Professional Documents

Culture Documents

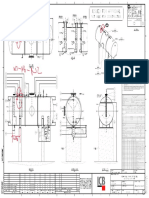

Frame

Uploaded by

dahlia_gingerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frame

Uploaded by

dahlia_gingerCopyright:

Available Formats

QSD 182 CONSTRUCTION TECHNOLOGY TIMBRE FRAME

DAHLIA BINTI AB AZIZ 2012611132 AP1142C

CONTENT

INTRODUCTION

BALLOON FRAME

PLATFROM FRAME

COMPARISON OF ADVANTAGES &DISADVANTAGES

COMPONENTS

11

METHOD OF CONSTRUCTION OF BALLOON FRAME

13

TIMBER FRAME | 2

METHOD OF CONSTRUCTION OF PLATFROM FRAME

17

COST

19

TECHNOLOGY &ENVIRONMENT

20

10

REFERENCE

21

INTRODUCTION

Framing, in construction of timber known as light-frame construction, is a building technique based around vertical structural members, usually called studs, which provide a stable frame to which interior and exterior wall coverings are attached, and covered by a roof made of horizontal ceiling joists and sloping rafters (or pre-fabricated roof trusses).

Light frame construction using standardized dimensional lumber has become the dominant construction method in North America and Australia because of its economy. Use of minimal structural materials allows builders to enclose a large area with minimal cost, while achieving a wide variety of architectural styles. The ubiquitous platform framing and the older balloon framing are the two different light frame construction systems used in North America.

Wall framing in house construction includes the vertical and horizontal members of exterior walls and interior partitions, both of bearing walls and non-bearing walls.

These stick members, referred to as studs, wall plates and lintels (headers), serve as a nailing base for all covering material and support the upper floor platforms, which provide the lateral strength along a wall.

The platforms may be the boxed structure of a ceiling and roof, or the ceiling and floor joists of the story above The technique is variously referred to colloquially in the building trades as stick and frame, stick and platform, or stick and box as the sticks (studs) give the structure its vertical support, and the box shaped floor sections with joists contained TIMBER FRAME | 3

within length-long post and lintels (more commonly called headers), supports the weight of whatever is above, including the next wall up and the roof above the top story.

The platform also provides the lateral support against wind and holds the stick walls true and square. Any lower platform supports the weight of the platforms and walls above the level of its component headers and joists.

There are three historically common methods of framing a house.

Post and beam, which is now used predominately in barn construction. Balloon framing using a technique suspending floors from the walls was common until the late 1940s, but since that time, platform framing has become the predominant form of house construction.[3]

Platform framing often forms wall sections horizontally on the sub-floor prior to erection, easing positioning of studs and increasing accuracy while cutting the necessary manpower. The top and bottom plates are end-nailed to each stud with two nails at least 3.25 in (83 mm) in length (16d or 16 penny nails). Studs are at least doubled (creating posts) at openings, the jack stud being cut to receive the lintels(headers) that are placed and end-nailed through the outer studs.[3]

Although the balloon frame was made famous by the western, but Malaysia also have their share of balloon frame in constructing their wooden home. In Malaysia, timber houses would not exceed more than two storey, and most contractor opted for a simpler method of constructing which is the balloon frame.

If we consider the time period when taking the comparison between the similarity and or the differences in the method applied in international timber construction industry and malaysians own industry, it would seem that Malaysian uses more of balloon fram e in their construction opposing the international method, specifically the western, which seem to use more of platform frame method in the same time period. TIMBER FRAME | 4

BALLOON FRAME

TIMBER FRAME | 5

Balloon framing was the initial framing breakthrough during the mid-1800s that led the building industry away from the use of heavy timber construction. The advent of smaller dimensionally cut lumber at saw mills and the manufacturing of nails resulted in the development of these more affordable and lighter structures. The relative lightness of this framing method compared to the use of heavy framing members led to the term balloon.

Early balloon framing is characterized by the tall open wall cavities it creates within the exterior wall assembly. These cavities generally extend the entire height of the home. The framing system relies on let-in bracing and/or floor and wall sheathing to provide lateral strength and resistance to wind.

TIMBER FRAME | 6

Balloon framed homes are generally designed so that dimensional lumber, extending from the sill plate to the top plate of the wall, provide support for all floors and the roof structure. Unfortunately, when these homes catch fire, the fire spreads very rapidly throughout the wall cavity and into the attached floor systems. Balloon framing is a method of wood construction also known as "Chicago construction" in the 19th century used primarily inScandinavia, Canada and the United States (up until the mid-1950s). It utilizes long continuous framing members (studs) that run from the sill plate to the top plate, with intermediate floor structures let into and nailed to them. Here the heights of window sills, headers and next floor height would be marked out on the studs with a storey pole. Once popular when long lumber was plentiful, balloon framing has been largely replaced by platform framing.

Although lumber was plentiful in 19th-century America, skilled labor was not. The advent of cheap machine-made nails, along with water-powered sawmills in the early 19th century made balloon framing highly attractive, because it did not require highly-skilled carpenters, as did the dovetail joints, mortises and tenons required by post-and-beam construction. For the first time, any farmer could build his own buildings without a timeconsuming learning curve.

It has been said that balloon framing populated the western United States and the western provinces of Canada. Without it, western boomtowns certainly could not have blossomed overnight. It is also a fair certainty that, by radically reducing construction costs, balloon framing improved the shelter options of poorer North Americans.

For example, many 19th-century New England working neighborhoods consist of balloon-constructed three-story apartment buildings referred to as triple deckers. The balloon frame is characterized by its use of thinner, standardized sawn framing members and machine-made nails, as opposed to the heavy timbers and complicated joinery used in traditional wooden construction methods.

Balloon framing utilizes continuous vertical framing members, called studs, which carry an equal distribution of the buildings vertical compressive load. The studs are usually 2x6 or 2x4 inches and are placed approximately sixteen inches apart.

TIMBER FRAME | 7

A major difference between balloon frame and previous wood framing techniques is its lack of girts, the horizontal framing members that held together the individuals bays of traditional framed buildings. Instead of girts, balloon framing utilizes the outer sheathing to make the buildings rigid, and the floor joists of upper stories rest on ledgers that are nailed horizontally across the studs. Before balloon framing was invented, traditional wood frame buildings, or braced frame buildings, had diagonal members between the posts, sills, and girts to brace the structure against wind pressure. The principal advantages that the balloon frame had over the traditional jointed frame were that it used one third the volume of lumber, involved less construction time and required less skilled labor. As a result, the balloon frame cost c.40% less to construct.7

The use of the machine cut nails was much less expensive than hand-wrought nails, and because the nails were used to attach all parts of the frame, no time-consuming mortise and tenon joinery or skilled carpenters were needed.

The cheap balloon frame buildings could even be prefabricated and shipped out via the railroad to the rapidly developing American West. Balloon framing was certainly an innovation derived from necessity that almost perfectly fit the industrial and social climate in the United States during the second half of the 19th century. It allowed for rapid growth in western towns, and provided affordable housing for many Americans.

Balloon frame also effects the population growth in Malaysia even today. Few years back, a lot of construction in FELDA uses this exact method when building their newly found area for production.

TIMBER FRAME | 8

PLATFORM FRAME

In Canada and the United States, the most common method of light-frame construction for houses and small apartment buildings as well as other small commercial buildings is platform framing. In builder parlance, platform framing might also nowadays be called (only partly correctly) 'stick framing' or 'stick construction' as each element is built up stick by stick, which was also true in the other stick framing method, in the obsolete and labor intensive, but previously fashionable, balloon framing method, wherein the outside walls were erected, headers hung, then floor joists were inserted into a box made of walls.

TIMBER FRAME | 9

In contrast, in platform framing a floor box and joists making up the platform is built and placed on a supporting under structure (Sill plates, headers, or beams) where it sits flat and gets fastened down against wind lifting with galvanized metal tie straps. Once the boxed floor platform is squared, leveled and fastened then subfloor, walls, ceilings, and roof are built onto and above that initial platform, which can be repeated floor by floor, 'without the slow downs and dangers of fastening and leveling rough-sawn joists of a new floor together to the walls from ladders extending one or even five stories up. Generally, the flooring ('platform') is constructed then the walls built on top of that layer, then another atop that, and so forth making for quick efficient labor saving construction methodologies and those have quickened further as technologies such as joist hangers have been developed to speed and enhance the technology. The methods and techniques have become so common and pervasive that even Skyscrapers use a modified form of platform framing techniques and indeed the same tools and technologies once construction builds the initial structural skeleton.

Comparison Balloon framing is one of the earlier wood construction methods. Light frames of wood are constructed around studs which run continuously from top to bottom of a building. The roof is a truss structure that consists of horizontal ceiling joists and sloping rafters. Platform framing is a more modern approach in construction. It utilizes plates to enable the upward extension of a building. Floor joists for each story are supported by the top plate of the floor underneath. The main difference between the two types occurs at the floor lines. Platform Framing Advantages It is a simpler construction process compared to balloon construction. The technique involved also makes it a quicker method of construction. One structure is constructed and is well supported by a foundation. Builders then use the first level as a platform to project the next floor. The process continues until the desired number of floors is achieved. Rafters and roof joists are erected on the final tier of walls. Platform framing utilizes less wood. Additionally, smaller pieces of wood can be used on the wall frames. No fire stopping is necessary because the stud spaces are enclosed by the floor platforms. The safety level for workers is higher with platform framing. This is because walls can be fabricated down on the floor. The technique also requires less labor. This helps to keep construction costs within reasonable limits. TIMBER FRAME | 10

Disadvantages Structural problems may occur after completion of the house. This is because the joists and headers experience interruption from the sub-floor. Vertical shrinkage is likely when the wood dries. This may destabilize siding materials, resulting in frequent maintenance. Balloon Framing Advantages Fewer problems are expected once construction is complete. Drywall cracking is unlikely. This adds to the durability of the building. Balloon construction is useful where a vaulted ceiling or two-story open foyer is desirable. Where a tall chimney is preferred, the balloon technique is also useful. With balloon framing, you get more flexibility in window design. Angled or arched window tops are easier to achieve. Large or vaulted windows are also more workable with the balloon technique than platform framing. The technique creates a higher resilience structure due to the longer wall frames used. The building is better able to withstand high speed or gusty winds. Disadvantages In the event of a fire, the building is likely to be destroyed more quickly. This is because the structure provides an easy path for fire to travel from one floor to the next. It becomes necessary to install fire stops on each level. Balloon framed buildings dont have insulation between a room and its exterior walls. This contributes to increased energy utilization, hence higher costs. Additionally, the long framing members used in construction pushes up construction costs. Walls constructed turn out to be very heavy. To raise these walls, more labor, skill and specialized equipment is required. It also increases the risk during work.

TIMBER FRAME | 11

COMPONENTS Foundation A foundation is the lowest and supporting layer of a structure. Foundations are generally divided into two categories: shallow foundations and deep foundations. Shallow foundations, often called footings, are usually embedded about a meter or so into soil. One common type is the spread footing which consists of strips or pads of concrete (or other materials) which extend below the frost line and transfer the weight from walls and columns to the soil or bedrock. A deep foundation is used to transfer the load of a structure down through the upper weak layer of topsoil to the stronger layer of subsoil below. Sole plate A sill plate or sole plate in construction and architecture is the bottom horizontal member of a wall or building to which vertical members are attached. The word plate is typically omitted in America and carpenters speak simply of the "sill". Other names are ground plate, ground sill, groundsel,[1] and mud sill. Sill plates are usually composed of lumber but can be any material. The timber at the top of a wall is often called a top plate, pole plate, wall plate or simply "the plate" Joist A joist is one of the horizontal supporting members that run from wall to wall, wall to beam, or beam to beam to support a ceiling, roof, or floor. It may be made of oriented strand board, plywood, wood, steel, or concrete. Typically, a beam is bigger than a joist, which is often supported by beams and laid out in repetitive patterns Fire stop A firestop is a fire protection system made of various components used to seal openings and joints in fire-resistance rated wall and/or floor assemblies. Firestops are designed to restore the fire-resistance ratings of wall and/or floor assemblies by impeding the spread of fire by filling the openings with fire-resistant materials. Unprotected openings in fire separations cancel out the fire-resistance ratings of the fire separations, allowing the spread of fire, usually past the limits of the fire safety plan of a building . TIMBER FRAME | 12

Floor A floor is the walking surface of a room or vehicle. Floors vary from simple dirt in a cave to many-layered surfaces using modern technology. Floors may be stone, wood, bamboo, metal, or any other material that can hold a person's weight. The levels of a building are often referred to as floors although a more proper term is storey. Floors typically consist of a subfloor for support and a floor covering used to give a good walking surface. Stud Wall framing in house construction includes the vertical and horizontal members of exterior walls and interior partitions. These members, referred to as studs, wall plates and lintels, serve as a nailing base for all covering material and support the upper floors, ceiling and roof. Interior partitions supporting floor, ceiling or roof loads are called loadbearing walls; others are called non-loadbearing or simply partitions. Interior loadbearing walls are framed in the same way as exterior walls. Studs are usually 1.5 in 3.5 in (38 mm 89 mm) lumber spaced at 16 in (410 mm) on centre. Rafter A rafter is one of a series of sloped structural members (beams) that extend from the ridge or hip to the wall plate, downslope perimeter or eave, and that are designed to support the roof deck and its associated loads.A type of beam that supports the roof of a building, In home construction rafters are typically made of wood. Exposed rafters can be a feature of traditional roof styles.

Both frames have quite the same component as the other thus making the component used in Malaysian construction industry the same as the component use in the western side. These are similarities in both method used. The components may be the same but the length and method of construction is different.

TIMBER FRAME | 13

METHOD OF CONSTRUCTING FOR PLATFORM FRAME Once the platform floor is laid down, the builder's crew can with chalk line, rule and pencil directly transfer an outline of the exterior and interior walls, their openings and relative locations with ease and precision from the plans or builders blue prints. As the survey group lays down the notations and chalk lines, a carpenter crew can follow behind and lay down 2x4 'bottom plates' and tack them to the floor box. The topmost wall plates are cut only to the outside dimensions of the walls. Butting two other two by fours against these cut to size and fastened bottom plate allows the crew to rule across all three with square and lay out studs, cripple studs, and openings for that particular wall. The two loose studs are then quickly flipped on edge after openings are cut in, and studs added on the marks with quick reliable end nailing through the respective top and bottom plates. A few minutes later the whole wall section can be levered up and aligned in place and braced for later application of the top plates and adjoining walls. The method provides builders options and flexibility such as when and where there is a floor-level opening (doorway) the next wall section can be aligned and fastened in place separately with the top plate added then used then a lintel and cripple studding added, or the entire wall could have been cut and joined at the top all along and lifted up as one entity. In the end, the outside walls are plumbed and fastened together with 'ell-configured reinforced corners' that provide nailing wood in the interior angles and strength to the building forming in effect wide posts at each corner and fastened lastly by overlapped top plates which stagger their joints from the ones capping each plate by which the studs are end nailed together. Each wall from top to bottom ends up with a doubled plate, studs, and a doubled plate, where structurally the doubled plates spread the weight of the roof and loading across the studs of the wall, ultimately to the foundation. Overall, the framed structure sits (most commonly) atop a concrete foundation on pressure treated wood 'sill', or 'beam'. When on concrete, the sill plate is anchored, usually with (embedded) 'J' bolts into the concrete substrate of the foundation wall. Generally these plates must be pressure treated to keep from rotting from condensing moisture. By various standards the bottom of the sill plate is located a minimum 6 inches (150 mm) above the finished grade (the surrounding ground) per standard builders practices, and frequently more dependent upon building codes of the relevant jurisdiction's local building codes. In North America, building codes may differ not only state to state, but town to town, the tighter specification applying at all times. TIMBER FRAME | 14

This distance, together with roofing overhangs, and other system factors, is most often selected both to prevent the sill-plate from rotting (due to the invasion of splashed water) as well as providing a termite barrier. The latter is particularly (more or less) important than anti-rotting considerations depending upon the geographical location. Alternatively, the room, room extension, deck or even a house can be built above concrete columns U.S. builders call piers some others call pilasters, another of many term misuses common to building trade parlance. In such cases, the pier (column) is usually required to rest on bed rock or extend well below the zone of average freezing soil depth (the same as a foundation) locally, and frequently is required to also have flared out or mushroomed bottom of greater surface than that the pier top (These are called 'big foots' in the building trade and building suppliers carry PVC molds to conserve concrete which allow a builder to satisfy area requirements and the building codes). Rigid pressure treated 'beams' (usually doubled or tripled up wider types of 2x boards) are attached to the piers using galvanized metal brackets and serve the same function as sills in foundation supported framing. The floors, walls and roof of a framed structure are created by assembling (using nails) consistently sized framing elements of dimensional lumber (e.g. 24s) at regular spacings (typically divisions of 4 and 8 feet, or such as 12, 16, 19.2, or 24 inches on center). The empty space formed between elements is called a stud bay in the wall and a joist bay in the floor or ceiling. The floors, walls and roof are typically made torsionally stable with the installation of a plywood or composite wood skin referred to as sheathing. Sheathing has very specific requirements (such as thickness and spacing of nailing). These measures allow a known amount of shear force to be resisted by the elements. Spacing the framing members properly usually allows them to align with the edges of standard sheathing. In the past, tongue and groove planks installed diagonally were used as sheathing. Occasionally, wooden or galvanized steel braces are used instead of sheathing. There are also engineered wood panels made for shear and bracing.The floor, or the platform in this framing type's name, is made up of joists (usually 2x6, 28, 210 or 212 depending on the span, on edge thus the wider joist supporting weight for a greater distance) that sit on supporting foundation walls, beams, columns or girders within and at right angle to doubled outside members also on edge (the band), forming a box. The outer perimeter is nearly the same (3 inch vs. 3.5 inches) width as the support sill. The joists will generally be installed across the shortest distance of any floor span rectangle. The outer layer of the band will overlap the inner layer with staggered end joints TIMBER FRAME | 15

creating a stronger box. If joist hangers are not used, the installation of the outer board in the band is delayed to allow through-nailing directly into the ends of the joists. The floor joists are spaced at 12 in, 16 in, and 24 in on center, depending upon the live load needs of the design the closer the spacing and the wider the floor joist dimension, the less the floor will flex. It is then usually covered with a 3/4-inch tongue-and-groove plywood subfloor. In the century past, 1x planks set at 45-degrees to the joists were used for the first subfloor layer, and a second layer of 1x planks set at 90-degrees to the floor cladding topped that as the second subfloor layer. In that same era, all flooring choices were a very short menu of choices between finished wood types or ceramic tiles versus today's extensive multipage menu of manufactured flooring types. Where the design calls for a framed floor, the resulting platform is where the framer will construct and stand that floor's walls (interior and exterior load bearing walls and spacedividing, non-load bearing partitions). Additional framed floors and their walls may then be erected to a general maximum of four in wood framed construction. There will be no framed floor in the case of a singlelevel structure with a concrete floor known as a slab on grade. Stairs between floors are framed by installing three 90-stepped stringers attached to wall structures and then placing the horizontal treads and vertical risers (usually about 14 of each for an 8-ft. ceiling) upon the planes formed by the stringers. A framed roof is an assembly of rafters and wall-ties supported by the top story's walls. Prefabricated and site-built trussed rafters are also used along with the more common stick framing method. Trusses are engineered to redistribute tension away from wall-tie members and the ceiling members. The roof members are covered with sheathing or strapping to form the roof deck for the finish roofing material Floor joists can be engineered lumber (trussed, I-joist, etc.), conserving resources with increased rigidity and value. They are semi-custom manufactured to allow access for runs of plumbing, HVAC, etc. and some 'common-needs' forms are pre-manufactured as semi-mass produced standard products made on a per order basis, like roofing trusses. Such products have a post-order lead time from several weeks to several months. Double framing is a style of framing used in some areas to reduce heat loss and air infiltration. Two walls are built around the perimeter of the building with a small gap in between. The inner wall carries the structural load of the building and is constructed as described above. TIMBER FRAME | 16

The exterior wall is not load bearing and can be constructed using lighter materials. Insulation is installed in the entire space between the outside edge of the exterior wall and the inside edge of the interior wall. The size of the gap depends upon how much insulation is desired. The vapor barrier is installed on the outside of the inner wall, rather than between the studs and drywall of a standard framed structure. This increases its effectiveness as it is not perforated by electrical and plumbing connections.

TIMBER FRAME | 17

METHOD OF CONSTRUCTION OF BALLOON FRAME The main difference between platform and balloon framing is at the floor lines. The balloon wall studs extend from the sill of the first story all the way to the top plate or end rafter of the second story. The platform-framed wall, on the other hand, is independent for each floor.[17] Balloon framing has several disadvantages as a construction method: 1. The creation of a path for fire to readily travel from floor to floor. This is mitigated with the use of firestops at each floor level. 2. The lack of a working platform for work on upper floors. Whereas workers can readily reach the top of the walls being erected with platform framing, balloon construction requires scaffolding to reach the tops of the walls (which are often two or three stories above the working platform). 3. The requirement for long framing members. 4. In certain larger buildings, a noticeable down-slope of floors towards central walls, caused by the differential shrinkage of the wood-framing members at the perimeter versus central walls. Larger balloon-framed buildings will have central bearing walls which are actually platform framed and thus will have horizontal sill and top plates at each floor level, plus the intervening floor joists, at these central walls. Wood will shrink much more across its grain than along the grain. Therefore, the cumulative shrinkage in the center of such a building is considerably more than the shrinkage at the perimeter where there are many fewer horizontal members. This problem, unlike the first three, takes time to develop and become noticeable. 5. Present-day balloon framing buildings often have higher heating costs, due to the lack of insulation separating a room from its exterior walls. However, this can be remedied through the addition of insulation, as with any other framed building.

Since steel is generally more fire-resistant than wood, and steel framing members can be made to arbitrary lengths, balloon framing is growing in popularity again in light gauge steel stud construction. Balloon framing provides a more direct load path down to the foundation. Additionally, balloon framing allows more flexibility for tradesmen in that it is significantly easier to pull wire, piping and ducting without having to bore through or work around framing members

TIMBER FRAME | 18

Foundation & Floor Assembly

Solid brick foundations are the norm in older homes that extensively utilize balloon framing. The sill plate may be made from rough-cut lumber or larger timbers with mortise and tenon joinery. Floor joists are rough-cut, 2x lumber generally spaced between 16 and 24 on center with their ends face nailed to the wall studs and supported by the sill or a ledger board (AKA: ribbon or ribband) on upper floors. Floor sheathing is typically composed of 1x diagonal or perpendicular planking. On a home unprotected by fire stops, the joist space between floors is generally open to the wall cavities created by the exterior wall framing.

Wall Assembly

Rough-cut dimensional lumber is generally used for wall framing, and studs are typically spaced beyond the normal stud spacing (16 on center) used today. Fire stopping is required in any new balloon frame construction but may or may not be present in older construction. Let-in bracing may also be incorporated into the framing system to provide additional strength to the wall framing, especially prior to the installation of wall sheathing. Wall sheathing is typically composed of 1x boards attached either perpendicular or diagonal to the wall framing. Wall cavities are sometimes insulated either during the initial construction or more commonly during a future upgrade to the home. Common 2x wood framing is used to frame the interior walls on these older homes and wood lathe strips and plaster is typically applied to the interior walls and ceilings as the finish material.

TIMBER FRAME | 19

COST the higher the number of components used, the higher the cost involve. It is stated that the construction of balloon frame is cheaper compared with the platform frame. Balloon frame have less component to handle, it may use longer length of stud but the overall cost would sided to platform as it uses more components which cause to increase the number of carpenter to be employed. With more components to attached together, the reinforcement to join all the components would effects the overall cost. It is because other factors and cost that Malaysian opted for balloon frame in constructing their timber homes. Most wooden building is built in a low income area such as in rural area where they would not even have a proper contractor, nevertheless, the concept of construction still using balloon frame in their method of construction. Apart from that, material to built balloon frame house is easily obtain as Malaysian is slightly known for its nature resource, thus long length timber is would not be a restricting factor in building such building. In the western area still favour timber structure even in well populated area. Even in their suburban area uses timber building that is why they prefer platform frame when building their houses. They build their houses more than two storey which exceed the balloon frame ability. The western would also try to use most of their space to the maximum, thus making platform frame favoured as its offer the flexibility of giving partition or level of floor. The cost of constructing of platform would not be a problem as the buyer of the house would be occupied by high class people. Also, western have technology advancement where Malaysia is lacking when involving timber construction.

TIMBER FRAME | 20

TECHNOLOGY & ENVIRONMENT It was explain earlier that platform frame is a newer method to construct a timber which means construction technology was given a lot of attention to improve the latter option. Since western people have more tendency in building timber building compared to Malaysian, it seems they have the technology and ability in improving in the construction using the platform frame. Malaysian focused more on concrete technology advancement as we uses more concrete base construction in building houses or other buildings. Environment also effects the tendency in using both types of frame. In Malaysia, mostly uses concrete wall because the weather is very hot and the tall height from the balloon frame provide ventilation where hot air would rise up and cool air would remain below and cool down the occupant. Instead in western area, platform frame gives them slow air movement thus keeping in heat that is treasured in winter.

TIMBER FRAME | 21

REFERENCES http://en.wikipedia.org/wiki/Rafter http://en.wikipedia.org/wiki/Framing_(construction)#Exterior_wall_studs http://en.wikipedia.org/wiki/Floor#Subfloor_construction http://en.wikipedia.org/wiki/Firestop http://en.wikipedia.org/wiki/Sill_plate http://www.housing.com/balloon-framing.html

TIMBER FRAME | 22

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cable Stayed Bridge (Content)Document70 pagesCable Stayed Bridge (Content)Ram Nepali100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Schedule of Quantity For Industrial BuildingDocument4 pagesSchedule of Quantity For Industrial BuildingShashankSinghNo ratings yet

- Transportation EngineeringDocument71 pagesTransportation EngineeringjifotNo ratings yet

- Axial Fan PerformanceDocument17 pagesAxial Fan Performancehassan wastiNo ratings yet

- Design-Coordination-Checklist Architectural Verfeb252020Document5 pagesDesign-Coordination-Checklist Architectural Verfeb252020KunnalNo ratings yet

- NSL Hollow Core Slabs 12jul16 - 2016 Edition PDFDocument24 pagesNSL Hollow Core Slabs 12jul16 - 2016 Edition PDFjohnkoh9950% (2)

- Desain Angkur BoltDocument23 pagesDesain Angkur BoltWidyanto TomiNo ratings yet

- Unit 4: Well and Caisson FoundationDocument93 pagesUnit 4: Well and Caisson FoundationJagadeeswar ReddyNo ratings yet

- IDEA Connection Theoretical Manual en Ver 8 0Document56 pagesIDEA Connection Theoretical Manual en Ver 8 0harislee100% (1)

- Turbulent Flow ModelingDocument11 pagesTurbulent Flow ModelingGhada OrabiNo ratings yet

- Types of WCDocument1 pageTypes of WCArcheia SumajitNo ratings yet

- Chersterton Arc S2 PDFDocument1 pageChersterton Arc S2 PDFMohamed NouzerNo ratings yet

- WaterproofingDocument2 pagesWaterproofinghoney4747No ratings yet

- Bending Stresses in Beams ExplainedDocument13 pagesBending Stresses in Beams ExplainedIsuru Udayanga NanayakkaraNo ratings yet

- Kerala Infrastructure Investment Fund Board (Kiifb)Document4 pagesKerala Infrastructure Investment Fund Board (Kiifb)Samseer R HNo ratings yet

- Set-2 AnswerDocument8 pagesSet-2 AnswerMARK ARQUE LACANARIANo ratings yet

- Rheological Characterization of Nano Particle Based Bio Modified BinderDocument17 pagesRheological Characterization of Nano Particle Based Bio Modified BinderAsif ZazaiNo ratings yet

- Boq Sector A-4Document62 pagesBoq Sector A-4fowzanNo ratings yet

- CICIND RepairDocument9 pagesCICIND RepairandyhrNo ratings yet

- EE2 Unit 2Document32 pagesEE2 Unit 2abel shimelesNo ratings yet

- Precast Construction Methodology in Construction Industry & Ashwin M JoshiDocument8 pagesPrecast Construction Methodology in Construction Industry & Ashwin M JoshigmontesroyNo ratings yet

- Design and Detailing of Movement JointsDocument28 pagesDesign and Detailing of Movement JointsTanveer AhmadNo ratings yet

- Design of Formwork for Concrete StructuresDocument30 pagesDesign of Formwork for Concrete StructuresSantosoNo ratings yet

- Stress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionDocument16 pagesStress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionAndrucruz CruzNo ratings yet

- 6-Beam-Column Members PDFDocument28 pages6-Beam-Column Members PDFKellen Brumbaugh100% (1)

- Curriculum Vitae: Personal DetailDocument2 pagesCurriculum Vitae: Personal DetailRahma 12No ratings yet

- Forced Air Accessories: Condensate Drain PansDocument16 pagesForced Air Accessories: Condensate Drain PansKamal AliyevNo ratings yet

- Technical Note: Guide To The Use of Grade 80 Reinforcing Bars in ACI 318-19Document16 pagesTechnical Note: Guide To The Use of Grade 80 Reinforcing Bars in ACI 318-19LARRY ALVARADO AJUNNo ratings yet

- Mec-02-3223-13-04-R03 - B (V-1324) (Adf Comments) PDFDocument1 pageMec-02-3223-13-04-R03 - B (V-1324) (Adf Comments) PDFAgustín DomínguezNo ratings yet

- ATC 34 Critical Review of Current Approaches To Earthquake Design - TOC ONLYDocument6 pagesATC 34 Critical Review of Current Approaches To Earthquake Design - TOC ONLYNoahNo ratings yet