Professional Documents

Culture Documents

Depressuring Flow

Uploaded by

Eng AlfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Depressuring Flow

Uploaded by

Eng AlfCopyright:

Available Formats

Depressuring Flow - Quick Manual Method

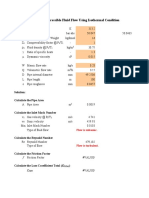

Depressuring system is provided in Oil and gas, Gas & LNG plant, etc to evacuate the inventory from process system as fast as possible so that the reduced internal pressure stresses is kept below the rupture stress. This has been discussed in "Depressuring within 15 minutes no longer applicable ?". Nevertheless, quick depressuring may lead to other problem such as low temperature embrittlement, excessive noise and vibration, etc. Depressure a high pressure would lead to low temperature of depressured system and failure due to low temperature embrittlement. Higher the depressuring rate, lower the temperature can be experienced by depressured system. Thus, the restriction orifice (RO) downstream of Blowdown Valve (BDV) in depressuring system primarily is to limit flow so that the temperature will not drop below the allowable lowest temperature limit of material. This has been discussed in "Don't misunderstood depressuring". Although depressuring shall be implemented within the shortest time possible, excessive depressuring may potentially lead to damage to equipment such as compressor seal, solid bed, etc. Thus, there are two type of depressuring as discussed in "Controlled and Noncontrolled Type Depressuring". Nevertheless, it is emphasized again here, depressuring system shall be designed to bring plant to safe level without any tolerance. Many depressuring systems are designed to depressure the system within 15 minutes follow recommendation in API 521. Nevertheless, one shall take note that the 15 minutes is sort of arbitrary and may be good for some system and configuration. Thus, in most recente API STD 521, the requirement has slightly changed where a depressuring system shall be designed such that the stress induced by internal pressure of a system is lower than stress allowable by the system. This may lead to shorter depressuringtime as discussed in "Depressuring within 15 minutes no longer applicable ?". Depressuring can be conducted using simple depressuring module in process simulator such HYSYS, PRO-II, etc. One shall understood there are limitation and accuracy issue in above mentioned depressuring modules and shall be used with care. There are other depressuring simulator such as LNGDYN by TECHNIP, BLOWDOWN by Imperial College, etc which are calculated rigorously and tested with real plant data. It is Always advisable to use these simulator for specific case. Assumption In this post, a manual depressuring method is introduced. This method is first introduced by Grote and are derived base on following assumptions : i) Critical flow throughout entire depressuring process ii) Constant mass flow throughout entire depressuring process iii) System being depressured is maintained as gaseous throughout entire depressuring process iv) Constant temperature, molecular weight and compressibility Methodology Following is the derivation of the manual equation.

Concluding Remark Equation [5] may be used for manual depressuring if a system inventory (initial mass, M0), depressuring time (t), initial (P0) and final pressure (P) are are known. One shall check the assumptions are valid before it is used. This equation may be used as quick method to determine the depressuring flowrate for quick estimate, however it is not recommended during detailed design.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ExxonMobil Product Data Guide 2005 (v.2)Document58 pagesExxonMobil Product Data Guide 2005 (v.2)Eng AlfNo ratings yet

- Metal Spinning Machines Technical Data 2007Document2 pagesMetal Spinning Machines Technical Data 2007Andres Lp100% (1)

- Cat 12MDocument28 pagesCat 12MLeandro Sal100% (1)

- Critical Flow of Compressible Fluid Calculations (ALF)Document3 pagesCritical Flow of Compressible Fluid Calculations (ALF)Eng AlfNo ratings yet

- Procedure and Scope: Good Luck, Ravi SankarDocument27 pagesProcedure and Scope: Good Luck, Ravi SankarRazook MohammedNo ratings yet

- Two-Phase Pressure Drops (ALF)Document7 pagesTwo-Phase Pressure Drops (ALF)Eng AlfNo ratings yet

- Pressure Drop For Compressible Fluid Flow Using Isothermal Condition (ALF)Document2 pagesPressure Drop For Compressible Fluid Flow Using Isothermal Condition (ALF)Eng AlfNo ratings yet

- How To Calculate Cycles, Blowdown, Evaporation, MakeupDocument2 pagesHow To Calculate Cycles, Blowdown, Evaporation, MakeupEng AlfNo ratings yet

- Air Solubility in WaterDocument2 pagesAir Solubility in WaterEng Alf100% (1)

- Noise LevelDocument1 pageNoise LevelEng AlfNo ratings yet

- Oléo Vegetal Soja Comp. (Mol %) MW (G/gmol) Comp. (WT %)Document17 pagesOléo Vegetal Soja Comp. (Mol %) MW (G/gmol) Comp. (WT %)Eng AlfNo ratings yet

- Estimativa de Propriedades de Óleos Vegetáis e Acidos Graxos 21.03.15.0Document87 pagesEstimativa de Propriedades de Óleos Vegetáis e Acidos Graxos 21.03.15.0Eng AlfNo ratings yet

- Noise LevelDocument1 pageNoise LevelEng AlfNo ratings yet

- Viscosity Corrections To Pump CurveDocument6 pagesViscosity Corrections To Pump CurveEng AlfNo ratings yet

- How To Calculate Cycles, Blowdown, Evaporation, MakeupDocument2 pagesHow To Calculate Cycles, Blowdown, Evaporation, MakeupEng AlfNo ratings yet

- High Pressure Knock Out Drum (ALF)Document12 pagesHigh Pressure Knock Out Drum (ALF)Eng AlfNo ratings yet

- Air Solubility in WaterDocument2 pagesAir Solubility in WaterEng Alf100% (1)

- How To Calculate Methane NumberDocument3 pagesHow To Calculate Methane NumberEng AlfNo ratings yet

- Pasta1 CRUDocument2 pagesPasta1 CRUEng AlfNo ratings yet

- Estimated Pressure Rise From Thermal Expansion Is Within The Design Limits of The Equipment or PipingDocument1 pageEstimated Pressure Rise From Thermal Expansion Is Within The Design Limits of The Equipment or PipingEng AlfNo ratings yet

- Estimativa Do Consumo de FG Das GTGsDocument3 pagesEstimativa Do Consumo de FG Das GTGsEng AlfNo ratings yet

- Acceleration Head For Reciprocating PumpsDocument2 pagesAcceleration Head For Reciprocating PumpsEng Alf100% (1)

- Depressuring Within 15 Minutes No Longer ApplicableDocument1 pageDepressuring Within 15 Minutes No Longer ApplicableEng AlfNo ratings yet

- Acceleration Head for Centrifugal PumpsDocument5 pagesAcceleration Head for Centrifugal PumpsEng AlfNo ratings yet

- Vent Flow Through Vent CondenserDocument2 pagesVent Flow Through Vent CondenserEng AlfNo ratings yet

- Acceleration Head For Reciprocating PumpsDocument2 pagesAcceleration Head For Reciprocating PumpsEng Alf100% (1)

- How To Calculate Cycles, Blowdown, Evaporation, MakeupDocument2 pagesHow To Calculate Cycles, Blowdown, Evaporation, MakeupEng AlfNo ratings yet

- JACOBIAN Implementation of EES Library File For SW PropertiesDocument40 pagesJACOBIAN Implementation of EES Library File For SW PropertiesEng AlfNo ratings yet

- Deaerator Venting Capacity CalculationsDocument2 pagesDeaerator Venting Capacity CalculationsEng Alf100% (1)

- Sizing vane mist eliminatorsDocument2 pagesSizing vane mist eliminatorsEng Alf75% (4)

- Feed InletDocument2 pagesFeed InletEng AlfNo ratings yet

- The Yuasa: Little Red ofDocument19 pagesThe Yuasa: Little Red ofManjunatha RevanasiddappaNo ratings yet

- Ravi Sir DLC PresentationDocument13 pagesRavi Sir DLC Presentationসৌগত রায় ঘটকNo ratings yet

- 03 Vgasic PDFDocument8 pages03 Vgasic PDFAnonymous idBsC1No ratings yet

- D173 PDFDocument2 pagesD173 PDFArnold RojasNo ratings yet

- Power Contactor 1250 A - HubbellDocument4 pagesPower Contactor 1250 A - Hubbellmanuel99a2kNo ratings yet

- LG AC Service ManualDocument80 pagesLG AC Service ManualFrengky RmNo ratings yet

- Ie 12 Lec Act IiiDocument2 pagesIe 12 Lec Act IiiLance JayomaNo ratings yet

- Motor Spec - IPOWER Rev01Document4 pagesMotor Spec - IPOWER Rev01GAGANNo ratings yet

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNo ratings yet

- 3M Prestige 70 Exterior PBDocument3 pages3M Prestige 70 Exterior PBDiego Ramirez FuentesNo ratings yet

- Secondary Physics Temp NotesDocument3 pagesSecondary Physics Temp NotesHarish PrabhuNo ratings yet

- B4A3Document6 pagesB4A3ashokclineNo ratings yet

- Annex Details of ValidityDocument5 pagesAnnex Details of ValidityAbhishek GoelNo ratings yet

- O Ring Troubleshoothing GuideDocument1 pageO Ring Troubleshoothing GuideLylla Damasceno DamascenoNo ratings yet

- Measure Young's Modulus and Determine Material PropertiesDocument13 pagesMeasure Young's Modulus and Determine Material PropertiesKerry-Ann WilliamsNo ratings yet

- Vulcan LIBS Analyser For QA QC - 2Document6 pagesVulcan LIBS Analyser For QA QC - 2Trần Văn LộcNo ratings yet

- Rate Analysis-KalikaDocument35 pagesRate Analysis-KalikaPujan Amit Gurung100% (1)

- Filtro Bacteriologico Puritan BennetDocument24 pagesFiltro Bacteriologico Puritan BennetRonald David ReyesNo ratings yet

- Balancing Redox ReactionsDocument2 pagesBalancing Redox ReactionsblobmarleyNo ratings yet

- Solutions of Solids in LiquidsDocument16 pagesSolutions of Solids in LiquidsNoorhalieza AliNo ratings yet

- MechanismDocument17 pagesMechanismm_er100No ratings yet

- Experimental Mechanics Laboratory ManualDocument76 pagesExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- Steel Coil AlignmentDocument1 pageSteel Coil AlignmentBalluff SensorsNo ratings yet

- Naphthaplast F 707 UlDocument2 pagesNaphthaplast F 707 UlÖmer ErcanNo ratings yet

- PIPE Elements 4 NIDocument88 pagesPIPE Elements 4 NIJd MagtibayNo ratings yet

- Chieftain 1800 SpecsDocument16 pagesChieftain 1800 SpecsPercy Luis Nima AlvaradoNo ratings yet

- XDB102 3Document3 pagesXDB102 3Young WuNo ratings yet

- Process of P-Xylene Production by Highly Selective Methylation of Toluene PDFDocument8 pagesProcess of P-Xylene Production by Highly Selective Methylation of Toluene PDFMarco Antonio FeriaNo ratings yet