Professional Documents

Culture Documents

Discussion

Uploaded by

mtrego9441Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discussion

Uploaded by

mtrego9441Copyright:

Available Formats

7.

0 Discussion

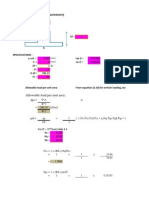

The experiment of the Direct Shear Stress is to determine the parameter of the shear strength of soil, to find the value of cohesion and also to find the angle of friction. By plotting the graph, which is the graph of shear stress versus strain, we can find for these values. (Refer to the graph).

For sample loading 1.75kg, a slight error of the data obtained, the value obtained from the dial gauge showed increases, decreases and increases return. This is because, the stretch of sand is not tested in the same condition. Therefore, uneven compression will occur and will cause the data obtained is not uniform.

In addition, erratum often occurs while taking the readings of the data. As it happens, because the dial gauges have some technical problem So, the readings that we took may have differed from what we were supposed to have taken. Another reason is, it may also happen when the equipments were not fixed in properly enough hence the data obtained as the result may slightly run from the one that we were supposed to obtain. The equipment we used were not cleaned properly before it was used to undergo the experiment. Old particles of sand and soil from previous experiments were still stuck onto the bottom of some of the plates hence the result of the experiment may be affected a little by this incident

8.0 Conclusion

As a conclusion, we can know that the objective of the experiment is to determine the parameter of shear strength of soil, cohesion and angle of friction was achieved. From the experiment that we have done, the value of cohesion, c is 0.00kN/m2 and the value of friction of angle is 36. The direct shear test has advantages and disadvantages. It is simple and fast especially for sands. The failure that occurs is along a single surface, which approximates observed slips or shear type failure in natural soils.

Direct shear test is useful when cohesion less soils are to be tested. In this test the failure plane is forced to occur at a predetermined location where both normal and shear stresses are acting; the sample is placed in a closed shear box, fixed at the base with the top free to translate under a horizontal force. The two portions of the box are spaced by using spacing screws to reduce the friction. The space should be at least as large as the largest sand particle. The box is then placed in the direct shear apparatus, and increasing horizontal load is applied with constant corresponding vertical load, and the horizontal deformation shall be recorded by using the dial gage. For each test shear stress-strain diagram is drawn in order to find out the ultimate stress, then the shear failure envelope is drawn by relating each ultimate shear stress to the normal stress corresponding to it in at least three tests.

The direct shear test can be used to measure the effective stress parameters of any type of soil as long as the pore pressure induced by the normal force and the shear force can dissipate with time. For the experiment we use the clean sands as a sample, so there is no problem as the pore pressure dissipates readily. However, in the case of highly plastic clays, it is merely necessary to have a suitable strain rate so that the pore pressure can dissipate with time.

Direct shear tests can be performed under several conditions. The sample is normally saturated before the test is run. The test can be run at the in-situ moisture

content. Before we find the value of cohesion and friction angle, we must plot the graph from the data that we get from the experiment. The results of the tests on each specimen are plotted on a graph with the peak (or residual) stress on the x-axis and the confining stress on the y-axis. The y-intercept of the curve which fits the test results is the cohesion, and the slope of the line or curve is the friction angle.

9.0 Questions

Question 1

a. Why perforated plate in this test with teeth? Plate with teeth is usedl to increase fiction and to produce a grip forces between the place and the sample and assists in distributing the shear stress evenly.

Perforated

Perforated

b. What maximum value of displacement before stop the test? The maximum value of displacement before stop the test is when the values from dial gauge are constant at least three times continuously or no more increase data and also when the incline value suddenly dropped so we stop the test.

Question 2

a. What is the purpose of a direct shear test? Which soil properties does it measure?

A direct shear test is a laboratory test used by geotechnical engineers to find the shear strength parameters of soil. The direct shear test measures the shear strength parameters which are the soil cohesion (c) and the angle of friction (). The results of the test are plotted on a graph with the peak stress on the x- axis and the confining stress on the y- axis. The yintercept of the curve which fits the test results is the cohesion and the slope of the line or curve is the friction angle.

b) Why do we use fixing screw in this test? What happen if you do not removed them during test?

We use fixing screw in this direct shear test because in order to avoid shear for happening before the experiment is carried out. If we do not remove them during the test, they will be no friction and the there will be no shear on the sample and thus the result will be not accurate.

10.0 Reference Braja M. Das, Principles of Geotechnical Engneering. Seventh Edition. SI Edition. Cengage Learning.

You might also like

- Direct Shear TestDocument11 pagesDirect Shear Testshahrolhazrien91% (34)

- Report Full Direct Shear Test Edit (Repaired)Document15 pagesReport Full Direct Shear Test Edit (Repaired)Asyraf Malik100% (15)

- Report-Direct Shear Test 1Document20 pagesReport-Direct Shear Test 1Ash BlackForest50% (2)

- Direct Shear Lab TestingDocument9 pagesDirect Shear Lab TestingMelissa SammyNo ratings yet

- Triaxial Test Report - Group 2Document20 pagesTriaxial Test Report - Group 2Khalidah RosmanNo ratings yet

- Tri Axial TestDocument10 pagesTri Axial TestAskart Nano Crime-artNo ratings yet

- Geotechnical Engineering Lab Report 2Document7 pagesGeotechnical Engineering Lab Report 2IanNo ratings yet

- Direct Shear TestDocument19 pagesDirect Shear Testshahrolhazrien75% (4)

- Shear Box TestDocument13 pagesShear Box TestNoor100% (1)

- Direct Shear Test Mohr Coulomb Failure EnvelopeDocument16 pagesDirect Shear Test Mohr Coulomb Failure EnvelopeNishanth Nanthakumar25% (4)

- Experiment No 1: Direct Shear TestDocument10 pagesExperiment No 1: Direct Shear TestAmir SultanNo ratings yet

- Direct Shear TestDocument19 pagesDirect Shear TestBusiNess100% (7)

- Direct Shear TestDocument14 pagesDirect Shear TestAmin SaufiNo ratings yet

- Determine Shear Strength Parameters Using Triaxial TestDocument4 pagesDetermine Shear Strength Parameters Using Triaxial TestRazakMaidenNo ratings yet

- Correlation between Schmidt Hammer and compressive strengthDocument9 pagesCorrelation between Schmidt Hammer and compressive strengthSANDESHNo ratings yet

- KNE373 Prac 1 - Direct Shear Strength TestDocument4 pagesKNE373 Prac 1 - Direct Shear Strength TestSebin GeorgeNo ratings yet

- Lab Direct Shear Test - NewDocument5 pagesLab Direct Shear Test - NewLaBuHiTamNo ratings yet

- VL2021220102506 Ast09Document6 pagesVL2021220102506 Ast09ty juNo ratings yet

- Direct Shear TestDocument24 pagesDirect Shear TestObaid Khalid100% (14)

- Civil Engineering Laboratory DSTDocument6 pagesCivil Engineering Laboratory DSTJuhil ZalavadiyaNo ratings yet

- G5 Direct ShearDocument5 pagesG5 Direct ShearFairiey Izwan AzaziNo ratings yet

- Shear Box Experiment ResultDocument5 pagesShear Box Experiment ResultBgee LeeNo ratings yet

- Direct Shear TestDocument4 pagesDirect Shear TestNajihaharifNo ratings yet

- Direct Shear Test Results and Angle of Repose AnalysisDocument12 pagesDirect Shear Test Results and Angle of Repose AnalysisAhmad Al-Rifai100% (4)

- Plagiarism Checker X Originality Report Similarity 14Document6 pagesPlagiarism Checker X Originality Report Similarity 14Kamran JUTTNo ratings yet

- Direct Shear Test: Measuring Soil Shear StrengthDocument4 pagesDirect Shear Test: Measuring Soil Shear StrengthQUEIZNo ratings yet

- Direct Shear Box and Ring Shear Test: Why Internal Friction VariesDocument17 pagesDirect Shear Box and Ring Shear Test: Why Internal Friction VariesBarry OcayNo ratings yet

- Mohr-Coulomb Shear Strength TheoryDocument12 pagesMohr-Coulomb Shear Strength TheoryJoseph JboyNo ratings yet

- Triaxial Compression TestDocument3 pagesTriaxial Compression TestNtsika SokasiNo ratings yet

- Direct Shear TestingDocument14 pagesDirect Shear TestingIlhamNo ratings yet

- Module 3 Shear Strength of SoilDocument7 pagesModule 3 Shear Strength of SoilJeth LawNo ratings yet

- Direct Shear Box TestDocument9 pagesDirect Shear Box TestMuhammad Yusoff Zakaria100% (1)

- Tests On SoilDocument47 pagesTests On Soilsroy.subhojit100% (1)

- Direct Shear TestDocument32 pagesDirect Shear TestVinay YadavNo ratings yet

- Lab#09 Direct Shear StrengthDocument4 pagesLab#09 Direct Shear StrengthMuhammad UsmanNo ratings yet

- Shear Strength Calculations: Mohr-Coulomb EquationDocument23 pagesShear Strength Calculations: Mohr-Coulomb EquationNouman AmjadNo ratings yet

- Lab 1 Direct Shear Lab 1 Direct Shear TestTestDocument9 pagesLab 1 Direct Shear Lab 1 Direct Shear TestTest7e1a8821100% (1)

- Direct Shear TestDocument4 pagesDirect Shear TestanasNo ratings yet

- Direct Shear TestDocument32 pagesDirect Shear TestVarun Shastry0% (1)

- Unconfined Compression Lab Rapor 2Document12 pagesUnconfined Compression Lab Rapor 2Abdulsamed GözeNo ratings yet

- Geotechnical Engineering Shear Strength TestsDocument29 pagesGeotechnical Engineering Shear Strength Testsmannie edet100% (1)

- Unconfined Compressive Strength Test Lecture NotesDocument6 pagesUnconfined Compressive Strength Test Lecture NotesNaba Kumar BhaumikNo ratings yet

- Lab Report #01 The Direct Shear Test (ASTM D-3080)Document18 pagesLab Report #01 The Direct Shear Test (ASTM D-3080)AHMED SOHELNo ratings yet

- Rebound Hammer PDFDocument6 pagesRebound Hammer PDFAnonymous AJy7S7flB100% (2)

- CV 311_Lab 4_Direct Shear Test (1)Document5 pagesCV 311_Lab 4_Direct Shear Test (1)avnishnandNo ratings yet

- Shear Tests On PhyllitesDocument8 pagesShear Tests On PhyllitesDelvin JacobsNo ratings yet

- Job-2 Direct Shear TestDocument10 pagesJob-2 Direct Shear TestMuhammad Umer Ali Bhatti Muhammad AliNo ratings yet

- Non Destructive Testing of ConcreteDocument56 pagesNon Destructive Testing of ConcreteAbbasabbasi100% (1)

- Triaxial Test ReportDocument2 pagesTriaxial Test ReportSaptarshiNo ratings yet

- Triaxial Test (UC)Document3 pagesTriaxial Test (UC)Aisha MalikNo ratings yet

- Direct ShearDocument4 pagesDirect ShearMUHAMMAD RIAZ AHMAD 2009-CIV-140No ratings yet

- Direct Shear Test Soil ReportDocument12 pagesDirect Shear Test Soil ReportNAJA MOHAMEDNo ratings yet

- Sun and Earth Modern User Reference Guide: Determining earth’s true surface shape as flat using the sunFrom EverandSun and Earth Modern User Reference Guide: Determining earth’s true surface shape as flat using the sunNo ratings yet

- Reservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsFrom EverandReservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- BackgroundDocument2 pagesBackgroundmtrego9441No ratings yet

- Bancuhan 2Document2 pagesBancuhan 2mtrego9441No ratings yet

- Design of RoadDocument15 pagesDesign of Roadmtrego9441100% (1)

- Asswdwddwd 2222 WDocument1 pageAsswdwddwd 2222 Wmtrego9441No ratings yet

- Background DeeDocument1 pageBackground Deemtrego9441No ratings yet

- Random Characters DocumentDocument1 pageRandom Characters Documentmtrego9441No ratings yet

- BackgroundDocument1 pageBackgroundmtrego9441No ratings yet

- Backgroundg HHDocument1 pageBackgroundg HHmtrego9441No ratings yet

- Background of StdyDocument1 pageBackground of Stdymtrego9441No ratings yet

- DESIGN FOUNDATION KAEDAH MAYERHOFFDocument84 pagesDESIGN FOUNDATION KAEDAH MAYERHOFFmtrego94410% (1)

- In ConclusionDocument3 pagesIn Conclusionmtrego944167% (6)

- Asswdwddwd 2222 WDocument1 pageAsswdwddwd 2222 Wmtrego9441No ratings yet

- The Researchers Chose The Topic About The Influence of Social Networking Sites To Be Studied Because It Is Shown Evidently That Most of TheDocument1 pageThe Researchers Chose The Topic About The Influence of Social Networking Sites To Be Studied Because It Is Shown Evidently That Most of Themtrego9441No ratings yet

- Silt TrapDocument6 pagesSilt Trapmtrego9441No ratings yet

- Bacground of StdyDocument1 pageBacground of Stdymtrego9441No ratings yet

- Background of StdyDocument1 pageBackground of Stdymtrego9441No ratings yet

- Bacground of StdyDocument1 pageBacground of Stdymtrego9441No ratings yet

- Background of StdyDocument1 pageBackground of Stdymtrego9441No ratings yet

- Digi Centre Operational TechnologyDocument6 pagesDigi Centre Operational Technologymtrego94410% (2)

- Aggregate impact test assesses toughness for pavement constructionDocument1 pageAggregate impact test assesses toughness for pavement constructionmtrego9441No ratings yet

- ReferenceDocument1 pageReferencemtrego9441No ratings yet

- Prosedur SSDocument8 pagesProsedur SSmtrego9441100% (1)

- Present TWDocument1 pagePresent TWmtrego9441No ratings yet

- Aggregate impact test assesses toughness for pavement constructionDocument1 pageAggregate impact test assesses toughness for pavement constructionmtrego9441No ratings yet

- F 1412 - 01 - Rje0mtiDocument6 pagesF 1412 - 01 - Rje0mtiYasmin AminNo ratings yet

- Getting A Good Fit: Selecting The Right Shaft and Housing ToleranceDocument2 pagesGetting A Good Fit: Selecting The Right Shaft and Housing Toleranceeng13No ratings yet

- Fluid Mechanics Test and Exam DetailsDocument8 pagesFluid Mechanics Test and Exam DetailsDiego FungNo ratings yet

- 4.DB Flats (1-7) & SMDB TypicalDocument9 pages4.DB Flats (1-7) & SMDB TypicalhpzenNo ratings yet

- Piper Arrow checklist guide for pilotsDocument3 pagesPiper Arrow checklist guide for pilotsmichael.s.lacy7874No ratings yet

- Cooling System Draining and Filling: Glycol UsageDocument10 pagesCooling System Draining and Filling: Glycol UsageluckinsideNo ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- KF Contro Ball Broch 3pc4bolt 1Document8 pagesKF Contro Ball Broch 3pc4bolt 1M CramerNo ratings yet

- 640 DradiatorblindDocument2 pages640 DradiatorblindMaxy ServiçosNo ratings yet

- By Amruta Pawar (4550) Bhavika Karkare (4521) Rasika Kadam (4519) Unnati Wadke (4565) Under The Guidance of Prof. MR A. K. JoshiDocument18 pagesBy Amruta Pawar (4550) Bhavika Karkare (4521) Rasika Kadam (4519) Unnati Wadke (4565) Under The Guidance of Prof. MR A. K. JoshiAmrutaNo ratings yet

- Casing AccessoriesDocument48 pagesCasing AccessoriesDigger Downhole ToolsNo ratings yet

- JC GGC 2011 Catalogue Low ResDocument52 pagesJC GGC 2011 Catalogue Low ResgaluNo ratings yet

- Lee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LDocument3 pagesLee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LReddyvari VenugopalNo ratings yet

- Carbs 101Document5 pagesCarbs 101Ashwin KumarNo ratings yet

- ProgManual - DXF (EZ Trak Programming and Operating Manual-March 2001)Document289 pagesProgManual - DXF (EZ Trak Programming and Operating Manual-March 2001)Mike Ham100% (1)

- HSU-7-9-12-14-18-22 HaerDocument93 pagesHSU-7-9-12-14-18-22 Haerprotek506No ratings yet

- Chemical Engg. 3rd SemDocument3 pagesChemical Engg. 3rd SemAVERAGENo ratings yet

- 4 K53 Code C1 Pre Trip 1Document2 pages4 K53 Code C1 Pre Trip 1abubakr fingerNo ratings yet

- UiiuDocument20 pagesUiiupravi2010No ratings yet

- PsychrometricsDocument32 pagesPsychrometricskdsahooNo ratings yet

- Vibrational Analysis of Machine Foundation ACI 351.3R-04 (FEA Method)Document9 pagesVibrational Analysis of Machine Foundation ACI 351.3R-04 (FEA Method)Randy CernaNo ratings yet

- Handbook of Practical Gear DesignDocument7 pagesHandbook of Practical Gear DesignPooria1989No ratings yet

- 2-Theory of SedimentationDocument11 pages2-Theory of SedimentationSheeraz AhmedNo ratings yet

- Cessna 172M CHECKLISTDocument3 pagesCessna 172M CHECKLISTDev ShahNo ratings yet

- BV DSG eDocument18 pagesBV DSG eIulianIonutRaduNo ratings yet

- 012.0 - Cat-6060 - Central Greasing System - AttachmentDocument50 pages012.0 - Cat-6060 - Central Greasing System - AttachmentJorby Cuadros100% (2)

- Elektrisk (Katalog - Ermax)Document267 pagesElektrisk (Katalog - Ermax)ionel1987No ratings yet

- New ChangeDocument68 pagesNew ChangeAnoop Kamla PandeyNo ratings yet

- Vibration BookDocument152 pagesVibration Bookrez_babu7430No ratings yet