDocument38 pagesToshiba NB520 Compal LA-6859Pash thonNo ratings yet

- 2007 DB Drag FinalsDocument4 pages2007 DB Drag FinalsTRELONo ratings yet

- Blinx01's Ultimate DVD Subbing GuideDocument12 pagesBlinx01's Ultimate DVD Subbing GuideloscanNo ratings yet

- Conveni Pack Technical Data (LRYCP DY1 R 407C)Document188 pagesConveni Pack Technical Data (LRYCP DY1 R 407C)HoàngViệtAnhNo ratings yet

- Yaskawa TM.J7.01Document96 pagesYaskawa TM.J7.01Salvador CrisantosNo ratings yet

- Test Procedure and MethodDocument1 pageTest Procedure and MethodkmiqdNo ratings yet

- Stockholm Metro Case Study 2 PDFDocument3 pagesStockholm Metro Case Study 2 PDFJenelle SandersNo ratings yet

- A Study On Welding Defects of Pressure VesselDocument24 pagesA Study On Welding Defects of Pressure Vesseladamahmad1992100% (1)

- Mouse 200Document2 pagesMouse 200Amjad AliNo ratings yet

- NNH4-65C-R6-V2: Electrical SpecificationsDocument4 pagesNNH4-65C-R6-V2: Electrical SpecificationsAntony López GálvezNo ratings yet

- RS232STATUSMONDocument1 pageRS232STATUSMONashish.boradNo ratings yet

- 2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Document4 pages2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Progress QueensNo ratings yet

- MUDPRO Plus Advanced Mud ReportingDocument2 pagesMUDPRO Plus Advanced Mud ReportinglarasNo ratings yet

- 15mm K115 GW-S CUP STD (SH005 1014 B)Document2 pages15mm K115 GW-S CUP STD (SH005 1014 B)Ionut BucurNo ratings yet