Professional Documents

Culture Documents

TSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina Elf

Uploaded by

iwansalmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina Elf

Uploaded by

iwansalmaCopyright:

Available Formats

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

TSP

PRHSESAF139

Rev 0

04/08/01

SIMULTANEOUS OPERATIONS

Authorisation Record ORIGINATOR

Signature

TECHNICAL AUTHORITY

Signature

ISSUING AUTHORITY

Signature

POSITION NAME DATE

HEAD OF HSE R. LEPOITEVIN A. DESPREZ 04 AOUT 2001

POSITION NAME DATE

TSP HSE MANAGER B. COTE 04 AOUT 2001

POSITION NAME DATE

SITE REPRESENTATIVE J. GALVES/A. MARCHAL 04 AOUT 2001 PAGE : 1 of 18

REV. 0 04th August 2001

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

TABLE OF CONTENTS

1 PURPOSE OF THE SIMOPS .....................................................................................................3

1.1 Main purpose...........................................................................................................3 1.2 Detailed objectives..................................................................................................3 1.3 SUPPORT AND CONTRIBUTING ELEMENTS.......................................................4 1.4 REFERENCES.........................................................................................................6 TSP HSE MANUAL.................................................................................................6

2 DOCUMENT CONTROL.............................................................................................................6

2.1 ISSUE......................................................................................................................6 2.2 DISTRIBUTION........................................................................................................6 2.3 REVIEW AND UPDATE ..........................................................................................6

3 OPERATIONS FORECAST & PLANNING.................................................................................7

3.1 OPERATIONS PLANNING .....................................................................................7 3.1.1 Step 1 : First turbo-generator running on diesel (HDEC Milestone A)...............7 3.1.2 Step 2. Take over by Production of Sea Water Intake and Plant Sea Water distribution..................................................................................................................7 Activities under Production responsibility ..................................................................7 3.1.3 Step 3 : Ready to receive fuel gas from Kangan and run generator/boiler on fuel gas . (HDEC Milestone D)....................................................................................7 3.1.4 Step 4 : 4 wells to be completed and ready for hook up on SPD3.....................7 3.1.5 Step 5 : Operation on behalf of HDEC by ODC. (Milestone E)..........................7 3.1.6 Step 6 : Final take over by Prod of SPD3 platform ready for gas production with 4 wells, Start sea line de watering..............................................................................7 3.1.7 Step 7. Take over by Production of partial onshore plant area: (HDEC Milestone F)................................................................................................................8 3.1.8 Step 8 : End of sea line de watering, gas-in of receiving facilities......................8 3.1.9 Step 9(a) : Take over by prod of Train 1 area (HDEC Milestone Process train 1)................................................................................................................................8 3.1.10 Step 10 : Start to export gas............................................................................8 3.1.11 Step 11 : Reach first production stage.............................................................8 3.2 SIMULTANEOUS OPERATIONS FORECAST........................................................8

4 RESPONSIBILITIES....................................................................................................................9

4.1 T.S.P. SITE MANAGER ..........................................................................................9 4.2 SIMULTANEOUS OPERATIONS LEADER ............................................................9 4.3 AREAS OF RESPONSIBILITIES ..........................................................................10 CONSTRUCTION AREAS......................................................................................10 UTILITY AREAS .....................................................................................................10 PRODUCTION AREAS...........................................................................................10 4.4 INSTALLATION AUTHORITY ...............................................................................10 CONSTRUCTION AREAS ......................................................................................10 UTILITY AREAS ( OPERATION DURING COMMISSIONING ) .................10 PRODUCTION AREAS...........................................................................................10 4.5 RESPONSIBILITIES OF THE INSTALLATION AUTHORITY ................................10

5 SUPERVISION .........................................................................................................................11 6 OPERATIONS MANAGEMENT AND ORGANISATION...........................................................12

6.1 OPERATIONS PLANNING....................................................................................12 6.2 OPERATION PREPARATION...............................................................................12 6.3 ORGANISATION FOR SIMOPS............................................................................13 6.4 MEETINGS............................................................................................................14 6.5 WORK PERMITS...................................................................................................15 6.5.1 SHARED AREAS............................................................................................15

REV. 0 04th August 2001 PAGE : 2 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

6.5.2 HAZARD IDENTICATION and IMPACTED ZONES........................................15 6.6 OPERATION CONTROL........................................................................................16 6.7 PLANT AND EQUIPMENT.....................................................................................16

7 PERSONNEL CONTROL..........................................................................................................17

7.1 AREAS WITH PERSONNEL ACCESS RESTRICTIONS ......................................17 7.2 ALARMS AND COMMUNICATION........................................................................17 7.3 MUSTERS.............................................................................................................17

8 AUTHORIZED SIMULTANEOUS OPERATIONS.....................................................................17 9 SHARED FACILITIES...............................................................................................................18

9.1 FIRE BRIGADE.....................................................................................................18 9.2 CLINIC AND AMBULANCE...................................................................................18 9.3 SEARCH AND RESCUE TEAM............................................................................18 9.4 SECURITY TEAM..................................................................................................18

PURPOSE OF THE SIMOPS

1.1 Main purpose

The main purpose of the Simultaneous Operation Safety Rules and Procedures is to provide all personnel involved with simultaneous operations on TOTAL /South Pars phase 2 and 3 with a knowledge of the relevant safe practices and procedures. Additionally, this Section is used to predetermine the compatibility, interference and limitations during the planning and operational stages of Simultaneous operations. It takes into account the specific design of the South Pars Phases 2 & 3 Installations and the TSP Organization. The present version addresses the specific situation of phased hand over to Production up to first gas export The activities concerned by this document are: - Construction activities (Lifting, Cold work /Hot works, etc.) - Commissioning Activities. - Operation of the utility system by ODC ( Operation during Commissioning ) Team conducted in geographical areas under construction authority and prior to hand over to Production. - Production activities after partial hand over to production. It is possible to forecast the equipment lay out , the number of personnel Involved and the safety status of a given area for determining Construction or Commissioning operations during routine production. This will optimize safety clearance , prevent obstructions / interference and minimize constraints. This is one of the objectives of the SIMOPS procedures. This document has addressed as many situations as possible. However, should the need arise, specific operations will have to be reviewed on a case by case basis.

1.2

Detailed objectives

PAGE : 3 of 18

REV. 0 04th August 2001

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

This Section called Simultaneous Operation Safety Rules and Procedures are referred to, in short, as SIMOPS. The objectives of the SIMOPS are to: - Highlight potential restrictions when forecasting and planning additional activities due to take place at the same time and location where long-term activities are performed.(for the purpose of this document, SIMOPS starts with the start-up of the first utilities i.e. electricity supply.) Ensure any activity or operation affecting an area, where another activity may be on going simultaneously, is reviewed and analyzed for potential interference or limitation. Establish a mechanism for review of proposed activities (e.g. meeting and identifying department participation).

Establish matrix to authorize simultaneous activities. Ensure simultaneous activities are controlled and performed in a safe manner by : Defining responsibilities of personnel involved Requiring the appointment of a SOL (Simultaneous Operation Leader) to coordinate activities within different organizations. Stating preventive measures to be implemented prior to starting simultaneous activities Limiting the number of simultaneous activities and / or the area affected Avoiding interference during operations Providing communication channels and procedures. Training of all personnel including communication of step changes. Minimize the potential for personnel injury and equipment damage by Controlling and restricting personnel access to areas of simultaneous activities Providing specific instruction for securing operations and mustering personnel in case of emergency Ensuring all personnel involved are aware of the specifics of simultaneous operations and of the procedures. Identifying hazards and evaluating the consequences of failures, to update matrix of allowed simultaneous activities.

1.3

SUPPORT AND CONTRIBUTING ELEMENTS

- Construction forecast and planning - Commissioning activities forecast and planning - Operation of utility system by ODC forecast and planning - Production activities forecast and planning

REV. 0 04th August 2001

PAGE : 4 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

- Review and analysis of potential simultaneous activities up to the end of construction / commissioning activities (after train 4 hand over) - Risk evaluation procedures - Permit to work system - Plant Design and engineering studies

REV. 0 04th August 2001

PAGE : 5 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

1.4

REFERENCES

TSP HSE MANUAL.

Standard 601 , Work Permit System Standard 300 series, risk evaluation Site Emergency Procedures Manual Site / Head Office ( existing ) Site / Tehran relative to construction period ( existing ) New Site Scenarios

DOCUMENT CONTROL

2.1 ISSUE

This document is issued by the site HSE Authority under the control of the Site Manager in charge at the time of issue or update.

2.2

DISTRIBUTION

This section is distributed as per list. These identified copies are controlled as per the general site control system. Whether the Site Manager. / The Operation Assistant or the Safety Authority feels an extended distribution is necessary, it is their responsibility to dispatch the relevant document. Minimum distribution List Construction Manager Commissionning Manager Operation Assistant HSE Manager Simultaneous Operations Leader Head of Construction Head of Production Head of Safety and FIFI Commissioning Site Leader HDEC Site Representative HDEC Commissioning Manager

2.3

REVIEW AND UPDATE

The Simultaneous Operations Safety Rules and Procedures will be reviewed and amended as necessary under the responsibility of the Site Manager, then the document will be updated through revisions.

REV. 0 04th August 2001

PAGE : 6 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

OPERATIONS FORECAST & PLANNING

3.1 OPERATIONS PLANNING

Two groups, Project (construction , commissioning & odc) and Production, will be performing operations on South Pars Phases 2 & 3 over the period 2001 2002 Construction and Commissioning activities are planned until end of 2002 Production is due to start in Dec 2001 Definition of start-up sequence:

3.1.1

Step 1 : First turbo-generator running on diesel (HDEC Milestone A)

- Due date : 25-5-2001 - Area under SIMOPS procedure: Turbo-generator area and SS1 - Activities under Project responsibility

3.1.2 Step 2. Take over by Production of Sea Water Intake and Plant Sea Water distribution.

- Due date : 30-07-2001 - Area under SIMOPS procedure: SWI area

Activities under Production responsibility

3.1.3 Step 3 : Ready to receive fuel gas from Kangan and run generator/boiler on fuel gas . (HDEC Milestone D)

- Due date : 1-9-2001 - Area under SIMOPS procedure: All gas pressurized lines and systems, corresponding generators, boilers and electrical substations - Activities under Project responsibility

3.1.4 Step 4 : 4 wells to be completed and ready for hook up on SPD3

- Due date : 30-9-2001 - Area under SIMOPS procedure: SPD3. Note : for information only.

3.1.5 Step 5 : Operation on behalf of HDEC by ODC. (Milestone E)

- Due date:01-10-01 - Area under SIMOPS Procedure: MEG, tanks and distribution, part of utilities, propane tank, Reception facilities (pressurized water) - Activities under Project responsibility

3.1.6 Step 6 : Final take over by Prod of SPD3 platform ready for gas production with 4 wells, Start sea line de watering

- Due date : 7-11-2001 - Area under SIMOPS procedure: SPD3. Note : for information only.

REV. 0 04th August 2001 PAGE : 7 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

3.1.7 Step 7. Take over by Production of partial onshore plant area: (HDEC Milestone F)

- Due date : 15-11-2001 - Area under SIMOPS procedure: MEG , reception facilities, part of utilities, condensate stabilization, condensate storage, export facilities, phase two flare , ESD ,F&G, DCS, Power distribution and systems which interface with equipment handed over to Production. - Activities under Production responsibility

3.1.8 Step 8 : End of sea line de watering, gas-in of receiving facilities

- Due date : 28-11-2001 - Area under SIMOPS procedure: as 3.1.7 and around sour water treatment and disposal. - Activities under Production responsibility

3.1.9 train 1) Step 9(a) : Take over by prod of Train 1 area (HDEC Milestone Process

- Due date : 20-12-2001 - Area under SIMOPS procedure: as 3.1.7, Train 1 and substation 2 excluding Sulphur Recovery Unit. - Activities under Production responsibility

Step 9(b) : Take over by prod of Train 1 area.

3.1.10

Due date : Area under SIMOPS procedure : as step 9(a) and Sulphur Recovery Unit. Activities under Production responsibility

Step 10 : Start to export gas

- Due date : 15-1-2002 - Area under SIMOPS procedure: No change - Activities under Production responsibility

3.1.11 Step 11 : Reach first production stage

- Due date : 1-3-2002 - Area under SIMOPS procedure: No change - Activities under Production responsibility Note: Next steps will be defined at later stage

3.2

SIMULTANEOUS OPERATIONS FORECAST

Construction , Commissioning, Utility systems running and Production Operations with potential interference between them should be forecasted to minimize any interference.

REV. 0 04th August 2001

PAGE : 8 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

Information relevant to simultaneous activities with a possible / potential impact to the other team should be given for every planned operation as well as for contingency and emergency situation. Simultaneous operations which are not authorized within this procedure, or simultaneous operations for which special precautions may be required shall be subject to a what if or risk evaluation. Urgent decisions regarding SIMOPS are the responsibility of the Site Manager

RESPONSIBILITIES

4.1 T.S.P. SITE MANAGER

The Site Manager is responsible for the Safety, Health and Welfare of all personnel working on the site. All supervisors working on the project assist the Site Manager. The TSP Site Managers responsibility for safety and coordination will be handed over to the Production Assistant at train one hand over (step 9). Up to step 4 The Site Manager takes responsibility as Simultaneous Operations Leader.

4.2

SIMULTANEOUS OPERATIONS LEADER

The Simultaneous Operations Leader (S.O.L) is responsible for proper coordination and safe simultaneous interfaces as well as identification and resolution of possible impact on other operations. He receives delegation for these responsibilities from the Site Manager. He liaises with all supervisors (Production, Construction, Commissioning, Maintenance, Safety, etc) and area /installation authorities. He ensures that the operational team duly enforce SIMOPS procedures. However both Construction and Production teams remain responsible for the safe management of their own operations. . The S.O.L. acts under guidance and control of the TSP Site Manager additionally he will report and liaise with Project and Production as required. It is the responsibility of the SOL to follow up the completion of listed activities and to report to the Site Manager any trend or omission which could potentially jeopardize the planning forecast. In the event of a disagreement regarding the safety of a proposed simultaneous operation or the continuation of an activity in progress, the

REV. 0 04th August 2001

PAGE : 9 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

matter should be decided by the SOL and referred to the Site Manager for approval ( if deemed necessary )

4.3

AREAS OF RESPONSIBILITIES

Four types of operational zones are defined on South Pars Phase 2 and 3 installations.

CONSTRUCTION AREAS

Under the responsibility of the Site Manager

COMMISSIONING AREAS

Under the responsibility of the Site Manager

UTILITY AREAS

Operated by ODC ( Operation during Commissioning ) under the responsibility of the Site Manager

PRODUCTION AREAS

Under the responsibility of the Operations Assistant

4.4

INSTALLATION AUTHORITY

One nominated person is in charge of each operational zone:

CONSTRUCTION AREAS

The HDEC Area Authority is the Installation Authority

COMMISSIONING AREAS

The Commissioning Manager is the Installation Authority

UTILITY AREAS ( OPERATION DURING COMMISSIONING )

Prior to hand over The Operation during Commissioning team operate and maintain utilities. The Commissioning Manager is the Installation Authority. However during phases where production operations are in hand, clear definition of interfaces should be set up and responsibilities shared for any activity having a potential impact on production, i.e. PCS, ESD, F&G, power sources and distribution, etc.

PRODUCTION AREAS

The Process and Utility Superintendents are the Installation Authorities on the areas handed over to Production.

4.5

RESPONSIBILITIES OF THE INSTALLATION AUTHORITY

In addition to the duties defined by the Permit to Work system (TSP PTW) the nominated Installation Authority is responsible for

REV. 0 04th August 2001

PAGE : 10 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

Ensuring planned operations have: Been properly evaluated as to their implications and potential consequences Been forecasted correctly in terms of time and duration. Ensuring Area Operators are fully aware of the SIMOPS as well as the implication and consequences of each of their operations in regard to the proximity of other teams personnel and equipment. Ensuring operations are performed within forecast. In case of delays, the area Authority should evaluate consequences of the delay then notify the Site Rep., SOL, and other interested parties as required. Ensuring that only essential personnel are authorized to enter areas affected by SIMOPS operations. Ensuring that involved personnel are aware of alarms and evacuation procedures.

SUPERVISION

Safety of SIMOPS operations is dependent to a great degree on the general communication, coordination and cooperation between the Supervisors and Authorities involved. Accurate evaluation and control of the operational parameters are of prime importance for SIMOPS operations, safety and efficiency. For this purpose commissioning will maintain two sets of permanently updated and marked-up copies of electrical online diagrams identifying energized circuits and P & IDs identifying pressurized equipment ,location of isolations (spades, spools, valves, etc) One copy for their own use the other copy for the SOL. In this respect, and in addition to the usual job preparation, supervisors should: Ascertain their operation has been duly planned and that the Site Manager. / SOL, Area Authority and other involved supervisors have been informed of the timing and about any potential constraint and interference. Confirm evaluation of starting time and duration. Confirm evaluation of potential constraints and interference. Check that operation and emergency procedures comply with SIMOPS context and to the current running / planned activities. Ensure both, equipment and personnel, are available and comply with SIMOPS. During the operation, direct control should be maintained by: Continuous supervision and monitoring

REV. 0 04th August 2001

PAGE : 11 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

Clear instruction, constantly updated according to progress and events. Enhanced checking and testing. Good communication and detailed instructions eg Tool Box Talks

OPERATIONS MANAGEMENT AND ORGANISATION

Planning highlights concurrent activities performed by different sections. A general agreement on work organization and schedule is reached to minimize disruption and promote communication between all parties.

6.1

OPERATIONS PLANNING

Construction , Commissioning and Production Departments issue planning forecasts which are reviewed by respective management to identify Simultaneous Operations. When SIMOPS are identified Managers will advise all affected parties and when required Construction / Commissioning planning will be updated to incorporate SIMOPS . Acceptance of planned operations , additional requirements and constraints will be approved by management and supervision. The operation program should give all relevant information relating to simultaneous operations including constraints, limitations, areas of conflict and include or refer to applicable emergency procedures. The SOL will inform all parties involved, obtain acceptance for the operation plan and any identified constraints. When conflicting operations are identified he will liaise with Project and / or Production who will decide which takes priority.

6.2

OPERATION PREPARATION

Prior to commencing SIMOPS the Site Manager / SOL will meet with all involved parties to verify all aspects of the operation , confirm emergency procedures, identify constraints, limitations and conflicting activities. Once the planning of the operation is confirmed and the detailed program and/or procedures approved, equipment and personnel are mobilized.

REV. 0 04th August 2001

PAGE : 12 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

6.3

ORGANISATION FOR SIMOPS

Project Phase up to Step 3

Acting as : Site Manager

SOL Installation Authorities Safety Authority

Construction TSP Construction Manager Not required HDEC Area Authorities

HSE Area Authorities

Commissioning TSP Construction Manager

Not required

Commissioning Manager

HSE Area Authorities

Project and Production Phases (Starting step 5 and up to train 1 hand over)*

Acting as : Site Manager

SOL

Up to step 8 TSP Construction Manager Required

Construction Commissioning / ODC

Starting step 9

Operations Assistant Required

Construction Commissioning / ODC

Installation Authorities

HDEC Area Authorities HDEC Area Authorities Commissioning Manager

Production

Commissioning Manager

Production

Process / Utility Superintendents

Safety Authority Project HSE Area Authorities

Process / Utility Superintendents

Project HSE Area Authorities

Production Head of FF & HSE

*After train 1 hand over to be defined later

Production Head of FF & HSE

REV. 0 04th August 2001

PAGE : 13 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

6.4

MEETINGS

Meetings are required to : Keep the highest standards of Safety awareness for all personnel. Ensure proper Communication, Cooperation and Coordination between the different teams working on the installations . Ensure proper planning and progress of simultaneous activities to minimize unproductive downtimes. Ensure strict application of the Safety Rules & Procedures and of the risk evaluation and work Permit System.

Meetings will be held : Prior to start-up of simultaneous activities : All supervisors and Authorities to be convened to a kick-off meeting by the Site Manager, SOL, to ensure that all precautions have been implemented and equipment is available . Daily Time and location to be agreed by the participants. In addition to usual topics and tasks, this meeting chaired by the Site Manager / SOL. is the opportunity for supervision personnel to: Review and confirm planning of future concurrent activities, according to the actual progress of running operations and to identify potential conflicts . Authorize work to be performed under the permit to work system highlighting SIMOPS events and address safety concerns . Daily Tool Box Talks. Specific emphasis will be given to the systems having a potential impact on production activities in hand and methods of raising the alarm to be taken in case of emergency. These may have to be changed to adapt to the SIMOPS context: eg. Areas barrierd off or temporarily used for a different purpose Escape routes, location of safety equipment Emergency drills: Should be performed in the context of simultaneous activities ( Alarms , Detection and communication systems to be defined and will be supported by a stand alone document )

REV. 0 04th August 2001 PAGE : 14 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

6.5

WORK PERMITS

The South Pars Work Permit System is applicable for SIMOPS on the site. The construction / commissioning procedure is in force for all activities performed up to partial hand over to production . Areas under production responsibility (post partial hand over) will be subject to the production work permit procedure.

6.5.1

SHARED AREAS

Shared area means : Personnel from both operations are present at the same moment of time at the same place. Operations will be performed in close proximity of personnel with potential hazards such as pressure testing and gas release for which safety barriers may not provide suitable protection due to the confined environment ( the minimum distance required may not always be practicable ) Areas where control, emergency and safety equipment in use for production are located Areas where Safety equipment, communication devices (telephone line ) are located Escape routes and temporary refuges. Areas through which live or pressurized lines pass. Different locations are defined on the Site. The manner in which these areas are shared depends how the Construction / Commissioning and Production operations are carried out.

6.5.2 HAZARD IDENTICATION and IMPACTED ZONES

Reference in standard 300 series and 600 series (standard 604 ISOLATION) The extent of zones under SIMOPS in each start-up phase are defined by using hazard identification techniques. For simultaneous activities that are a combination of Commissioning / Construction activities during Production operations, a risk evaluation will be done based on the specifics of the operations, under the present SIMOPS rules and procedures and on HSE standard 300 series guidance. The results of this feasibility study will be incorporated in the operation program and should be accepted by Management and Supervision prior to starting SIMOPS operations.

REV. 0 04th August 2001

PAGE : 15 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

6.6

OPERATION CONTROL

The control of simultaneous operations is the responsibility of the Site Manager in charge at the time of the operation. The SOL is designated to assist him in coordinating and planning activities. The preparation of the SIMOPS operations as far as organization, equipment , material and procedures are concerned, is shared between TSP construction and production organizations. To assist these organizations in preparing for pre determined start-up phases, checklists will be prepared prior to each step and responsibilities allocated to the disciplines / individuals in charge.

6.7

PLANT AND EQUIPMENT

Subject to the requirements defined in the appended checklists all plant and equipment existing and new purchase must conform to hazardous area classification, other plant and equipment will be subject to and controlled by the Permit to Work System. Examples will include but are not limited to : Vehicles : see note. Electrical equipment Power tools IS communication system Lifting equipment Hand tools

All plant and equipment for use within controlled areas ( ie live ) will be subject to pre inspection , plant id cards and tagging Personal protective equipment and escape equipment must be suitable for use within a sour ( H2S ) service environment. Note : Refer to Vehicle Access Procedures

REV. 0 04th August 2001

PAGE : 16 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

PERSONNEL CONTROL

( Note :This section will be further defined within a stand alone document )

7.1

AREAS WITH PERSONNEL ACCESS RESTRICTIONS

Access between areas will be controlled by badges, manned security , the permit to work system and from step 9 electronic badge readers.

7.2

ALARMS AND COMMUNICATION

Communications will be provided in accordance with emergency and operational requirements.

7.3

MUSTERS

Whenever mustering personnel is required, all construction / commissioning and production personnel will normally muster outside the potentially impacted area. All personnel must be provided with H2S escape masks. The list of personnel in the area will be identified and controlled.

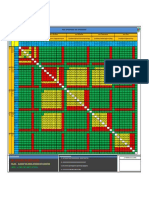

AUTHORIZED SIMULTANEOUS OPERATIONS

The table ( appendix 1) applies during routine operations. In the event of an abnormal situation , simultaneous operations must be stopped and made safe . Authorization from the SOL will be required for resumption of simultaneous operations.

REV. 0 04th August 2001

PAGE : 17 of 18

TOTAL FINA ELF

TOTAL SOUTH PARS TSP-P-PR-HSE-SAF- 139

TSP - PRODUCTION SIMULTANEOUS OPERATIONS

SHARED FACILITIES

(Note : This section to be further defined )

9.1 9.2 9.3 9.4

FIRE BRIGADE CLINIC AND AMBULANCE SEARCH AND RESCUE TEAM SECURITY TEAM

REV. 0 04th August 2001

PAGE : 18 of 18

You might also like

- Process Safety ManagementDocument28 pagesProcess Safety ManagementIndranil Hatua100% (13)

- 3S HSE MS Docs ContentDocument85 pages3S HSE MS Docs Contentrashid zamanNo ratings yet

- Directory Energy Taiwan SmartDocument21 pagesDirectory Energy Taiwan SmartWeslyn LeeNo ratings yet

- SimopsDocument24 pagesSimopsgilbertotiburcio100% (1)

- Pdo HseDocument33 pagesPdo HseElencheliyan Pandeeyan0% (1)

- Standard Safety Practices ManualDocument350 pagesStandard Safety Practices Manualrs_hendarsah100% (12)

- Commisioning Execution PlanDocument38 pagesCommisioning Execution PlanOmar Tocmo100% (3)

- HAZOP Saudi Aramco HAZOP GuidelinesDocument92 pagesHAZOP Saudi Aramco HAZOP Guidelinesjakejohns100% (15)

- Simultaneous Operations (SIMOPS) HSE Procedure for Pars Oil & Gas CompanyDocument24 pagesSimultaneous Operations (SIMOPS) HSE Procedure for Pars Oil & Gas CompanyOsman KozuNo ratings yet

- SIMOPS Check ListDocument8 pagesSIMOPS Check ListWawan Setiawan100% (2)

- Process Safety Management GuideDocument39 pagesProcess Safety Management Guidesl1828100% (6)

- SP 2062 HSE Specification Specifications For HSE CasesDocument84 pagesSP 2062 HSE Specification Specifications For HSE CasesDaniel Martinez0% (1)

- Simultaneous Operations (SIMOPS)Document156 pagesSimultaneous Operations (SIMOPS)Ahmed Lepda100% (3)

- Cat TransfDocument15 pagesCat TransfaliarababadiNo ratings yet

- Heidelberg Cement Sustainability ReportDocument52 pagesHeidelberg Cement Sustainability ReportCSRMedia NetworkNo ratings yet

- Aramco - Risk Assessment PDFDocument14 pagesAramco - Risk Assessment PDFali bahmaniNo ratings yet

- Chevron Hazard Analysis Guidelines 2012Document10 pagesChevron Hazard Analysis Guidelines 2012valdivijNo ratings yet

- 11 SIMOPs Procedure 11Document14 pages11 SIMOPs Procedure 11riyazali100% (5)

- Petroleum Development Oman L.L.C.: H S & So Management Drilling and Well InterventionDocument67 pagesPetroleum Development Oman L.L.C.: H S & So Management Drilling and Well Interventionxu zhao0% (1)

- Process Safety Management PDFDocument31 pagesProcess Safety Management PDFMuhammad Husnul Khuluq100% (4)

- Project Execution Plan For TankDocument3 pagesProject Execution Plan For Tankiwansalma100% (1)

- Simops MatrixDocument17 pagesSimops MatrixthinkpadNo ratings yet

- BUNDUQ-HSE-SOP-05 Simultaneous Operations (SIMOPS)Document56 pagesBUNDUQ-HSE-SOP-05 Simultaneous Operations (SIMOPS)Rizwana100% (1)

- OIMS Exxon-Mobil PDFDocument16 pagesOIMS Exxon-Mobil PDFAle SanzNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Isand Drilling HSE Case Nov 08 Rev A02lDocument310 pagesIsand Drilling HSE Case Nov 08 Rev A02lSalim Muftah100% (5)

- HSE Bridging Document - OnGC & Quippo - CleanedDocument27 pagesHSE Bridging Document - OnGC & Quippo - CleanedAnindra ByatshoshNo ratings yet

- Mopo SimopsDocument1 pageMopo SimopsMichael GanNo ratings yet

- HSE Specification - Flora and Fauna ProtectionDocument11 pagesHSE Specification - Flora and Fauna ProtectionrwerwerwNo ratings yet

- 03a-Simultaneous Operations Operational ProcedureDocument11 pages03a-Simultaneous Operations Operational Proceduremichel louis friedman100% (1)

- Guide For Process Safety in DesignDocument35 pagesGuide For Process Safety in DesignpoundingNo ratings yet

- Nema SM 24 1991 R2002Document93 pagesNema SM 24 1991 R2002surawutwijarn100% (2)

- Hsse S 005 - Hsse in ProjectsDocument11 pagesHsse S 005 - Hsse in ProjectsAHMED AMIRANo ratings yet

- NGMSA TQ Fence Levels 122Document2 pagesNGMSA TQ Fence Levels 122Sehna SerajNo ratings yet

- HSE Practice SIMOPS ProcedureDocument17 pagesHSE Practice SIMOPS ProcedureAjay Krishnan80% (5)

- SIMOPS SMG 06-007-2016 (Final)Document18 pagesSIMOPS SMG 06-007-2016 (Final)Ayman Alradi100% (1)

- Offshore SafetyDocument114 pagesOffshore SafetyGNo ratings yet

- SIMOPS Procedure - Pro-Saf-010-Ieoc Rev01-FinalDocument13 pagesSIMOPS Procedure - Pro-Saf-010-Ieoc Rev01-Finalkhaled100% (2)

- Manta To Richmond SIMOPS Risk Matrix FINALDocument1 pageManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- Safe Work Methode For HDD BoringDocument1 pageSafe Work Methode For HDD Boringiwansalma100% (3)

- Shell Develops Spacing Chart for Unconventional Gas OperationsDocument15 pagesShell Develops Spacing Chart for Unconventional Gas OperationsthinkpadNo ratings yet

- Simops SafetyDocument9 pagesSimops SafetyJahel Looti100% (2)

- Simultaneous Operations (SIMOPS) TERM OF REFERANCE (TORDocument25 pagesSimultaneous Operations (SIMOPS) TERM OF REFERANCE (TORkokykarkar80% (5)

- Hemp HazidDocument17 pagesHemp HazidrwerwerwNo ratings yet

- Standard MaterialDocument29 pagesStandard MaterialTiar Rahman100% (1)

- Simops Mopo MatrixDocument6 pagesSimops Mopo MatrixPrathap SelvamNo ratings yet

- Identification of Safety Critical Equipment (SCE) : GuideDocument28 pagesIdentification of Safety Critical Equipment (SCE) : Guidemoustafa100% (1)

- Preventive and Predictive Maintenance Strategies PDFDocument3 pagesPreventive and Predictive Maintenance Strategies PDFcakendriNo ratings yet

- Simultaneous Operations (SIMOPS)Document19 pagesSimultaneous Operations (SIMOPS)Desmond Chang71% (7)

- Emergency Response Plans for Noble Bully II Drilling RigDocument36 pagesEmergency Response Plans for Noble Bully II Drilling RigGeorge MedeirosNo ratings yet

- Spirax Sarco - Product OverviewDocument24 pagesSpirax Sarco - Product OverviewgunnarthorsenNo ratings yet

- Understanding Oil and Gas HSE Management (37Document34 pagesUnderstanding Oil and Gas HSE Management (37Madhur ChopraNo ratings yet

- EPRI - Component Engineering Guidelines - 2005 - 108p - 1011896 - Tags - ModificationDocument108 pagesEPRI - Component Engineering Guidelines - 2005 - 108p - 1011896 - Tags - ModificationKhalidPeerNo ratings yet

- ErC-DU Planning Manual 10aug2009Document45 pagesErC-DU Planning Manual 10aug2009berto_diego100% (14)

- Simultaneous OperationsDocument22 pagesSimultaneous OperationsOgbadiboNo ratings yet

- I. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17Document15 pagesI. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17KehindeNo ratings yet

- PR-1971 2016 PDFDocument39 pagesPR-1971 2016 PDFradhouane100% (1)

- HSE Plan - FPSO Topside PDFDocument48 pagesHSE Plan - FPSO Topside PDFdndudc100% (3)

- PSSR Checksheet - Offshore Asset - DraftDocument6 pagesPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- SIMOPs Matrix - Combined - Rev-1Document1 pageSIMOPs Matrix - Combined - Rev-1DebadityachatterjeeNo ratings yet

- SimopsDocument6 pagesSimopsravikrss100% (2)

- Simops Risk AssessmentDocument3 pagesSimops Risk Assessmentzineddinmakram100% (1)

- Cir317 Pans Ops-NoiseDocument88 pagesCir317 Pans Ops-Noiseicyreg100% (1)

- Planning Communicating SIMOPSDocument26 pagesPlanning Communicating SIMOPSantonNo ratings yet

- Confined Space Entry Safety - Never Enter Without Gas TestingDocument1 pageConfined Space Entry Safety - Never Enter Without Gas Testingramod100% (1)

- Health, Safety & Environmental Requirements for ContractsDocument21 pagesHealth, Safety & Environmental Requirements for ContractsSachin GanvirNo ratings yet

- TN 015 Overrides 15Document8 pagesTN 015 Overrides 15Luis SantosNo ratings yet

- Section 4 - Grave Emergency ShutdownDocument19 pagesSection 4 - Grave Emergency ShutdownHammad MasoodNo ratings yet

- Ar Chivos 1218 ADocument178 pagesAr Chivos 1218 Ashujad77No ratings yet

- SSP 30599 Rev EDocument84 pagesSSP 30599 Rev ECHPNo ratings yet

- British StandardsDocument12 pagesBritish Standardsniginp67% (3)

- List Customer MHE PC 45Document4 pagesList Customer MHE PC 45iwansalmaNo ratings yet

- Butterfly Valve 20 Inch.Document7 pagesButterfly Valve 20 Inch.iwansalma100% (1)

- Traffic Signs ManualDocument334 pagesTraffic Signs Manualiwansalma100% (1)

- Rental AlatDocument1 pageRental AlatiwansalmaNo ratings yet

- Project Execution Plan For TankDocument3 pagesProject Execution Plan For TankiwansalmaNo ratings yet

- Oil N Gas EPC PracticeDocument4 pagesOil N Gas EPC PracticeiwansalmaNo ratings yet

- General Health and Safety Information For PillingDocument8 pagesGeneral Health and Safety Information For PillingiwansalmaNo ratings yet

- EHLV Installation - First HalfDocument40 pagesEHLV Installation - First HalfKHA120096 StudentNo ratings yet

- Unit 2: Standards, Certification and Marking: ObjectivesDocument15 pagesUnit 2: Standards, Certification and Marking: ObjectivesHaianh PhamNo ratings yet

- HB 4355 - Downstream Oil Industry Regulation Act of 2011Document16 pagesHB 4355 - Downstream Oil Industry Regulation Act of 2011Bayan Muna Party-listNo ratings yet

- UAE B2b Email Database SampleDocument32 pagesUAE B2b Email Database Sampleirfan aminNo ratings yet

- Em Siprotec5 Broschuere enDocument8 pagesEm Siprotec5 Broschuere enferomagnetizamNo ratings yet

- Det 375Document10 pagesDet 375nicesreekanthNo ratings yet

- OGDCL Risk ManagementDocument15 pagesOGDCL Risk ManagementAbNo ratings yet

- Areas of Specialisation in GENCO and DISCO - PPDocument33 pagesAreas of Specialisation in GENCO and DISCO - PPchdiNo ratings yet

- Ck040 CUPLA 72dpi PDFDocument158 pagesCk040 CUPLA 72dpi PDFMochammad Waris S100% (1)

- Indian Standard Time debate over NE statesDocument2 pagesIndian Standard Time debate over NE statesvijaynarayan guptaNo ratings yet

- Tugas 2Document14 pagesTugas 2Tri Sunanda FathanahNo ratings yet

- Blog JetsDocument16 pagesBlog JetsJames RaitNo ratings yet

- Complete Selfprotection Technolgy To Minimize The Failures of Distribution Transformer.Document24 pagesComplete Selfprotection Technolgy To Minimize The Failures of Distribution Transformer.Sambit SunyaniNo ratings yet

- PCM Brochure Mining and Minerals enDocument7 pagesPCM Brochure Mining and Minerals enAnonymous ItzBhUGoiNo ratings yet

- SCH4U 5 Factors That Affect Reaction Rates HandoutDocument2 pagesSCH4U 5 Factors That Affect Reaction Rates HandoutMichelle NgNo ratings yet

- Badger Daylighting PitchDocument16 pagesBadger Daylighting PitchAnonymous Ht0MIJNo ratings yet

- Electrical Interview GuideDocument9 pagesElectrical Interview GuideKrishnamoorthi VenkatesanNo ratings yet

- 26 2833 01 Silicone Antifoams For Oil Gas Processing Selection GuideDocument2 pages26 2833 01 Silicone Antifoams For Oil Gas Processing Selection GuideZhan FangNo ratings yet

- Samsung AQV18NSD Service ManualDocument96 pagesSamsung AQV18NSD Service Manualgabbo24100% (5)

- Fail-safe power supply solutionsDocument24 pagesFail-safe power supply solutionsparas99No ratings yet

- Salami Catalog Group3 Zupcaste PumpeDocument32 pagesSalami Catalog Group3 Zupcaste Pumpeado_22No ratings yet