Professional Documents

Culture Documents

GPM or GPH Flow Based On PVC Pipe Size

Uploaded by

Aziz Khan KakarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GPM or GPH Flow Based On PVC Pipe Size

Uploaded by

Aziz Khan KakarCopyright:

Available Formats

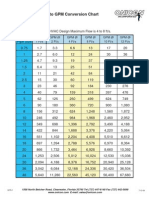

GPM/GPH Flow based on PVC Pipe Size

There are now 3 charts on this page showing water flow through a pipe. These 3

charts come from 3 different sources, and they all are just general guidelines. and should not be relied on as a precise source for information or as a substitute for engineering. The data between them does vary. In the chart to the left is a general guideline for how much liquid a pipe of specific size can flow in GPM (Gallons Per Minute) & GPH (Gallons Per Hour.) There are three columns. (Well there are really six, but each column is shown in Gallons per minute, and then again as Gallons per Hour.) The first set of columns would be the minimum you would expect for the pipe size shown using nothing but gravity to power the flow. The 2nd set of columns show what you can expect using an average pump with a pressure from 20 to 100psi. The 3rd set of columns is the maximum flow based on maximum recommended velocity of the liquid in the pipe. You may exceed this, but you will have to contend with excessive noise and exceedingly high inertial impacts. (I.e. Possible system failure due to hydraulic hammer effects.) This is a very general guide and is subject to many variables. Pressure, noise allowance, bends, fittings, viscosity, etc. affect how much liquid will flow through a pipe of given size. If you can accept more noise and have higher pressure, you can pump more at the risk of system failure. If you have a lot of bends and fittings you will flow less. The flow rates shown should not produce unacceptable noise, however, many variables affect noise, so this is no guarantee that the system will be noiseless. Sometimes experimentation is the only sure way to know if a system will be noisy or not. The flow rates shown are for water, with viscosity of 1. Higher viscosity liquids will flow less, lower viscosity liquids may flow more. Note: One of the benefits of using Flex PVC pipe is being able to make long gradual bends instead of using fittings which will allow more flow with less noise, less back pressure, and less load on the pump. In other words, a more efficient system.

*

"High Pressure" is a general and non-specific figure. What might be "high pressure" for 1/2" pipe (600psi) may not be "high pressure" for 2" pipe (280psi). There are just too many variables to consider to give a real world number. The fact of the matter is, on a pressurized system, the pump will dictate the flow and pressure as much as the pipe used. To achieve the flow figures in the peak column, it's assuming there are no bends and a short straight flow path. If your system has bends and T's, Wyes, etc, you should go to a larger pipe to achieve the flow desired. Also feed pressure effects the system. If the feed pressure is too low, you can get cavitation and you'll damage the pump and flow very little.

Water Flow Chart #1 The chart below takes into consideration the potential damage from hydraulic hammer (shock) and noise considerations due to excessive fluid velocity. You can flow more than what is shown in the chart (see Chart #2 below) however, you may run into problems if you do.

Assume Gravity Flow. About 6f/s flow velocity, also suction side of pump Assume Average Pressure. (20-100PSI) About 12f/s flow velocity Assume "High Pressure" PEAK flow. About 18f/s flow velocity*

Sch 40 Pipe Size 1/2" 3/4" 1" 1.25" 1.5" 2" 2.5" 3" 4" 5" 6" 8"

ID (range) .50.60" .75.85" 1.001.03" 1.251.36" 1.501.60" 1.952.05" 2.352.45" 2.903.05" 3.853.95" 4.955.05" 5.855.95" 7.96"

GPM OD

(with minimal pressure loss & noise)

GPH

(with minimal pressure loss & noise)

GPM

(with minimal pressure loss & noise)

GPH

(with minimal pressure loss & noise)

GPM

(with significant pressure loss & noise)

GPH

(with significant pressure loss & noise)

.85" 1.06" 1.33" 1.67" 1.90" 2.38" 2.89" 3.50" 4.50"

7 gpm 11 gpm 16 gpm 25 gpm 35 gpm 55 gpm 80 gpm 140 gpm 240 gpm

420 gph 660 gph 960 gph

14 gpm 23 gpm 37 gpm

840 gph 1,410 gph 2,220 gph 3,750 gph 4,830 gph 7,650 gph 11,400 gph 16,350 gph 28,800 gph 45,000 gph 66,000 gph 114,000 gph

21 gpm 36 gpm 58 gpm 100 gpm 126 gpm 200 gpm 300 gpm 425 gpm 700 gpm 1100 gpm 1700 gpm 2800 gpm

1,260 gph 2,160 gph 3,510 gph 5,940 gph 7,560 gph 12,000 gph 17,550 gph 25,650 gph 42,000 gph 66,000 gph 102,000 gph 168,000 gph

1,500 gph 62 gpm 2100 gph 3300 gph 4800 gph 8400 gph 14,400 gph 22,800 gph 33,000 gph 57,000 gph 81 gpm 127 gpm 190 gpm 273 gpm 480 gpm 750 gpm 1100 gpm 1900 gpm

5.563" 380 gpm 6.61" 550 gpm

8.625" 950 gpm

Water Flow Chart #2

Here is yet another set of data predicting the amount of flow through a straight piece of pipe. If you add any direction change (90's, 45's Tees, Wyes, etc) or potention restrictions (valves, elevation change, obstruction, etc) these estimates will also change. Pressure Flow in GPM through pipe ID in inches

PSI 20 30 40 50 60 75 100 125 150 200

1" 1.25" 1.5" 2" 26 47 32 58 38 68 43 77 47 85 53 95 62 112 70 126 77 139 90 162 76 94 110 124 137 153 180 203 224 262

2.5"

3" 468 582 680 767 846 955

4" 997

5" 2895

161 290 200 360 234 421 264 475 291 524 329 591 384 690 433 779 478 859

1240 3603 1449 4209 1635 4748 1804 5239 2035 5910

1115 2377 6904 1258 2681 7788 1388 2958 8593

558 1004 1621 3455 10038

Water Flow Chart #3 Below is another data set we've run across. What is shows is how much flow you will get across a stainless metal ball valve of the length specified with a 1PSI pressure drop from one side of the valve to the other. Size (ID, inches) Length (inches) Flow (GPM) 1/2 4.25 26 3/4 4.62 50 1 5.00 94 1-1/2 6.50 260 2 7.00 480 2-1/2 7.50 750 3 8.00 1300 4 9.00 2300 6 15.50 5400

Note: The data is for water through the valve only, and does not take into account the rest of the system. It does not give flow velocity, so there is some question as to the applicability of the data. The data comes from a book for industrial piping and probably assumes a massive pump, high flow velocities and metallic pipes. (Ie, where water hammer and noise are less of a concern than with PVC pipe.) As always, "you mileage may vary."

You might also like

- Plumbing Engineering Design Handbook Vol 2 2004Document9 pagesPlumbing Engineering Design Handbook Vol 2 2004inorg_chem0% (1)

- Manage pool plant performance with this interactive toolDocument4 pagesManage pool plant performance with this interactive tooljarabos8609No ratings yet

- Pump MathsDocument10 pagesPump MathsSakib RafeeNo ratings yet

- Tuttle and Bailey CircularDocument2 pagesTuttle and Bailey CircularTalha BaigNo ratings yet

- Codes Doc 1626 PDFDocument42 pagesCodes Doc 1626 PDFrakeshamechNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- A Performance Comparison of Vapour-Compression Refrigeration System UsingDocument10 pagesA Performance Comparison of Vapour-Compression Refrigeration System UsingVIKNESWARAN S KNo ratings yet

- PH008 - Grease Interceptor Sizing REVISEDDocument8 pagesPH008 - Grease Interceptor Sizing REVISEDcoolth2No ratings yet

- Return Air Square: Ceiling DiffuserDocument1 pageReturn Air Square: Ceiling DiffuserEnak Cenir100% (1)

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Hydroheater Auto Manual VersionDocument45 pagesHydroheater Auto Manual VersionVishal Nawalgaria100% (3)

- Geberit Piping Systems Catalogue 2010/2011Document95 pagesGeberit Piping Systems Catalogue 2010/2011Catalin Frincu0% (1)

- ME 415 Energy Systems Design TutorialDocument54 pagesME 415 Energy Systems Design TutorialcmahendrNo ratings yet

- Weil Pump Flow and Basin Sizing Calculator (EDocFind - Com)Document15 pagesWeil Pump Flow and Basin Sizing Calculator (EDocFind - Com)mohdnazirNo ratings yet

- TrapDocument4 pagesTrapdcsamaraweeraNo ratings yet

- Pipe SizingDocument16 pagesPipe SizingnagarajhebbarNo ratings yet

- Sand Oil Interceptor Sizing Calculations 90 SubmittalDocument4 pagesSand Oil Interceptor Sizing Calculations 90 SubmittalBRANDONNo ratings yet

- CALCULATE ORIFICE DIAMETER FLOWDocument4 pagesCALCULATE ORIFICE DIAMETER FLOWNaseer HydenNo ratings yet

- Ed Policy 3 PDFDocument49 pagesEd Policy 3 PDFTajudeen IbrahimNo ratings yet

- Chillers - CatalogDocument2 pagesChillers - Catalogdéborah_rosalesNo ratings yet

- Calculating Pressure LossDocument2 pagesCalculating Pressure LossAhmed MoustafaNo ratings yet

- Use of Rational Formula For Hydraulic Analysis & Design: PDH Course H147 (2 PDH)Document27 pagesUse of Rational Formula For Hydraulic Analysis & Design: PDH Course H147 (2 PDH)Angghy NaghaNo ratings yet

- Indian Standards 1172.1993Document18 pagesIndian Standards 1172.1993Misama NedianNo ratings yet

- Ozone Treatment of Cooling Tower WaterDocument26 pagesOzone Treatment of Cooling Tower WaterLh KooNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Pressurised Deaerator Head-Technical Information PDFDocument2 pagesPressurised Deaerator Head-Technical Information PDFel doctolNo ratings yet

- Price List-IDocument1 pagePrice List-Imohan_27109150No ratings yet

- Pipe Sizing NomogramDocument1 pagePipe Sizing NomogramAleksandarSashaStankovichNo ratings yet

- Lokring I Single Ring 01.07.2013Document58 pagesLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- EbaraDocument10 pagesEbarachu42No ratings yet

- The Service FactorDocument6 pagesThe Service FactorsxpNo ratings yet

- Forbes Marshall Consultancy specifications for compressed air accessoriesDocument2 pagesForbes Marshall Consultancy specifications for compressed air accessoriessppatilNo ratings yet

- Ashrae - Ambient Conditions - AhmedabadDocument2 pagesAshrae - Ambient Conditions - AhmedabadDaniel BrownNo ratings yet

- Fan ESP CalculationDocument6 pagesFan ESP CalculationAyesha SiddiquaNo ratings yet

- Pressure Volume Calculator 02Document6 pagesPressure Volume Calculator 02Jenny Cecilia Ureña ZuriNo ratings yet

- Accumulator Sizing DataDocument6 pagesAccumulator Sizing DataSubham GhantaNo ratings yet

- Non Circular Pipe FrictionDocument3 pagesNon Circular Pipe Frictionravi_radanNo ratings yet

- Water Treatment Catalogue GuideDocument12 pagesWater Treatment Catalogue GuideJim TsikasNo ratings yet

- Flow Velocity (FT/S) To GPM Conversion ChartDocument1 pageFlow Velocity (FT/S) To GPM Conversion Chartmonaco59No ratings yet

- Kelani Cable - ArmouredDocument1 pageKelani Cable - Armouredsukiraj Rasalingam100% (1)

- MVAC Duct Pressure Drop (Reference Summary)Document19 pagesMVAC Duct Pressure Drop (Reference Summary)Cheng Chun TingNo ratings yet

- Water Distribution ManualDocument20 pagesWater Distribution ManualOxfamNo ratings yet

- Data Sheet of Bronze Ferrule ValvesDocument1 pageData Sheet of Bronze Ferrule ValvesAfzalNo ratings yet

- LA Plumbing Code Bulletin on Domestic Water Pipe SizingDocument20 pagesLA Plumbing Code Bulletin on Domestic Water Pipe Sizing63ragtopNo ratings yet

- Woods Silencer Catalogue and Technical DataDocument12 pagesWoods Silencer Catalogue and Technical DataJagatjeet MaanNo ratings yet

- IsolationBase CatalogDocument8 pagesIsolationBase CatalogarturslaveNo ratings yet

- Compressed Air SystemDocument7 pagesCompressed Air Systemacmvorg50% (2)

- 1-Sanitary Drainage SystemsDocument20 pages1-Sanitary Drainage Systemsraja bharathiNo ratings yet

- How to Size Pressure TankDocument2 pagesHow to Size Pressure TanksamehNo ratings yet

- Terrain Rainwater BrochureDocument56 pagesTerrain Rainwater BrochureterinthomasNo ratings yet

- Compressor Inlet Piping - Compressed Air Best PracticesDocument10 pagesCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadNo ratings yet

- Minor Loss Coefficients in Pipes and Tubes ComponentsDocument2 pagesMinor Loss Coefficients in Pipes and Tubes ComponentsSurendra ReddyNo ratings yet

- Hap48 ManualDocument140 pagesHap48 ManualAdnanNo ratings yet

- Fan noise in ventilation ductsDocument9 pagesFan noise in ventilation ductslkakeanNo ratings yet

- Booster PDSDocument3 pagesBooster PDSsunii19847908No ratings yet

- D. Design Load D.1. Loading DataDocument14 pagesD. Design Load D.1. Loading DataEdNo ratings yet

- Niagara Middle East Water Catalog MEWC41013Document78 pagesNiagara Middle East Water Catalog MEWC41013mahmoodNo ratings yet

- Water Flow Based On Pipe SizeDocument7 pagesWater Flow Based On Pipe SizeGeorge KyawNo ratings yet

- Piping Systems Srac 1994Document6 pagesPiping Systems Srac 1994maheshNo ratings yet

- 079 088Document10 pages079 088منير أحمدNo ratings yet

- ConcreteDocument102 pagesConcreteUmar Saba100% (1)

- 8 Ocean ChemistryDocument9 pages8 Ocean ChemistryAziz Khan KakarNo ratings yet

- Forest Plant ProductionDocument2 pagesForest Plant ProductionAziz Khan KakarNo ratings yet

- Constructionofroadspresentations 131221071548 Phpapp02Document30 pagesConstructionofroadspresentations 131221071548 Phpapp02Aziz Khan KakarNo ratings yet

- Micro Catchment Based Water HarvestingDocument4 pagesMicro Catchment Based Water HarvestingAziz Khan KakarNo ratings yet

- Modernizing Road Construction Plans and Documentation: September 2016Document61 pagesModernizing Road Construction Plans and Documentation: September 2016Aziz Khan KakarNo ratings yet

- ConcreteDocument102 pagesConcreteUmar Saba100% (1)

- Applying Subsurface Utility Engineering To Highway and Road ProjectsDocument30 pagesApplying Subsurface Utility Engineering To Highway and Road ProjectsAziz Khan KakarNo ratings yet

- EulaDocument21 pagesEulaFNo ratings yet

- Improving Food Security and Livelihoods in Dryland Systems Through Integrated Agricultural ResearchDocument76 pagesImproving Food Security and Livelihoods in Dryland Systems Through Integrated Agricultural ResearchAziz Khan KakarNo ratings yet

- Islamic Principles for Sustainable Water ManagementDocument87 pagesIslamic Principles for Sustainable Water ManagementAziz Khan KakarNo ratings yet

- Water Harvesting Past and FutureDocument28 pagesWater Harvesting Past and FuturethadikkaranNo ratings yet

- Water Harvesting StructuresDocument1 pageWater Harvesting StructuresAziz Khan KakarNo ratings yet

- Land LevellingDocument1 pageLand LevellingAziz Khan KakarNo ratings yet

- TerracesDocument11 pagesTerracesAziz Khan KakarNo ratings yet

- How To Measure Soil InfiltrationDocument1 pageHow To Measure Soil InfiltrationAziz Khan Kakar100% (1)

- Runoff FarmingDocument39 pagesRunoff FarmingAziz Khan KakarNo ratings yet

- How To Determin Furrow LengthDocument1 pageHow To Determin Furrow LengthAziz Khan KakarNo ratings yet

- Hillside TerracesDocument4 pagesHillside TerracesAziz Khan KakarNo ratings yet

- Furrow Irrigation DurationDocument1 pageFurrow Irrigation DurationAziz Khan KakarNo ratings yet

- Reduce Erosion with Terrace/Hillside DitchesDocument4 pagesReduce Erosion with Terrace/Hillside DitchesAziz Khan KakarNo ratings yet

- Check Dams 2Document5 pagesCheck Dams 2Aziz Khan KakarNo ratings yet

- Gabion BasketsDocument1 pageGabion BasketsAziz Khan KakarNo ratings yet

- This Notice in TED WebsiteDocument2 pagesThis Notice in TED WebsiteAziz Khan KakarNo ratings yet

- Soil Moisture Sensor IntroductionDocument21 pagesSoil Moisture Sensor IntroductionAziz Khan KakarNo ratings yet

- What Is Furrow Irrigation?Document1 pageWhat Is Furrow Irrigation?Aziz Khan KakarNo ratings yet

- Check Dams Slow ErosionDocument6 pagesCheck Dams Slow ErosionAziz Khan KakarNo ratings yet

- Check Dams SE-4: Description and PurposeDocument5 pagesCheck Dams SE-4: Description and PurposeAziz Khan KakarNo ratings yet

- Citrus Irrigation RecommendationsDocument5 pagesCitrus Irrigation RecommendationsAziz Khan KakarNo ratings yet

- Solubility of Titanium Dioxide in Cosmetic FormulationsDocument10 pagesSolubility of Titanium Dioxide in Cosmetic FormulationsMeiNo ratings yet

- API 2H Grade 50 Steel Plate SpecificationDocument3 pagesAPI 2H Grade 50 Steel Plate SpecificationJym GensonNo ratings yet

- Ammonia: Latent Heat of OFDocument34 pagesAmmonia: Latent Heat of OFCastoriadisNo ratings yet

- 2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)Document4 pages2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)AnnafiNo ratings yet

- Biological Indicators TOC PDFDocument20 pagesBiological Indicators TOC PDFnsk79in0% (1)

- CARB in Industrial FansDocument8 pagesCARB in Industrial FansJurun_Bidanshi100% (1)

- Gasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™Document1 pageGasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™dilo0987No ratings yet

- Analytical Chemistry Topics Lecture (Adamson University)Document10 pagesAnalytical Chemistry Topics Lecture (Adamson University)Rolie CastroNo ratings yet

- ME 331 Thermodynamics II Lecture 3cDocument31 pagesME 331 Thermodynamics II Lecture 3cJosell CaipangNo ratings yet

- Hair Waving Natural Product Dillenia Indica Seed Sap PDFDocument3 pagesHair Waving Natural Product Dillenia Indica Seed Sap PDFAna NunesNo ratings yet

- Ethanol Production by Fermentation and DistillationDocument3 pagesEthanol Production by Fermentation and DistillationChris WarnerNo ratings yet

- Food AdulterationDocument25 pagesFood AdulterationHemlata SoniNo ratings yet

- FM Lab ManualDocument70 pagesFM Lab ManualRishi PatilNo ratings yet

- A307 10Document6 pagesA307 10solrac4371No ratings yet

- Alternative-Refrigerants R22 GBDocument12 pagesAlternative-Refrigerants R22 GBMon PerezNo ratings yet

- Bio Molecules 9Document3 pagesBio Molecules 9SilVI MARDELNo ratings yet

- Equal Percentage Control Valves and Applications - Control NotesDocument6 pagesEqual Percentage Control Valves and Applications - Control NotesShubham PisalNo ratings yet

- Patrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossDocument9 pagesPatrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossBrahian Alexander RinconNo ratings yet

- DNeasy® Mericon® Food HandbookDocument32 pagesDNeasy® Mericon® Food HandbookmarianariasNo ratings yet

- 150 CDocument13 pages150 Crobert carbungcoNo ratings yet

- Fatty Acids: Avid NnekenDocument44 pagesFatty Acids: Avid NnekenCory AmeliaNo ratings yet

- Shear Friction MattockDocument10 pagesShear Friction MattockSisina Anish100% (1)

- Sibco CatalogueDocument112 pagesSibco CatalogueMonika SenNo ratings yet

- Mae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsDocument28 pagesMae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsmibarjanNo ratings yet

- Lipids Classification and FunctionsDocument4 pagesLipids Classification and FunctionsThalia PacamalanNo ratings yet

- BN-DG-C01A Plant Layout - General RequirementsDocument11 pagesBN-DG-C01A Plant Layout - General RequirementsatramanathanNo ratings yet

- Interpreting Spectra for Organic CompoundsDocument4 pagesInterpreting Spectra for Organic CompoundsIván SalazarNo ratings yet

- Reservoir Characterization and Performance Prediction in Waterflooded Reservoir Using Capacitance-Resistance ModelDocument20 pagesReservoir Characterization and Performance Prediction in Waterflooded Reservoir Using Capacitance-Resistance ModelRay YudaNo ratings yet

- PHYS 2225 Lab 13 Dispersion and Geometric OpticsDocument6 pagesPHYS 2225 Lab 13 Dispersion and Geometric OpticsT. ArchulettaNo ratings yet

- D Block ElementDocument48 pagesD Block ElementPrabhakar BandaruNo ratings yet