Professional Documents

Culture Documents

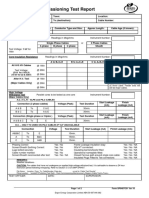

IEC 840 - Type Test

Uploaded by

Kapil VatsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IEC 840 - Type Test

Uploaded by

Kapil VatsCopyright:

Available Formats

60840 IEC:2011

21

A table of the subclause references to be considered during a type test on a cable system is given in Annex C.

NOTE Tests on terminations referring to environmental conditions are not specified in this standard.

12.2

Range of type approval

When type tests have been successfully performed on one or more cable system(s) of specific cross-section(s), and of the same rated voltage and construction, the type approval shall be considered as valid for cable systems within the scope of this standard with other crosssections, rated voltages and constructions provided that all the conditions of a) to f) are met:

NOTE 1 valid. Type tests which have been successfully performed according to the previous edition of this standard are

a) the voltage group is not higher than that of the tested cable system(s);

NOTE 2 In this context, cable systems of the same rated voltage group are those of rated voltages having a common value of U m, highest voltage for equipment, and the same test voltage levels (see Table 4, column 1 and 2).

b) the conductor cross-section is not larger than that of the tested cable; c) the cable and the accessories have the same or similar constructions as that of the tested cable system(s);

NOTE 3 Cables and accessories of similar construction are those of the same type and manufacturing process of insulation and semi-conducting screens. Repetition of the electrical type tests is not necessary on account of the differences in the conductor or connector type or material or of the protective layers applied over the screened cores or over the main insulation part of the accessory, unless these are likely to have a significant effect on the results of the test. In some instances it may be appropriate to repeat one or more of the type tests (e.g. bending test, heating cycle test and/or compatibility test).

d) the calculated nominal electrical stress and the impulse voltage stress calculated using nominal dimensions at the cable conductor screen do not exceed the respective calculated stresses of the tested cable system(s) by more than 10 %; e) the calculated nominal electrical stress at the cable insulation screen and the impulse voltage stress calculated using nominal dimensions do not exceed the respective calculated stresses of the tested cable system(s); f) the calculated nominal electrical stresses and the impulse voltage stresses calculated using nominal dimensions within the main insulation parts of the accessory and at the cable and accessory interfaces do not exceed the respective calculated stresses of the tested cable system(s).

The type tests on cable components (see 12.5) only need to be carried out on samples from cables of different voltage ratings and/or conductor cross-sectional areas if different materials and/or different manufacturing processes are used to produce them. However, repetition of the ageing tests on pieces of completed cable to check compatibility of materials (see 12.5.4) may be required if the combination of materials applied over the screened core is different from that of the cable on which type tests have been carried out previously. A type test certificate signed by the representative of a competent witnessing body, or a report by the manufacturer giving the test results and signed by the appropriate qualified officer, or a type test certificate issued by an independent test laboratory, shall be acceptable as evidence of type testing. 12.3 Summary of type tests

The type tests shall comprise the electrical tests on the complete cable system as specified in 12.4, and the appropriate non-electrical tests on cable components and completed cable specified in 12.5.

2012-01-19, () .

You might also like

- Imo Sample Paper Class-2Document2 pagesImo Sample Paper Class-2srijani pal0% (1)

- Business StatisticsDocument506 pagesBusiness StatisticsLokesh Baskaran100% (22)

- Hipot testing ensures electrical safetyDocument5 pagesHipot testing ensures electrical safetySumit SawaiNo ratings yet

- Electrical Panels MCB & Cable Size Calculation (1.1.17)Document29 pagesElectrical Panels MCB & Cable Size Calculation (1.1.17)RupeshKumarNo ratings yet

- Generator Neutral Conductor SizingDocument10 pagesGenerator Neutral Conductor SizingCatrina Federico100% (1)

- Ase L1 PDFDocument50 pagesAse L1 PDFsidhuNo ratings yet

- 33 KV VLF Method - Statement For ATSDocument4 pages33 KV VLF Method - Statement For ATSTesting PLQNo ratings yet

- Effect of DC Testing On XLPE Insulated CablesDocument6 pagesEffect of DC Testing On XLPE Insulated Cablesnamsaigon316No ratings yet

- EHV - Grounding TransformerDocument23 pagesEHV - Grounding Transformerm kh100% (1)

- MV SWGR TestingDocument4 pagesMV SWGR TestingAmr ElkadyNo ratings yet

- HIPOT Testing (Dielectric Strength Test)Document5 pagesHIPOT Testing (Dielectric Strength Test)Wathik AbmNo ratings yet

- Testing of Circuit Breaker Classification of The Test: (H) Short Line Fault Tests (N) Reactor Current Switching TestsDocument14 pagesTesting of Circuit Breaker Classification of The Test: (H) Short Line Fault Tests (N) Reactor Current Switching TestsRANGASWAMY SNo ratings yet

- 06-POWER AND CONTROL CABLE - Rev5 PDFDocument14 pages06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutNo ratings yet

- High Voltage TestingDocument53 pagesHigh Voltage TestingMohit NehraNo ratings yet

- Testing Grounding SystemsDocument69 pagesTesting Grounding SystemsAndita Tri BudiantoNo ratings yet

- HV Cable CommissioningDocument2 pagesHV Cable CommissioningAtchut Rao100% (1)

- Branch Circuits and Feeders IIDocument60 pagesBranch Circuits and Feeders IIBelayneh TadesseNo ratings yet

- Rectifier O and M Manual - Nuberg - FluoderDocument59 pagesRectifier O and M Manual - Nuberg - FluoderAnujGargNo ratings yet

- Field Testing and Diagnostic Methods for Power CablesDocument22 pagesField Testing and Diagnostic Methods for Power CablesanuragpugaliaNo ratings yet

- CABLE Sheath Test - 3 15.10.17Document1 pageCABLE Sheath Test - 3 15.10.17Khalid AwanNo ratings yet

- What Is VLFDocument9 pagesWhat Is VLFnysa6987No ratings yet

- CBSE Class 2 Maths Question Paper Set ADocument2 pagesCBSE Class 2 Maths Question Paper Set AGayatri75% (4)

- Method Statement For Testing & Commissioning of Disabled Toilet Alarm DTA SystemDocument3 pagesMethod Statement For Testing & Commissioning of Disabled Toilet Alarm DTA Systemvin ssNo ratings yet

- CT of AcdbDocument3 pagesCT of Acdbmaheshknm100% (1)

- Polarity / Vector Group TestDocument6 pagesPolarity / Vector Group TestHassan AbdoNo ratings yet

- Xlpe Cable Commissioning Test Procedure Following Iec StandardDocument5 pagesXlpe Cable Commissioning Test Procedure Following Iec StandardAkd Deshmukh100% (2)

- Surge ArresterDocument17 pagesSurge ArrestermoosuhaibNo ratings yet

- L3 U304 Session 1 Earthing and BondingDocument40 pagesL3 U304 Session 1 Earthing and Bondinggeorgeowen100% (1)

- Insulation Resistance Testing of Cables in The Field-Rev-01Document22 pagesInsulation Resistance Testing of Cables in The Field-Rev-01Jalal AlbadriNo ratings yet

- Handbook On Power Cables For General ServicesDocument65 pagesHandbook On Power Cables For General ServicesPavanNo ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- Cable TerminationDocument2 pagesCable Terminationapandey070273No ratings yet

- SP0407C01 HV Cable Commissioning Test ReportDocument2 pagesSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantNo ratings yet

- 33 SCF Tower Span 18mDocument25 pages33 SCF Tower Span 18mamrit90320No ratings yet

- PT TestingDocument7 pagesPT TestingNaveedNo ratings yet

- Relay and Multifunctional Substation Test System: Sverker 900Document12 pagesRelay and Multifunctional Substation Test System: Sverker 900Stelvio QuizolaNo ratings yet

- On-Site Testing of Gas Insulated Substations with AC VoltageDocument6 pagesOn-Site Testing of Gas Insulated Substations with AC VoltageThirumalNo ratings yet

- Reduced Series ReactorDocument10 pagesReduced Series ReactorclicknagpalNo ratings yet

- HVPNL technical specification for 220V DC battery chargerDocument6 pagesHVPNL technical specification for 220V DC battery chargerKapil VatsNo ratings yet

- Voltage Withstand TestDocument4 pagesVoltage Withstand Testmshahidshaukat100% (1)

- Measurement of Insulation Resistance (IR) - Part 2 - EEP PDFDocument16 pagesMeasurement of Insulation Resistance (IR) - Part 2 - EEP PDFHeri SulaimanNo ratings yet

- Standard SDocument7 pagesStandard SMohan Kumar67% (3)

- GJU MBA 4th Sem NotesDocument41 pagesGJU MBA 4th Sem NotesKapil Vats100% (3)

- RER615 IEC 60870-5-101 - 104 Communication Protocol ManualDocument40 pagesRER615 IEC 60870-5-101 - 104 Communication Protocol ManualРоман ВоеводаNo ratings yet

- Suitability of test voltages for XLPE cable testingDocument34 pagesSuitability of test voltages for XLPE cable testingHo Jun XianNo ratings yet

- Pre-Commissioning Tests AC Equipment ListDocument5 pagesPre-Commissioning Tests AC Equipment ListnagarajanNo ratings yet

- National Disaster Management Plan-2016Document8 pagesNational Disaster Management Plan-2016Kapil VatsNo ratings yet

- Mv-105 Cable - Field Acceptance Testing - A Cable Manufacturer'S PerspectiveDocument7 pagesMv-105 Cable - Field Acceptance Testing - A Cable Manufacturer'S PerspectiveMarcelo Gomes PlanteirNo ratings yet

- Testing and Commissioning of MV CablesDocument8 pagesTesting and Commissioning of MV CablesYJoe18No ratings yet

- 52224-mt - High Voltage Testing TechniquesDocument2 pages52224-mt - High Voltage Testing TechniquesSRINIVASA RAO GANTANo ratings yet

- How To Use A Megger Insulation TesterDocument2 pagesHow To Use A Megger Insulation TesterRakesh Babu0% (1)

- Modular Home Hipot Testing ComparisonDocument1 pageModular Home Hipot Testing ComparisonTTaanNo ratings yet

- 12-SDMS-02 REV. 02: Saudi Electricity CompanyDocument20 pages12-SDMS-02 REV. 02: Saudi Electricity CompanyMichael Camit EsoNo ratings yet

- Sandwich panel span tables PU/PIRDocument1 pageSandwich panel span tables PU/PIRniginpNo ratings yet

- CL-NG-6460-002-034 Checklist For Disconnect & Grounding Switches Rev00Document2 pagesCL-NG-6460-002-034 Checklist For Disconnect & Grounding Switches Rev00WajahatNo ratings yet

- LV Switchgear Dielectric TestsDocument2 pagesLV Switchgear Dielectric TestswaseemsamsodienNo ratings yet

- Field Test andDocument38 pagesField Test andharigopalk12100% (1)

- Milli Volt DropDocument2 pagesMilli Volt Dropkazishah100% (1)

- Protection Application Philosophy GuideDocument11 pagesProtection Application Philosophy GuideRichman MakwiramitiNo ratings yet

- MV Cable Termination (Heat Shrink)Document25 pagesMV Cable Termination (Heat Shrink)Muhammad SajjadNo ratings yet

- Haryana Vidyut Prasaran Nigam LTD.: Technical SpecificationDocument39 pagesHaryana Vidyut Prasaran Nigam LTD.: Technical SpecificationLalitha BhavaniNo ratings yet

- 33kV Jointing Manual Section 4Document84 pages33kV Jointing Manual Section 4Egbodor PeterNo ratings yet

- Part 7 - High Voltage Safety RulesDocument8 pagesPart 7 - High Voltage Safety RuleswilisNo ratings yet

- Testing & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981Document14 pagesTesting & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981PKNo ratings yet

- MV Solution Up To 6.4 MVA: Medium Voltage Station For Decentralized PV Systems With 1500 V String InvertersDocument4 pagesMV Solution Up To 6.4 MVA: Medium Voltage Station For Decentralized PV Systems With 1500 V String InvertersDoan Anh TuanNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- 33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARDocument9 pages33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARSatyajit RaiNo ratings yet

- MV Cable Insulation and VLF Test Report-Is1-C.b-circuit 1Document2 pagesMV Cable Insulation and VLF Test Report-Is1-C.b-circuit 1Ahmed RabaaNo ratings yet

- IEEE STD ANSI-IEEE STD 67-1972Document48 pagesIEEE STD ANSI-IEEE STD 67-1972abdou sami100% (1)

- Insulation Resistance (IR) Guide: Minimum Values for Electrical EquipmentDocument8 pagesInsulation Resistance (IR) Guide: Minimum Values for Electrical EquipmentAbdullah Al AsikNo ratings yet

- Voltage Control and Power Factor Improvement TechniquesDocument24 pagesVoltage Control and Power Factor Improvement Techniquesrv_andeNo ratings yet

- T. in The Case of Current-Limiting Fuses, The Maximum Arc Energy May Occur at Current LevelsDocument20 pagesT. in The Case of Current-Limiting Fuses, The Maximum Arc Energy May Occur at Current Levelsnandana_849065438No ratings yet

- Tests verify equipment performanceDocument6 pagesTests verify equipment performancem khNo ratings yet

- Inspection and Test Procedures for Metal BuswaysDocument5 pagesInspection and Test Procedures for Metal BuswaysHafidz BandungNo ratings yet

- Mil STD 202g Method 301Document3 pagesMil STD 202g Method 301ytumayNo ratings yet

- Inspect and Test Medium- and High-Voltage CablesDocument4 pagesInspect and Test Medium- and High-Voltage Cablespedro perezNo ratings yet

- Edufever GK Test Series for Class 2Document2 pagesEdufever GK Test Series for Class 2Kapil VatsNo ratings yet

- Haryana Excise Policy 2019-2020Document51 pagesHaryana Excise Policy 2019-2020tsrinivasan5083100% (1)

- 12 RajeshwariBhimSing 503 512 PDFDocument11 pages12 RajeshwariBhimSing 503 512 PDFKapil VatsNo ratings yet

- Expansion of An Existing Power System - A StudyDocument100 pagesExpansion of An Existing Power System - A StudyKapil VatsNo ratings yet

- HRD Functions Training DevelopmentDocument12 pagesHRD Functions Training DevelopmentChitra ChauhanNo ratings yet

- Approved+vendors +upto+01.07.2019Document36 pagesApproved+vendors +upto+01.07.2019Kapil VatsNo ratings yet

- PlanSocioMains2015 1Document15 pagesPlanSocioMains2015 1Mayuresh DeshpandeNo ratings yet

- HRTankD ThinkDocument57 pagesHRTankD ThinkGuruKPONo ratings yet

- Supplementary Sept.17 - 050917Document2 pagesSupplementary Sept.17 - 050917Kapil VatsNo ratings yet

- What Is The Role of An Entrepreneur in Economic DevelopmentDocument4 pagesWhat Is The Role of An Entrepreneur in Economic DevelopmentKapil VatsNo ratings yet

- 1 - Pa Culture Upsc CCRTDocument2 pages1 - Pa Culture Upsc CCRTKapil VatsNo ratings yet

- 2nd Sem Date SheetDocument2 pages2nd Sem Date SheetKapil VatsNo ratings yet

- Advertising and PR Basics: Definitions, Classifications and GrowthDocument369 pagesAdvertising and PR Basics: Definitions, Classifications and GrowthriomjNo ratings yet

- MNGT ScienceTheoryPracticeDocument10 pagesMNGT ScienceTheoryPracticeKapil VatsNo ratings yet

- Copy Testing TechniquesDocument19 pagesCopy Testing TechniquesKapil VatsNo ratings yet

- Unit-19 Disaster Managemnt StartgeiesDocument20 pagesUnit-19 Disaster Managemnt StartgeiesKapil VatsNo ratings yet

- Sales ManagementDocument202 pagesSales ManagementdsatyNo ratings yet

- 23 - Pdfsam - Part2mba General Scheme FinalDocument8 pages23 - Pdfsam - Part2mba General Scheme FinalKapil VatsNo ratings yet

- Sponsored Links: Content of This Website, With Proper Credit (A Link Pointing To The Source)Document2 pagesSponsored Links: Content of This Website, With Proper Credit (A Link Pointing To The Source)Kapil VatsNo ratings yet

- Financial Management 230113Document283 pagesFinancial Management 230113Kapil VatsNo ratings yet

- Financial Management Guide to MergersDocument142 pagesFinancial Management Guide to MergersCNo ratings yet

- Santoshsahni - Blogspot.in: Capital Budgeting DecisionsDocument46 pagesSantoshsahni - Blogspot.in: Capital Budgeting DecisionsKapil VatsNo ratings yet

- AFM PaperDocument2 pagesAFM PaperKapil VatsNo ratings yet

- Managerial Economoics PapaerDocument3 pagesManagerial Economoics PapaerKapil VatsNo ratings yet

- Inti Sci June 2017 P2Document17 pagesInti Sci June 2017 P2Ashe KennedyNo ratings yet

- Industrial accelerometers for widespread applicationsDocument13 pagesIndustrial accelerometers for widespread applicationsLutfi NurafifNo ratings yet

- EDD Electrostatic De-ionisation DeviceDocument37 pagesEDD Electrostatic De-ionisation DeviceWilliam Burry F. GellaNo ratings yet

- Tech Spec For DC String CablesDocument6 pagesTech Spec For DC String CablesPaari BNo ratings yet

- Spec 45440Document2 pagesSpec 45440ger80No ratings yet

- FYH Series Preformed Armor RodDocument3 pagesFYH Series Preformed Armor RodhcindustryNo ratings yet

- Computer Hardware BookDocument336 pagesComputer Hardware BookbharathydglNo ratings yet

- EDOC-Technology & Testing of Interphase SpacersDocument27 pagesEDOC-Technology & Testing of Interphase SpacersEl Comedor BenedictNo ratings yet

- 2150 CuttersDocument8 pages2150 Cuttersrayyan2007No ratings yet

- Basics of Electricity: Siemens STEP 2000 CourseDocument44 pagesBasics of Electricity: Siemens STEP 2000 CourseEveraldo SantanaNo ratings yet

- Extra High Voltage TransmissionDocument26 pagesExtra High Voltage TransmissionPrabir Kumar PatiNo ratings yet

- Bahrain Electricity RegulationsDocument50 pagesBahrain Electricity RegulationsMuhammad RazaNo ratings yet

- Choosing A ConductorDocument12 pagesChoosing A ConductorclodNo ratings yet

- V-90HT SC: Power and Control CablesDocument2 pagesV-90HT SC: Power and Control Cablessurag1982No ratings yet

- 04 Essex WiresDocument39 pages04 Essex WiresRenzo Rios Roque0% (1)

- Electrician Interview QuestionsDocument2 pagesElectrician Interview QuestionsAsanTubigKoNo ratings yet

- Ohe IDocument41 pagesOhe IAnonymous sENwj8nwq100% (11)

- Cired WG 2015-2 Losses ReportDocument114 pagesCired WG 2015-2 Losses ReportSHAAM ENGNo ratings yet

- Jumper CableDocument1 pageJumper CableAnang QosimNo ratings yet

- Arc Flas SafetyDocument64 pagesArc Flas SafetySafithri AprianiNo ratings yet