Professional Documents

Culture Documents

Aggregate Drying Burners Spanish

Uploaded by

Didier Angel Lopez RinconCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Drying Burners Spanish

Uploaded by

Didier Angel Lopez RinconCopyright:

Available Formats

ASTEC

A G G R E G A T E D R Y I N G B U R N E R S

For Hot Mi x Asphal t Faci l i t i es

Aggregate Drying Burners

Quemador de secadores de agregados

QUEMADORES DE SECADORES DE AGREGADOS

Par a pl ant as de asf al t o de mezcl a en cal i ent e

Astec, Inc. disea, fabrica y comercializa plantas de asfalto de

mezcla en caliente con proceso batch y continuo, equipo de

remediacin de suelos y componentes relacionados. Astec, Inc.

se ha convertido en el lder del mercado en plantas de asfalto de

mezcla en caliente al ser una empresa impulsada por los clientes.

Al escuchar a nuestros clientes y comprender cada aspecto de sus

negocios, somos capaces de proporcionar productos nuevos que

resuelven sus problemas y mejoran su rentabilidad.

El grupo de ingenieros de quemadores de Astec, Inc. trabaja junto

con los clientes para desarrollar sistemas de quemadores que

cubran diversas necesidades. Cada quemador es examinado antes

de abandonar las instalaciones para asegurar un funcionamiento

rpido y sencillo durante su instalacin. Los quemadores de Astec

son avanzados tecnolgicamente y respaldados por el excelente

servicio de Astec .

ASTEC

A S T E C P E R F I L D E L A C OMPA A

Combat the rising cost of energy without

sacricing performance or reliability. The Astec

Phoenix Coal burner uses the latest multiple-fuel

burning technology to dramatically lower energy

costs. This innovative combustion technology is

a truly reliable answer to high energy costs.

ASTEC

P H OE NI X

C OA L

2.5M. WMS. 12-06

Combata los crecientes costos de energa sin sacricar rendimiento

o conabilidad. El quemador de carbn Phoenix de Astec utiliza la

tecnologa ms reciente en quemado mltiple de combustible para reducir

dramticamente los costos de energa. Esta innovadora tecnologa en

combustin es una verdadera solucin conable a los altos costos de energa.

ASTEC

QUE MADORE S DE C HARBON P HOE NI X

LATEST COMBUSTION TECHNOLOGY

Designed to burn bituminous coal, the Phoenix Coals

combustion system uses a coal preparation skid that

pulverizes and delivers coal as the burner demand

requires it. Another innovative feature of the Phoenix

Coal burner is that it does not use a refractory

combustion chamber.

MULTIPLE FUEL OPTIONS

The Phoenix Coal Burner uses either Gas, #2 Oil,

Recycled Fuel Oil, or Heavy Oil as a support fuel for

continuous ignition of the pulverized bituminous coal.

The Phoenix Coal burner can also re at 100% of rated

capacity on the support fuel if the coal supply is

not available.

COMPACT FLAME SHAPE

The innovative compact design of the burner and its

combustion system also produces a compact ame that is

easily adapted to modern aggregate dryer designs.

NO VISIBLE STACK EMISSIONS

The Phoenix Coal produces emissions comparable to those

achieved when burning waste oil as a fuel. In fact, the Phoenix

Coal produces no smoke. Stack emissions are at 0% opacity,

meaning nothing but sky can be seen through the plume.

COAL

Over 90% of the United States can be permitted to

burn coal.

The coal prep skid pulverizes the coal for use by

the burner.

Astec frequently tests burners before shipping to

ensure quality.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 20,000 75 100 80

P

C

1

5

0

P

C

1

2

5

P

C

1

0

0

P

C

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 26,667 75 100 80

125 500 tph 33,417 100 100 80

150 600 tph 40,167 125 125 90

LA TECNOLOGA EN COMBUSTIN MS

MODERNA

Diseado para quemar carbn bituminoso, el sistema de combustin

del quemador de carbn Phoenix implementa un depsito con la

preparacin de carbn que pulveriza y suministra carbn segn la

demanda del quemador. Otra caracterstica innovadora del quemador

de carbn Phoenix es que no utiliza una cmara de combustin

refractaria.

OPCIONES MLTIPLES EN COMBUSTIBLE

El quemador de carbn Phoenix utiliza gas, aceite n 2, gasleo

reciclado o aceite pesado como combustible de ayuda para la

ignicin continua del carbn bituminoso pulverizado. El quemador de

carbn Phoenix tambin puede encenderse a una capacidad nominal

del 100% para abastecer al combustible de ayuda en caso de que el

suministro de carbn no se encuentre disponible.

FORMA COMPACTA DE LA LLAMA

El innovador diseo compacto del quemador y su sistema de combustin

tambin produce una llama compacta que puede adaptarse fcilmente

a los diseos modernos de secadores de agregado.

EMISIONES DEL TUBO DE ESCAPE NO

VISIBLES

El quemador Phoenix produce emisiones que se comparan con

aquellas que se alcanzan cuando se quema aceite usado para

usar como combustible. De hecho, el Phoenix no genera humo. Las

emisiones del tubo de escape alcanzan una opacidad del 0%, lo que

significa una visibilidad ptima a travs del penacho de humos.

LATEST COMBUSTION TECHNOLOGY

Designed to burn bituminous coal, the Phoenix Coals

combustion system uses a coal preparation skid that

pulverizes and delivers coal as the burner demand

requires it. Another innovative feature of the Phoenix

Coal burner is that it does not use a refractory

combustion chamber.

MULTIPLE FUEL OPTIONS

The Phoenix Coal Burner uses either Gas, #2 Oil,

Recycled Fuel Oil, or Heavy Oil as a support fuel for

continuous ignition of the pulverized bituminous coal.

The Phoenix Coal burner can also re at 100% of rated

capacity on the support fuel if the coal supply is

not available.

COMPACT FLAME SHAPE

The innovative compact design of the burner and its

combustion system also produces a compact ame that is

easily adapted to modern aggregate dryer designs.

NO VISIBLE STACK EMISSIONS

The Phoenix Coal produces emissions comparable to those

achieved when burning waste oil as a fuel. In fact, the Phoenix

Coal produces no smoke. Stack emissions are at 0% opacity,

meaning nothing but sky can be seen through the plume.

COAL

Over 90% of the United States can be permitted to

burn coal.

The coal prep skid pulverizes the coal for use by

the burner.

Astec frequently tests burners before shipping to

ensure quality.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 20,000 75 100 80

P

C

1

5

0

P

C

1

2

5

P

C

1

0

0

P

C

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 26,667 75 100 80

125 500 tph 33,417 100 100 80

150 600 tph 40,167 125 125 90

Alrededor del 90% de los Estados Unidos tiene

permiso para quemar carbn.

LATEST COMBUSTION TECHNOLOGY

Designed to burn bituminous coal, the Phoenix Coals

combustion system uses a coal preparation skid that

pulverizes and delivers coal as the burner demand

requires it. Another innovative feature of the Phoenix

Coal burner is that it does not use a refractory

combustion chamber.

MULTIPLE FUEL OPTIONS

The Phoenix Coal Burner uses either Gas, #2 Oil,

Recycled Fuel Oil, or Heavy Oil as a support fuel for

continuous ignition of the pulverized bituminous coal.

The Phoenix Coal burner can also re at 100% of rated

capacity on the support fuel if the coal supply is

not available.

COMPACT FLAME SHAPE

The innovative compact design of the burner and its

combustion system also produces a compact ame that is

easily adapted to modern aggregate dryer designs.

NO VISIBLE STACK EMISSIONS

The Phoenix Coal produces emissions comparable to those

achieved when burning waste oil as a fuel. In fact, the Phoenix

Coal produces no smoke. Stack emissions are at 0% opacity,

meaning nothing but sky can be seen through the plume.

COAL

Over 90% of the United States can be permitted to

burn coal.

The coal prep skid pulverizes the coal for use by

the burner.

Astec frequently tests burners before shipping to

ensure quality.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 20,000 75 100 80

P

C

1

5

0

P

C

1

2

5

P

C

1

0

0

P

C

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 26,667 75 100 80

125 500 tph 33,417 100 100 80

150 600 tph 40,167 125 125 90

A menudo, Astec prueba los quemadores antes de

enviarlos para garantizar su calidad.

LATEST COMBUSTION TECHNOLOGY

Designed to burn bituminous coal, the Phoenix Coals

combustion system uses a coal preparation skid that

pulverizes and delivers coal as the burner demand

requires it. Another innovative feature of the Phoenix

Coal burner is that it does not use a refractory

combustion chamber.

MULTIPLE FUEL OPTIONS

The Phoenix Coal Burner uses either Gas, #2 Oil,

Recycled Fuel Oil, or Heavy Oil as a support fuel for

continuous ignition of the pulverized bituminous coal.

The Phoenix Coal burner can also re at 100% of rated

capacity on the support fuel if the coal supply is

not available.

COMPACT FLAME SHAPE

The innovative compact design of the burner and its

combustion system also produces a compact ame that is

easily adapted to modern aggregate dryer designs.

NO VISIBLE STACK EMISSIONS

The Phoenix Coal produces emissions comparable to those

achieved when burning waste oil as a fuel. In fact, the Phoenix

Coal produces no smoke. Stack emissions are at 0% opacity,

meaning nothing but sky can be seen through the plume.

COAL

Over 90% of the United States can be permitted to

burn coal.

The coal prep skid pulverizes the coal for use by

the burner.

Astec frequently tests burners before shipping to

ensure quality.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 20,000 75 100 80

P

C

1

5

0

P

C

1

2

5

P

C

1

0

0

P

C

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 26,667 75 100 80

125 500 tph 33,417 100 100 80

150 600 tph 40,167 125 125 90

El depsito con la preparacin de carbn pulveriza

el carbn que se usar en el quemador.

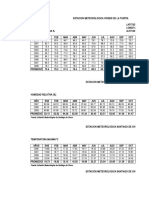

ESPECIFICACIONES DE LA COMBUSTIN

CON BAJO EXCESO DE AIRE

M

O

D

E

L

O

Capacidad

nominal en

kW (con

20% de XSA)

Capacidad

de secado

de agregado

nominal a 5%

de humedad

(mtph)

Capacidad

de aire del

quemador

m3/min

Potencia del

ventilador

interno en

kW

Aire de la atom.

de aceite m3/min

Fuego bajo Fuego alto

P

C

7

5

21961 272 566 56 2.8 2.3

P

C

1

0

0

29281 363 755 75 2.8 2.3

P

C

1

2

5

36601 454 946 93 2.8 2.3

P

C

1

5

0

43982 544 1,137 112 3.5 2.5

Las condiciones anteriores son estndares a 21 C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada

tamao para obtener ms informacin y flujos y presiones especficas. La capacidad de secado del agregado nominal en base a las

temperaturas tpicas del tubo de escape de 115.6 C, 0.2 cal/g C de calor especfico en el agregado. La capacidad mxima del

diseo del quemador es 110% de la capacidad nominal.

The Astec Phoenix Talon utilizes the latest

burner technology to deliver very low emissions

combined with energy efciency. With the

optional silencing package, its even possible

to have a phone conversation on the burner

platform while it is ring.

ASTEC

P H OE NI X

T A L ON

2.5M. WMS. 12-06

El Phoenix Talon de Astec utiliza la tecnologa ms reciente de quemadores

para suministrar muy bajos niveles de emisiones en combinacin con

buena eciencia en el consumo de energa. Con el paquete silenciador

opcional, es posible mantener una conversacin telefnica en la

plataforma del quemador mientras est en funcionamiento.

ASTEC

QUE MADORE S P HOE NI X

TAL ON

ADVANCED EMISSION REDUCTION

The Phoenix Talon series uses precise, high quality

mixing of air and gaseous fuel to achieve remarkable

emission reduction. Radial gas injectors thoroughly mix air

and fuel for low CO and NOx emissions. The advanced

emission technology is not limited to gaseous fuel. The

advanced compressed air, oil nozzle and air swirler design

achieves self-recirculation and very rapid burning for some

of the lowest oil ring emissions available today.

ELECTRIC POWER EFFICIENCY

The variable speed main combustion blower drive helps

provide precise ring rate control and uses signicantly

less electrical energy. It also eliminates the need for an air

damper and for drive motor adjustments and maintenance.

FIRING EFFICIENCY & COMPACT FLAME SIZE

High quality mixing of air and fuel creates the most compact

ame available with a small combustion zone. This ensures

that all of the fuel is combusted for peak efciency without

taking away valuable dryer heating capacity.

RELIABLE FIRING

For maximum reliability and start-up ease, all Astec burners

are thoroughly tested before shipping.

The swirler and other components of the nose ensure

flame stability and optimum shape.

The Phoenix Talon uses significantly less electric

power than conventional burners due to the variable

frequency drive used to control its combustion air

blower and low body pressure.

The Phoenix Talons compact flame shape is

compatible with most drums without complicated

flame adjustment.

TALON

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 100 85

P

T

1

5

0

P

T

1

2

5

P

T

1

0

0

P

T

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

Natura| Cas: N0x - 40 PPH & 60 - 250 PPH. Number 2 Fue| 0||: 70 PPH & 60 - 200 PPH.

100 400 tph 1.3 mill. 75 100 80

125 500 tph 1.6 mill. 100 110 80

150 600 tph 2 mill. 125 125 90

REDUCCIN AVANZADA DE LAS EMISIONES

La serie Phoenix Talon utiliza una mezcla de aire y combustible gaseoso

precisa y de alta calidad para alcanzar una importante reduccin de

las emisiones. Los inyectores de gas radiales mezclan completamente

el aire y el combustible para alcanzar bajos niveles de CO y NOx. La

tecnologa avanzada de emisiones no se limita al combustible gaseoso.

El diseo avanzado del sistema de aire comprimido, de la boquilla de

aceite y de la turbina hace posible que se logre una autorecirculacin

y combustin muy rpida en algunos de los sistemas de emisiones ms

bajos en combustin de aceite disponibles en la actualidad.

EFICIENCIA EN ALIMENTACIN ELCTRICA

El mando de velocidad variable del ventilador principal de combustin

suministra un control exacto del rgimen del fuego y consume mucha

menos energa. Tampoco es necesario un regulador de aire ni realizar

ajustes ni mantenimientos del motor de traccin.

EFICIENCIA DE COMBUSTIN Y LLAMA

COMPACTA

La mezcla de aire y combustible de alta calidad genera la llama ms

compacta disponible, con una zona de combustin pequea. Esto

garantiza que el combustible se queme totalmente para lograr la mayor

eficiencia sin disminuir la valiosa capacidad de calentamiento con secador.

COMBUSTIN CONFIABLE

Para obtener la mayor confiabilidad y un arranque sencillo, todos los

quemadores de Astec son meticulosamente sometidos a prueba antes

de ser enviados.

ADVANCED EMISSION REDUCTION

The Phoenix Talon series uses precise, high quality

mixing of air and gaseous fuel to achieve remarkable

emission reduction. Radial gas injectors thoroughly mix air

and fuel for low CO and NOx emissions. The advanced

emission technology is not limited to gaseous fuel. The

advanced compressed air, oil nozzle and air swirler design

achieves self-recirculation and very rapid burning for some

of the lowest oil ring emissions available today.

ELECTRIC POWER EFFICIENCY

The variable speed main combustion blower drive helps

provide precise ring rate control and uses signicantly

less electrical energy. It also eliminates the need for an air

damper and for drive motor adjustments and maintenance.

FIRING EFFICIENCY & COMPACT FLAME SIZE

High quality mixing of air and fuel creates the most compact

ame available with a small combustion zone. This ensures

that all of the fuel is combusted for peak efciency without

taking away valuable dryer heating capacity.

RELIABLE FIRING

For maximum reliability and start-up ease, all Astec burners

are thoroughly tested before shipping.

The swirler and other components of the nose ensure

flame stability and optimum shape.

The Phoenix Talon uses significantly less electric

power than conventional burners due to the variable

frequency drive used to control its combustion air

blower and low body pressure.

The Phoenix Talons compact flame shape is

compatible with most drums without complicated

flame adjustment.

TALON

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 100 85

P

T

1

5

0

P

T

1

2

5

P

T

1

0

0

P

T

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

Natura| Cas: N0x - 40 PPH & 60 - 250 PPH. Number 2 Fue| 0||: 70 PPH & 60 - 200 PPH.

100 400 tph 1.3 mill. 75 100 80

125 500 tph 1.6 mill. 100 110 80

150 600 tph 2 mill. 125 125 90

La turbina y otros componentes del extremo garantizan

la estabilidad de la llama y su ptima forma.

ADVANCED EMISSION REDUCTION

The Phoenix Talon series uses precise, high quality

mixing of air and gaseous fuel to achieve remarkable

emission reduction. Radial gas injectors thoroughly mix air

and fuel for low CO and NOx emissions. The advanced

emission technology is not limited to gaseous fuel. The

advanced compressed air, oil nozzle and air swirler design

achieves self-recirculation and very rapid burning for some

of the lowest oil ring emissions available today.

ELECTRIC POWER EFFICIENCY

The variable speed main combustion blower drive helps

provide precise ring rate control and uses signicantly

less electrical energy. It also eliminates the need for an air

damper and for drive motor adjustments and maintenance.

FIRING EFFICIENCY & COMPACT FLAME SIZE

High quality mixing of air and fuel creates the most compact

ame available with a small combustion zone. This ensures

that all of the fuel is combusted for peak efciency without

taking away valuable dryer heating capacity.

RELIABLE FIRING

For maximum reliability and start-up ease, all Astec burners

are thoroughly tested before shipping.

The swirler and other components of the nose ensure

flame stability and optimum shape.

The Phoenix Talon uses significantly less electric

power than conventional burners due to the variable

frequency drive used to control its combustion air

blower and low body pressure.

The Phoenix Talons compact flame shape is

compatible with most drums without complicated

flame adjustment.

TALON

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 100 85

P

T

1

5

0

P

T

1

2

5

P

T

1

0

0

P

T

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

Natura| Cas: N0x - 40 PPH & 60 - 250 PPH. Number 2 Fue| 0||: 70 PPH & 60 - 200 PPH.

100 400 tph 1.3 mill. 75 100 80

125 500 tph 1.6 mill. 100 110 80

150 600 tph 2 mill. 125 125 90

La forma compacta de la llama del Phoenix Talon es

compatible con la mayora de los tambores sin ajuste

complicado de la llama.

ADVANCED EMISSION REDUCTION

The Phoenix Talon series uses precise, high quality

mixing of air and gaseous fuel to achieve remarkable

emission reduction. Radial gas injectors thoroughly mix air

and fuel for low CO and NOx emissions. The advanced

emission technology is not limited to gaseous fuel. The

advanced compressed air, oil nozzle and air swirler design

achieves self-recirculation and very rapid burning for some

of the lowest oil ring emissions available today.

ELECTRIC POWER EFFICIENCY

The variable speed main combustion blower drive helps

provide precise ring rate control and uses signicantly

less electrical energy. It also eliminates the need for an air

damper and for drive motor adjustments and maintenance.

FIRING EFFICIENCY & COMPACT FLAME SIZE

High quality mixing of air and fuel creates the most compact

ame available with a small combustion zone. This ensures

that all of the fuel is combusted for peak efciency without

taking away valuable dryer heating capacity.

RELIABLE FIRING

For maximum reliability and start-up ease, all Astec burners

are thoroughly tested before shipping.

The swirler and other components of the nose ensure

flame stability and optimum shape.

The Phoenix Talon uses significantly less electric

power than conventional burners due to the variable

frequency drive used to control its combustion air

blower and low body pressure.

The Phoenix Talons compact flame shape is

compatible with most drums without complicated

flame adjustment.

TALON

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 100 85

P

T

1

5

0

P

T

1

2

5

P

T

1

0

0

P

T

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

Natura| Cas: N0x - 40 PPH & 60 - 250 PPH. Number 2 Fue| 0||: 70 PPH & 60 - 200 PPH.

100 400 tph 1.3 mill. 75 100 80

125 500 tph 1.6 mill. 100 110 80

150 600 tph 2 mill. 125 125 90

El Phoenix Talon consume mucho menos energa

elctrica que los quemadores convencionales gracias

al mando de frecuencia variable que se utiliza para

controlar su ventilador de aire de combustin y la

baja presin de la carrocera.

ESPECIFICACIONES DE LA COMBUSTIN

CON BAJO EXCESO DE AIRE

M

O

D

E

L

O

Capacidad

nominal

en kW

(con 20% de

XSA)

Capacidad

de secado

de agregado

nominal a 5%

de humedad

(mtph)

Capacidad

de aire del

quemador

m3/min

Potencia del

ventilador

interno en

kW

Aire de la atom. de aceite

m3/min

Fuego bajo Fuego alto

P

T

2

5

0

14641 181 314 30 2.8 2.3

P

T

2

7

5

21961 272 472 45 2.8 2.4

P

T

2

1

0

0

29281 363 625 56 2.8 2.3

P

T

2

1

2

5

36601 454 712 75 2.8 2.3

P

T

2

1

5

0

43922 544 944 93 3.5 2.5

Las condiciones anteriores son estndares a 21 C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada

tamao para obtener ms informacin y flujos y presiones especficas. La capacidad de secado del agregado nominal en base a las

temperaturas tpicas del tubo de escape de 115.6 C, 0.2 cal/g C de calor especfico en el agregado. La capacidad mxima del

diseo del quemador es igual a su capacidad nominal.

A robust build and simple, accessible construction

makes the Phoenix Fury burner a great cost-effective

choice. Compared to other open-fred designs, the

Fury burner achieves better emissions and fuel-

effciency by putting 50% more combustion air

through the burner.

ASTEC

P H OE NI X

F U R Y B U R NE R

Una fabricacin slida y simple y una construccin econmica hacen

del quemador Phoenix Fury una alternativa excelente y rentable.

Comparado con otros diseos de fuego abierto, el quemador Fury logra

mejores emisiones y rendimiento del combustible al permitir el paso de

50% ms aire de combustin a travs del quemador.

ASTEC

QUE MADORE S P HOE NI X

F URY

LOW COST

Success in the aggregate and HMA industries

depends on proftability. The Astec Phoenix Fury

burner is the low cost alternative to more expensive

total air designs.

SIMPLICITY

The simple and accessible construction makes

burner maintenace easy: while its rugged build

keeps maintenance costs to a minimum.

EFFICIENCY

Rapidly swirling, high-energy air is the key to the

Fury burners effcient combustion. The swirling air

and fame are created by the fxed internal spin

vanes, high-pressure blower, and high velocity

nose.

COMPACT FLAME SHAPE

The Phoenix Fury burner cleanly and effciently

burns oil or gas. Its compact fame makes it

compatible with virtually all drum designs without

complicated adjustments.

BETTER EMISSIONS

The Astec Fury burner is designed to put 50% more

combustion air through the burner than competi-

tive designs. This means higher combustion quality,

better emissions, and higher effciency combustion

throughout the entire fring range of the burner.

NO COMPRESSED AIR

The Astec designed pre-flming fuel nozzle utilizes

the combustion air from the high-pressure blower

to atomize fuel. This eliminates the need for com-

pressed air at the burner, and helps increase

nozzle life.

RELIABILITY

Each burner is also thoroughly tested before leav-

ing the Astec burner facility to make start-up at your

facility as fast as possible. For the most reliable oil

light-off, even under cold and harsh conditions, the

Fury burner is supplied with Astecs exclusive heat

tracing and insulation system.

Simple construction makes burner maintenance easy.

The compact flame enables the Fury burner to work

with virtually all drum designs.

FURY

Above conditions are standard 70F and sea level. See detailed capacity per-

formance sheets for each size for more information and specifc fows and

pressures. Nominal aggregate drying capacity based on typical exhaust stack

temperatures at 240F, 0.24 btu/Ibm F specifc heat in the aggregate.

M

O

D

E

L

P

F

5

0

P

F

7

5

P

F

1

0

0

Rated

Capacity

Millions

of

BTU/HR

Burner

Air

Capacity

SCFH

Integral

Blower

Horsepower

Nominal

Aggregate

Drying

Capacity

at 5%

Moisture

50 60 200 tph

0.65

Mill.

1 Mill.

1.3 Mill.

300 tph

400 tph

75 75

100 125

BURNER FIRING SPECIFICATIONS

BAJO COSTO

El xito en la industria de agregados o de HMA depende de la

rentabilidad. El quemador Phoenix Fury de Astec es la alternativa

de bajo costo frente a otros diseos ms costosos totalmente de aire.

SIMPLICIDAD

La construccin simple y econmica del quemador hace que sea

de fcil mantenimiento: su fabricacin resistente mantiene los

costos de mantenimiento al mnimo.

EFICIENCIA

El aire rpidamente arremolinado y dinmico es la clave para

que el quemador Fury logre una combustin eficiente. Las paletas

fijas con rotacin interna, el soplador de alta presin y el extremo

de gran velocidad generan la llama y el aire arremolinado.

FORMA COMPACTA DE LA LLAMA

El quemador Phoenix Fury quema combustible o gas de una forma

limpia y eficiente. Su llama compacta hace que sea compatible con

casi todos los diseos de tambor sin ajustes complicados.

MEJORES EMISIONES

El quemador Fury de Astec est diseado para colocar 50% ms aire

de combustin a travs de quemador que otros diseos competitivos.

Esto significa ms calidad en la combustin, mejores emisiones y

mayor eficiencia en todo el rango de combustin del quemador.

SIN AIRE COMPRIMIDO

El diseo de Astec de la boquilla de combustible recubierta utiliza

el aire de combustin del soplador de alta presin para atomizar

el combustible. Esto elimina la necesidad de comprimir el aire en el

quemador y ayuda a incrementar la vida til de la boquilla.

CONFIABILIDAD

Todos los quemadores tambin son sometidos a prueba antes

de salir de la fbrica Astec para que puedan comenzar a

funcionar lo ms rpido posible en su instalacin. Para obtener

la temperatura de encendido ms confiable del aceite, incluso

en condiciones fras y adversas, el quemador Fury cuenta con el

sistema de aplicacin de calor y aislamiento exclusivo de Astec.

Su construccin simple hace que el mantenimiento

del quemador sea sencillo.

La llama compacta permite que el quemador Fury

trabaje con casi todos los diseos de tambor.

ESPECIFICACIONES DEL QUEMADOR

M

O

D

E

L

O

Capacidad

nominal en

kW

Capacidad

de

secado de

agregado

nominal

a 5% de

humedad

(mtph)

Capacidad

de aire del

quemador

m3/min

Potencia

del

ventilador

interno en

kW

P

F

5

0

14641 181 195 45

P

F

7

5

21961 272 292 56

P

F

1

0

0

29281 363 389 93

Las condiciones anteriores son estndares a 21 C del nivel del mar. Vea la

capacidad detallada, las hojas de rendimiento de cada tamao para obtener ms

informacin y flujos y presiones especficas. La capacidad de secado del agregado

nominal en base a las temperaturas tpicas del tubo de escape de 115.6 C, 0.2

cal/g C de calor especfico en el agregado. La capacidad mxima del diseo del

quemador es igual a su capacidad nominal.

Astecs premium Ultra Low NOx Phoenix Phantom burner leads the pack

with the lowest available combustion and noise emissions (gaseous

fuels only). The Phantom also achieves the highest electrical energy

efciency with innovations like variable speed drives. The Phantom offers

advanced mixing technology and the latest technological innovations to

deliver the absolute minimum gaseous emissions available today.

ASTEC

P H OE NI X

P H A NT OM

2.5M. WMS. 12-06

El quemador Phoenix Phantom premium con nivel ultra bajo de NOx es el lder

en quemadores gracias a la combustin y a las emisiones de ruido ms bajas

disponibles (slo combustibles gaseosos). El quemador Phantom tambin alcanza la

ms alta eciencia en el consumo de energa elctrica gracias a innovaciones como

los mandos de velocidad variable. Ofrece tecnologa avanzada de mezclado y las

innovaciones tecnolgicas ms modernas para poder proporcionar las emisiones

gaseosas mnimas ms ecientes en la actualidad.

ASTEC

QUE MADORE S P HOE NI X P HANT OM

Natural gas injection and mixing: uniformly green

color indicates complete mixing of air/gas.

Velocity magnitude increases as air and natural

gas mix.

The premium Phoenix Phantom is used where

emissions limits are a driving concern, (typically

the Phantom is not supplied with optional oil nozzle

because its premium Ultra-Low emissions technology

applies to gaseous fuel)

LEAN BURN PREMIX FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 60% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

75 300 tph 1.3 mill. 100

100

400 tph

1.7 mill. 125

125

500 tph 2.2 mill. 150

150 600 tph 2.6 mill. 200

P

P

1

5

0

P

P

1

2

5

P

P

1

0

0

P

P

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

*18 PPH N0x & 200 PPH 60 at 37 02 reference.

*Advert|sed numbers are ach|evab|e |n some cond|t|ons but not guaranteed.

ADVANCED EMISSION REDUCTION

The Phoenix Phantom is the only burner available in the hot

mix asphalt industry using the most advanced technology

to precisely and completely mix the air and gaseous fuel to

achieve an advanced low NOx and CO method called lean

burn premix. Phantom employs a multiple parallel turbulent

tube mixer to achieve near perfect mixing of fuel and air.

RELIABLE FIRING & ADVANCED DESIGN

The Phoenix Phantom is thoroughly tested before leaving

the factory to ensure reliability and start-up ease.

Highly efcient variable speed blower controls provide

damper-less air ow control. Combustion air and fuel

ow meters can be combined with Astec PLC/Computer

Burner Controls for the most precise and reliable burner

control available.

FIRING EFFICIENCY & COMPACT FLAME SIZE

When running in lean burn mode, near perfect mixing of

air and fuel before burning produces the most compact

ame available. The compact ame size contributes to

efciency, ensuring that all of the fuel is combusted without

taking away valuable dryer heating capacity like other low

emission methods that use ue gas recirculation or water

injection methods.

PHANTOM

Path Lines Colored by Velocity Magnitude (ft/s)

1.75e+02

1.66e+02

1.57e+02

1.49e+02

1.40e+02

1.57e+02

1.31e+02

1.22e+02

1.14e+02

1.05e+02

9.61e+01

8.74e+01

7.87e+01

6.99e+01

6.12e+01

5.24e+01

4.37e+01

3.50e+01

2.62e+01

1.75e+01

8.74e+00

0.00e+00

Z

X

Y

Gas Concentration

0.10

0.08

0.06

0.05

0.03

REDUCCIN AVANZADA DE LAS EMISIONES

El Phoenix Phantom es el nico quemador disponible en la industria

de la mezcla de asfalto en caliente que implementa la tecnologa ms

avanzada para mezclar el aire y el combustible gaseoso en forma

completa y precisa para poder alcanzar el mtodo de bajo nivel de

NOx y CO denominado combustible premezclado de proporcin

pobre. El quemador Phantom emplea un mezclador de tubo de flujo

paralelo mltiple y turbulento para lograr la mezcla de combustible y

aire casi a la perfeccin.

COMBUSTIN CONFIABLE Y DISEO

AVANZADO

El Phoenix Phantom es meticulosamente sometido a prueba antes de

salir de la fbrica para garantizar confiabilidad y un arranque sencillo.

Los controles del ventilador de velocidad variable de gran eficiencia

brindan un control del flujo de aire de menor registro. Los flujmetros del

aire de combustin y combustible pueden combinarse con los controles

del quemador por PLC/computadora de Astec para lograr el control

ms preciso y confiable disponible.

EFICIENCIA DE COMBUSTIN Y LLAMA

COMPACTA

Cuando el modo de combustible de proporcin pobre est activado, la

mezcla de aire casi perfecta previa a la combustin produce la llama

ms compacta disponible. El tamao compacto de la llama contribuye

a alcanzar la mejor eficiencia, garantizando que todo el combustible

se queme sin disminuir la valiosa capacidad de calentamiento con

secador como lo hacen otros mtodos con bajos niveles de emisiones,

que utilizan los mtodos de recirculacin de la emanacin de gas o

de inyeccin de agua

Natural gas injection and mixing: uniformly green

color indicates complete mixing of air/gas.

Velocity magnitude increases as air and natural

gas mix.

The premium Phoenix Phantom is used where

emissions limits are a driving concern, (typically

the Phantom is not supplied with optional oil nozzle

because its premium Ultra-Low emissions technology

applies to gaseous fuel)

LEAN BURN PREMIX FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 60% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

75 300 tph 1.3 mill. 100

100

400 tph

1.7 mill. 125

125

500 tph 2.2 mill. 150

150 600 tph 2.6 mill. 200

P

P

1

5

0

P

P

1

2

5

P

P

1

0

0

P

P

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

*18 PPH N0x & 200 PPH 60 at 37 02 reference.

*Advert|sed numbers are ach|evab|e |n some cond|t|ons but not guaranteed.

ADVANCED EMISSION REDUCTION

The Phoenix Phantom is the only burner available in the hot

mix asphalt industry using the most advanced technology

to precisely and completely mix the air and gaseous fuel to

achieve an advanced low NOx and CO method called lean

burn premix. Phantom employs a multiple parallel turbulent

tube mixer to achieve near perfect mixing of fuel and air.

RELIABLE FIRING & ADVANCED DESIGN

The Phoenix Phantom is thoroughly tested before leaving

the factory to ensure reliability and start-up ease.

Highly efcient variable speed blower controls provide

damper-less air ow control. Combustion air and fuel

ow meters can be combined with Astec PLC/Computer

Burner Controls for the most precise and reliable burner

control available.

FIRING EFFICIENCY & COMPACT FLAME SIZE

When running in lean burn mode, near perfect mixing of

air and fuel before burning produces the most compact

ame available. The compact ame size contributes to

efciency, ensuring that all of the fuel is combusted without

taking away valuable dryer heating capacity like other low

emission methods that use ue gas recirculation or water

injection methods.

PHANTOM

Path Lines Colored by Velocity Magnitude (ft/s)

1.75e+02

1.66e+02

1.57e+02

1.49e+02

1.40e+02

1.57e+02

1.31e+02

1.22e+02

1.14e+02

1.05e+02

9.61e+01

8.74e+01

7.87e+01

6.99e+01

6.12e+01

5.24e+01

4.37e+01

3.50e+01

2.62e+01

1.75e+01

8.74e+00

0.00e+00

Z

X

Y

Gas Concentration

0.10

0.08

0.06

0.05

0.03

Inyeccin de gas natural y mezclado: el color verde

uniforme indica la mezcla completa de aire/gas.

Natural gas injection and mixing: uniformly green

color indicates complete mixing of air/gas.

Velocity magnitude increases as air and natural

gas mix.

The premium Phoenix Phantom is used where

emissions limits are a driving concern, (typically

the Phantom is not supplied with optional oil nozzle

because its premium Ultra-Low emissions technology

applies to gaseous fuel)

LEAN BURN PREMIX FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 60% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

75 300 tph 1.3 mill. 100

100

400 tph

1.7 mill. 125

125

500 tph 2.2 mill. 150

150 600 tph 2.6 mill. 200

P

P

1

5

0

P

P

1

2

5

P

P

1

0

0

P

P

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

*18 PPH N0x & 200 PPH 60 at 37 02 reference.

*Advert|sed numbers are ach|evab|e |n some cond|t|ons but not guaranteed.

ADVANCED EMISSION REDUCTION

The Phoenix Phantom is the only burner available in the hot

mix asphalt industry using the most advanced technology

to precisely and completely mix the air and gaseous fuel to

achieve an advanced low NOx and CO method called lean

burn premix. Phantom employs a multiple parallel turbulent

tube mixer to achieve near perfect mixing of fuel and air.

RELIABLE FIRING & ADVANCED DESIGN

The Phoenix Phantom is thoroughly tested before leaving

the factory to ensure reliability and start-up ease.

Highly efcient variable speed blower controls provide

damper-less air ow control. Combustion air and fuel

ow meters can be combined with Astec PLC/Computer

Burner Controls for the most precise and reliable burner

control available.

FIRING EFFICIENCY & COMPACT FLAME SIZE

When running in lean burn mode, near perfect mixing of

air and fuel before burning produces the most compact

ame available. The compact ame size contributes to

efciency, ensuring that all of the fuel is combusted without

taking away valuable dryer heating capacity like other low

emission methods that use ue gas recirculation or water

injection methods.

PHANTOM

Path Lines Colored by Velocity Magnitude (ft/s)

1.75e+02

1.66e+02

1.57e+02

1.49e+02

1.40e+02

1.57e+02

1.31e+02

1.22e+02

1.14e+02

1.05e+02

9.61e+01

8.74e+01

7.87e+01

6.99e+01

6.12e+01

5.24e+01

4.37e+01

3.50e+01

2.62e+01

1.75e+01

8.74e+00

0.00e+00

Z

X

Y

Gas Concentration

0.10

0.08

0.06

0.05

0.03

El quemador premium Phoenix Phantom se utiliza

donde los lmites de las emisiones generan prob-

lemas (comnmente, el Phantom no cuenta con una

boquilla de aceite opcional porque su tecnologa

premium con niveles de emisiones ultra bajas se

aplica al combustible gaseoso).

La magnitud de la velocidad aumenta a medida que

el aire y el gas natural se mezclan.

Natural gas injection and mixing: uniformly green

color indicates complete mixing of air/gas.

Velocity magnitude increases as air and natural

gas mix.

The premium Phoenix Phantom is used where

emissions limits are a driving concern, (typically

the Phantom is not supplied with optional oil nozzle

because its premium Ultra-Low emissions technology

applies to gaseous fuel)

LEAN BURN PREMIX FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 60% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

75 300 tph 1.3 mill. 100

100

400 tph

1.7 mill. 125

125

500 tph 2.2 mill. 150

150 600 tph 2.6 mill. 200

P

P

1

5

0

P

P

1

2

5

P

P

1

0

0

P

P

7

5

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

*18 PPH N0x & 200 PPH 60 at 37 02 reference.

*Advert|sed numbers are ach|evab|e |n some cond|t|ons but not guaranteed.

ADVANCED EMISSION REDUCTION

The Phoenix Phantom is the only burner available in the hot

mix asphalt industry using the most advanced technology

to precisely and completely mix the air and gaseous fuel to

achieve an advanced low NOx and CO method called lean

burn premix. Phantom employs a multiple parallel turbulent

tube mixer to achieve near perfect mixing of fuel and air.

RELIABLE FIRING & ADVANCED DESIGN

The Phoenix Phantom is thoroughly tested before leaving

the factory to ensure reliability and start-up ease.

Highly efcient variable speed blower controls provide

damper-less air ow control. Combustion air and fuel

ow meters can be combined with Astec PLC/Computer

Burner Controls for the most precise and reliable burner

control available.

FIRING EFFICIENCY & COMPACT FLAME SIZE

When running in lean burn mode, near perfect mixing of

air and fuel before burning produces the most compact

ame available. The compact ame size contributes to

efciency, ensuring that all of the fuel is combusted without

taking away valuable dryer heating capacity like other low

emission methods that use ue gas recirculation or water

injection methods.

PHANTOM

Path Lines Colored by Velocity Magnitude (ft/s)

1.75e+02

1.66e+02

1.57e+02

1.49e+02

1.40e+02

1.57e+02

1.31e+02

1.22e+02

1.14e+02

1.05e+02

9.61e+01

8.74e+01

7.87e+01

6.99e+01

6.12e+01

5.24e+01

4.37e+01

3.50e+01

2.62e+01

1.75e+01

8.74e+00

0.00e+00

Z

X

Y

Gas Concentration

0.10

0.08

0.06

0.05

0.03

ESPECIFICACIONES DEL COMBUSTIBLE PREMEZCLADO

DE PROPORCIN POBRE

M

O

D

E

L

O

Capacidad nominal

en kW

(con 20% de XSA)

Capacidad de

secado de agregado

nominal a 5% de

humedad

Capacidad

de aire del

quemador m3/min

Potencia del

ventilador interno

en kW

P

P

7

5

21961 272 614 75

P

P

1

0

0

29281 363 802 93

P

P

1

2

5

36601 454 1,038 112

P

P

1

5

0

43922 544 1,227 149

Las condiciones anteriores son estndares a 21 C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada

tamao para obtener ms informacin y flujos y presiones especficas. La capacidad de secado del agregado nominal en base a las

temperaturas tpicas del tubo de escape de 115.6 C, 0.2 cal/g C de calor especfico en el agregado. La capacidad mxima del

diseo del quemador es 110% de la capacidad nominal. *Los nmeros publicados se obtienen en ciertas condiciones, pero no est

completamente garantizado.

The Whisper Jet delivers unmatched reliability

and hassle-free maintenance. The Whisper Jet

cleanly and efciently burns oil or gas and

its compact ame makes it compatible with

virtually all drum designs without complicated

adjustments.

ASTEC

WH I S P E R J E T

2.5M. WMS. 12-06

ASTEC

QUE MADORE S WHI S P E R J E T

El quemador Whisper Jet brinda una conabilidad sin igual y fcil

mantenimiento. El Whisper Jet quema combustible o gas de una forma

limpia y eciente, y su llama compacta hace que sea compatible con

casi todos los diseos de tambores sin ajustes complicados.

TROUBLE-FREE MAINTENANCE & OPERATION

Maintenance and downtime are virtually eliminated by

the careful design of the Whisper Jet burner. The Whisper

Jet burner uses the highest quality, eld-proven components.

Each burner is also fully tested before leaving the Astec

burner factory to make start-up at your facility as fast as

possible. For the most reliable oil light-off, even under cold

and harsh conditions, the Whisper Jet is supplied with

Astecs exclusive heat tracing and insulation system.

LOW COMBUSTION AND NOISE EMISSIONS

The Whisper Jet uses unique patented technology to burn

cleanly and efciently. True to its name, the Whisper Jet is

designed and equipped to reduce burner noise over

competitive burners.

EFFICIENT COMBUSTION

Rapidly swirling high energy air is the key to the Whisper

Jets efcient combustion. The swirling air and ame are

created by the xed internal spin vanes and the patented

castellated nose, ring, and nozzle design.

Whisper Jets compact flame shape eliminates drum

overheating and does not require complicated flame

shape adjustments for best combustion efficiency.

The heavy-duty main fan damper is constructed to

provide years of trouble-free operation.

Whisper Jets patented design promotes more rapid

mixing and combustion.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 90 55

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 1.3 mill. 100 90 55

125 500 tph 1.6 mill. 125 120 70

150 600 tph 2 mill. 150 140 90

50 200 tph 650,000 50 80 55

W

J

1

5

0

W

J

1

2

5

W

J

1

0

0

W

J

7

5

W

J

5

0

MANTENIMIENTO Y FUNCIONAMIENTO

SIN PROBLEMAS

El mantenimiento y tiempo de inactividad prcticamente desaparecen

gracias al diseo cuidadoso del quemador Whisper Jet. El Whisper

Jet utiliza los componentes de ms alta calidad y de rendimiento

comprobado. Todos los quemadores tambin son sometidos a

prueba antes de salir de la fbrica Astec para que puedan comenzar

a funcionar lo ms rpido posible en su instalacin. Para obtener

la temperatura de encendido ms confiable del aceite, incluso en

condiciones fras y adversas, el Whisper Jet cuenta con el sistema de

aplicacin de calor y aislamiento.

BAJA COMBUSTIN Y EMISIONES DE

RUIDOS

El quemador Whisper Jet emplea una exclusiva tecnologa patentada

para quemar de manera limpia y eficiente. Fiel a su nombre, el Whisper

Jet est diseado y equipado para reducir el ruido generado por el

quemador de una forma ms eficiente que los de la competencia.

COMBUSTIN EFICIENTE

El aire rpidamente arremolinado y dinmico es la clave para que el

Whisper Jet logre una combustin eficiente. El aire arremolinado y la

llama se generan por las paletas fijas con rotacin interna y por el

diseo encastillado patentado de la punta, anillo y boquilla.

La forma compacta de la llama del Whisper Jet evita

el recalentamiento del tambor y no se deben realizar

ajustes complicados respecto de la llama para lograr

una mejor eficiencia de combustin.

TROUBLE-FREE MAINTENANCE & OPERATION

Maintenance and downtime are virtually eliminated by

the careful design of the Whisper Jet burner. The Whisper

Jet burner uses the highest quality, eld-proven components.

Each burner is also fully tested before leaving the Astec

burner factory to make start-up at your facility as fast as

possible. For the most reliable oil light-off, even under cold

and harsh conditions, the Whisper Jet is supplied with

Astecs exclusive heat tracing and insulation system.

LOW COMBUSTION AND NOISE EMISSIONS

The Whisper Jet uses unique patented technology to burn

cleanly and efciently. True to its name, the Whisper Jet is

designed and equipped to reduce burner noise over

competitive burners.

EFFICIENT COMBUSTION

Rapidly swirling high energy air is the key to the Whisper

Jets efcient combustion. The swirling air and ame are

created by the xed internal spin vanes and the patented

castellated nose, ring, and nozzle design.

Whisper Jets compact flame shape eliminates drum

overheating and does not require complicated flame

shape adjustments for best combustion efficiency.

The heavy-duty main fan damper is constructed to

provide years of trouble-free operation.

Whisper Jets patented design promotes more rapid

mixing and combustion.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 90 55

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 1.3 mill. 100 90 55

125 500 tph 1.6 mill. 125 120 70

150 600 tph 2 mill. 150 140 90

50 200 tph 650,000 50 80 55

W

J

1

5

0

W

J

1

2

5

W

J

1

0

0

W

J

7

5

W

J

5

0

Hay un regulador resistente del ventilador principal

que brinda aos de funcionamiento sin problemas.

TROUBLE-FREE MAINTENANCE & OPERATION

Maintenance and downtime are virtually eliminated by

the careful design of the Whisper Jet burner. The Whisper

Jet burner uses the highest quality, eld-proven components.

Each burner is also fully tested before leaving the Astec

burner factory to make start-up at your facility as fast as

possible. For the most reliable oil light-off, even under cold

and harsh conditions, the Whisper Jet is supplied with

Astecs exclusive heat tracing and insulation system.

LOW COMBUSTION AND NOISE EMISSIONS

The Whisper Jet uses unique patented technology to burn

cleanly and efciently. True to its name, the Whisper Jet is

designed and equipped to reduce burner noise over

competitive burners.

EFFICIENT COMBUSTION

Rapidly swirling high energy air is the key to the Whisper

Jets efcient combustion. The swirling air and ame are

created by the xed internal spin vanes and the patented

castellated nose, ring, and nozzle design.

Whisper Jets compact flame shape eliminates drum

overheating and does not require complicated flame

shape adjustments for best combustion efficiency.

The heavy-duty main fan damper is constructed to

provide years of trouble-free operation.

Whisper Jets patented design promotes more rapid

mixing and combustion.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 90 55

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 1.3 mill. 100 90 55

125 500 tph 1.6 mill. 125 120 70

150 600 tph 2 mill. 150 140 90

50 200 tph 650,000 50 80 55

W

J

1

5

0

W

J

1

2

5

W

J

1

0

0

W

J

7

5

W

J

5

0

El diseo patentado del Whisper Jet promueve mez-

clado y combustin ms rpidos.

TROUBLE-FREE MAINTENANCE & OPERATION

Maintenance and downtime are virtually eliminated by

the careful design of the Whisper Jet burner. The Whisper

Jet burner uses the highest quality, eld-proven components.

Each burner is also fully tested before leaving the Astec

burner factory to make start-up at your facility as fast as

possible. For the most reliable oil light-off, even under cold

and harsh conditions, the Whisper Jet is supplied with

Astecs exclusive heat tracing and insulation system.

LOW COMBUSTION AND NOISE EMISSIONS

The Whisper Jet uses unique patented technology to burn

cleanly and efciently. True to its name, the Whisper Jet is

designed and equipped to reduce burner noise over

competitive burners.

EFFICIENT COMBUSTION

Rapidly swirling high energy air is the key to the Whisper

Jets efcient combustion. The swirling air and ame are

created by the xed internal spin vanes and the patented

castellated nose, ring, and nozzle design.

Whisper Jets compact flame shape eliminates drum

overheating and does not require complicated flame

shape adjustments for best combustion efficiency.

The heavy-duty main fan damper is constructed to

provide years of trouble-free operation.

Whisper Jets patented design promotes more rapid

mixing and combustion.

LOW EXCESS AIR FIRING SPECS

Rated Capacity

Millions of

BTU/HR

(with 20% XSA)

Nominal Aggregate

Drying Capacity

at 5% Moisture

Burner Air

Capacity

SCFH

Integral

Blower

Horsepower

Oil Atomizing

Air Requirement

SCFM

Low Fire High Fire

75 300 tph 1 mill. 75 90 55

M

O

D

E

L

Above cond|t|ons are standard at 70` F at sea |eve|. 8ee deta||ed capac|ty, performance sheets for each s|ze

for more |nformat|on and spec|c 0ows and pressures. Nom|na| aggregate dry|ng capac|ty based on typ|ca|

exhaust stack temperatures of 240` F, 0.2 TU|Lbm F spec|c heat |n the aggregate. urner max|mum

des|gn capac|ty |s 1107 of rated capac|ty.

100 400 tph 1.3 mill. 100 90 55

125 500 tph 1.6 mill. 125 120 70

150 600 tph 2 mill. 150 140 90

50 200 tph 650,000 50 80 55

W

J

1

5

0

W

J

1

2

5

W

J

1

0

0

W

J

7

5

W

J

5

0

ESPECIFICACIONES DE LA COMBUSTIN

CON BAJO EXCESO DE AIRE

M

O

D

E

L

O

Capacidad

nominal

en kW

(con 20% de

XSA)

Capacidad

de secado

de agregado

nominal a 5%

de humedad

(mtph)

Capacidad

de aire del

quemador

m3/min

Potencia del

ventilador

interno en

kW

Aire de la atom. de aceite

m3/min

Fuego bajo Fuego alto

W

J

5

0

14641 181 307 45 1.4 1.6

W

J

7

5

21961 272 472 56 2.1 1.6

W

J

1

0

0

29281 363 614 75 2.8 1.6

W

J

1

2

5

36601 454 755 93 3.5 2.0

W

J

1

5

0

43922 544 944 112 4.2 2.5

Las condiciones anteriores son estndares a 21 C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada

tamao para obtener ms informacin y flujos y presiones especficas. La capacidad de secado del agregado nominal en base a las

temperaturas tpicas del tubo de escape de 115.6 C, 0.2 cal/g C de calor especfico en el agregado. La capacidad mxima del

diseo del quemador es 110% de la capacidad nominal.

2.5M. WMS. 12-06

You might also like

- Herramientas ROTATIVAS para Maquinado en Fresa (MILLING)Document1,500 pagesHerramientas ROTATIVAS para Maquinado en Fresa (MILLING)Felipe PerillaNo ratings yet

- Bases para El Cálculo de Una Banda TransportadoraDocument45 pagesBases para El Cálculo de Una Banda Transportadoraluisjala100% (1)

- Nalcool 2000Document13 pagesNalcool 2000Escobar Valderrama0% (1)

- Combustible para Centrales de Producción de EnergíaDocument45 pagesCombustible para Centrales de Producción de EnergíaIrwing Rengifo MaurtuaNo ratings yet

- Curso de PipingDocument87 pagesCurso de Piping063-20 Lasmargaritas100% (1)

- Manual Burner Pro03Document29 pagesManual Burner Pro03Sofía Mesa PérezNo ratings yet

- Hoja de Datos de Seguridad - Petróleo Combustible No. 5 PDFDocument10 pagesHoja de Datos de Seguridad - Petróleo Combustible No. 5 PDFMachx MasterNo ratings yet

- Curso Fundamentos de Combustion y Operacion en Hornos (HCH)Document467 pagesCurso Fundamentos de Combustion y Operacion en Hornos (HCH)Milagros MorantesNo ratings yet

- Manual de Operación UAB18EDocument474 pagesManual de Operación UAB18Epedroandres143No ratings yet

- Normas DinDocument8 pagesNormas DinMaNu LTPNo ratings yet

- Quemador de premezcla EQA 76Document4 pagesQuemador de premezcla EQA 76Martin QuinteroNo ratings yet

- 01 Montaje y Mantenimiento de PoleasDocument16 pages01 Montaje y Mantenimiento de Poleaswilson alejandroNo ratings yet

- PFC Jesus Jabonero (Final)Document160 pagesPFC Jesus Jabonero (Final)Jose Angel Chirguita100% (1)

- Memoria de CalculoDocument9 pagesMemoria de CalculoAntonio AnglesNo ratings yet

- Vertical Roller MillesDocument8 pagesVertical Roller Millesb3t0_3100% (1)

- Prueba Analisis de VibracionesDocument3 pagesPrueba Analisis de Vibracioneslucas . asNo ratings yet

- Oilfield Drilling Equipment SpanischDocument36 pagesOilfield Drilling Equipment Spanischtavogus1985No ratings yet

- Descripcion Sistema Empacado 3Document55 pagesDescripcion Sistema Empacado 3ewis02No ratings yet

- (ES) Plan de Mantenimiento InfraspeakDocument25 pages(ES) Plan de Mantenimiento InfraspeakÍtalo SQNo ratings yet

- 9852 1912 05i Operators Instruction Simba 1254Document77 pages9852 1912 05i Operators Instruction Simba 1254Andres Atehortua100% (1)

- Laboratorio de Refrigeración PDFDocument7 pagesLaboratorio de Refrigeración PDFalex carvajalNo ratings yet

- Sopletes CondorDocument17 pagesSopletes Condorosvaldo lopez100% (1)

- Diseño en FundicionesDocument29 pagesDiseño en FundicionesTD DeysiNo ratings yet

- Diseno de MazarotasDocument19 pagesDiseno de MazarotasRonald Gomez OrellanaNo ratings yet

- Análisis de Prueba de Aceite Tomada de Un Motor de Combustión InternaDocument5 pagesAnálisis de Prueba de Aceite Tomada de Un Motor de Combustión InternaLuis David CarreraNo ratings yet

- Catalogo DLBDocument40 pagesCatalogo DLBJose Manuel Bautista MartinezNo ratings yet

- Copia de Repuestos Plasser Bp007ypbr400Document14 pagesCopia de Repuestos Plasser Bp007ypbr400leonardonanez100% (1)

- Diseño de Extrusora 1Document140 pagesDiseño de Extrusora 1predeleytorNo ratings yet

- Tolerancias ISO-VibracionesDocument3 pagesTolerancias ISO-VibracionesDiego LaraNo ratings yet

- TPM Tiempos ProductivosDocument151 pagesTPM Tiempos ProductivosJorge Luis Reyes Lopez50% (2)

- La guía definitiva para tomar rizos (en o menosDocument32 pagesLa guía definitiva para tomar rizos (en o menosDroda50% (2)

- WM10 - 2114 E Nov13Document52 pagesWM10 - 2114 E Nov13Michael roa parraNo ratings yet

- Torque y torquímetro: definición, tipos e invenciónDocument22 pagesTorque y torquímetro: definición, tipos e invenciónJosue LlamoccaNo ratings yet

- Jacinto FJDocument191 pagesJacinto FJAlci-des Huacho OsorioNo ratings yet

- Instructivo Alineación de Equipo Horizontal y VerticalDocument19 pagesInstructivo Alineación de Equipo Horizontal y VerticalrichardNo ratings yet

- Introduccion A Las Turbinas de GasDocument30 pagesIntroduccion A Las Turbinas de GasRoger Gustavo Apaza QuispeNo ratings yet

- Manual Venanzetti (Modelo Nuestro Vv81b6)Document56 pagesManual Venanzetti (Modelo Nuestro Vv81b6)edgarlimasNo ratings yet

- Optibelt Catalogo de Productos IndustrialesDocument62 pagesOptibelt Catalogo de Productos IndustrialesdicedisaNo ratings yet

- Examen final mecánica básica conceptos hidráulica fuerza presiónDocument3 pagesExamen final mecánica básica conceptos hidráulica fuerza presiónJorge Jesus Nayhua GamarraNo ratings yet

- Motores y Generadores SíncronosDocument34 pagesMotores y Generadores SíncronosLeo Charris BNo ratings yet

- Manual LogoDocument322 pagesManual LogoPablo BianchiNo ratings yet

- Trabajo de Grado - Diseño de Turbina KaplanDocument67 pagesTrabajo de Grado - Diseño de Turbina Kaplanjesus riveroNo ratings yet

- Diccionario para Ingenieros - RobbDocument340 pagesDiccionario para Ingenieros - RobbDavid Álvarez BáezNo ratings yet

- Resolución OPDS #112607Document12 pagesResolución OPDS #112607Cesar Armando LanzNo ratings yet

- Desarme Motor ZanellaDocument6 pagesDesarme Motor ZanellappanicciaNo ratings yet

- Diccionario - Tecnico.Maritimo1 (Ingles - Español-Español - Ingles)Document706 pagesDiccionario - Tecnico.Maritimo1 (Ingles - Español-Español - Ingles)Manuelux Codi100% (3)

- Guía Grundfos para suministro de aguaDocument74 pagesGuía Grundfos para suministro de aguaYashay JulianNo ratings yet

- MOTOR EMDRIVE - Fundamentos PDFDocument12 pagesMOTOR EMDRIVE - Fundamentos PDFAnonymous a2CDNe5w7No ratings yet

- Mantencion PreventivaDocument87 pagesMantencion Preventivaluis acevedoNo ratings yet

- Reposteria Chilena PDFDocument44 pagesReposteria Chilena PDFalejandroNo ratings yet

- Caldera Bosch Therm 8000 PDFDocument44 pagesCaldera Bosch Therm 8000 PDFcarr123100% (1)

- Presentacion 841 Plus (Español)Document29 pagesPresentacion 841 Plus (Español)Martin G RomoNo ratings yet

- Data Sheet Mp1000 Crusher - En.esDocument6 pagesData Sheet Mp1000 Crusher - En.esRub HuarNo ratings yet

- DRAGAS-EXCAVACIÓN SUBACUÁTICADocument37 pagesDRAGAS-EXCAVACIÓN SUBACUÁTICAAlex C Vasquez ANo ratings yet

- 02-Reseña Del ProductoDocument25 pages02-Reseña Del Productooscar vergaraNo ratings yet

- Pirotec InnovacionDocument1 pagePirotec InnovacionFrancisco Javier Bastidas M.No ratings yet

- 1598 - SpanienDocument5 pages1598 - Spanienja23gonzNo ratings yet

- Hornos Verticales para CalDocument8 pagesHornos Verticales para CalCesar Veliz LopezNo ratings yet

- El Mejor Libro de Preparación Para Tu Examen De Licencia De Operador De CalderaFrom EverandEl Mejor Libro de Preparación Para Tu Examen De Licencia De Operador De CalderaNo ratings yet

- Cunetas Especificaciones TecnicasDocument7 pagesCunetas Especificaciones TecnicasIvan GuerreroNo ratings yet

- Articulo670 07Document5 pagesArticulo670 07Didier Angel Lopez RinconNo ratings yet

- Articulo642 07Document12 pagesArticulo642 07Didier Angel Lopez RinconNo ratings yet

- Articulo632 07Document4 pagesArticulo632 07Didier Angel Lopez RinconNo ratings yet

- Articulo661 07Document7 pagesArticulo661 07Didier Angel Lopez RinconNo ratings yet

- Articulo631 07Document6 pagesArticulo631 07Didier Angel Lopez RinconNo ratings yet

- Tuberia de Concreto SiempleDocument7 pagesTuberia de Concreto SiempleDamian Vega GNo ratings yet

- Articulo662 07Document7 pagesArticulo662 07Didier Angel Lopez RinconNo ratings yet

- Estructuras de AceroDocument34 pagesEstructuras de AceroEduardo Carrillo DiazNo ratings yet

- Articulo641 07Document14 pagesArticulo641 07Didier Angel Lopez RinconNo ratings yet

- Articulo630 07Document29 pagesArticulo630 07Camilo PrietoNo ratings yet

- Tablas de Especificaciones de Acero de ConstruccionDocument9 pagesTablas de Especificaciones de Acero de ConstruccionRaul Madrigal BravoNo ratings yet

- Articulo622 07Document7 pagesArticulo622 07Didier Angel Lopez RinconNo ratings yet

- Articulo623 07Document6 pagesArticulo623 07Didier Angel Lopez RinconNo ratings yet

- Articulo610 07Document7 pagesArticulo610 07Didier Angel Lopez RinconNo ratings yet

- Articulo620 07Document11 pagesArticulo620 07Didier Angel Lopez RinconNo ratings yet

- Articulo600 07Document10 pagesArticulo600 07PESATRILLANo ratings yet

- Especificacion PilotesDocument13 pagesEspecificacion PilotesWilliam MercadoNo ratings yet

- Articulo510 07Document8 pagesArticulo510 07Jose Andres Taquez ZambranoNo ratings yet

- Articulo501 07Document7 pagesArticulo501 07Didier Angel Lopez RinconNo ratings yet

- Norma INV E-108-07Document17 pagesNorma INV E-108-07Fredy SierraNo ratings yet

- Articulo500 07Document51 pagesArticulo500 07Didier Angel Lopez RinconNo ratings yet

- Requisitos pernos y barras anclaje túnelDocument10 pagesRequisitos pernos y barras anclaje túnelDidier Angel Lopez RinconNo ratings yet

- Articulo466 07Document6 pagesArticulo466 07Didier Angel Lopez RinconNo ratings yet

- Determinación reactividad potencial agregadoDocument11 pagesDeterminación reactividad potencial agregadojucagalNo ratings yet

- Articulo103 07Document4 pagesArticulo103 07Marce Pantoja PachajoaNo ratings yet

- Recuperacion de QuebradasDocument52 pagesRecuperacion de QuebradasCarlin JCNo ratings yet

- Cálculo líneas carga roldanasDocument26 pagesCálculo líneas carga roldanasAlejandro ZuñigaNo ratings yet