Professional Documents

Culture Documents

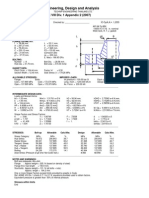

PTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washing

Uploaded by

alvinchuanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC & Branch Calc_ASME B31.3_Upto NPS 24 for hot water washing

Uploaded by

alvinchuanCopyright:

Available Formats

1

Only RED font cells are meant for Input.

PMS Line Class ID =

washing

Select / Input Special Requirements, if any =

ASME Flange Rating =

PN 320

hot water washing

Fluid / Service =

hot water washing

Material Specification =

A312 Gr TP304

Quality Factor, E =

1.00

Pipe Manufacturing Type =

Design Pressure =

200.00 barg

= 2900.75 psig

Please input pressure value in barg.

Design Temperature =

75.0C

= 167.0F

Please input temperature value in C.

Allow. Stress @ 75C =

Please check from Table A-1 of ASME B31.3 Latest Ed

Low Temperature Process

Material Type: Austenitic steels (TP304, 310, 316, 321, 347)

Seamless Pipe or Tube

20.000 ksi

= 137.90 MPa

10 Corrosion Allowance =

0.00 mm

= 0.00 inch

Mill Tolerance =

11 Y Coefficient @ 75C =

0.4

Valid for t<D/6

Please check from ASME B31.3 Table 304.1.1.

12 Ratio of (P/SE) =

0.145

Check Passed.

13 tpressure =

(P x D) / [2 x {(S.E) + (P.Y)}]

14

(Valid for t<D/6)

12.5%

Please inpu

= (2,900.8 x D) / [2 x {(20,000.0 x 1.00) + (2,900.8 x 0.

= 0.0685423764 x D inch

15 Where,

(As per para. 304.1.2 of of ASME B31.3 2002 Edition)

16

D = Outside diameter of pipe in inch and also derived in mm;

17

P = Internal design gage pressure in psi and also derived in bar;

Refer ASME B36.10M-1996

18

tmin = Minimum required thickness, including mechanical, corrosion and erosion allowances;

19

tpressure = Pressure design thickness, as calculated in accordance with para. 304.1.2, for internal pressure;

20

S = Allowable stress value from Table A-1 of ASME B31.3;

21

E = Quality factor from Table A-1A or A-1B of ASME B31.3;

22

Y = Coefficient from Table 304.1.1 of ASME B31.3, valid for t<D/6;

23

T = The minimum wall thickness for the pipe selected or purchased, considering manufacturer's minus

24

tolerance shall be NOT less than t min. For t min, refer Column "A" and for T, refer Column "B".

25

(All nomenclatures, definitions and parameters are generally in accordance with ASME B31.3 2002 Edition.)

26

Selected

27

Pipe NPS

Pipe OD

tpressure

28

inch (mm)

D (mm)

(mm)

29

tmin

Sch /

Nominal

(mm)

Thk. (inch)

Min. Thk.

Max.Allow.

Thk. (mm)

T (mm)

P (barg)

Tnom

Column "B"

Column "A"

Ratio

(D/t)

Check (>6)

30

" (15)

21.34

1.46

1.46

Sch.40S

2.77

2.42

344.4

8.8

31

" (20)

26.67

1.83

1.83

Sch.40S

2.87

2.51

280.9

10.6

32

1" (25)

33.40

2.29

2.29

Sch.40S

3.38

2.96

262.7

11.3

33

1" (32)

42.16

2.89

2.89

Sch.40S

3.56

3.11

216.3

13.6

34

1" (40)

48.26

3.31

3.31

Sch.40S

3.68

3.22

194.6

15.0

35

2" (50)

60.33

4.13

4.13

Sch.40S

3.91

3.42

163.9

17.6

36

2" (65)

73.03

5.01

5.01

Sch.40S

5.16

4.51

179.3

16.2

37

3" (80)

88.90

6.09

6.09

Sch.40S

5.49

4.80

155.7

18.5

38

3" (90)

101.60

6.96

6.96

Sch.80S

8.08

7.07

203.2

14.4

39

4" (100)

114.30

7.83

7.83

Sch.80S

8.56

7.49

190.7

15.3

40

5" (125)

141.30

9.69

9.69

Sch.80S

9.53

8.33

170.7

17.0

41

6" (150)

168.28

11.53

11.53

Sch.80S

10.97

9.60

164.9

17.5

42

8" (200)

219.08

15.02

15.02

Sch.100

15.09

13.20

174.6

16.6

43

10" (250)

273.05

18.72

18.72

Sch.100

18.26

15.98

169.3

17.1

44

12" (300)

323.85

22.20

22.20

Sch.100

21.44

18.76

167.5

17.3

45

14" (350)

355.60

24.37

24.37

Sch.100

23.83

20.85

169.6

17.1

46

16" (400)

406.40

27.86

27.86

Sch.100

26.19

22.91

162.8

17.7

47

18" (450)

457.20

31.34

31.34

Sch.100

29.36

25.69

162.3

17.8

48

20" (500)

508.00

34.82

34.82

Sch.100

32.54

28.47

161.8

17.8

49

22" (550)

558.80

38.30

38.30

Sch.100

34.93

30.56

157.7

18.3

50

24" (600)

609.60

41.78

41.78

Sch.100

38.89

34.03

161.1

17.9

51

Notes:

1. The user shall arrive at the worst case P-T condition, based on maximum (P/SE) ratio.

52

2. The user shall be responsible to check the allowable stress value for the material & temp.

53

3. The user shall be responsible to check the applicable Y Coefficient value for the material & temp.

PTC & Branch Calc_ASME B31.3_Upto NPS 24

Version: 1.11

XXXX

JOB NUMBER

CALCULATION NUMBER

XXXX

XXXX - washing - PTC - 001

REV.

CLIENT:

XXXX

PROJECT:

XXXX

LOCATION:

XXXX

CALC. BY

DATE

CHKD. BY

DATE

SUBJECT:

Internal Pressure Thk. Calc. Sheet

Name

07-May-03

Name

07-May-03

BB

dition.

ut

.4)}]

96.

Check

(T>tmin)

Passed.

Passed.

Passed.

Passed.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Passed.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

Not Valid.

PIPE

CLASS

washing

SH 1 OF 1

You might also like

- ASME B31 3 Calculator V2Document11 pagesASME B31 3 Calculator V2gerrydimayuga100% (3)

- Pipe Branch Calculation SheetDocument9 pagesPipe Branch Calculation Sheetjleonos100% (3)

- ASME-B31-4 CalcDocument9 pagesASME-B31-4 Calcshafeeqm3086100% (1)

- Wall Thickness Calculation for Piping SystemsDocument47 pagesWall Thickness Calculation for Piping Systemsthinhvipro100% (1)

- Design Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal PressureDocument10 pagesDesign Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal Pressurefaisman100% (1)

- Pipe Wall Thickness Calculation According ASME B31 3Document93 pagesPipe Wall Thickness Calculation According ASME B31 3linhcdt3100% (1)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Wall Thickness Pipeline (Gas) B31Document25 pagesWall Thickness Pipeline (Gas) B31Rais Brian Abdurahman100% (6)

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet

- Pipe BranchDocument761 pagesPipe Branchjnmanivannanmech50% (2)

- Asme b31 3 03 PDFDocument3 pagesAsme b31 3 03 PDFAtallah BoufatahNo ratings yet

- Branch Reinforcement Calculation: Pipe Material Design Temperature Design Pressure Allowable StressDocument32 pagesBranch Reinforcement Calculation: Pipe Material Design Temperature Design Pressure Allowable Stressnitin_bir100% (3)

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Flange Leakage CheckDocument1 pageFlange Leakage CheckPhornlert WanaNo ratings yet

- Piping Code ComparisonDocument5 pagesPiping Code ComparisonAndy Hakim83% (6)

- Pipes. Wall Thickness Calculation According ASME B31.3Document125 pagesPipes. Wall Thickness Calculation According ASME B31.3musaveerNo ratings yet

- Wall Thickness 2Document18 pagesWall Thickness 2Imam Zulfir RamandhaNo ratings yet

- Flange From Plate - Asme 16.5Document1 pageFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- ASME B31.3 Process Piping Wall Thickness CalculationDocument27 pagesASME B31.3 Process Piping Wall Thickness CalculationJesus Magallanes SNo ratings yet

- Piping Office CalculatorsDocument5 pagesPiping Office CalculatorsJohn PaulNo ratings yet

- PVElite Course by Mr. AsgarzadeganDocument79 pagesPVElite Course by Mr. AsgarzadeganSaam Sasanian33% (3)

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- Thickness Calculation For PipeDocument7 pagesThickness Calculation For PipeNAYEEM100% (5)

- Area replacement calculation for CC1 E-1A LNG Vaporizer branchDocument2 pagesArea replacement calculation for CC1 E-1A LNG Vaporizer branchJahsbuck100% (1)

- AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSDocument33 pagesAS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSaike_5No ratings yet

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocument3 pagesDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanNo ratings yet

- Pipes. Wall Thickness Calculation According ASME B31.3Document4 pagesPipes. Wall Thickness Calculation According ASME B31.3sowman tung100% (2)

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (2)

- Calculation As Per Asme b31.3Document8 pagesCalculation As Per Asme b31.3Rajkumar ANo ratings yet

- Reinforcement Pad CalculationDocument4 pagesReinforcement Pad CalculationMohammad AbdullahNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Nozzle Pipe Length CalculatorDocument5 pagesNozzle Pipe Length CalculatorRyan Goh Chuang HongNo ratings yet

- Sif B31 3Document24 pagesSif B31 3vuqar0979100% (1)

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinNo ratings yet

- Pipe Thickness Calculation As Per ASME B31.3Document3 pagesPipe Thickness Calculation As Per ASME B31.3vipulNo ratings yet

- ASME B31.3 - 2008 PipeCalculationDocument6 pagesASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Design Data: 4" Weldolet CalculationDocument2 pagesDesign Data: 4" Weldolet Calculationgrabetty100% (2)

- ASME CALculationDocument6 pagesASME CALculationMakrame BattazNo ratings yet

- ASME B31.3 InterpretationDocument743 pagesASME B31.3 Interpretationiangregorrustria100% (3)

- Pipe wall thickness calculation sheet for high pressure natural gas lineDocument1 pagePipe wall thickness calculation sheet for high pressure natural gas lineAris KancilNo ratings yet

- Steel Pipe Design Calculation For SeamlessDocument4 pagesSteel Pipe Design Calculation For SeamlessA SubinNo ratings yet

- ASME B31.3 wall thickness calcDocument11 pagesASME B31.3 wall thickness calcAnonymous wIPMQ5rhNo ratings yet

- Case Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLDocument13 pagesCase Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedNo ratings yet

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- 1CG101 150#RF Optional Comments: Non-Lethal A106 GR B Seamless Pipe or Tube Utility Service NitrogenDocument9 pages1CG101 150#RF Optional Comments: Non-Lethal A106 GR B Seamless Pipe or Tube Utility Service NitrogenAshish ShahNo ratings yet

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4Denstar Ricardo Silalahi50% (2)

- Pipe Sizing and Wall Thickness Calculation SheetDocument2 pagesPipe Sizing and Wall Thickness Calculation SheetWijayantoNo ratings yet

- Piping Thickness Calculation With An ExampleDocument10 pagesPiping Thickness Calculation With An ExampleMahendran KuppusamyNo ratings yet

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Retirement ThicknessDocument7 pagesRetirement ThicknessKamal UddinNo ratings yet

- SU Blind Plate ThicknessDocument2 pagesSU Blind Plate Thicknessmanoj19801226100% (1)

- 1CS101 IBR 150#RF Optional Comments: Non-Lethal A106 GR B Seamless Pipe or Tube IBR L P Steam, M P SteamDocument9 pages1CS101 IBR 150#RF Optional Comments: Non-Lethal A106 GR B Seamless Pipe or Tube IBR L P Steam, M P SteamAshish ShahNo ratings yet

- ASME B31.3 Straight PipesDocument1 pageASME B31.3 Straight PipesvelagasumanthNo ratings yet

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 pagesPipe Cap Thickness Calculation for ASME Section VIIILcm TnlNo ratings yet

- KHAZZAN/MAKAREM EWT PROJECT piping design parametersDocument25 pagesKHAZZAN/MAKAREM EWT PROJECT piping design parametersRajeshvbNo ratings yet

- Mass BalanceDocument4 pagesMass BalancealvinchuanNo ratings yet

- Relative Discharging Power of Pipe LineDocument1 pageRelative Discharging Power of Pipe LinealvinchuanNo ratings yet

- DD - 22 Floatation of Circular PipeDocument6 pagesDD - 22 Floatation of Circular PipealvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- Diversity FactorDocument3 pagesDiversity FactorgafscottNo ratings yet

- DG Flowrate Comparison PDFDocument1 pageDG Flowrate Comparison PDFalvinchuanNo ratings yet

- Solve Differential EquationDocument4 pagesSolve Differential EquationalvinchuanNo ratings yet

- Heat Loss From An Insulated Pipe CalculationsDocument2 pagesHeat Loss From An Insulated Pipe CalculationsalvinchuanNo ratings yet

- SSP Simplified Submission Process OverviewDocument1 pageSSP Simplified Submission Process OverviewalvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- Extracts of SS636Document2 pagesExtracts of SS636alvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- SSP Simplified Submission Process OverviewDocument1 pageSSP Simplified Submission Process OverviewalvinchuanNo ratings yet

- Auto ClaveDocument1 pageAuto ClavealvinchuanNo ratings yet

- SS 532-2016+corr 1 - PreviewDocument11 pagesSS 532-2016+corr 1 - PreviewalvinchuanNo ratings yet

- API Sizing KIM - XLSMDocument1 pageAPI Sizing KIM - XLSMalvinchuanNo ratings yet

- Pipeline Analysis & Calculation Environment: Pipe SelectionDocument6 pagesPipeline Analysis & Calculation Environment: Pipe SelectionalvinchuanNo ratings yet

- Bio Detention BasinDocument45 pagesBio Detention BasinalvinchuanNo ratings yet

- ABCWatersDesignGuidelines 2011Document104 pagesABCWatersDesignGuidelines 2011Jackson TanNo ratings yet

- Expansion Tank SizingDocument2 pagesExpansion Tank SizingSK NGNo ratings yet

- Restrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazineDocument1 pageRestrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazinealvinchuanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- Pipe thickness calculations as per ASME B31.3Document1 pagePipe thickness calculations as per ASME B31.3alvinchuanNo ratings yet

- Singapore Rainfall Equations PDFDocument2 pagesSingapore Rainfall Equations PDFalvinchuanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- ConsumptionDocument2 pagesConsumptionalvinchuanNo ratings yet

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDocument2 pagesSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- Assessing Student Learning OutcomesDocument20 pagesAssessing Student Learning Outcomesapi-619738021No ratings yet

- CPS Layoffs BreakdownDocument21 pagesCPS Layoffs BreakdownjroneillNo ratings yet

- LTC2410 Datasheet and Product Info - Analog DevicesDocument6 pagesLTC2410 Datasheet and Product Info - Analog DevicesdonatoNo ratings yet

- Basic Concepts of Citrix XenAppDocument13 pagesBasic Concepts of Citrix XenAppAvinash KumarNo ratings yet

- Interview Question SalesforceDocument10 pagesInterview Question SalesforcesomNo ratings yet

- EJC H2 Math P1 With Solution PDFDocument23 pagesEJC H2 Math P1 With Solution PDFKipp SohNo ratings yet

- Adjutant-Introuvable BASIC VERSIONDocument7 pagesAdjutant-Introuvable BASIC VERSIONfurrypdfNo ratings yet

- Mega Goal 4Document52 pagesMega Goal 4mahgoubkamel0% (1)

- Liugong 938 Wheel Loader Parts ManualDocument20 pagesLiugong 938 Wheel Loader Parts Manualjonathan100% (49)

- Applied Physics Mini Launcher Lab ReportDocument12 pagesApplied Physics Mini Launcher Lab ReportTalharashid RamzanNo ratings yet

- Impact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityDocument14 pagesImpact of Endurance Exercise Training in the Fasted State on Muscle Metabolism and Insulin SensitivityYo Vivo Fit Pablo y KarlaNo ratings yet

- Lake Isle of Innisfree Lesson Plan BV ZGDocument4 pagesLake Isle of Innisfree Lesson Plan BV ZGapi-266111651100% (1)

- 1F4 Catalog0808Document12 pages1F4 Catalog0808Edwin Ng0% (1)

- Solwezi General Mental Health TeamDocument35 pagesSolwezi General Mental Health TeamHumphreyNo ratings yet

- How To Use Hyper-V Snapshot Revert, Apply, and Delete OptionsDocument15 pagesHow To Use Hyper-V Snapshot Revert, Apply, and Delete OptionsKaran MishraNo ratings yet

- Solution Manual For Illustrated Guide To The National Electrical Code 7th Edition Charles R MillerDocument24 pagesSolution Manual For Illustrated Guide To The National Electrical Code 7th Edition Charles R MillerHenryJohnsonaswek97% (39)

- Exploratory Data Analysis: M. SrinathDocument19 pagesExploratory Data Analysis: M. SrinathromaNo ratings yet

- Rumi and ReligionDocument2 pagesRumi and ReligionJustin LiewNo ratings yet

- PLC of MaggiDocument19 pagesPLC of Maggikrati agarwalNo ratings yet

- Picco Tac 1095 N Hydrocarbon ResinDocument2 pagesPicco Tac 1095 N Hydrocarbon ResindevanandamqaNo ratings yet

- Automated Crime Reporting SystemDocument101 pagesAutomated Crime Reporting SystemDeepak Kumar60% (10)

- ECE 4400 Performance Analysis Local Computer Networks HomeworkDocument2 pagesECE 4400 Performance Analysis Local Computer Networks HomeworkNguyen Phi HungNo ratings yet

- SLU Missalette 2016 Capping (Not-Final)Document18 pagesSLU Missalette 2016 Capping (Not-Final)Teanu Jose Gabrillo TamayoNo ratings yet

- Adapting Cognitive Behavioral Techniques To Address Anxiety and Depression in Cognitively Able Emerging Adults On The Autism SpectrumDocument3 pagesAdapting Cognitive Behavioral Techniques To Address Anxiety and Depression in Cognitively Able Emerging Adults On The Autism SpectrumVini PezzinNo ratings yet

- Laser Engrave Co2 System BJ-1390Document5 pagesLaser Engrave Co2 System BJ-1390Sasa TodorovicNo ratings yet

- Brochure HorticultureDocument46 pagesBrochure HorticulturezulfiqaralimalikNo ratings yet

- 2018 Diesel TOYOTA Jun11Document90 pages2018 Diesel TOYOTA Jun11eko sulistyo75% (4)

- Cat IQ TestDocument3 pagesCat IQ TestBrendan Bowen100% (1)

- All Types of Switch CommandsDocument11 pagesAll Types of Switch CommandsKunal SahooNo ratings yet

- Unit 01 Family Life Lesson 1 Getting Started - 2Document39 pagesUnit 01 Family Life Lesson 1 Getting Started - 2Minh Đức NghiêmNo ratings yet