Professional Documents

Culture Documents

Y Series

Uploaded by

aries26marchOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Y Series

Uploaded by

aries26marchCopyright:

Available Formats

Hi-Static

Fan Coil Units

(Y-series)

Range 600 cfm to 2100 cfm

( 285 l/s to 990 l/s )

Bulletin # 065/2009 (NEW)

SKM Fan Coil Units

Hi-Static Fan Coil Units

Introduction

Contents

Introduction .........................................2

Legend................................................2

Nomenclature .....................................2

General Features................................3

Component Features ..........................3

Options ...............................................4

Application Flexibility ..........................6

Physical Data & Electrical Data ..........7

Nominal Capacity Ratings ..................7

Correction Factors ..............................9

Sound Data ......................................10

Air Delivery .......................................12

Capacity Ratings ........................ 16-22

Control System Description ..............23

Selection Procedure .........................24

Valves & Controls .............................25

DX Connection Sizes........................26

Machine Weights ..............................26

Dimensional Data .............................27

Guide Specifications .........................31

Legend

The following legends are used throughout

this manual:

AFR ...... Air Flow Rate

BEP ...... Baked Enamel Paint

cfm ....... Cubic feet per minute

dB ........ Decibels

EADB .... Entering Air Dry Bulb

EAWB .... Entering Air Wet Bulb

ET ......... Evaporating Temperature

EWT ...... Entering Water Temperature

ESP ...... External Static Pressure

Ft .......... Total Capacity Factor

ftwg ...... Feet of Water Gauge

Fs ........ Sensible Capacity Factor

GPM .... Gallons per minute

Hz ........ Hertz

inwg ...... Inch of Water Gauge

kW ........ Kilowatts

kg ......... Kilograms

kPa ...... Kilo Pascals

LADB .... Leaving Air Dry Bulb

LAWB ... Leaving Air Wet Bulb

lbs .........

l/s ..........

MBh ......

NC ........

OD ........

Ph .........

Pa .........

SC ........

SCCF ....

SPL .......

TC .........

TCCF ....

TR ........

USgpm ..

V ...........

WFR .....

WTR .....

WPD .....

Pounds weight (British units)

Liters per second

1000 Btuh

Noise Criteria

Outside Diameter

Phase

Pascals

Sensible Capacity

Sensible Capacity Correction

Factor

Sound Pressure Level

Total Capacity

Total Capacity Correction Factor

Tons of refrigeration = 12 MBH

US Gallons per minute

Volts

Water Flow Rate

Water Temperature Rise

Water Pressure Drop

F C U - DY x - 1 2 / 4 2 / X G

Direct Drive

Series

Hi - Static Fan Coil Units from SKM are

low noise, 3-speed units and available in

varied configurations with many options

and accessories.

Hi - Static Fan Coil Units are easily installed

and serviced. Hi - Static Fan Coil Units

feature high operating efficiency, low

operating cost and quiet, energy efficient

fan motors.

Hi - Static Fan Coil Units are designed and

built in the Gulf to meet requirements

of high sensible heat ratio, durability,

minimum maintenance needs.

Deliveries on Hi - Static Fan Coil Units are

reliably prompt. For those urgent jobs,

Hi - Static Fan Coil Units can be delivered,

on request, as fast as required, handled

the way they will be installed, with or

without factory piped valve package to

reduce field installation time and piping

time to an absolute minimum.

Hi - Static Fan Coil Units, are rated in

accordance with standard ARI - 440.

Nomenclature

Fan Coil Unit

Hi - Static Fan Coil Units from SKM are a

complete line of fan coil units to meet

most air conditioning requirements. High

quality units are available for installation

in apartments and single or multi room

offices, schools, clinics, etc.

G=Galvanised Finish

F=Painted FInish

Hi - Static Fan Coil Units, another quality

product from SKM which is:

Type of cooling coil:

X = DX coil,

W = Chilled Water Coil

No. of rows for hot water coil

(1, 2, 3, 4 or 6 rows; 0 for nil)

C:

P:

E:

F:

Ceiling suspended concealed

Ceiling suspended with plenum

Ceiling suspended exposed

Floor mounted concealed

No. of rows for cooling coil

(3, 4 or 6 rows)

Unit size nom. x 100 cfm

(06,08,10,12,15,18 & 21)

Built in the Gulf...for the world.

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

General Features

Component Features

Hi - Static fan coil units manufacturerd by SKM have been

designed with the requirment of the Middle East market foremost

in consideration.

Coils

Hi - Static fan coil units are ideally suited for installation in chilled

water or DX applications to meet air conditioning requirements

of individual rooms throughout the year. Increasingly, architects

require a hidden indoor unit with custom enclosure to match the

aesthetic requirements of the space. The cooling medium can

be refrigerant for DX applications in:

Small Residences

Apartment Houses

Cooling & heating coils are manufactured from 3/8 (9.5mm)

OD seamless copper tubes mechanically bonded to high

efficiency wavy corrugated aluminium fins. Copper fins are

available as an option.

Coils are factory leak tested by air pressure at 300 psig

(2068 kPa) under water. Air vent is standard. Chilled water

cooling coils are available in 3, 4 and 6 rows. Heating coils are

available in 1, 2, 3, 4 & 6 rows. DX coils are available in 3, 4 &

6 rows. Coil connections are plain tube extensions supplied

LH or RH as required for chilled water and DX units.

Small Commercial Establishments

Mosques

For individual room temperature control in chilled water

applications, Hi - Static fan coils can be an ideal solution on

major projects involving:

Apartment Complexes

Distributor for DX type Hi - Static fan coils is provided as

standard with correct sizes and quantity of outlet pipes. Coils

are rated in accordance with ARI - 410. Hi - Static fan coil

units can be supplied with a maximum total of 6 rows/coil as

follows :

Office Blocks

Cooling and heating with 4 and 2 pipe system combination

up to a total of 6 rows only.

Hospitals & Clinics

Maximum 6 row cooling coil and electric heater battery.

Shopping Malls & Centers

Maximum 6 row DX cooling coil and electric heater battery.

Airports

Hi-rise Buildings

Fan / Motor

Hotels & Motels

Commercial Developments

Schools & Colleges

Libraries

Hi - Static fan coil units provide flexibility of architectural design,

economy of operation and space usage, individual room control

with privacy, quietness, versatility of location and installation,

and multiplicity of control system. All these reasons make the

Hi - Static series fan coils the first choice as Hi - Static Fan Coil

units from SKM are: Built in the Gulf...for the world.

Features:

Hi - Static fan coil units use centrifugal double inlet double width

low noise fans direct driven by single phase, 3-speed permanent

split capacitor motor. These motors have integral thermal

protection, low temperature rise, are highly efficient, have high

power factor and operate almost noiselessly with permanent

lubricated sleeve bearings.

Motor Technical Data

All motors used in High Static Fan Coil Units are inherently

protected by means of thermal cut-out embedded in the

winding. This thermal cut-out is calibrated to trip out when the

winding reaches a pre determined temperature. The thermal

cut out will automatically reset when the temperature returns

to a safe limit.

High efficiency coil with high efficiency wavy corrugated fins.

Hi-efficiency, low power consumption PSC electric motor.

Hi-efficiency forward curved fan for quiet operation.

Manual air vent.

Heavy gauge galvanised casing & fan housing. Hot dip is

standard.

Insulated heavy gauge drain pan.

Isolating grommet for additional vibration isolation.

Quick electrical connections.

Efficiency and Power Factor

SKM High Static Fan Coil Units are equipped with permanent

split capacitor motors because of their high efficiency and

higher power factor than that of shaded pole motors being

used by many other manufacturers of fan coil units.

The efficiency range of permanent split capacitor motors varies

between 50 & 60 % as compared to 30 to 40 % for shaded pole

motors with power factor 0.6 to 0.7 while the power factor of a

permanent split capacitor motor approaches 1.0.

SKM chooses permanent split capacitor motor on the basis

of their higher efficiency and power factor in order to maintain

the total power factor of the installation above a set minimum

value.

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Casing

Capacity

Units are constructed from high gauge galvanised steel sheet

complying with ASTM-A653 and JSIG-3302 for maximum

protection against corrosion. On request, as option, electrostatic

polyster powder coating on zinc coated galvanized and

phosphatised sheets are available. Colors available ivory white

(RAL 7032) or light grey (RAL 8019) at no extra charge. Other

colors available as a further option, on request, at additional

charge.

Maximum capacity of the electric heater is determined by

the air capacity of the particular model. Table 1 shows the

2 variations available for each model in the Hi - Static fan

coil units.

Contactors and Controls

Contactors are not included as standard and must be

field supplied and installed.

Drain Pan

Fabricated from heavy gauge zinc coated steel sheets, painted

irrespective of the type of finish for unit casing and insulated from

outside by 4 mm thick polyethylene foam insulation for maximum

protection against sweating and corrosion. Drain pan is extended

to include coil, headers and U - bends. Drain connection 3/4

(19mm) O.D. is provided for removal of condensation.

Heater Elements

U shape finned tubular heating element constructed

from high quality 80/20 nickel chrome resistance wire

connected to terminal pins and centered in a metal tube

with galvanized steel fin.

The elements are isolated from the casing. Separate

power source is required for the heaters.

Options

The standard options available for Hi - Static Fan Coil Units

include :

Automatic Air Vent

(specify option AAV)

Electric Heaters

(specify option FEH)

Unit Size

06

08

10

12

15

18

21

Number of Heater Elements

Variant 2

Variant 1

2 x 1.0

1 x 1.0

2 x 1.5

1 x 1.5

3 x 1.5

1 x 1.0 + 1 x 1.5

2 x 3.0

1 x 3.0

2 x 3.0

1 x 3.0

2 x 4.0

1 x 4.0

2 x 4.0

1 x 4.0

Application

Table 1

Electric heaters are available on all Models of High Static

Fan Coil Units for:

Thermostats

(wall mounted decorative type)

1. Heating during winter without the need for a central boiler

or hot water source. The chilled water is a two pipe system

allowing year round temperature control. Thermostat

should be suitable for Heat-Off-Cool manual change over

and with Fan ON-Auto mode. (See page #23).

Cooling only or Cooling/Heating thermostats with 3 speed switch.

Details on pages 23.

Unit mounted thermostats available for DYF models only. For

other models consult SKM.

2. Incremental heat during peak heating season when cooling

coil is circulating hot water in a two pipe system and is unable

to meet full heating requirements of the space.

Double Skin Units

High Static Fan Coil Units with factory built heating elements

as shown in Table 1 are available in two variants. Order

should specify FEH1 for variant 1 and FEH2 for variant 2.

Each variant is provided with one high limit safety cut-out

(Auto Reset) and arranged for 1 stage operation at 220-240V

1 PH 50/60Hz.

Recommended for all units installed in locations having a

high temperature difference between supply air temperature

and surrounding environment of the Hi - Static fan coil units.

This option is available for DYP models only. Additional sound

attenuation is achieved with double skinning. Cold bridges are

avoided fully in the sandwich construction.

For any other special requirements like thermostats,

controls, power supply, etc. please contact SKM.

Controls

(specify option DSU)

Various options on valve packages and control systems are

available. 8 different valve packages are available factory

installed or loose for field mounting along with 3 options on

control packages. Full details of options available see full writeup on pages 23-25.

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Auxillary and / or Double Insulated Drain Pans

Available for models DYC and DYP only to provide extended

and additional protection against condensation below valve

packages.

Options available :

1. Auxiliary drip lip supplied loose to be fitted on the edge of the

drain pan under the valves. Specify option ADP.

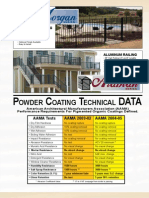

Powder Coated Decorative Finish

(specify option BEP)

Available for models DYF only where required for exposed

installation. Model DYE comes standard with this option. Colors

available ivory white (RAL 7032) or light grey (RAL 8019).

Specify with option code BEP. Optionally other RAL colors may

be available. Specify color with code BEP.

Supply and Return Air Grille

Powder coated discharge grille and/or return grille available for

DYE & DYF. Double deflection discharge grille available under

option code GDD. Single deflection discharge or return grille

available under option code RAG.

Figure 1

Grills are powder coated to match color of unit, if option BEP

ordered or in standard aluminium finish if option BEP not required

or ordered.

Discharge Plenum

(Specify option GDP)

2. Double skin drain pan with heavy gauge galvanised steel

internal & external skin. The inner and outer skins are filled

with fibre glass insulation. Internal skin additionally protected

with painted finish. Specify option PDI.

A discharge plenum for free standing DYF models only is

available. Option BEP must be ordered with this option. Option

GDP includes, in addition, a double deflection supply grille and

a single deflection return air grille, powder coated in matching

color. Colors available ivory white (RAL 7032) or light grey

(RAL 8019). Specify with option code.

NOTE:

1. The Low Speed wiring is Factory disabled for direct expansion

(DX) coil units.

Figure 2

2. A separate power feeder is required for units supplied with

optional factory installed electric heaters.

3. Stainless steel drain pan insulated from outside with 4mm thick

polyethylene foam insulation. Specify option SDP.

4. Double skin drain pan with stainless steel internal skin and

heavy gauge galvanized steel outer skin sandwiched between

a fibre glass insulation. Specify option PSID.

3. The maximum Ampere shown in Table 2, page #7 is the total

Amps per unit.

4. Full Load inductive current (Amps) rating of 3 speed switch

must be greater than the maximum Amps of the unit.

5. Maximum allowable fuse rating for any unit size must not

exceed 15 Amps/250 Vac.

6. The units are suitable for electrical system where voltage

supplied to the unit should not vary 10% of the listed

voltage.

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Application Flexibility

3. DYE

Hi - Static fan coil units are available in a capacity range of

600-2100 cfm (283-991 l/s), in various models having 7 sizes

each. Configurations available include ceiling suspended

horizontal or vertical floor mounted.

Ceiling suspended, exposed type includes basic DYC, plus a

cabinet with removable access panels lined with 1/2 fibre glass

insulation. Units are supplied with 1 cleanable filter. Units are

painted with electrostatically applied polyster powder coat and

can be supplied with supply and return air grilles on request.

1. DYC

4. DYF

Ceiling suspended, concealed application with DX or chilled

water coils.

Floor mounted, vertical supply with 1 cleanable filter. Units

can be supplied with supply and return grill on request with

electrostatic polyster powder coat, oven-baked. Units have

a removable access panel to provide complete access to coil

and motor blower section.

All units can be supplied for either free or ducted air delivery.

2. DYP

Ceiling suspended for concealed applications, includes a

factory installed plenum. The plenum is lined with 1/2 glass

fibre insulation. Units are supplied with 1 cleanable filter as

standard.

DYC

For options available, refer to page 4-5.

SUPPLY

GRILL

RETUR N AIR

DYP

SUPPLY

GRILL

FR EE

RETURN

RETURN AIR

DYE

SUPPLY

GRILL

FREE

RETURN

RETURN AIR

DYE

FREE S UPPLY

FREE R ETURN

SUPPLY AIR

FREE

RETURN

(GRILLS OPTIONAL)

DUCTED

SUPPLY

GRILL

SUPPLY

GRILL

DYF

Figure 3

RETURN AIR

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Physical & Electrical Data

Unit Size

cfm

l/s

inch

mm

inch

mm

ft

m

#

Watts

#

Nominal Airflow Rate

Type

Fin Height

Coil

Fin Length

Face Area

Type

Code

Quantity

Type

Size

Quantity

Fan

50 Hz.

Speed

60 Hz.

Speed

Maximum Amps.

Motor

High

Medium

Low

High

Medium

Low

06

08

10

12

15

18

21

600

800

1000

1200

1500

1800

2100

283

378

472

566

708

849

991

Copper tubes mechanically bonded to Hi-Efficiency wavy corrugated Aluminium Fins

12

12

16

12

12

16

16

305

305

406

305

305

406

406

20

24

24

36

42

42

48

508

610

610

914

1067

1067

1219

1.7

2.0

2.7

3.0

3.5

4.7

5.3

0.15

0.19

0.25

0.28

0.33

0.43

0.50

Double Inlet Double Width Centrifugal Forward Curve Direct Drive

7-7

7-7

9-7

7-7

7-7

9-7

9-7

1

1

1

2

2

2

2

220-240V/1Ph/50-60Hz, 3 Speed Electric Motor with Permanent Split Capacitor

150

150

150

150

150

150

150

1

1

1

2

2

2

2

1.10

1.15

1.22

2.20

2.30

2.44

2.80

0.80

0.80

0.75

1.60

1.60

1.50

1.70

0.60

0.60

0.50

1.20

1.20

1.00

1.00

1.12

1.22

1.40

2.24

2.40

2.80

3.20

0.80

0.80

0.80

1.60

1.60

1.60

1.80

0.50

0.60

0.50

1.00

1.20

1.00

1.00

Table 2

Nominal Capacity Ratings

Models DYC, DYP, DYE & DYF

Chilled Water Coils

3 Rows

Size

06

08

10

12

15

18

21

Nominal Airflow

Rate

Total

Capacity

4 Rows

Water

Sensible Water Flow

Pressure

Capacity

Rate

Drop

Total

Capacity

6 Rows

Water

Sensible Water Flow

Pressure

Capacity

Rate

Drop

Total

Capacity

Water

Sensible Water Flow

Pressure

Capacity

Rate

Drop

cfm

MBh

MBh

gpm

ftwg

MBh

MBh

gpm

ftwg

MBh

MBh

gpm

ftwg

l/s

600

283

800

378

1000

472

1200

566

1500

708

1800

849

2100

991

kW

16.1

4.7

21.1

6.2

27.1

8.0

30.0

8.8

37.5

11.0

47.4

13.9

51.5

15.1

kW

11.3

3.3

14.7

4.3

18.8

5.5

21.5

6.3

26.6

7.8

33.2

9.7

37.3

10.9

l/s

3.2

0.2

4.2

0.3

5.4

0.3

6.0

0.4

7.5

0.5

9.5

0.6

10.3

0.7

kPa

7.5

22.3

13.0

38.7

12.2

36.3

5.5

16.3

8.7

26.1

7.9

23.7

3.7

11.1

kW

20.1

5.9

25.3

7.4

31.9

9.4

38.0

11.1

45.1

13.2

55.3

16.2

65.6

19.2

kW

13.6

4.0

17.4

5.1

22.0

6.4

26.1

7.7

31.5

9.2

38.6

11.3

45.4

13.3

l/s

4.0

0.3

5.1

0.3

6.4

0.4

7.6

0.5

9.0

0.6

11.1

0.7

13.1

0.8

kPa

13.3

39.7

10.7

32.0

7.2

21.7

9.9

29.5

7.2

21.6

4.7

14.0

6.8

20.2

kW

23.8

7.0

31.6

9.3

40.3

11.8

47.3

13.9

58.3

17.1

71.9

21.1

85.0

24.9

kW

15.9

4.7

21.1

6.2

26.8

7.9

31.6

9.3

39.0

11.4

47.9

14.0

56.3

16.5

l/s

4.8

0.3

6.3

0.4

8.1

0.5

9.5

0.6

11.7

0.7

14.4

0.9

17.0

1.1

kPa

4.2

12.7

7.6

22.8

7.1

21.1

7.0

21.0

8.5

25.4

6.6

19.6

9.5

28.3

Table 3

Notes:

Chilled water capacity ratings are based on nominal air flow rate; air entering temperature DB/WB 80/67oF (26.5/19.4oC), 45oF

(7.2oC) entering chilled water temperature and 10oF (5.5oC) water temperature rise.

For conditions other than rated, use SKM FCU Computer Selection Software.

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Nominal Capacity Ratings

Models DYC, DYP, DYE & DYF

Size

06

08

10

12

15

18

21

Direct Expansion Coil (R-22)

3 Rows

4 Rows

6 Rows

Nominal Airflow

Rate

Total Capacity

Sensible Capacity

Total Capacity

Sensible Capacity

Total Capacity

Sensible Capacity

cfm

l/s

600

283

800

378

1000

472

1200

566

1500

708

1800

849

2100

991

MBh

kW

21.2

6.2

26.7

7.8

34.6

10.1

40.1

11.8

48.3

14.2

61.3

18.0

70.8

20.8

MBh

kW

13.2

3.9

16.8

4.9

21.6

6.3

25.2

7.4

30.6

9.0

38.4

11.3

44.4

13.0

MBh

kW

24.9

7.3

31.8

9.3

40.8

12.0

47.7

14.0

57.9

17.0

72.7

21.3

84.1

24.6

MBh

kW

15.5

4.5

19.9

5.8

25.4

7.5

29.9

8.8

36.4

10.7

45.3

13.3

52.5

15.4

MBh

kW

29.3

8.6

37.8

11.1

48.2

14.1

56.7

16.6

69.4

20.3

86.1

25.2

99.8

29.2

MBh

kW

18.2

5.3

23.7

6.9

30.1

8.8

35.5

10.4

43.6

12.8

53.7

15.8

62.3

18.3

Table 4

Note :

Direct expansion capacity ratings based on nominal air flow rate, air entering temperature, 80/67oF (26.5/19.4oC) DB/WB, 40oF

(4.4oC) evaporating temperature.

Nominal Capacity Ratings

Models DYC, DYP, DYE & DYF

Size

06

08

10

12

15

18

21

Nominal

Airflow

Rate

Hot Water Coil

1 Row

2 Rows

3 Rows

Water

Total

Water Flow

Pressure

Capacity

Rate

Drop

Water

Total

Water Flow

Pressure

Capacity

Rate

Drop

Water

Total

Water Flow

Pressure

Capacity

Rate

Drop

cfm

MBh

gpm

ftwg

MBh

gpm

ftwg

MBh

gpm

ftwg

l/s

600

283

800

378

1000

472

1200

566

1500

708

1800

849

2100

991

kW

23.0

6.8

29.3

8.6

36.9

10.8

43.0

12.6

52.2

15.3

66.5

19.5

77.7

22.8

l/s

2.3

0.2

2.9

0.2

3.7

0.2

4.3

0.3

5.2

0.3

6.7

0.4

7.8

0.5

kPa

4.0

11.9

6.8

20.2

2.6

7.6

3.3

10.0

5.0

15.0

4.6

13.6

6.5

19.4

kW

39.1

11.5

50.5

14.8

64.4

18.9

75.8

22.2

88.0

25.8

111.0

32.5

129.1

37.9

l/s

3.9

0.3

5.1

0.3

6.4

0.4

7.6

0.5

8.8

0.6

11.1

0.7

12.9

0.8

kPa

6.7

20.0

12.9

38.4

8.4

25.0

12.6

37.5

3.1

9.4

2.8

8.3

3.9

11.8

kW

49.0

14.4

63.7

18.7

81.5

23.9

95.6

28.0

117.8

34.5

146.8

43.0

171.2

50.2

l/s

4.9

0.3

6.4

0.4

8.2

0.5

9.6

0.6

11.8

0.7

14.7

0.9

17.1

1.1

kPa

4.3

12.9

8.2

24.6

7.4

22.2

8.0

23.9

13.9

41.5

11.7

34.9

17.7

52.8

Table 5

Note :

Table 5 data based on Nominal Air Flow, 70 oF (21.1oC) entering air temperature, 180/160oF (82.2/71.1oC) entering/leaving hot water

temperature. For other conditions use SKM FCU selection software.

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Air Flow Correction Factors

(Other than nominal air flow)

1.4

1.3

1.2

1.1

1.0

TOTAL CAPACITY

0.9

0.8

0.7

SENSIBLE CAPACITY

0.6

0.5

0.4

0.3

40

30

50

60

70

80

90

100

110

120

140

130

Actual Air

Flow / Nom.

Air Flow %

Total Cooling Capacity

Ft

Sensible Capacity

(Cooling or Heating)

Fs

30

40

50

60

70

80

90

100

110

120

130

140

150

0.43

0.53

0.62

0.70

0.78

0.86

0.94

1.00

1.07

1.13

1.19

1.26

1.33

0.38

0.47

0.57

0.67

0.76

0.85

0.93

1.00

1.07

1.14

1.21

1.28

1.30

Table 6

150

ACTUAL AIR FLOW / NOMINAL AIR FLOW %

Figure 4

Altitude Correction Factors

1.0

Elevation

0.96

Ft.

1000

2000

4000

5000

6000

SENSIBLE CAPACITY

TOTAL CAPACITY

0.92

0.88

m

305

610

1219

1525

1829

Total

Capacity

Sensible

Capacity

0.99

0.97

0.95

0.94

0.92

0.96

0.92

0.84

0.80

0.76

Table 7

0.84

0.80

0

1000

2000

3000

4000

5000

6000 Ft.

305

610

915

1219

1525

1829 Mtr.

ELEVATION

Figure 5

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Sound Data

50 Hz

Sound Power Level dB(A)

Size

10

12

15

18

21

Speed

4 Rows

3 Rows

125

53.6

51.1

45.8

49.3

49.0

43.2

46.6

45.0

43.0

54.6

52.1

46.8

50.3

50.0

44.2

47.6

46.0

44.0

58.3

56.8

250

55.4

52.2

46.3

61.5

56.1

52.6

60.0

55.1

51.1

56.4

53.2

47.3

62.5

57.1

53.6

61.0

56.1

52.1

63.5

60.0

500

59.4

56.9

52.8

60.4

57.2

53.8

61.3

58.3

54.3

60.4

57.9

53.8

61.4

58.2

54.8

62.3

59.3

55.3

64.5

66.1

1K

62.8

59.4

49.4

62.1

58.2

53.8

62.8

53.8

53.3

63.8

60.4

50.4

63.1

59.2

54.8

63.8

54.8

54.3

66.3

64.8

2K

59.1

55.5

48.5

60.7

55.4

49.7

59.9

55.8

49.2

60.1

56.5

49.5

61.7

56.4

50.7

60.9

56.8

50.2

68.5

67.3

4K

57.2

53.0

45.0

58.1

52.8

46.0

57.8

52.0

47.0

58.2

54.0

46.0

59.1

53.8

47.0

58.8

53.0

48.0

68.4

66.8

8K

51.3

46.4

36.5

51.6

45.0

36.7

45.6

40.6

35.5

52.3

47.4

37.5

52.6

46.0

37.7

46.6

41.6

36.5

58.7

56.8

A

66.8

63.5

56.7

67.9

63.5

59.1

67.7

62.6

58.9

67.8

64.5

57.7

68.9

64.5

60.1

68.7

63.6

59.9

73.9

72.8

125

53.7

51.3

46.3

49.3

49.0

43.4

46.2

44.6

42.6

54.7

52.3

47.3

50.3

50.0

44.4

47.2

45.6

43.6

58.2

56.7

250

55.5

52.4

46.6

61.5

56.0

52.8

59.5

54.6

50.6

56.5

53.4

47.6

62.5

57.0

53.8

60.5

55.6

51.6

63.4

59.8

500

59.4

57.0

53.0

60.3

57.2

53.8

60.8

57.8

53.8

60.4

58.0

54.0

61.3

58.2

54.8

61.8

58.8

54.8

64.1

65.2

1K

62.8

59.4

54.0

62.1

58.3

54.0

62.2

53.2

52.7

63.8

60.4

55.0

63.1

59.3

55.0

63.2

54.2

53.7

65.8

64.5

2K

59.0

53.2

49.0

60.6

55.5

50.0

59.2

55.1

48.5

60.0

54.2

50.0

61.6

56.5

51.0

60.2

56.1

49.5

67.9

66.9

6 Rows

4K

57.1

53.1

45.6

58.0

52.8

46.1

57.2

51.4

46.4

58.1

54.1

46.6

59.0

53.8

47.1

58.2

52.4

47.4

67.7

66.3

8K

51.2

46.5

37.2

51.5

44.9

37.0

44.1

40.1

35.0

52.2

47.5

38.2

52.5

45.9

38.0

45.1

41.1

36.0

57.9

56.3

A

66.8

63.3

58.2

67.9

63.5

59.3

67.2

62.0

58.3

67.8

64.3

59.2

68.9

64.5

60.3

68.2

63.0

59.3

73.4

72.3

125

53.8

51.5

46.9

49.2

48.9

43.7

44.0

42.4

40.4

54.8

52.5

47.9

50.2

49.9

44.7

45.0

43.4

41.4

58.1

56.6

250

55.6

52.5

47.2

61.4

56.1

53.1

56.6

51.7

47.7

56.6

53.5

48.2

62.4

57.1

54.1

57.6

52.7

48.7

63.3

59.4

500

59.4

57.0

53.3

60.2

57.3

53.9

57.9

54.9

50.9

60.4

58.0

54.3

61.2

58.3

54.9

58.9

55.9

51.9

63.3

63.4

1K

62.8

59.4

54.5

62.1

58.4

54.3

59.2

50.2

49.7

63.8

60.4

55.5

63.1

59.4

55.3

60.2

51.2

50.7

65.0

63.9

2K

59.0

55.7

49.8

60.5

55.6

50.6

56.4

52.3

45.7

60.0

56.7

50.8

61.5

56.6

51.6

57.4

53.3

46.7

67.0

66.2

4K

57.1

53.2

46.4

57.9

52.8

46.3

54.4

48.6

43.6

58.1

54.2

47.4

58.9

53.8

47.3

55.4

49.6

44.6

66.4

65.4

8K

51.2

46.5

37.2

51.5

44.9

37.0

45.1

40.1

35.0

52.2

47.5

38.2

52.5

45.9

38.0

46.1

41.1

36.0

57.9

56.3

A

66.8

63.7

58.7

67.8

63.6

59.6

64.3

59.2

55.4

67.8

64.7

59.7

68.8

64.6

60.6

65.3

60.2

56.4

72.6

71.5

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low 54.4 58.0 65.7 62.7 65.2 64.2 53.8 71.0 54.5 58.1 65.3 62.6 65.1 64.0 53.7 70.8 54.6 58.1 64.6 62.5 64.9 63.7 53.7 70.5

Table 8

* Based on 0.2 in.Wg (50 Pa) External Static Pressure

Casing Attenuation

125

250

500

1000

2000

4000

8000

DYP, DYE, DYF

DYC

10

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Sound Data

60 Hz

Sound Power Level dB(A)

Size

10

12

15

18

21

Speed

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

3 Rows

125

48.3

45.6

38.9

47.8

47.6

38.1

48.0

47.7

38.2

49.3

46.6

39.9

48.8

48.6

39.1

45.2

30.3

24.1

52.0

49.1

39.0

250

56.0

50.4

47.3

60.1

53.1

46.3

59.1

52.2

45.5

57.0

51.4

48.3

61.1

54.1

47.3

55.9

36.9

30.7

63.1

60.3

50.0

500

59.2

52.4

47.7

59.5

56.8

50.8

60.8

58.1

51.9

60.2

53.4

48.7

60.5

57.8

51.8

56.5

38.0

32.9

64.1

62.0

53.7

1K

60.6

52.8

45.8

61.2

56.5

49.7

62.9

58.1

51.1

61.6

53.8

46.8

62.2

57.2

50.7

59.3

39.2

33.2

67.2

64.1

54.1

2K

54.5

46.9

37.2

59.2

53.1

45.6

60.0

53.8

46.2

55.5

47.9

41.3

60.2

54.1

46.6

56.7

37.5

31.2

65.4

61.2

50.8

6 Rows

4 Rows

4K

50.9

43.2

32.2

56.4

50.6

42.3

58.1

52.1

43.5

51.9

44.2

36.6

56.4

51.6

43.3

55.6

36.3

29.6

64.4

59.3

48.2

8K

42.0

34.6

22.9

49.8

41.4

30.9

45.8

38.1

28.4

43.0

35.6

27.0

50.8

42.4

31.9

45.7

29.0

22.6

53.7

47.0

36.5

A

64.6

57.7

52.2

66.7

61.8

55.0

67.5

62.8

55.9

65.6

58.7

53.4

67.6

62.7

56.0

64.1

45.0

39.0

72.2

68.8

59.0

125

48.3

46.4

39.0

47.9

47.2

37.8

48.1

47.4

38.0

49.3

47.4

40.0

48.9

48.2

38.8

45.3

30.3

23.9

52.1

49.0

39.0

250

56.0

48.3

47.3

60.3

52.6

46.3

59.1

51.6

45.4

57.0

49.3

48.3

61.3

53.6

47.3

55.9

36.9

30.4

63.0

60.0

50.0

500

59.2

52.6

47.7

59.5

56.3

50.8

60.8

57.6

51.9

60.2

53.6

48.7

60.5

57.3

51.8

56.5

38.0

32.5

64.0

61.7

53.7

1K

60.6

53.0

45.9

61.3

56.0

49.9

62.9

57.5

51.2

61.6

54.0

46.9

62.3

57.0

50.9

59.4

39.2

32.8

67.1

63.8

54.1

2K

54.5

53.2

37.4

59.3

52.6

45.5

60.0

53.3

46.1

55.5

54.2

38.4

60.3

53.6

46.5

56.7

37.5

30.8

65.2

60.9

50.8

4K

50.9

43.5

32.4

56.4

50.1

42.2

58.1

51.7

43.4

51.9

44.5

33.4

57.4

51.1

43.2

55.7

36.3

29.3

64.1

59.0

48.2

8K

42.0

35.0

23.1

49.8

41.1

30.9

45.9

37.8

28.5

43.0

36.0

24.1

47.8

42.1

31.9

45.7

29.0

22.4

53.3

46.8

36.5

A

64.6

58.6

52.2

66.8

62.3

55.0

67.6

62.3

55.9

65.6

59.6

53.2

67.7

62.3

56.1

64.2

45.0

38.6

72.0

68.5

59.0

125

48.0

47.7

39.0

47.9

46.3

37.4

48.0

46.4

37.5

49.0

48.7

40.0

48.9

47.3

38.4

45.2

30.4

23.3

51.8

48.3

39.0

250

55.7

49.3

47.4

60.7

51.6

46.4

59.1

50.3

45.2

56.7

50.3

48.4

61.7

52.6

47.4

55.9

37.1

29.7

63.1

59.1

50.0

500

58.9

53.0

47.9

59.6

55.3

50.8

60.8

56.4

51.8

59.9

54.0

48.9

60.6

56.3

51.8

56.5

38.2

31.8

64.0

60.8

53.7

1K

60.2

53.5

46.2

61.5

55.0

50.2

62.9

56.2

51.3

61.2

54.5

47.2

62.5

56.0

51.2

59.3

39.4

32.1

67.1

62.9

54.1

2K

54.2

47.8

37.8

59.4

51.6

45.3

60.0

52.1

45.7

55.2

48.8

38.8

60.4

52.6

46.3

56.7

37.7

30.2

64.8

60.0

50.8

4K

50.7

44.1

32.9

56.5

49.2

42.0

58.1

50.6

43.2

51.7

45.1

33.9

57.5

50.2

43.0

55.6

36.5

28.7

63.6

58.2

48.2

8K

41.0

34.0

22.1

49.8

40.1

29.9

44.9

36.1

27.0

43.0

36.0

24.1

50.8

42.1

31.9

45.7

29.0

22.4

53.3

46.8

36.5

A

64.3

58.2

52.4

67.0

60.3

55.1

67.5

61.1

55.8

65.2

59.2

53.4

68.0

61.3

56.1

64.1

45.1

38.0

71.9

67.6

59.0

Table 9

* Based on 0.2 in.Wg (50 Pa) External Static Pressure

Casing Attenuation

125

250

500

1000

2000

4000

8000

DYP, DYE, DYF

DYC

Air Conditioning Equipment . Built in the Gulf... for the World

11

SKM Fan Coil Units

Hi-Static Fan Coil Units

Air Flow Rates (50 Hz)

Model DYC

Nom

AFR

Size

cfm

l/s

06

600

283

08

800

378

3 Rows

Speed

DYC

6

8

10

High

12

15

18

21

6

8

10

Medium

12

15

18

21

6

8

10

Low

12

15

18

21

inwg

Pa

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

0.1

25

683

322

793

374

1035

488

1311

619

1526

720

1923

907

2250

1062

507

239

593

280

699

330

1009

476

1231

581

1401

661

1612

761

387

183

465

219

454

214

758

358

944

445

950

448

1086

512

0.2

50

665

314

764

361

983

464

1279

604

1487

702

1809

854

2110

996

490

231

579

273

710

335

976

461

1202

567

1398

660

1607

758

369

174

445

210

459

217

718

339

902

426

974

460

1113

525

0.3

75

645

304

740

349

912

430

1241

586

1449

684

1666

786

1938

915

469

221

562

265

695

328

934

441

1167

551

1345

635

1545

729

338

160

423

200

464

219

656

310

856

404

959

453

1096

517

10

1000

472

12

1200

566

15

1500

708

4 Rows

External Static Pressure

0.4

100

619

292

717

338

826

390

1191

562

1403

662

1501

708

1742

822

439

207

540

255

655

309

871

411

1119

528

1250

590

1434

677

301

142

398

188

433

204

581

274

802

378

864

408

988

466

0.1

25

674

318

780

368

1017

480

1295

611

1506

711

1875

885

2189

1033

502

237

589

278

703

332

998

471

1221

576

1405

663

1617

763

385

182

461

218

453

214

752

355

935

441

952

449

1088

513

0.2

50

657

310

754

356

959

453

1261

595

1469

693

1754

828

2041

963

485

229

575

271

709

335

965

455

1192

563

1389

655

1596

753

364

172

441

208

460

217

708

334

893

421

977

461

1116

527

0.3

75

636

300

732

345

885

418

1220

576

1429

674

1611

760

1870

882

463

218

558

263

689

325

919

434

1154

545

1325

625

1521

718

333

157

419

198

463

218

645

304

846

399

951

449

1086

512

18

1800

849

21

2100

991

6 Rows

0.4

100

607

286

707

334

800

378

1165

550

1379

651

1449

684

1679

792

431

203

534

252

645

304

851

402

1102

520

1225

578

1405

663

296

140

394

186

427

202

571

269

793

374

849

401

970

458

0.1

25

633

299

758

358

952

449

1236

583

1469

693

1786

843

1904

898

463

218

582

275

687

324

918

433

1201

567

1377

650

1373

648

366

173

455

215

443

209

725

342

917

433

890

420

887

419

0.2

50

614

290

737

348

893

421

1199

566

1432

676

1659

783

1785

842

446

210

567

268

685

323

884

417

1168

551

1340

632

1370

647

344

162

435

205

453

214

677

319

875

413

912

430

906

428

0.3

75

591

279

714

337

822

388

1151

543

1386

654

1518

716

1644

776

424

200

548

259

659

311

836

395

1124

530

1266

597

1318

622

314

148

413

195

451

213

614

290

828

391

883

417

902

426

0.4

100

559

264

685

323

742

350

1087

513

1325

625

1363

643

1483

700

392

185

521

246

612

289

767

362

1064

502

1163

549

1226

579

279

132

387

183

410

193

544

257

773

365

785

370

821

387

Table 10

12

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Air Flow Rates (50 Hz)

Model DYP, DYE & DYF

Nom

AFR

Speed

DYP

DYE

DYF

6

8

10

High

12

15

18

21

6

8

10

Medium

12

15

18

21

6

8

10

Low

12

15

18

21

Size

cfm

l/s

06

600

283

08

800

378

3 Rows

10

1000

472

12

1200

566

15

1500

708

4 Rows

18

1800

849

21

2100

991

6 Rows

External Static Pressure

inwg

0.1

0.2

0.3

0.4

0.1

0.2

0.3

0.4

0.1

0.2

0.3

0.4

Pa

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

25

671

317

775

366

1007

475

1289

608

1499

707

1855

875

2163

1021

500

236

587

277

705

333

993

469

1216

574

1406

663

1617

763

384

181

459

217

453

214

748

353

930

439

953

450

1089

514

50

653

308

750

354

947

447

1254

592

1462

690

1730

816

2012

949

482

227

573

270

708

334

959

453

1186

560

1382

652

1588

749

362

171

440

208

461

218

702

331

888

419

977

461

1117

527

75

631

298

728

344

872

411

1211

571

1420

670

1585

748

1839

868

460

217

555

262

685

323

911

430

1146

541

1313

620

1507

711

331

156

418

197

462

218

639

302

841

397

946

446

1081

510

100

601

284

702

331

786

371

1153

544

1368

646

1423

672

1648

778

426

201

531

251

639

302

839

396

1092

515

1210

571

1389

655

295

139

393

185

426

201

566

267

787

371

842

397

962

454

25

663

313

764

361

986

465

1272

600

1480

698

1805

852

2099

991

495

234

583

275

708

334

983

464

1206

569

1405

663

1615

762

381

180

456

215

452

213

741

350

921

435

957

452

1093

516

50

644

304

741

350

922

435

1235

583

1443

681

1678

792

1948

919

478

226

569

269

705

333

946

446

1174

554

1368

646

1571

741

358

169

436

206

462

218

692

327

879

415

978

462

1117

527

75

620

293

719

339

848

400

1187

560

1399

660

1535

724

1779

840

453

214

550

260

677

319

894

422

1131

534

1292

610

1482

699

326

154

414

195

461

218

629

297

832

393

935

441

1069

504

100

588

277

691

326

763

360

1124

530

1340

632

1377

650

1594

752

417

197

524

247

629

297

819

386

1073

506

1186

560

1359

641

291

137

389

184

421

199

557

263

778

367

827

390

945

446

25

622

294

745

352

922

435

1213

572

1445

682

1715

809

1845

871

457

216

576

272

689

325

905

427

1186

560

1367

645

1378

650

362

171

450

212

443

209

713

336

904

427

894

422

887

419

50

602

284

725

342

861

406

1170

552

1403

662

1589

750

1721

812

439

207

560

264

679

320

867

409

1148

542

1315

621

1358

641

338

160

430

203

455

215

662

312

861

406

912

430

909

429

75

576

272

700

330

790

373

1116

527

1350

637

1450

684

1580

746

415

196

539

254

647

305

814

384

1099

519

1233

582

1294

611

308

145

407

192

447

211

600

283

813

384

870

411

895

422

100

541

255

667

315

711

336

1046

494

1282

605

1302

614

1423

672

381

180

511

241

598

282

742

350

1034

488

1127

532

1196

564

275

130

382

180

404

191

533

252

759

358

767

362

808

381

Table 11

Air Conditioning Equipment . Built in the Gulf... for the World

13

SKM Fan Coil Units

Hi-Static Fan Coil Units

Air Flow Rates (60 Hz)

Model DYC

Nom

AFR

Size

cfm

l/s

06

600

283

08

800

378

3 Rows

Speed

DYC

6

8

10

High

12

15

18

21

6

8

10

Medium

12

15

18

21

6

8

10

Low

12

15

18

21

inwg

Pa

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

0.1

25

563

266

733

346

945

446

1111

524

1451

685

1803

851

2141

1010

428

202

553

261

599

283

854

403

1149

542

1155

545

1326

626

310

146

429

202

503

237

602

284

869

410

986

465

1126

531

0.2

50

575

271

722

341

951

449

1129

533

1429

674

1813

856

2151

1015

411

194

534

252

569

269

817

386

1109

523

1124

530

1293

610

284

134

405

191

430

203

550

260

818

386

860

406

983

464

0.3

75

575

271

710

335

954

450

1125

531

1405

663

1812

855

2145

1012

386

182

514

243

577

272

767

362

1067

504

1165

550

1341

633

256

121

381

180

380

179

496

234

769

363

778

367

889

420

10

1000

472

12

1200

566

15

1500

708

4 Rows

External Static Pressure

0.4

100

566

267

696

328

948

447

1103

521

1377

650

1792

846

2116

999

359

169

493

233

608

287

710

335

1023

483

1225

578

1410

665

229

108

358

169

356

168

443

209

720

340

741

350

846

399

0.1

25

568

268

729

344

947

447

1121

529

1441

680

1808

853

2147

1013

425

201

549

259

591

279

847

400

1136

536

1143

539

1313

620

307

145

426

201

493

233

595

281

859

405

965

455

1103

521

0.2

50

576

272

718

339

953

450

1130

533

1418

669

1814

856

2150

1015

406

192

530

250

568

268

807

381

1097

518

1127

532

1297

612

281

133

401

189

424

200

543

256

809

382

848

400

970

458

0.3

75

573

270

705

333

953

450

1118

528

1393

657

1806

852

2135

1008

382

180

510

241

581

274

756

357

1055

498

1179

556

1357

640

254

120

378

178

377

178

491

232

761

359

772

364

883

417

18

1800

849

21

2100

991

6 Rows

0.4

100

560

264

690

326

944

445

1091

515

1363

643

1778

839

2095

989

354

167

489

231

613

289

700

330

1011

477

1233

582

1418

669

227

107

355

168

355

168

439

207

713

336

739

349

844

398

0.1

25

546

258

721

340

913

431

1096

517

1420

670

1833

865

1826

862

393

185

540

255

566

267

779

368

1113

525

1108

523

1132

534

291

137

418

197

470

222

572

270

840

396

892

421

940

444

0.2

50

548

259

709

335

916

432

1091

515

1396

659

1826

862

1833

865

374

176

521

246

551

260

740

349

1074

507

1114

526

1102

520

267

126

395

186

407

192

523

247

793

374

787

371

815

385

0.3

75

540

255

695

328

913

431

1070

505

1368

646

1799

849

1826

862

352

166

502

237

571

269

693

327

1032

487

1177

555

1141

538

241

114

372

176

366

173

473

223

746

352

718

339

731

345

0.4

100

524

247

679

320

900

425

1035

488

1334

630

1754

828

1800

849

327

154

481

227

600

283

642

303

988

466

1212

572

1201

567

216

102

350

165

346

163

424

200

701

331

689

325

693

327

Table 12

14

Air Conditioning Equipment . Built in the Gulf... for the World

SKM Fan Coil Units

Hi-Static Fan Coil Units

Air Flow Rates (60 Hz)

Model DYP, DYE & DYF

Nom

AFR

Speed

DYP

DYE

DYF

6

8

10

High

12

15

18

21

6

8

10

Medium

12

15

18

21

6

8

10

Low

12

15

18

21

Size

cfm

l/s

06

600

283

08

800

378

3 Rows

10

1000

472

12

1200

566

15

1500

708

4 Rows

18

1800

849

21

2100

991

6 Rows

External Static Pressure

inwg

0.1

0.2

0.3

0.4

0.1

0.2

0.3

0.4

0.1

0.2

0.3

0.4

Pa

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

cfm

l/s

25

570

269

727

343

949

448

1124

530

1437

678

1810

854

2148

1014

424

200

546

258

588

277

842

397

1130

533

1138

537

1307

617

306

144

424

200

489

231

592

279

853

403

956

451

1092

515

50

576

272

715

337

953

450

1129

533

1414

667

1814

856

2149

1014

404

191

527

249

568

268

801

378

1091

515

1130

533

1300

613

280

132

400

189

423

200

541

255

804

379

844

398

964

455

75

571

269

703

332

952

449

1115

526

1388

655

1802

850

2129

1005

379

179

507

239

584

276

750

354

1049

495

1187

560

1367

645

254

120

377

178

377

178

489

231

757

357

771

364

881

416

100

558

263

687

324

941

444

1084

512

1357

640

1770

835

2085

984

352

166

487

230

616

291

694

327

1005

474

1235

583

1421

671

228

108

354

167

355

168

439

207

710

335

738

348

844

398

25

574

271

723

341

951

449

1129

533

1426

673

1813

856

2151

1015

420

198

542

256

582

275

833

393

1118

528

1131

534

1300

613

303

143

420

198

481

227

585

276

844

398

938

443

1072

506

50

576

272

711

336

954

450

1125

531

1403

662

1811

855

2143

1011

400

189

523

247

568

268

790

373

1079

509

1137

537

1309

618

277

131

397

187

417

197

535

252

796

376

833

393

952

449

75

568

268

698

329

949

448

1104

521

1375

649

1791

845

2113

997

375

177

503

237

589

278

739

349

1037

489

1201

567

1383

653

251

118

374

176

375

177

484

228

750

354

766

361

875

413

100

551

260

682

322

935

441

1069

504

1342

633

1752

827

2060

972

348

164

483

228

619

292

685

323

993

469

1237

584

1422

671

226

107

351

166

354

167

434

205

704

332

737

348

842

397

25

548

259

714

337

915

432

1095

517

1405

663

1830

864

1831

864

388

183

534

252

560

264

767

362

1096

517

1102

520

1119

528

287

135

413

195

460

217

563

266

826

390

871

411

919

434

50

545

257

702

331

916

432

1081

510

1379

651

1812

855

1832

865

369

174

515

243

552

260

726

343

1056

498

1129

533

1105

521

264

125

391

185

402

190

516

244

781

369

775

366

804

379

75

534

252

687

324

908

428

1053

497

1348

636

1775

838

1815

856

346

163

495

234

579

273

680

321

1015

479

1196

564

1157

546

239

113

369

174

364

172

467

220

736

347

713

336

727

343

100

515

243

669

316

890

420

1012

478

1311

619

1720

812

1779

840

322

152

475

224

604

285

631

298

971

458

1208

570

1209

571

215

101

347

164

346

163

420

198

691

326

687

324

692

327

Table 13

Air Conditioning Equipment . Built in the Gulf... for the World

15

SKM Fan Coil Units

Hi-Static Fan Coil Units

Chilled Water

Capacity Ratings (DYP - 3 Rows)

50 Hz

Size

Speed

High

Medium

Low

High

Medium

Low

High

10

Medium

Low

High

12

Medium

Low

High

15

Medium

Low

High

18

Medium

Low

High

21

Medium

Low

ESP

inwg

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

0.1

0.2

0.3

Air Flow Rate Total Capacity

Pa

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

25

50

75

cfm

671

653

631

500

482

460

384

362

331

775

750

728

587

573

555

459

440

418

1007

947

872

705

708

685

453

461

462

1289

1254

1211

993

959

911

748

702

639

1499

1462

1420

1216

1186

1146

930

888

841

1855

1730

1585

1406

1382

1313

953

977

946

2163

2012

1839

1617

1588

1507

1089

1117

1081

l/s

317

308

298

236

227

217

181

171

156

366

354

344

277

270

262

217

208

197

475

447

411

333

334

323

214

218

218

608

592

571

469

453

430

353

331

302

707

690

670

574

560

541

439

419

397

875

816

748

663

652

620

450

461

446

1021

949

868

763

749

711

514

527

510

MBh

17.13

16.88

16.58

14.64

14.35

14.00

12.76

12.38

11.83

20.70

20.34

20.02

18.12

17.92

17.67

15.94

15.58

15.15

27.22

26.36

25.37

22.94

22.99

22.58

18.02

18.20

18.22

31.13

30.68

30.13

27.12

26.60

25.85

23.34

22.62

21.60

37.44

36.97

36.44

33.68

33.22

32.61

29.17

28.47

27.68

48.11

46.47

44.35

41.58

41.19

40.08

33.92

34.37

33.79

52.35

50.26

47.81

44.55

44.14

43.01

36.87

37.31

36.74

kW

5.02

4.95

4.86

4.29

4.21

4.10

3.74

3.63

3.47

6.07

5.96

5.87

5.31

5.25

5.18

4.67

4.57

4.44

7.98

7.73

7.44

6.72

6.74

6.62

5.28

5.33

5.34

9.12

8.99

8.83

7.95

7.80

7.58

6.84

6.63

6.33

10.97

10.84

10.68

9.87

9.74

9.56

8.55

8.35

8.11

14.10

13.62

13.00

12.19

12.07

11.75

9.94

10.07

9.90

15.34

14.73

14.01

13.06

12.94

12.61

10.81

10.94

10.77

Sensible

Capacity

60 Hz

Water Flow

Rate

MBh

kW

gpm

12.12 3.55 3.43

11.91 3.49 3.38

11.65 3.41 3.32

10.02 2.94 2.93

9.79 2.87 2.87

9.50 2.78 2.80

8.46 2.48 2.55

8.14 2.39 2.48

7.69 2.25 2.37

14.39 4.22 4.14

14.09 4.13 4.07

13.83 4.05 4.00

12.14 3.56 3.62

11.97 3.51 3.58

11.74 3.44 3.53

10.37 3.04 3.19

10.09 2.96 3.12

9.76 2.86 3.03

18.87 5.53 5.44

18.15 5.32 5.27

17.27 5.06 5.07

15.17 4.45 4.59

15.21 4.46 4.60

14.89 4.36 4.52

11.35 3.33 3.60

11.49 3.37 3.64

11.50 3.37 3.64

22.47 6.59 6.23

22.08 6.47 6.14

21.59 6.33 6.03

18.99 5.57 5.42

18.56 5.44 5.32

17.94 5.26 5.17

15.80 4.63 4.67

15.18 4.45 4.52

14.30 4.19 4.32

26.58 7.79 7.49

26.17 7.67 7.39

25.69 7.53 7.29

23.30 6.83 6.74

22.93 6.72 6.64