Professional Documents

Culture Documents

Turtles

Uploaded by

shobhit2310Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turtles

Uploaded by

shobhit2310Copyright:

Available Formats

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) CAD and CAE Software Other Predictive and Analytical Software Acoustic and Structural Testing Equipment (Bench and Vehicle) Prototype Fabrication Equipment Metallurgical Analysis Lab Engine Dynamometer Lab

5) With Who ?

(Comp, Skills, Training, etc) CAD Designers FEA/CAE Specialists Product Engineers Materials Specialists Integration Engineers Testing Technicians

1)Process

Product Design, Testing & Development; Service Engineering

Support Division Production Facilities by: Providing product definitions which may be Manufactured, are Profitable and Service Compatible Providing the necessary testing and engineering to support normal production. Support the customer by providing a product Definition that: Meets the vehicle performance targets Installs easily in vehicle assembly Meets the cost targets of the program team Meets program timing requirements

3) Inputs

Customer Requirements Vehicle Performance Targets Materials Requirements Packaging Space Available Durability Targets NVH Requirements Manufacturing Constraints Program Cost Constraints

2) Outputs

Product Definition Prints and GDT CAD Models Materials Specifications Development Prototypes DV Testing Results PV testing results

7) How Effective ?

(Measurable objectives) QOS Measurables Annual Engineering Budget Customer Satisfaction with Product/Vehicle Requirements met Program Timing Met

6) How

(Methods, procedures, techniques, etc)

Process Owner: ESPG-NAO

VP Engineering

Product Development Process Standard Test Procedures Design Guides & Standards Product Failure Mode Knowledge Base (lessons learned)

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) JDE APQP monitoring DMR process Scorecard process PPV tracking by supplier

5) With Who ?

(Comp, Skills, Training, etc) Finance SQA/ ASQ Divison Buyers Plant Buyers

1)Process 3) Inputs

Program tracking sheets DMR alerts Spend by supplier for cost and panel status

Supplier Partnership

Establish, manage and maintain a best panel of suppliers for series production and program launch.

2) Outputs

Monthly reporting to Product Group and Division staff in LIG.

7) How Effective ?

(Measurable objectives) -PPM -PPV -LCC -Number of suppliers

6) How

(Methods, procedures, techniques, etc) Monthly reviews for cost and quality Faurecia Core procedures Weekly reviews on LCC

Process Owner:

ESPG-NAO

VP-Purchasing and Supply Chain Management

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What?

(Materials, equipment, etc)

5) With Who?

(Comp, Skills, Training, etc)

7 Quality Basics Procurement System Managing The Change PSE for ME Principles

Advanced Manufacturing engineers Internal and external training Lessons learned Expert Networks

3) Inputs

-Product Design DFMEA Supplier PPAPs Process Flow Capital Requirements

1) Process - Process Design & Manufacturing Development

2) Outputs

Manufacturing processes meet all customer & organizational requirements with respect to: Plant Readiness Validated Process Capable Processes Efficient Processes Customer PPAP approval PFMEA

Process Architecture PMT and Footprint strategy development Capacity/Capital Management

7) How Effective?

(Measurable objectives)

6) How

(Methods, procedures, techniques, etc)

3 PR Run @ Rate PPAP TRS R3

Management review Customer specific documents Faurecia engineering documents

Process Owner: Manufacturing Engineering Director

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) Work Packages Program Dashboards Business Plans Checklists (GR, FM, other) OPX2 System & Master timeline

5) With Who ?

(Comp, Skills, Training, etc) Program Core Team & WPO extended teams Function Departments (Mfg, Purc, Eng, Quality)

3) Inputs

Program Award Program Kick-off Mtg Work Package Owners status reports Initial Business Plans Program Dashboards FM milestones, QVRs

1)Process Program Management

PSC (Division Management) PRC (PG Management)

2) Outputs

Monthly Programs status G/Y/R, Gate results G/Y/R.Program Delivered Quality, Cost, Delivery, and Performance targets on time, within budget, at target.

Manage Programs from acquisition phase through series production to deliver Quality, Cost, Delivery and Performance (remove and Customer) targets.

7) How Effective ?

(Measurable objectives) -FES indicators -PMS Key Indicators for Time To Pass Gates, First Pass Yield, First Time Through, Confidence Index, Programs Status. All measured monthly. -Sop Status report -Customer systems -PLRs

6) How

(Methods, procedures, techniques, etc) FCP FAU-P-DSC-2240 and related procedures mentioned therein, Gate Review Procedure All FCPs in Development leg of FES triangle and more ESPG PMS Manual Lola, Best Practices, BIKE, LEGO, Program Portal

Process Owner: ESPG-NAO

Director of Program Management (with support from PMS Network and PG Functional Managers)

Created by J.Oliver Director-NAO Division PMS

Approved by M. Dewitt ESPG PMS Manager

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) JDE Cost models Faurecias Business plans

5) With Who ?

(Comp, Skills, Training, etc) Manufacturing functions Plant controllers R&D functions

1)Process 3) Inputs

-Costing information -Actual costs

CONTROL PROGRAM PROFITABILITY

Support Division and CBU in achieving program targeted profitability Support initiatives to improve program profitability

2) Outputs

P&L per program Updated Business plan per program

7) How Effective ?

(Measurable objectives) -Objectives of VCM/ OI & IRR -Achieving targeted results

6) How

(Methods, procedures, techniques, etc) Plant visits and audits Comparison Cost model versus Actual costs Managing R&O lists

Process Owner:

VP Finance Program Controller

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc)

5) With Who ?

(Comp, Skills, Training, etc)

FES System FCP Manual 7 Core Values

Divisional Staff Divisional HR Support & Staff Division EE Mgr. Plant HR Mgrs.

3) Inputs

Faurecia Strategy Faurecia PMT HR Strategy Employee Expectations Local Regulations

1)Process Employee Empowerment

Application of Business Management System to ensure: Verification of Employee Empowerment (EE) system implementation and effectiveness

2) Outputs

Product & plant processes meet all customer & organizational requirements with respect to: Trained competent workforce Career opportunities Employee motivation & productivity Mature industrial relations

7) How Effective ?

(Measurable objectives)

6) How

(Methods, procedures, techniques, etc) Internal and external audits Management review OHP validation Administrative processes Management development Compensation and Benefits Training and succession plans OAR/APDR processes Effective communication

- Absenteeism Rate - Employee Turnover - Improvement Ideas - Internal Mobility - R3 Efficiency

Process Owner: VP Human Resources

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) PCs Email Phone Calls Faurecia Intranet Local IT

5) With Who ?

(Comp, Skills, Training, etc) Users Power Users Managers Local IT

1)Process IT

2) Outputs

Support ESPG-NAO Division and Plant IT functions and tools through system maintenance, uptime, and continuous improvement activities. These functions and tools consist of: Applications (J D Edwards, Future3, Covisint, etc.) Network/Infrastructure/Security Engineering Systems User Support Help Desk FAQs Help Desk Statistics Documentation on Intranet

3) Inputs

Help Desk System Project Requests System monitoring Interaction with sites

7) How Effective ?

(Measurable objectives) -Meeting Objectives -Achieving Budgeted Targets -Part of OAR

6) How

(Methods, procedures, techniques, etc) Plant visits Management Meetings Training Sessions

Process Owner:

IT Director

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) JDE Microsoft Office E-mail Faurecia Intranet

5) With Who ?

(Comp, Skills, Training, etc) Finance VP Operations Manager PCL ESPG PCL Managers

3) Inputs

Regular Plant visits Weekly PCL Scorecard FES Indicators

1)Process PC&L

Support Division and Plants in defining and achieving PCL Objectives: Inventory $ and % MPM Customer Delivery Scores FES Initiatives per FCPs

2) Outputs

Monthly LIG Metrics PCL Intranet site Weekly PCL Conference calls Quarterly PCL Mgr meeting

7) How Effective ?

(Measurable objectives) -Meeting Objectives -Achieving Budgeted Targets -Part of OAR

6) How

(Methods, procedures, techniques, etc) Plant visits Weekly Conference Calls Plant Audits JDE Action Plans

Process Owner:

ESPG-NAO Director, PC&L

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) 7 Quality Basics Breakthrough Quality Plan Procurement System Managing The Change FES Tools FCPs

5) With Who ?

(Comp, Skills, Training, etc) Plant Managers & plant teams Internal and external training Lessons learned FES Network- Division FES Network- Prodcut Group

1)Process

MANUFACTURINGProduction and Service

Application of Business Management System to ensure: Verification of plant effectiveness Verification of product conformity to customer requirements (PPAP) Verification of FES activities effectiveness

3) Inputs

Customer Demand Employee Training Capable Product & Processes TPM Deployment Correct Inventory Level Manufacturing Schedule PMS Process CAPex Core Teams

2) Outputs

Product & plant processes meet all customer & organizational requirements with respect to: Optimized Manufacturing Quantities Polyvalence, polycompetence employees PMs attained on time Quality Product FES Audit Scores

7) How Effective ?

(Measurable objectives) FR0t, FR1t Scrap and rework Delivery Performance Schedule Attainment TRS Productivity PPOH, PPM, Customer Complaints FES Indicators

6) How Process Owner: ESPG-NAO VP-Operations

(Methods, procedures, techniques, etc) FES audits Management review LIG Reviews PMS Gate Reviews

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) Stainless Steel Tubing/ Flat Stock Purchased Components Fabrication/ Inspection Equipment CNC Machining Centers

5) With Who ?

(Comp, Skills, Training, etc) Prototype Prod. Engineers Prototype Group Leaders Prototype Technicians Prototype Inspection Techs

3) Inputs

Blue Prints, Proto Control Plans, EBOM, Check Lists Engineering Sample Order System (ESO) Prototype Build Package

1)Process Prototype Design, Testing & Manufacturing

Fabricate Prototype Samples to support OEM Customers, Internal Testing and Manufacturing Plant requirements for Development, Testing, Fit & Function. Fabricate Tooling, Dies and Fixtures to support Internal Build, Testing and Manufacturing Plants requirements.

2) Outputs

Fabricated Hot & Cold End Prototype Exhaust Systems & Components. Tools, Dies & Fixtures

7) How Effective ?

(Measurable objectives) Monthly QOS Metrics: - 6mr Defects per 1,000 (D/1000) - Samples Delivered On Time - Labor Hours per Part - Samples Shipped per Month

6) How

(Methods, procedures, techniques, etc) Tool/ Die/ Fixture Building Tube Bending, Forming Component Fabrication Welding (Manual & Automatic)

Process Owner: ESPG-NAO

VP Engineering, Prototype Manager

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc) Managers Legal background Legal Treatises Outside Counsel where appropriate

5) With Who ?

(Comp, Skills, Training, etc) Legal Managers

1)Process 3) Inputs

-Facts gathered internally -Any applicable documents -Discussions with appropriate Faurecia personnel

LEGAL FUNCTIONS

Support Division-level functions and Plants with: Draft and review of contracts Resolution of commercial disputes with Customers and Suppliers

2) Outputs

Legal Documents approved for signature Resolved disputes and/or litigation

7) How Effective ?

(Measurable objectives) -Litigation avoidance due to properly drafted contracts - Delay-avoidance in plant modifications due to legal disputes

6) How

(Methods, procedures, techniques, etc) Comprehensive review and understanding of facts.

Process Owner:

Manager of Tax & Legal ; Asst. Treasurer; Asst. General Counsel

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

4) With What ?

(Materials, equipment, etc)

5) With Who ?

(Comp, Skills, Training, etc)

Faurecia HSE Requirements External Legal Requirements Best Management Practices

Plant Manager HSE Designate

1)Process 3) Inputs

FR0/FR1 Data QRQC 8D Data ESPG Requirements

HSE

Application of HSE Management System: Provide Framework for HSE Network Implement HSE PMT/Strategy

2) Outputs

Standardized HSE Mgmt. System. Reduction in FR0/FR1 ISO 14001 Certification

7) How Effective ?

(Measurable objectives)

6) How

(Methods, procedures, techniques, etc)

FR0/FR1 Data Internal Review External(3rd Party) Review

Process Owner: ESPG-NAO HSE Director/Manager

Facility Review Gate Reviews HSE PMT

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

FAURECIA EXHAUST SYSTEMS, NORTH AMERICA, INC

Title: Process Turtle Diagram Form No.: QP-CRP-T4-003-01 # of 15 Issue Date: 22-5-07 Revision: 01

Issued by: K. Kimmet, C. Miller, S. Rich Approved By: P. Bethune

Note: Printed copies are uncontrolled unless that have an original approval signature in the title block

You might also like

- Turtle Diagram Rev'01Document2 pagesTurtle Diagram Rev'01Ankur Parshav100% (6)

- Turtle Diagram For AuditDocument5 pagesTurtle Diagram For AuditSelvaraj Simiyon100% (3)

- Process Audit Preparation GuideDocument5 pagesProcess Audit Preparation GuideNumpetch Somsw100% (6)

- Turtle For Process MapDocument0 pagesTurtle For Process MapGhulam Mustafa100% (1)

- ISO 9001 Quality Procedure Context of the OrganizationDocument1 pageISO 9001 Quality Procedure Context of the OrganizationKarim HakimNo ratings yet

- Customer-focused quality processesDocument8 pagesCustomer-focused quality processesSathyaprakash HsNo ratings yet

- Process Audit Preparation "Turtle Diagram"Document27 pagesProcess Audit Preparation "Turtle Diagram"khwanta-bta93% (44)

- Summary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesDocument8 pagesSummary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesStephen Lim Kean Jin100% (2)

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- Competence For Internal AuditorsDocument2 pagesCompetence For Internal AuditorsSachin Ramdurg100% (1)

- Internal Audit ChecklistDocument37 pagesInternal Audit ChecklistSumeet Rathee100% (5)

- C4 Turtle Diagram Process Design ProcessDocument1 pageC4 Turtle Diagram Process Design Processcao thanh quocNo ratings yet

- Turtle Diagrams - IATF - 16949 - 2016Document8 pagesTurtle Diagrams - IATF - 16949 - 2016Sathyaprakash Hs100% (1)

- The Process Approach QuestionsDocument6 pagesThe Process Approach QuestionsDwinanda SeptiadhiNo ratings yet

- Process Audit Turtle DiagramDocument1 pageProcess Audit Turtle DiagramJoel Alcantara100% (3)

- Company Name: Engineering Location: Customer Name: Model Year / PlatformDocument45 pagesCompany Name: Engineering Location: Customer Name: Model Year / Platformsuresh kumar0% (1)

- Project Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneDocument2 pagesProject Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneNikita Fatah EntingNo ratings yet

- ASQ Mistake Proofing Presentation 021909Document34 pagesASQ Mistake Proofing Presentation 021909cmlim100% (1)

- Layer Process AuditDocument8 pagesLayer Process AuditR JNo ratings yet

- Process Maps and Turtle Diagrams ExampleDocument2 pagesProcess Maps and Turtle Diagrams ExampleJohn Oo100% (1)

- Turtle Diagram Manufacturing ProcedureDocument1 pageTurtle Diagram Manufacturing ProcedureBAla100% (2)

- APQP Phases ActivitiesDocument1 pageAPQP Phases Activitiesaorto3919No ratings yet

- ISO 9001 Key Process Turtle TemplateDocument1 pageISO 9001 Key Process Turtle TemplateShirleyNo ratings yet

- Layered AuditDocument2 pagesLayered AuditJohn Hall100% (2)

- CSR Matrix (Example Only)Document24 pagesCSR Matrix (Example Only)hmp90100% (1)

- Turtle Diagram PPAPDocument1 pageTurtle Diagram PPAPDL50% (2)

- Sensors and RFID: The Unbeatable Team For Advanced Error ProofingDocument13 pagesSensors and RFID: The Unbeatable Team For Advanced Error ProofingRamasubramanian SankaranarayananNo ratings yet

- IATF 16949 Mandatory Documents ListDocument2 pagesIATF 16949 Mandatory Documents ListLuis Alejandro60% (5)

- 8D - One Page 8-D Report Rev 007 Duplicate PKG ID-UNITDocument7 pages8D - One Page 8-D Report Rev 007 Duplicate PKG ID-UNITEdgar LopezNo ratings yet

- IATF AwarenessDocument137 pagesIATF Awarenessnichecon1100% (3)

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- Core Tools PDFDocument1 pageCore Tools PDFsentrakerjaan100% (3)

- Process Turtle Diagram - Assignment EngineeringDocument1 pageProcess Turtle Diagram - Assignment EngineeringShara Jane DelmoNo ratings yet

- 94% Process Audit ChecklistDocument2 pages94% Process Audit ChecklistAshutosh Singh100% (2)

- Process Name: QMS Process Process Name: QMS Process: Turtle DiagramDocument4 pagesProcess Name: QMS Process Process Name: QMS Process: Turtle DiagramLesly Les100% (1)

- Clause 4 Context of The OrganizationDocument9 pagesClause 4 Context of The OrganizationChristine Mae PizaNo ratings yet

- IATF 16949 DocumenDocument1 pageIATF 16949 Documenpunitg_2No ratings yet

- Control and management of documented information and organizational knowledgeDocument1 pageControl and management of documented information and organizational knowledgeNilton de Olivera100% (1)

- SPC Training Material - 18!04!2018Document34 pagesSPC Training Material - 18!04!2018Rajesh KumarNo ratings yet

- Copy of APQP Check List - Ford (Blank)Document9 pagesCopy of APQP Check List - Ford (Blank)feiraluremaNo ratings yet

- Evidences To Be Maintained As Per APQP For PMDocument3 pagesEvidences To Be Maintained As Per APQP For PMSachin RamdurgNo ratings yet

- Checklist of Documentation As Per IATF 16949:2016Document10 pagesChecklist of Documentation As Per IATF 16949:2016Arun Kumar Sharma100% (2)

- Supplier Quality Assurance Manual - Rev. 06Document40 pagesSupplier Quality Assurance Manual - Rev. 06Sundaramoorthy ArumugamNo ratings yet

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixhmp9060% (5)

- IATF 16949 QMS Requirements MatrixDocument1 pageIATF 16949 QMS Requirements MatrixJOECOOL67100% (5)

- GAGE CALIBRATION PROCESSDocument1 pageGAGE CALIBRATION PROCESSsemaphore689% (9)

- Turtle Diagram For PDCA AuditDocument4 pagesTurtle Diagram For PDCA AuditProf100% (18)

- Audit Checklist Process ApproachDocument7 pagesAudit Checklist Process Approachsrinivas8587100% (3)

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- 2 Handout IATF 16949 Clause Map 2016 To 2009 PDFDocument5 pages2 Handout IATF 16949 Clause Map 2016 To 2009 PDFMohini Marathe100% (2)

- Iatf Gap Analysis ToolDocument100 pagesIatf Gap Analysis ToolKumaravel100% (3)

- IATF 16949 Mandatory Records and DocumentsDocument3 pagesIATF 16949 Mandatory Records and DocumentsSathyaprakash Hs100% (2)

- IATF Process Audit Check Sheet FormatDocument14 pagesIATF Process Audit Check Sheet Formatukavathekar71% (7)

- Process Audit Preparation "Turtle Diagram": Design & DevelopmentDocument7 pagesProcess Audit Preparation "Turtle Diagram": Design & Developmentkhwanta-bta100% (2)

- APQP Internal Assessment Checklist: Development PhaseDocument3 pagesAPQP Internal Assessment Checklist: Development PhaseRandhir Kanwar100% (1)

- Lessons Learned From Former Dynamics AX ImplementationsDocument40 pagesLessons Learned From Former Dynamics AX ImplementationsbekirkatNo ratings yet

- 02-F-02 APQP Timing PlanDocument2 pages02-F-02 APQP Timing Planshobhit2310100% (1)

- MSA Reference Manual 4th EditionDocument241 pagesMSA Reference Manual 4th EditionMukhammadali Shukuraliev100% (2)

- Battery Rules 2001Document17 pagesBattery Rules 2001shobhit2310No ratings yet

- Cause and Effect DiagramDocument1 pageCause and Effect DiagramdantesosaNo ratings yet

- Training Guide Cement & ConcreteDocument5 pagesTraining Guide Cement & Concreteshobhit2310No ratings yet

- IATF 16949 Webinar Slides 3.7.17 Final PDFDocument47 pagesIATF 16949 Webinar Slides 3.7.17 Final PDFwanphen kawnawanichNo ratings yet

- BS 3424 - 5 PDFDocument12 pagesBS 3424 - 5 PDFshobhit2310100% (1)

- Supplier Quality ManualDocument24 pagesSupplier Quality Manualshobhit2310100% (1)

- 578 PDFDocument9 pages578 PDFshobhit2310No ratings yet

- Kai Zen Forms MaDocument14 pagesKai Zen Forms Mashobhit2310No ratings yet

- Registration of EIA Consultant OrganizationsDocument41 pagesRegistration of EIA Consultant Organizationsshobhit2310100% (1)

- Ilo Osh 2001Document30 pagesIlo Osh 2001Pewi GomezNo ratings yet

- Lean Manufacturing Competitiveness Scheme 30Document20 pagesLean Manufacturing Competitiveness Scheme 30vijaygarge59No ratings yet

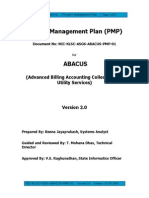

- Project Management Plan (PMP) : (Advanced Billing Accounting Collection and Utility Services)Document53 pagesProject Management Plan (PMP) : (Advanced Billing Accounting Collection and Utility Services)shobhit2310No ratings yet

- Ilo Osh 2001Document30 pagesIlo Osh 2001Pewi GomezNo ratings yet

- Gage R RDocument8 pagesGage R Rshobhit2310No ratings yet

- CEO Series SampleDocument140 pagesCEO Series Sampleshobhit2310100% (1)

- Energize Hazop: Case HistoriesDocument6 pagesEnergize Hazop: Case Historiesshobhit2310No ratings yet

- Gage R&RDocument1 pageGage R&Rshobhit2310No ratings yet

- MANUAL - DisasterSampleDocument13 pagesMANUAL - DisasterSampleAlvinMatabangNo ratings yet

- QMS Audit - Checklist - IsO 9001 - 2008Document27 pagesQMS Audit - Checklist - IsO 9001 - 2008Rizaldi DjamilNo ratings yet

- Gage R&RDocument10 pagesGage R&Rshobhit2310No ratings yet

- Process CapabilityDocument13 pagesProcess CapabilityEricka100% (1)

- Cateora18ePPt Ch02 Final 7-19-19 AccessibleDocument38 pagesCateora18ePPt Ch02 Final 7-19-19 Accessiblenguyễn dũngNo ratings yet

- Ultra Petroleum Corp. NAV Model by Geography and Reserve TypeDocument158 pagesUltra Petroleum Corp. NAV Model by Geography and Reserve TypeFarisyah Melladia UtamiNo ratings yet

- Project Report On KFCDocument60 pagesProject Report On KFCSiavash Wared75% (44)

- FDR Report 2021 v1.0 3 November 2021Document96 pagesFDR Report 2021 v1.0 3 November 2021Seba CabezasNo ratings yet

- Tender Acceptance Letter 265Document1 pageTender Acceptance Letter 265150819850No ratings yet

- Epc Epcm ChartDocument1 pageEpc Epcm ChartSylvester Mokgokone Rakgate89% (9)

- ATOS Standard Quality PlanDocument18 pagesATOS Standard Quality PlanAkram FerchichiNo ratings yet

- Group 1 - Atlas ElectricaDocument27 pagesGroup 1 - Atlas ElectricaRenneil LagmanNo ratings yet

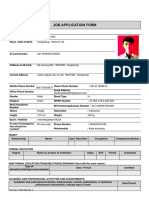

- Job Application FormDocument3 pagesJob Application Formdodi maulanaNo ratings yet

- PMC - Scope of ServicesDocument8 pagesPMC - Scope of ServicesAr Kajal GangilNo ratings yet

- ISIP4112 ILMU PENGANTAR EKONOMI INISIASI 5 Struktur PasarDocument32 pagesISIP4112 ILMU PENGANTAR EKONOMI INISIASI 5 Struktur Pasarmanik suciNo ratings yet

- Components, Life Limited Components and Configuration Control - Sofema Aviation ServicesSofema Aviation ServicesDocument4 pagesComponents, Life Limited Components and Configuration Control - Sofema Aviation ServicesSofema Aviation ServicesadelNo ratings yet

- Accounting For Managers Test 5Document12 pagesAccounting For Managers Test 5Hero CourseNo ratings yet

- HBR Case StudyDocument12 pagesHBR Case StudyPinuccio GianfrancoNo ratings yet

- Adama Science and Technology University: Transport Management SystemDocument14 pagesAdama Science and Technology University: Transport Management SystemkemalNo ratings yet

- Balance of Payments AccountingDocument4 pagesBalance of Payments AccountingDanielleNo ratings yet

- Case Analysis of Kmart's 2002 Bankruptcy and Turnaround StrategyDocument5 pagesCase Analysis of Kmart's 2002 Bankruptcy and Turnaround StrategyMarvin MacaraegNo ratings yet

- Chapter 1 - Introduction To Cost AccountingDocument34 pagesChapter 1 - Introduction To Cost AccountingGlaiza Lipana PingolNo ratings yet

- Internal Audit CharterDocument5 pagesInternal Audit CharterUrsu BârlogeaNo ratings yet

- Banking in EthiopiaDocument3 pagesBanking in EthiopiaTilaye AleneNo ratings yet

- Assignment Acc106 Jan 2012Document11 pagesAssignment Acc106 Jan 2012irfanzzz75% (8)

- 06.06.2023 Duzenlendi MT-103 - 202Document2 pages06.06.2023 Duzenlendi MT-103 - 202Murat BıçakNo ratings yet

- Cost Accounting Lecture-102Document3 pagesCost Accounting Lecture-102Tracy Lyn Macasieb NavidadNo ratings yet

- ACC102-Chapter1new 002Document18 pagesACC102-Chapter1new 002Logs MutaNo ratings yet

- Toyota Organizational StructureDocument4 pagesToyota Organizational StructureSarthak ChincholikarNo ratings yet

- Temporary National Economic CommitteeDocument364 pagesTemporary National Economic CommitteerwdavisNo ratings yet

- Why Are You Leaving Your Job Sample AnswersDocument5 pagesWhy Are You Leaving Your Job Sample AnswersKien Trung NguyenNo ratings yet

- Candidate Details Sheet with Contact and Professional InfoDocument16 pagesCandidate Details Sheet with Contact and Professional InfoShubham Tyagi100% (1)

- Boring Company LVCC Loop FundDocument25 pagesBoring Company LVCC Loop FundMaria MeranoNo ratings yet

- Interim President COO Employment Agreement - April 23 2018 - DraftDocument5 pagesInterim President COO Employment Agreement - April 23 2018 - DraftShelby DanielsenNo ratings yet