Professional Documents

Culture Documents

CSL 1013

Uploaded by

oscar horacio floresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSL 1013

Uploaded by

oscar horacio floresCopyright:

Available Formats

2so-c20 CSL-1013

COMMERCIAL

b Indianapolis.Indiana 46206

SERVICE

LETTER

Detroit Diesel Allison

Page 1 of 7 August 25, 1972 FAA-DER Approved SUBJECT: CECO Fuel Control Throttle Shaft O-Ring Seal Replacement

Currently, DDA published a Commercial Engine Bulletin (250-C20 CEB-1022), providing instructions to replace the throttle shaft and cutoff valve shaft O-ring seals with improved durability seals whenever a fuel control was returned to an overhaul facility for any reason (e.g., repair, overhaul, or calibration). Since it may be some time before a control is returned to overhaul, this CSL provides authority for a qualified operator or his line maintenance personnel to replace only the two throttle shaft O-ring seals at his earliest convenience. However, the operator or line mechanic must meet the following qualification: 1. 2. The operator or line mechanic must be checked out and approved by an authorized CECO distributor, or The operator or line mechanic must be checked and approved by a CECO representative. All CECO fuel control assemblies prior to P/N 6877542 (CECO P/N 104000A5) Serial No. 2AAC 1096. It is suggested that both throttle shaft O-ring seals should be replaced at the earliest convenience. Checkout and approval before accomplishing this CSL from an authorized CECO Distributor or CECO representative. New Part No. MS9021-012 --__-__-__ Nomenclature O-ring Lockwire (0.020 in.) Qly 2 AR

EFFECTMTY: COMPLIANCE: PREREaUISfTE:

PARTS:

Revision No. 3 March 31, 1976

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1013 Page 2

COMMERCIAL

PROCEDURE: 1.

SERVICE

LETTER

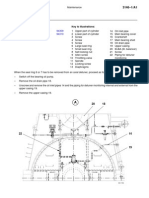

Remove fuel control from engine in accordance with 250-C20 Operation and Maintenance Manual. Matchmark the outer surface of Lever P/N 93466 (2, Figure 1) Adapter P/N 93470 (3), and Throttle Shaft P/N 94123 (12) to ensure reinstallation in the same position with respect to each other. Remove Nut P/N 94376-3 (l), Lever (2), and Adapter (3) from Throttle Shaft (12). Remove Nut NAS1022CO8 (4), loosen only bottom nut (4A) on cutoff lever link (17) approximate one-half turn, and lift Cutoff Lever Assembly P/N 93434 (5) off and move out of the way. Remove lock wire and Idle Stop Screw MS35275-214 (6). Remove Spring Pin MS39086-131 (6A). NOTE: Some units may have both the screw and the pin installed, while other units may have only the stop screw or the spring pin. (7).

2.

a. Remove lock wire and two Screws AN503-6-4 NOTE: Removal of spring (9) is optional for easier access to parts.

CAUTION: 3.

NOTE EXACT POSITION OF SPRING (9) PRIOR TO REMOVAL.

Remove Cotter Pin MS24554-151 (8) and Spring P/N 93606 (9). CAUTION: BEFORE REMOVING IDLE ADJUSTMENT SCREW P/N 94133 (lo), USE A GREASE PENCIL TO INDEX SCREW TO CASTING SPOT FACE AND MEASURE AND NOTE HEIGHT IN RELATION TO SPOT FACE.

4.

Using hex head wrench, remove Idle Adjustment Screw P/N 94133 (10). Remove and discard Packing P/N 78109-005 (11).

Revision No. 3 March 31, 1976 Published August 25, 1972

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1013 Page 3

COMMERCIAL

NOTE:

SERVICE

LETTER

The screw is retained in the housing with a helicoil insert. Some difficulty may be encountered in backing screw out.

5.

Rotate the Throttle Shaft P/N 94123 (12) to cutoff (C.O.) position. Insert the provided depression tool in idle shaft adjustment screw hole and engage into cam ramp of Piston Follower Cam P/N 94434 (13). Pull throttle shaft straight up until it stops. Turn throttle shaft to MAK position. Pry spring loaded cam away from throttle shaft against spring pressure being careful not to lose engagement in cam. Leave tool engaged with cam. Remove Throttle Shaft P/N 94123 (12) and Quadrant P/N 93463 (14). NOTE: Do not remove Nut NAS1291C06M (lfi), Spring Seat P/N 93464 (16), and Cutoff Lever Link P/N 94341 (17) from throttle shaft.

6.

7.

Remove both O-ring Seals P/N 78146-012 (18) from throttle shaft and discard. CAUTION: PREFORMED PACKINGS ARE EASILY DAMAGED BY TOOLS, FINGER NAILS, ETC.

8.

Liberally lubricate packings using MIL-L-6081B Grade 1010 and install new O-ring Seals MS9021-012 in throttle shaft O-ring grooves. Install Quadrant P/N 93463 (14) (with letters facing toward you) in throttle shaft groove. ,Using suitable tool, depress Piston Cam Follower P/N 94434 (13). Orient throttle shaft to MAK position and insert into housing. Rotate to C.O. position and bottom. Install Spring P/N 93606 (9) and Cotter Pin MS24665-151 (8). Engage spring in linkage spring seat.

9.

Revision No. 1 November 30, 1972 Published August 25, 1972

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1013 Page 4

COMMERCIAL

10. 11. Inspect throttle

SERVICE

LETTER

shaft per 250-C20 CSL-1010.

Loosely install shaft hold-down Screws AN503-6-4 (7). Set throttle shaft pointer to 30 on quadrant plate and install Rigging Pin STD 67182 (if unavailable use 0.1560 to 0.1565 dia. drill rod) through throttle shaft, quadrant, and into housing. Set quadrant plate to 30 and tighten screws to 8 to 12 inch-pounds. Wire screws together. CAUTION: LUBRICATE THREADS OF SCREW. DO NOT PERMIT EXCESS LUBRICANT TO ENTER CASTING.

12.

Install Packing P/N 78109-005 (11) on idle adjustment screw. Lubricate threads of Screw P/N 94133 (10) with anti-seize compound MIL-T-5544 and reinstall idle adjustment screw to height and marked position (see step 4). Tighten screw ensuring that running torque exceeds 6.5 inch pounds minimum. Install Screw P/N MS35275-214 (6) and tighten 4-6 inch pounds. Secure with lock wire. Reinstall Cutoff Lever Assembly P/N 93434 (5). Install and tighten Nut NAS1022CO8 (4) to 18-22 inch pounds. Retighten bottom nut (4A) on cutoff lever link (17). Install Adapter P/N 93470 (3), Lever P/N 93466 (2), and Nut P/N 94376-3 (1). Ensure that adapter (3) serrations are correctly meshed with the throttle shaft (12) and lever (2) serrations prior to tightening nut (1). Tighten nut to 65-85 lb. inches. Reidentify reworked controls by stamping the letter C on the identification plate (See Figure 2). Record the Serial Number of the reworked control in the White Pages, Part III of the Engine Log Book.

13. 14.

15.

16.

Revision No. 2 March 5, 1973 Published August 25, 1972

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-C20 CSL-1013 Page 5

COMMERCIAL

17.

SERVICE

LETTER

Reinstall the fuel control and perform idle trim and cutoff operational checks in accordance with the Engine Operation and Maintenance Manual.

L. 0. Davidson Service Manager Gas Turbine Engines MJK:aw

Revision No. 2 March 5, 1973 Published August 25, 1972

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-c20 CSL-1013 Pase 6

Revision No. 3 March 31, 1976 Published August 25, 1972

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

250-c20 Page 7

CSL-1013

STAMP C HERE ON COMPLIANCE

(3 MOD.

FUELCONTROL NO. -

I

FUEL

SEIR.

CONTROL

IDENTIFICATION FIGURE 2

PLATE

Rolls-Royce Proprietary Data Uncontrolled Printed Copy

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- CSL1013Document7 pagesCSL1013Asep HidayatNo ratings yet

- Axial Detuner MaintenanceDocument5 pagesAxial Detuner MaintenanceKarthik ReddiarNo ratings yet

- 1971 Chevy Overhaul ManualDocument505 pages1971 Chevy Overhaul ManualCharlie Moretti100% (1)

- 32 BrakeDocument63 pages32 BrakeTung NguyenNo ratings yet

- Automatic Transaxle System: PrecautionDocument21 pagesAutomatic Transaxle System: PrecautionJorge NegrettiNo ratings yet

- Esquema Hidraulico ManitouDocument26 pagesEsquema Hidraulico Manitouctorres_505746No ratings yet

- Transmission and Transfer Gear (Power Shift)Document8 pagesTransmission and Transfer Gear (Power Shift)ariel rubioNo ratings yet

- Engine Rear Oil SealDocument3 pagesEngine Rear Oil SealJoel Majeed StroudeNo ratings yet

- CLEVELAND 199-512 Repair Kit For Master Cylinder 10-30, 10-30A, 10-30C & 10-30DDocument6 pagesCLEVELAND 199-512 Repair Kit For Master Cylinder 10-30, 10-30A, 10-30C & 10-30DBrunoNo ratings yet

- Toyota Corolla+c52 Shift ManualDocument221 pagesToyota Corolla+c52 Shift Manualdaswine100% (4)

- CSL 1007Document11 pagesCSL 1007oscar horacio flores100% (1)

- 02 04DukeAirServiceGuide PDFDocument7 pages02 04DukeAirServiceGuide PDFgeert janNo ratings yet

- Axial Power Turbine (09TS13)Document2 pagesAxial Power Turbine (09TS13)ПавелNo ratings yet

- Altronic V Service Manual (FORM AV SM)Document15 pagesAltronic V Service Manual (FORM AV SM)francis_mouille_iiNo ratings yet

- 980F Wheel Loader 8CJ00001-UP (MACHINE) POWERED BY 3406 Engine (SEBP1966 - 57) - Systems & ComponentsDocument10 pages980F Wheel Loader 8CJ00001-UP (MACHINE) POWERED BY 3406 Engine (SEBP1966 - 57) - Systems & ComponentsTransportation MaintananceNo ratings yet

- 21B Clutch OverhaulDocument8 pages21B Clutch OverhaultakedashindenNo ratings yet

- Catalogo Despiece Vickers PVH131 - 141Document9 pagesCatalogo Despiece Vickers PVH131 - 141Manuel Carvallo0% (1)

- SB3-1-102Document6 pagesSB3-1-102jussmeeeNo ratings yet

- PerkinsDocument12 pagesPerkinsDalibor Sopina Duc100% (2)

- Pumps: Vane Type Single PumpsDocument2 pagesPumps: Vane Type Single PumpsFernando SabinoNo ratings yet

- 980F WHEEL LOADER 3HK00001-UP (MACHINE) POWERED BY 3406 ENGINE (SEBP1999 - 01) - Systems & ComponentsDocument9 pages980F WHEEL LOADER 3HK00001-UP (MACHINE) POWERED BY 3406 ENGINE (SEBP1999 - 01) - Systems & ComponentsTransportation MaintananceNo ratings yet

- Removing and Installing Cylinder Head (Cylinder Head Assembly) - ALLDATA Repair Vento 1.6ltsDocument5 pagesRemoving and Installing Cylinder Head (Cylinder Head Assembly) - ALLDATA Repair Vento 1.6ltsFran SanchezNo ratings yet

- Automatic Transaxle (Service) (Gf4ax-El)Document53 pagesAutomatic Transaxle (Service) (Gf4ax-El)МаксNo ratings yet

- Group 4 Disassembly and Assembly: 1. Main PumpDocument23 pagesGroup 4 Disassembly and Assembly: 1. Main PumpPriscila RodriguesNo ratings yet

- Ve Pump Denso Repair ManualDocument32 pagesVe Pump Denso Repair ManualHenry Hla Khine98% (40)

- 2rz - Valve Clearance InspectionDocument5 pages2rz - Valve Clearance Inspectionberdeaberdea100% (1)

- Inst Cylinder HeadDocument8 pagesInst Cylinder Headmanuel1357100% (1)

- 8 7 PDFDocument54 pages8 7 PDFHector Renzo Zarate RodriguezNo ratings yet

- Dolmar 116si 120si ServiceDocument20 pagesDolmar 116si 120si ServiceslickattitudewiNo ratings yet

- Arme & Desarme Base de Filtros Tractor D4HDocument6 pagesArme & Desarme Base de Filtros Tractor D4HAlex Consuegra MedinaNo ratings yet

- 41 Manual Transmission TransaxleDocument85 pages41 Manual Transmission TransaxleTung NguyenNo ratings yet

- Convertidor de Torque D5BDocument13 pagesConvertidor de Torque D5BDeyner PerezNo ratings yet

- Food Processor ©Document17 pagesFood Processor ©pukymottoNo ratings yet

- Manual de Servicio/partes/operacion Compresor Quincy Modelo 350 - 350 Quincy Compressor Manual Operation/service/spare PartsDocument20 pagesManual de Servicio/partes/operacion Compresor Quincy Modelo 350 - 350 Quincy Compressor Manual Operation/service/spare PartsTalleres Lilo100% (2)

- 5L E Ve Pump Denso Repair ManualDocument32 pages5L E Ve Pump Denso Repair ManualEfrain Di Matias100% (14)

- 2008+2009 CBR1000RR Clutch Update InstructionsDocument36 pages2008+2009 CBR1000RR Clutch Update InstructionsClyson McWilliams100% (10)

- Hydraulic Pump Repair GuideDocument234 pagesHydraulic Pump Repair GuideVeselina Gaidarska91% (22)

- Adjust Valve Clearance 1ZZ-FE EngineDocument11 pagesAdjust Valve Clearance 1ZZ-FE EngineAlan Dell SnyderNo ratings yet

- Manitou Hyd Pump Repair ManualDocument48 pagesManitou Hyd Pump Repair ManualArdian Makhmud100% (2)

- Automatic TransaxleDocument25 pagesAutomatic Transaxlethanhchuongtp100% (1)

- Operator'S Manual 6544X-X 6546X-X: 4-1/4" AIR MOTORSDocument8 pagesOperator'S Manual 6544X-X 6546X-X: 4-1/4" AIR MOTORSGezzy Boys 28No ratings yet

- Telescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPDocument14 pagesTelescoping Cylinder - Remove and Install: S/N - 3RN4015-UP S/N - 3PN2027-UP S/N - 5WM6021-UPdaryanto widodoNo ratings yet

- Ve Pump Denso Repair Manual PDFDocument32 pagesVe Pump Denso Repair Manual PDFNikola Mitev100% (2)

- Piston Pumps: VickersDocument9 pagesPiston Pumps: VickersRodrigo Andrade ScarpaNo ratings yet

- Disassembly TranmissionDocument12 pagesDisassembly TranmissionKhải Triệu QuốcNo ratings yet

- AC Compressor ServicingDocument28 pagesAC Compressor Servicinggentiles mdqNo ratings yet

- Engine Mechanical ECHO 2002Document85 pagesEngine Mechanical ECHO 2002Tomas Dominguez100% (1)

- Multigraphics 1450/1650 Heavy-Duty Drive Motor Conversion KitDocument8 pagesMultigraphics 1450/1650 Heavy-Duty Drive Motor Conversion KitporqNo ratings yet

- Dynaco c101 c102 Dump Pump PDFDocument7 pagesDynaco c101 c102 Dump Pump PDFnbgearsNo ratings yet

- Automatic Transaxle Service ProceduresDocument50 pagesAutomatic Transaxle Service Proceduresjavier guardiaNo ratings yet

- Manual Valve 966cDocument5 pagesManual Valve 966cHector VallesNo ratings yet

- Caterpillar Cat 245D EXCAVATOR (Prefix 7ZJ) Service Repair Manual (7ZJ00001 and Up)Document29 pagesCaterpillar Cat 245D EXCAVATOR (Prefix 7ZJ) Service Repair Manual (7ZJ00001 and Up)rpoy9396615No ratings yet

- GROUP 4 DISASSEMBLY AND ASSEMBLYDocument43 pagesGROUP 4 DISASSEMBLY AND ASSEMBLYPriscila RodriguesNo ratings yet

- Number: Group: Date:: Transmission (Sales Code DG6)Document6 pagesNumber: Group: Date:: Transmission (Sales Code DG6)Mohamed AhmedNo ratings yet

- Engine (WL, WL Turbo, WL-3, WLT-3) : Drive BeltDocument16 pagesEngine (WL, WL Turbo, WL-3, WLT-3) : Drive Beltpavel35No ratings yet

- TM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1Document883 pagesTM-9-2320-280-20-1 HMMWV Unit Maintnance Vol 1AUGieDogie1100% (6)

- DR6000 MK2 Diversity Receiver Manual, Installation & OperationDocument39 pagesDR6000 MK2 Diversity Receiver Manual, Installation & Operationoscar horacio floresNo ratings yet

- Introduction To Aircraft Performance, Selection and Design PDFDocument168 pagesIntroduction To Aircraft Performance, Selection and Design PDFAnres Anres DictadorNo ratings yet

- QRH Rev 43DDocument294 pagesQRH Rev 43Doscar horacio floresNo ratings yet

- Apu B 767Document103 pagesApu B 767gm&oNo ratings yet

- TM 9 2320 280 10 Operators Manual HMMWVDocument407 pagesTM 9 2320 280 10 Operators Manual HMMWVAUGieDogie1100% (16)

- TM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3Document1,151 pagesTM-9-2320-280-20-3 HMMWV Unit Maintnance Vol 3AUGieDogie1100% (5)

- Sketch A320Document33 pagesSketch A320oscar horacio floresNo ratings yet

- TM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2Document945 pagesTM-9-2320-280-20-2 HMMWV Unit Maintnance Vol 2AUGieDogie1100% (4)

- CEB1110Document4 pagesCEB1110oscar horacio floresNo ratings yet

- LeitholdDocument1,383 pagesLeitholdsethokiba67% (3)

- MCDP Remote Panel WireDocument6 pagesMCDP Remote Panel Wireoscar horacio floresNo ratings yet

- CEB1115Document6 pagesCEB1115oscar horacio floresNo ratings yet

- Detroit Diesel AllisonDocument1 pageDetroit Diesel Allisonoscar horacio floresNo ratings yet

- CEB1112Document5 pagesCEB1112oscar horacio floresNo ratings yet

- CEB1113Document1 pageCEB1113oscar horacio floresNo ratings yet

- CEB1111Document5 pagesCEB1111oscar horacio floresNo ratings yet

- CEB1101Document5 pagesCEB1101oscar horacio floresNo ratings yet

- CEB1109Document6 pagesCEB1109oscar horacio floresNo ratings yet

- CEB1106Document4 pagesCEB1106oscar horacio floresNo ratings yet

- CEB1107Document5 pagesCEB1107oscar horacio floresNo ratings yet

- CEB1108Document5 pagesCEB1108oscar horacio floresNo ratings yet

- CEB1103Document31 pagesCEB1103oscar horacio floresNo ratings yet

- HKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled PrintedDocument10 pagesHKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled Printedoscar horacio floresNo ratings yet

- CEB1102Document1 pageCEB1102oscar horacio floresNo ratings yet

- CEB1100Document4 pagesCEB1100oscar horacio floresNo ratings yet

- CEB1104Document8 pagesCEB1104oscar horacio floresNo ratings yet

- CEB1099Document6 pagesCEB1099oscar horacio floresNo ratings yet

- CEB1097Document5 pagesCEB1097oscar horacio floresNo ratings yet

- CEB1098Document8 pagesCEB1098oscar horacio floresNo ratings yet

- Jaw Couplings Installation Guide: Jaw In-Shear (LS, CS)Document5 pagesJaw Couplings Installation Guide: Jaw In-Shear (LS, CS)Eliana EmizasNo ratings yet

- Vogel - Operating InstructionsDocument45 pagesVogel - Operating InstructionsduongpndngNo ratings yet

- Spare Parts Catalog: 9 S 1310 TO Material Number: 1324.001.048Document56 pagesSpare Parts Catalog: 9 S 1310 TO Material Number: 1324.001.048Imran AliNo ratings yet

- Edoc - Pub Service Manual All HondaDocument8 pagesEdoc - Pub Service Manual All HondahoeboelNo ratings yet

- SOP for IQC Inspection of Sticker ItemsDocument14 pagesSOP for IQC Inspection of Sticker Itemsswapon kumar shillNo ratings yet

- Despiece Rodillo King PDFDocument14 pagesDespiece Rodillo King PDFNelson CortesNo ratings yet

- Procharger Manual (2011-2014 Ford Mustang 3.7)Document52 pagesProcharger Manual (2011-2014 Ford Mustang 3.7)JuanCamilo A.No ratings yet

- B30D 6Document143 pagesB30D 6Teknik MakinaNo ratings yet

- Desviador Delantero Altus 370Document1 pageDesviador Delantero Altus 370Asno SalvajeNo ratings yet

- ATAD Brochure August 10 2018 PDFDocument127 pagesATAD Brochure August 10 2018 PDFHai Tran0% (1)

- 1971 Parts Manual Triumph 650 SDocument85 pages1971 Parts Manual Triumph 650 SEdward Peña ANo ratings yet

- Installation Guidelines: Coastal Wave™Document33 pagesInstallation Guidelines: Coastal Wave™michael turcotteNo ratings yet

- 6 Mini Satellite-Antenna Rotator MkIIDocument20 pages6 Mini Satellite-Antenna Rotator MkIIRADIO LU5HANo ratings yet

- Aprilia rsv4 RF RR Service Station Manual 2017Document558 pagesAprilia rsv4 RF RR Service Station Manual 2017Eka ZuwandyNo ratings yet

- Holding-Down Bolt Design - SANS 10162 - 2005 Material Strength PropertiesDocument7 pagesHolding-Down Bolt Design - SANS 10162 - 2005 Material Strength PropertiesShaikh Muhammad AteeqNo ratings yet

- Mold Components DmeDocument316 pagesMold Components DmenoeneiraNo ratings yet

- RHOWPA Pole Mount: Installation GuideDocument2 pagesRHOWPA Pole Mount: Installation GuideunstrainNo ratings yet

- POS CAL 26PF No09 Beam6a BG Typ H200x200x8x12 R0Document17 pagesPOS CAL 26PF No09 Beam6a BG Typ H200x200x8x12 R0Nguyễn Duy QuangNo ratings yet

- Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric SeriesDocument6 pagesSurface Discontinuities of Bolts, Screws, and Studs, Inch and Metric SeriesJohanna MartinezNo ratings yet

- Abaqus For Engineer SampleDocument63 pagesAbaqus For Engineer Sample17pgme001No ratings yet

- Union Special 61400ABDocument16 pagesUnion Special 61400ABJared TylerNo ratings yet

- Clamping Heads For LathesDocument10 pagesClamping Heads For Lathesinvic7usNo ratings yet

- Besam SW200i-IG ADDENDUM For Swing Door Operator Installation and Service Manual InstructionsDocument54 pagesBesam SW200i-IG ADDENDUM For Swing Door Operator Installation and Service Manual InstructionsXavierNo ratings yet

- Roto Therm Pressure GaugeDocument24 pagesRoto Therm Pressure GaugeGovundan GuruNo ratings yet

- Ehu15 30R ManualDocument50 pagesEhu15 30R ManualSal TargarienNo ratings yet

- Pool Filtration PDF Document Aqua Middle East FZCDocument22 pagesPool Filtration PDF Document Aqua Middle East FZCAdolfsmith69No ratings yet

- Bomba de Calor JandyDocument96 pagesBomba de Calor JandyHumberto TorresNo ratings yet

- Forging and Screw Press Import Data 2008-2013Document29 pagesForging and Screw Press Import Data 2008-2013Kirit ShahNo ratings yet

- Hyster 910442 03 03 srm0231Document16 pagesHyster 910442 03 03 srm0231jonathanrioscNo ratings yet

- Design Igienic Imbinari Demontabile Filetate (DOC 13©EHEDG)Document3 pagesDesign Igienic Imbinari Demontabile Filetate (DOC 13©EHEDG)George GhirasimescuNo ratings yet