Professional Documents

Culture Documents

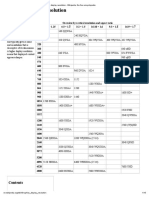

SR No Paper Name Sintering Alkali Activation Pelletization

Uploaded by

suraj1111Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SR No Paper Name Sintering Alkali Activation Pelletization

Uploaded by

suraj1111Copyright:

Available Formats

Sr No 1

Paper Name Properties of concrete made with alkaliactivated fly ash lightweight aggregate (AFLA):

Sintering

Alkali Activation ( for paste with 10% NaOH, 15% sodium silicate, and 5% MnO2, cured at room temperature after 24 h of moisture curing at 50 _C.) specific gravity 1.85 (SSD),and 1.66 (OD) water absorption 11.8%, unit weight 972 kg/m3, and solid volume 58.6%, compressive strength 33.9 MPa

Pelletization:

Manufacture and performance of lightweight aggregate from municipal solid waste incinerator fly ash and reservoir sediment for self-consolidating lightweight concrete:

maximum content of MSWI fly ash should be less than 30%. specific gravity 0.88 -1.69 g/cm3 crushing strength 13.43 MPa compressive strengths 25-55 MPa electrical resistivity 8.5 k .cm ultrasonic pulse velocity 3600 m/s,

Effect of lightweight fly ash aggregate microstructure On the strength of concretes Strength and elastic properties of structural lightweight concretes

fresh and oven-dry density LWC < 2000 kg/m3. modulus of elasticity LWC < normal-weight concrete. compressive strength LWC < normalweight concrete

Effects of cold-bonded fly ash aggregate properties on the shrinkage cracking of lightweight concretes Durability of lightweight concretes with lightweight fly ash aggregates

Optimization of properties of fly ash aggregates for highstrength lightweight concrete production

strength and modulus of elasticity LWAC < NWAC. Compressive - 42.3 MPa ,splitting tensile strength - 3.7 MPa and modulus of elasticity 19.6 GPa < LWBC and LWGC. 28-day water absorption ( 8.9 %) Water penetration (36 mm) fresh and oven-dry densities < 2000 kg/m3. specific gravity (1.52OD), water absorption (19.1%), crushing strength (4.9MPa). Slump, (15.5cm) Fresh density(1960 kg/m3) Air content (4.3 %) 28-day compressive strength (53.5 MPa)

10

Characteristics of lightweight concrete containing mineral admixtures Techno-commercial perspective study for sintered fly ash light-weight aggregates in India Effects of fly ash properties on characteristics of coldbonded fly

specific gravity density reduction of 85% in the water

ash lightweight aggregates

absorption. compressive strength 60 MPa specific gravity 1.78, water absorption 27% by weight,

Sr no Paper name Properties of concrete made 1 with alkali-activated fly ash lightweight aggregate (AFLA):

Process and result Alkali Activation: ( for paste with 10% NaOH, 15% sodium silicate, and 5% MnO2, cured at room temperature after 24 h of moisture curing at 50 _C.) specific gravity 1.85 (SSD),and 1.66 (OD) water absorption 11.8%, unit weight 972 kg/m3, and solid volume 58.6%, compressive strength 33.9 MPa Sintering: maximum content of MSWI fly ash should be less than 30%. specific gravity 0.88 -1.69 g/cm3 crushing strength 13.43 MPa compressive strengths 25-55 MPa electrical resistivity 8.5 k .cm ultrasonic pulse velocity 3600 m/s,

Manufacture and performance of lightweight aggregate from municipal solid waste incinerator fly ash and reservoir sediment for selfconsolidating lightweight concrete: Effect of lightweight fly ash aggregate microstructure On the strength of concretes Strength and elastic properties of structural lightweight concretes

Sintering: fresh and oven-dry density LWC < 2000 kg/m3. modulus of elasticity LWC < normal-weight concrete. compressive strength LWC < normal-weight concrete. Compressive strength 37.8 MPa modulus of elasticity 60.2 MPa 60% increase in the compressive strength, irrespective of w/c,

Effects of cold-bonded fly ash aggregate properties on the shrinkage cracking of lightweight concretes

As crushing strength then modulus of elasticity , splitting tensile strength lower free shrinkage and higher tensile strength 6 Durability of lightweight concretes with lightweight fly ash aggregates Sintering: strength and modulus of elasticity LWAC < NWAC. Compressive - 42.3 MPa ,splitting tensile strength - 3.7 MPa and modulus of elasticity 19.6 GPa < LWBC and LWGC. 28-day water absorption ( 8.9 %) Water penetration (36 mm) fresh and oven-dry densities < 2000 kg/m3. Sintering: specific gravity (1.52OD), water absorption (19.1%), crushing strength (4.9MPa). Slump, (15.5cm) Fresh density(1960 kg/m3) Air content (4.3 %) 28-day compressive strength (53.5 MPa) SLWAC with 515% silica fume on weight basis, caused up to 57% and 14% increase in compressive strength and modulus of elasticity, respectively, compared to mixes without silica fume. But, adding up to 10% fly ash, as partial cement replacement by weight, to the same mixes, caused about 18% decrease in compressive strength, with no change in modulus of elasticity, compared to mixes without fly ash.

Optimization of properties of fly ash aggregates for highstrength lightweight concrete production

Characteristics of lightweight concrete containing mineral admixtures

10

Techno-commercial perspective study for sintered fly ash light-weight aggregates in India Effects of fly ash properties on characteristics of cold-bonded fly ash lightweight aggregates

Pelletization: specific gravity - density reduction of 85% in the water absorption. compressive strength 60 MPa specific gravity 1.78, water absorption 27% by weight,

You might also like

- B777 ChecklistDocument2 pagesB777 ChecklistMarkus Schütz100% (1)

- Teacher Evaluation in A Blended Learning EnviornmentDocument11 pagesTeacher Evaluation in A Blended Learning Enviornmentapi-287748301No ratings yet

- Tribology of Polymeric Nanocomposites: Friction and Wear of Bulk Materials and CoatingsFrom EverandTribology of Polymeric Nanocomposites: Friction and Wear of Bulk Materials and CoatingsNo ratings yet

- Advanced English Communication Skills LaDocument5 pagesAdvanced English Communication Skills LaMadjid MouffokiNo ratings yet

- Product Details LightStrong AAC Block - ClientsDocument92 pagesProduct Details LightStrong AAC Block - ClientsYuki-Pauline NagatoNo ratings yet

- Estimation and Costing by M Chakraborty PDFDocument4 pagesEstimation and Costing by M Chakraborty PDFAakash Kamthane0% (3)

- BRKCCT-1002 Cisco Live Contact CenterDocument44 pagesBRKCCT-1002 Cisco Live Contact CenterArun GuptaNo ratings yet

- High Performance HTP eDocument14 pagesHigh Performance HTP ejohnny_cashedNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Cooling Tower 3DTrasar ManualDocument90 pagesCooling Tower 3DTrasar ManualArevaLemaNo ratings yet

- Bill of Materials SampleDocument31 pagesBill of Materials SampleOcsi YeahNo ratings yet

- Human Resouce ManagementDocument8 pagesHuman Resouce Managementsuraj1111No ratings yet

- Experimental Studies On High Perfirmance Concrete Using MetakaolinDocument25 pagesExperimental Studies On High Perfirmance Concrete Using Metakaolinచిమ్ముల సందీప్ రెడ్డిNo ratings yet

- Development of High Strength High Performance Concrete Using Indian MetakaolinDocument10 pagesDevelopment of High Strength High Performance Concrete Using Indian Metakaolindigvijay singhNo ratings yet

- Micro Silica in ConcreteDocument7 pagesMicro Silica in ConcreteFeraydoon NasratzadaNo ratings yet

- Experimental Investigations To Demonstrate The Influence of GGBS On Compressive Strength of Medium and High Strength ConcreteDocument7 pagesExperimental Investigations To Demonstrate The Influence of GGBS On Compressive Strength of Medium and High Strength ConcreteMallesh MaranurNo ratings yet

- Dharmendra Kumar Roll No 7259363Document27 pagesDharmendra Kumar Roll No 7259363Neeraj MehtaNo ratings yet

- Incorporation of Silica Fume in ConcreteDocument4 pagesIncorporation of Silica Fume in ConcreteNikhil JainNo ratings yet

- Nagarjuna College of Engineering and TechnologyDocument38 pagesNagarjuna College of Engineering and TechnologySaurav BaranwalNo ratings yet

- Light Weight ConcreteDocument5 pagesLight Weight Concretemanoj kaushikNo ratings yet

- Bean BallsDocument31 pagesBean BallsYathish143No ratings yet

- Mix DesignDocument27 pagesMix DesignSoni Mishra TiwariNo ratings yet

- High Strength Concrete Using Chemical AdmixtureDocument21 pagesHigh Strength Concrete Using Chemical AdmixtureYati AggarwalNo ratings yet

- Foam ConcreteDocument12 pagesFoam Concretealexnlima852No ratings yet

- Experimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Document11 pagesExperimental Study On Self Compacting Concrete SSC Using Ggbs and Fly Ash 1 11Shilpa ShiNo ratings yet

- Silica Fumes On M25Document7 pagesSilica Fumes On M25KARTIKNo ratings yet

- Mestrovic-Rpc MaterialDocument8 pagesMestrovic-Rpc MaterialB.R. MallurNo ratings yet

- Optimum Performance of Stabilized Ede Laterite As An Alternative Construction MaterialDocument8 pagesOptimum Performance of Stabilized Ede Laterite As An Alternative Construction MaterialBukunmiNo ratings yet

- Nano Materials IN Concrete: BY T Raj Kumar Reddy CE121535Document29 pagesNano Materials IN Concrete: BY T Raj Kumar Reddy CE121535Rajkumar ReddyNo ratings yet

- Experimental Study On Light Weight Concrete by Using Light Expanded Clay Aggregate (LECA)Document6 pagesExperimental Study On Light Weight Concrete by Using Light Expanded Clay Aggregate (LECA)IJRASETPublicationsNo ratings yet

- Cube Tests Doc-20181030-Wa0009Document6 pagesCube Tests Doc-20181030-Wa0009kundayi shavaNo ratings yet

- Concrete BasicsDocument6 pagesConcrete BasicstariqsingNo ratings yet

- Advancement in Concrete TechnnologyDocument12 pagesAdvancement in Concrete TechnnologypadmanabhanNo ratings yet

- Partial Replacement of Cement in Concrete With Sugarcane Bagasse AshDocument63 pagesPartial Replacement of Cement in Concrete With Sugarcane Bagasse AshManasa MadugulaNo ratings yet

- The Effect of Using Waste Glass WG As Partial ReplDocument6 pagesThe Effect of Using Waste Glass WG As Partial ReplLyjen MendizNo ratings yet

- 4.d.special ConcretesDocument16 pages4.d.special ConcretesArun KrishnaNo ratings yet

- Super Lightweight Magnesium Phosphate Cement Foamed ConcreteDocument33 pagesSuper Lightweight Magnesium Phosphate Cement Foamed ConcreteMrinal AgarwalNo ratings yet

- Combined Effect of Ground Granulated Blast Furnace Slag and Metakaolin On Mechanical Properties of Self Compacting ConcreteDocument7 pagesCombined Effect of Ground Granulated Blast Furnace Slag and Metakaolin On Mechanical Properties of Self Compacting ConcreteinventionjournalsNo ratings yet

- A Study On The Creep and Shrinkage ofDocument6 pagesA Study On The Creep and Shrinkage ofAngga Fajar SetiawanNo ratings yet

- ICCSI32 - Shruthi B SDocument8 pagesICCSI32 - Shruthi B Ssavinaybharadwaj23122000No ratings yet

- Experimental Study On Thermal and Mechanical Properties of Refractory Cementitious CompositesDocument29 pagesExperimental Study On Thermal and Mechanical Properties of Refractory Cementitious Compositesuthra mohanNo ratings yet

- Effects of Polypropylene Fibers On The PropertiesDocument18 pagesEffects of Polypropylene Fibers On The PropertiesRaviwan IntaratNo ratings yet

- Light Weight Concrete: Seminar OnDocument21 pagesLight Weight Concrete: Seminar OnSanket GuptaNo ratings yet

- Durability Characteristics OF Self Compacting Concrete: Presentation ONDocument26 pagesDurability Characteristics OF Self Compacting Concrete: Presentation ONMonika DhaklaNo ratings yet

- MukundminerpresentationDocument34 pagesMukundminerpresentationmukundchandNo ratings yet

- Performance of Self-Compacting Concrete at Room and After Elevated Temperature Incorporating Silica FumeDocument7 pagesPerformance of Self-Compacting Concrete at Room and After Elevated Temperature Incorporating Silica FumeC H TSENo ratings yet

- JairamDocument26 pagesJairamJairamMiryalaNo ratings yet

- Durability Study of Low Calcium Fly Ash Geopolymer ConcreteDocument7 pagesDurability Study of Low Calcium Fly Ash Geopolymer Concretethisisatest402003No ratings yet

- Use of RHADocument25 pagesUse of RHAMohini BhartiNo ratings yet

- Presented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversityDocument20 pagesPresented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversitySaurabh AgrawalNo ratings yet

- 32 Autocompactant 17.04.2011 PDFDocument8 pages32 Autocompactant 17.04.2011 PDFDarius StanciuNo ratings yet

- Use of Recycled Glass in Architectural MortarDocument7 pagesUse of Recycled Glass in Architectural MortarTung-Chai LingNo ratings yet

- Lightweight Self-Compacting Concrete With Sintered FL y Ash AggregateDocument10 pagesLightweight Self-Compacting Concrete With Sintered FL y Ash AggregateMustafaMahdiNo ratings yet

- The Performance of Pretensioned Prestressed Concrete Beams Made With Lightweight ConcreteDocument10 pagesThe Performance of Pretensioned Prestressed Concrete Beams Made With Lightweight ConcreteAshfaq AhmedNo ratings yet

- Workability and Mechanical Properties of Alkali Activated Slag ConcreteDocument4 pagesWorkability and Mechanical Properties of Alkali Activated Slag ConcretesanjusamsonNo ratings yet

- Coconut Shell As Partial Replacement of Coarse Aggregate in ConcreteDocument4 pagesCoconut Shell As Partial Replacement of Coarse Aggregate in ConcreteGelo LibanNo ratings yet

- Lightweight ConcreteDocument8 pagesLightweight ConcreteMADDIBOINA SISINDRINo ratings yet

- Seminar On "Silica Fume As An Admixture in Concrete" by Rahim 1Document29 pagesSeminar On "Silica Fume As An Admixture in Concrete" by Rahim 1RAHUL GUNDEBOMMUNo ratings yet

- Analysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureDocument33 pagesAnalysis of Self Compacting Concrete by Partial Replacement of Cement With Industrial Waste Under Variable TemperatureThe CiVil Engineering ESENo ratings yet

- 2.b.2.5. Mechanical Properties of Reactive Powder Concrete Containing Mineral Admixtures Under Different Curing Regimes - 3 PDFDocument9 pages2.b.2.5. Mechanical Properties of Reactive Powder Concrete Containing Mineral Admixtures Under Different Curing Regimes - 3 PDFHammad SalahuddinNo ratings yet

- 2020 Materials 13 05754 v2Document15 pages2020 Materials 13 05754 v2puritacasualidadNo ratings yet

- The Durability of Normal Strength Concrete: An Experimental StudyDocument9 pagesThe Durability of Normal Strength Concrete: An Experimental StudyJayesh BhanderiNo ratings yet

- 2 Concrete Bridge Materials and PropertiesDocument37 pages2 Concrete Bridge Materials and PropertiesPraveen BhandariNo ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Strength Properties of ConcreteDocument5 pagesStrength Properties of ConcreteDäYøø BàMønNo ratings yet

- GopinathDocument42 pagesGopinathperadhivansachinNo ratings yet

- Mestrovic RPC MaterialDocument8 pagesMestrovic RPC Materialriski.230110019No ratings yet

- 220 Cipher TechniqueDocument10 pages220 Cipher Techniquecagedraptor100% (1)

- Assign#1Document2 pagesAssign#1Edrielle ValdezNo ratings yet

- Norma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Document42 pagesNorma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Jorge Roman SantosNo ratings yet

- 01 SQL ErrorsDocument2,085 pages01 SQL ErrorsM. temNo ratings yet

- A-VIP Compressor BrochureDocument6 pagesA-VIP Compressor BrochureHans Hans SadzNo ratings yet

- Lighting Lighting: Smartbright Direct Panel G2Document2 pagesLighting Lighting: Smartbright Direct Panel G2Devin Yhojan Viafara MancillaNo ratings yet

- NHD Works Cited 2015Document9 pagesNHD Works Cited 2015miakellerNo ratings yet

- Broaching PrsDocument41 pagesBroaching PrsParag PatelNo ratings yet

- Comparison Between Six-Stroke and Four-Stroke EngineDocument15 pagesComparison Between Six-Stroke and Four-Stroke EnginefaizanbasharatNo ratings yet

- Energy Cable Accessories Epp1984 EngDocument156 pagesEnergy Cable Accessories Epp1984 EngSathiyanathan ManiNo ratings yet

- JCCS Internet Safety CollaborationDocument9 pagesJCCS Internet Safety Collaborationnoble010No ratings yet

- White BoxDocument9 pagesWhite BoxAmitsonu222No ratings yet

- 晴天木塑目录册Document18 pages晴天木塑目录册contaeduNo ratings yet

- Manas Lahon: Areas of Interests EducationDocument2 pagesManas Lahon: Areas of Interests EducationmanaslahonNo ratings yet

- Server Side - Java - Using Rmi With Apache JservDocument16 pagesServer Side - Java - Using Rmi With Apache JservTotoAlipioNo ratings yet

- 8 Candidate Quiz Buzzer Using 8051Document33 pages8 Candidate Quiz Buzzer Using 8051prasadzeal0% (1)

- Final Soil Test ReportDocument7 pagesFinal Soil Test ReportPrateek JhanjiNo ratings yet

- C3691 - NEC, NPN Transistor, 100v, 7v Base, 5A, High Switching SpeedDocument3 pagesC3691 - NEC, NPN Transistor, 100v, 7v Base, 5A, High Switching SpeedLangllyNo ratings yet

- Graphics Display Resolution - Wikipedia, The Free EncyclopediaDocument15 pagesGraphics Display Resolution - Wikipedia, The Free EncyclopediaKarun KumarNo ratings yet

- H S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolDocument58 pagesH S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolCRISTIANNo ratings yet

- Wind Energy: by Kushagra JainDocument16 pagesWind Energy: by Kushagra JainAkash TalekarNo ratings yet

- Corona ConcernsDocument5 pagesCorona ConcernsIvanNo ratings yet