Professional Documents

Culture Documents

Colgate

Uploaded by

Sneha Lundia AgrawalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Colgate

Uploaded by

Sneha Lundia AgrawalCopyright:

Available Formats

Supply Chain Management

Colgate-Palmolive

SAP Customer Success Story

128

CHAPTER 5

SAP Customer Success Story

Colgate supports its worldwide brands with mySAP Supply Chain Management

Colgate-Palmolive Company does things globally, and it does things right. The company manages all its brands globally, and in November of 1999, it kicked off the Colgate Global Supply Chain initiative to do the same for its supply chain. Colgate wanted to leverage the investment in its core SAP R/3 solution to further enhance supply-chain performance worldwide. The business goal: improve service to retail and internal customers, reduce inventory, and improve margins. Colgate selected mySAP Supply Chain Management (mySAP SCM) to power its supply chain management initiative. Using SAP Advanced Planner and Optimiser (SAP APO), Colgate got the metrics it was looking for. It improved on-time and complete orders from 70%to 98% for vendor-managed inventory (VMI) replenishment. It increased compliance levels for intracompany replenishment. And it improved customer order fullment to 95%. Colgate also lowered inventory by 10% and reduced overall order cycle times. mySAP SCM uses the power of the Internet to extend supply-chain technology beyond the enterprise. It provides companies like Colgate and their partners and customers with complete visibility into business-critical data. This includes instant, real-time access to information about orders, forecasts, production plans, and such key performance indicator as inventory levels and fullment rates. This enables companies to improve their competitive position by increasing service quality and reducing their investment in inventory. The capabilities of mySAP SCM are

critical to enabling Colgate to take the next logical steps in enhancing global supply-chain performance, says Esat Sezer, Colgates director of global information technology. mySAP SCM delivers solutions on three key fronts. It enables Colgate to gain visibility into global logistics data. It allows us to optimise our operations through the use of advanced mathematical planning functions. And it provides a platform for collaboration with our customer and partners. By leveraging mySAP SCM, we are truly progressing toward excellence in supply-chain planning across our worldwide operations.

The capabilities of mySAP SCM are critical to enabling Colgate to take the next logical steps in enhancing global supply-chain performance.

Case study by SAP

129

Supply Chain Management

A consumer products leader

Colgate-Palmolive Company is a U.S. $9.4-billion global consumer products powerhouse headquartered in New York. Colgate manufactures and markets a wide variety of products in the United States and around the world, including toothpaste, soaps, laundry detergents, and pet foods. The company operates in more than 200 countries, with approximately 70% of sales coming from international operations. Some 80% of Colgates employees are located outside the United States. The company built its mySAP SCM initiative on the foundation of the SAP enterprise solution. Colgate began rolling out the SAP core solution in 1995 to improve operations through consistent, global support for nancial analysis, logistics planning, and other business processes. The SAP implementation was also an enabler for a standardisation drive across Colgate that encompassed all general naming conventions, formulas, raw materials, manufacturing data and processes, and nancial information. These initiatives contributed to large gains in efciency across Colgate worldwide. For example, in the operations arena, the SAP enterprise solution helped consolidate manufacturing facilities. But consumer packaged goods is a ercely competitive global marketplace. Although Colgate had achieved signicant improvements through its SAP enterprise infrastructure, there was still work to be done. For example, Colgate had improved on-time and complete-order fullment rates to around 90% with the implementation of SAP R/3, but it wanted to move these numbers higher with more visibility into demand and capacity constraints. Through SAP, Colgate had also reduced order cycle times from nine days to ve days in North America, but these cycle times still represented unacceptably high internal costs.

130

Case study by SAP

CHAPTER 5

Focus on the supply chain

The Colgate Global Supply Chain initiative was the answer. Within the initiative, Colgate identied three major supply-chain strategies. The rst was to roll out a VMI program with key accounts to signicantly reduce channel inventory and cycle times. Colgate also wanted to implement a cross-border sourcing programme, moving it from a regional to a global sourcing model. This transition would improve forecasts, reduce safety stock, consolidate assets, and leverage economies of scale worldwide. Finally, Colgate wanted to implement collaborative planning processes with its downstream subsidiaries to manage promotional demand and to synchronise activities across the supply chain. Within Colgate, VMI is a pull process by which the company replenishes customer distribution centres based on a daily transmission of inventory and demand information. The current VMI focus is North America, where 40% of cases shipped from ve plants is managed using VMI. The implementation includes 40 distribution centres at 12 customers covering all categories of Colgate products (about 1,000 SKUs). Because mySAP SCM enables Colgate to more precisely match supply and demand, the result is lower nished-goods inventories, higher rates for on-time and complete orders, and reduced replenishment cycle times. The VMI business process is supported by mySAP SCMs supply network planning capabilities. Daily inventory levels and demand from customer distribution centre are transmitted to mySAP SCM, which then calculates the replenishment orders. mySAP SCM incorporates plant capacity information to determine the production requirements and any supply constraints. The replenishment orders are then transmitted back to the customers via EDI for acknowledgement and for handling customer information-processing requirements. The benets Colgate has realised through VMI including 98% on-time and complete-order compliance and a one-day replenishment order cycle will be multiplied as the implementation expands across North America and other geographic regions.

Case study by SAP

131

Supply Chain Management

Truly global sourcing

Colgates Cross-Border Sourcing (CBS) initiative incorporates demand and global sourcing information to create a pull process and move from monthly forecasting to weekly replenishment. Colgate got results quickly: an increase in shipments, higher case ll rates, a reduction in replenishment-order cycle times, and an 8% inventory reduction. In the new business model, supply plants assume responsibility for replenishing the Colgate distribution centres. (Previously, Colgate sales subsidiaries developed monthly, often inaccurate demand forecasts to determine the replenishment requirements from offshore manufacturing sites.) The new weekly replenishment is driven by visibility into customer orders owing through in-country Colgate distribution centre and then to the supplying plants. Replenishment requirements are also calculated from demand information provided by Colgate sales subsidiaries, such as increased demand from promotions. The CBS business process is also supported by mySAP SCM, which calculates replenishment orders based on daily demand signals and inventory levels. This matches demand and supply more exactly, and coupled with specic order pegging, reduces the impact of forecast inaccuracies. The result is lower nished-goods inventory levels, reduced replenishment cycle times, and greater rates of on-time and complete orders for both internal replenishment and customer orders. Colgate has also improved case ll rates and asset utilisation by using nitecapacity replenishment planning techniques. The more exible, more responsive replenishment system has resulted in more frequent shipments to the distribution centres, but there has been no signicant impact on transportation costs because of better overall planning.

132

Case study by SAP

CHAPTER 5

Demand planning

Colgate U.S. uses mySAP.coms demand planning capabilities and the mySAP SCM collaborative engine to provide a tool for communicating demand information to supplier and synchronising planning across the supply-chain network. mySAP SCM statistically computes the base demand to drive repeatable replenishment processes and incorporates changes resulting from promotions. Promotional demand management independent of base demand represents crucial information for driving manufacturing, product nishing, and distribution. The collaboration engine supports the collaborative process for promotional demand by enabling the exchange of up-to-date planning information, exception-based management, and tracking of performance measures like forecast accuracy.

Realising benets

The three major components of Colgates supply-chain strategies are supported by mySAP.coms real-time integration model, where changes in stock, sales orders, and other relevant parameters are updated in real time between customer and internal ERP systems and mySAP SCM. This ensures that modications to the plan can be enacted rapidly, which is especially important for planning promotions. Colgate expects to multiply the impact of the current implementations signicantly as its VMI, CBS, and collaborative engine implementations are rolled out to all brands and plants. Improved visibility throughout the supply chain means accurate, up-to-date, consistent data will be available to support management decisions concerning tactical and strategic plans. Colgate will also use mySAP Business Intelligence (mySAP BI) for quick access to even more consolidated and ner-grained information to support decision making throughout its organisation. Through its supply-chain initiative, Colgate is now better positioned to contend with the forces driving the consumer products industry today, including price competition, expanding global trade, and the use of promotional campaigns. These business drivers are motivating Colgate to pursue continued cost reductions through all aspects of its business and to leverage collaborative tools that improve links with its global customers. Colgate is also working to leverage e-business tools that strengthen both internal integration as well as links with partners and customers.

Case study by SAP

133

Supply Chain Management

Continuous improvement

Even with its successes to date, Colgate continues to pursue supply-chain improvements that will enhance its competitive position. In addition to extending the use of VMI, CBS, and the collaborative engine globally, Colgate is working with SAP to develop repetitive manufacturing functionality in mySAP SCMs production planning and detailed scheduling capabilities. This will enable repeated production runs using a single bill of material (BOM), back ushed material requirements, production alterations arising from short-term changes in demand, and the ability to distinguish making versus nishing as separable manufacturing processes in Colgates promotion-driven environment. Colgate is also supporting development of a mySAP SCM -related wave algorithm to optimise repetitive manufacturing amid potential sudden peaks and valleys in requirements and nite-capacity constraints. Because supply requirements vary in a promotions-driven environment, third-party manufacturing contractors are becoming increasingly important to Colgates business. Colgate expects to leverage mySAP SCM-enabled collaborative planning link with these contractor as well. Colgate is also planning to use mySAP SCMs transportation planning and scheduling capabilities to optimise its transportation network and to realise additional cost savings. Colgate will also pursue various forms of collaboration with customers and partners by participating in consumer goods industry marketplaces that provide exchanges for collaborative demand, procurement, and logistics planning. While moving quickly to achieve these and other goals, Colgate has already realised its many objectives through mySAP Supply Chain Management: supply-chain visibility, increased planning-cycle speeds, efcient asset utilisation through global sourcing, reduced costs, and better customer service.

134

Case study by SAP

CHAPTER 5

Business in brief

Colgate is continually improving its operations to maintain and extend its leadership position in worldwide consumer packaged goods. Focusing on the supply chain, Colgate wanted to upgrade performance by replacing a regional sourcing model with a fully globalised supply chain to improve service to retail and internal customers and to reduce inventory and total delivered costs.

Solution differentiators

Colgate chose mySAP Supply Chain Management for its tight integration with the core SAP enterprise solution. The SAP Advanced Planner and Optimiser (SAP APO) element of mySAP Supply Chain Management also provided functions that open a window onto global logistics information; advanced mathematical planning functions to optimise worldwide operations; and a global platform for customer and partner collaboration.

Case study by SAP

135

You might also like

- Operations Management - MBA 7061 N02Document27 pagesOperations Management - MBA 7061 N02abdallah abdNo ratings yet

- Walmart (Demand Forcast&capacity Planning or Current Capacity Related Strategies)Document4 pagesWalmart (Demand Forcast&capacity Planning or Current Capacity Related Strategies)Ove Kabir Eon 17319230% (1)

- Evolution of Operations Management Past, Present and FutureDocument30 pagesEvolution of Operations Management Past, Present and Futurenaveni100% (1)

- Inventory Optimization 2Document4 pagesInventory Optimization 2PankajSinghBhatiNo ratings yet

- Spare Parts ProcedureDocument3 pagesSpare Parts Proceduresurya agung100% (1)

- Role of Information in Supply ChainDocument20 pagesRole of Information in Supply ChainnomanashrafNo ratings yet

- Kodak SupplychainDocument20 pagesKodak SupplychainMohammad Javid KhanNo ratings yet

- Materials ManagementDocument347 pagesMaterials Managementhare001671% (7)

- Essentials of Effective SCMDocument10 pagesEssentials of Effective SCMAntony ThuruthelNo ratings yet

- Colgate PalmoliveDocument2 pagesColgate PalmoliveVaswee Dubey100% (1)

- Sap SCM Colgate CsDocument8 pagesSap SCM Colgate Csapi-3725984100% (1)

- Ho Chi Minh City University of Economics and Finance Faculty of EconomicsDocument21 pagesHo Chi Minh City University of Economics and Finance Faculty of EconomicsNghĩa Trương HữuNo ratings yet

- Case Study Colgate PalmoliveDocument6 pagesCase Study Colgate PalmoliveSWATHI KRISHNA M R100% (1)

- What Is Supply Chain ManagementDocument6 pagesWhat Is Supply Chain ManagementHusain ShiyajiNo ratings yet

- Colgate PalmoliveDocument9 pagesColgate Palmolivechitrasandhya100% (9)

- Case ReportDocument7 pagesCase ReportAbdullah Sulaiman AlorainiNo ratings yet

- Supply Chain Management of Colgate PalmoliveDocument12 pagesSupply Chain Management of Colgate PalmoliveSai Vasudevan88% (8)

- How to Optimise Your Supply Chain to Make Your Firm Competitive!From EverandHow to Optimise Your Supply Chain to Make Your Firm Competitive!Rating: 1 out of 5 stars1/5 (1)

- MANUFACTURING PLANNING AND CONTROL SYSTEMS FOR SUPPLY CHAIN MANAGEMENT: The Definitive Guide for ProfessionalsFrom EverandMANUFACTURING PLANNING AND CONTROL SYSTEMS FOR SUPPLY CHAIN MANAGEMENT: The Definitive Guide for ProfessionalsNo ratings yet

- Supply Chain Business Startup Guide: Step-by-Step Tips for SuccessFrom EverandSupply Chain Business Startup Guide: Step-by-Step Tips for SuccessNo ratings yet

- CSCP Final Report Vols1-2Document141 pagesCSCP Final Report Vols1-2Valerie F. LeonardNo ratings yet

- Customer Relationship Management in India - Case of Volkswagen IndiaDocument20 pagesCustomer Relationship Management in India - Case of Volkswagen IndiaPratik Mohapatra94% (17)

- 5 TH Module of Supply Chain ManagementDocument18 pages5 TH Module of Supply Chain ManagementSunil ChauhanNo ratings yet

- Supply Chain OptimisationDocument2 pagesSupply Chain Optimisationf.kipruNo ratings yet

- APPLICATIONSDocument4 pagesAPPLICATIONSMOHAMMAD ASYRAF NAZRI SAKRINo ratings yet

- Kimberly Clarke - Supply ChainDocument3 pagesKimberly Clarke - Supply ChainMeeNa NakapromNo ratings yet

- 1935510212+tofig Dadashov+SCMDocument15 pages1935510212+tofig Dadashov+SCMTofiq DadashovNo ratings yet

- Quiz 2 SCM BDocument3 pagesQuiz 2 SCM BGurlal SinghNo ratings yet

- Organising and Planning For LSCM FunctionsDocument13 pagesOrganising and Planning For LSCM FunctionsAnab ZaishaNo ratings yet

- Adidas AG AR2010 Global OperationsDocument4 pagesAdidas AG AR2010 Global OperationsSanju MathewNo ratings yet

- Quiz GSCMDocument3 pagesQuiz GSCMGurlal SinghNo ratings yet

- PPPDocument6 pagesPPPshreyikapNo ratings yet

- Staples - "Removing The Seams in The Supply Chain": Company Profile and Business ContextDocument8 pagesStaples - "Removing The Seams in The Supply Chain": Company Profile and Business ContextSwapan Kumar SahaNo ratings yet

- PLM Direction For 2008-2010Document17 pagesPLM Direction For 2008-2010Adam SobkowiczNo ratings yet

- A Simpler Way To Modernize Your Supply ChainDocument7 pagesA Simpler Way To Modernize Your Supply Chainquad111No ratings yet

- Casestudy: Lean Value Chain: Demand SegmentationDocument3 pagesCasestudy: Lean Value Chain: Demand SegmentationraiyanduNo ratings yet

- Genpact Whitepaper Supply Chain OptimizationDocument4 pagesGenpact Whitepaper Supply Chain OptimizationGops KrishnaNo ratings yet

- Postponement For Profitability 065283Document14 pagesPostponement For Profitability 065283akashkrsnaNo ratings yet

- SAP e Book 60 Pages Ebook The Supply Chain Optimization HandbookDocument8 pagesSAP e Book 60 Pages Ebook The Supply Chain Optimization HandbookRajivNo ratings yet

- What Other Supply Chain Opportunities Should West Marine Pursue As The Company Looks Forward?Document3 pagesWhat Other Supply Chain Opportunities Should West Marine Pursue As The Company Looks Forward?Gaurav MadanpuriNo ratings yet

- SAP Journey in BPCLDocument5 pagesSAP Journey in BPCLneelgalaNo ratings yet

- Sem 2 Mba Winter 2013Document10 pagesSem 2 Mba Winter 2013bhandari0148No ratings yet

- Assignment Questions Winter2013 NewDocument95 pagesAssignment Questions Winter2013 NewTushar AhujaNo ratings yet

- Realizing Demand Driven Supply ChainDocument14 pagesRealizing Demand Driven Supply ChainbslnarasimhanNo ratings yet

- Module 8 Managing The Supply ChainDocument6 pagesModule 8 Managing The Supply ChainCharlie MaineNo ratings yet

- A Simpler Way To Modernize Your Supply ChainDocument23 pagesA Simpler Way To Modernize Your Supply ChainragerahulNo ratings yet

- Chase SAS - Market-Driven Demand ManagementDocument5 pagesChase SAS - Market-Driven Demand ManagementStevoIlicNo ratings yet

- Easychair Preprint: Archit BansalDocument8 pagesEasychair Preprint: Archit Bansalferdyanta_sitepuNo ratings yet

- P&G: Customer Centricity and The Responsive Supply ChainDocument2 pagesP&G: Customer Centricity and The Responsive Supply ChainShahbazHaiderNo ratings yet

- A Simpler Way To Modernize Your Supply ChainDocument3 pagesA Simpler Way To Modernize Your Supply Chainmanshi choudhuryNo ratings yet

- Colgate Case StudyDocument7 pagesColgate Case Studyphongvan_DuNo ratings yet

- A Literature Analysis of WalmartDocument11 pagesA Literature Analysis of WalmartharpreetNo ratings yet

- ColgateDocument3 pagesColgateganal2girish0% (1)

- Acc Cement UpdatedDocument6 pagesAcc Cement UpdatedMayank VyasNo ratings yet

- Enterprise Rsource Planning (Erp) OPM 632Document8 pagesEnterprise Rsource Planning (Erp) OPM 632Adawiyah AmnaNo ratings yet

- BWP SB Dairy IndustryDocument4 pagesBWP SB Dairy IndustryRavi MauryaNo ratings yet

- Strategic Sourcing and Segmentation: Prescriptive Control Tower ApproachDocument12 pagesStrategic Sourcing and Segmentation: Prescriptive Control Tower ApproachRoshan KumarNo ratings yet

- Demand Management:: Customize Products Through The Use of Product Completion CentersDocument13 pagesDemand Management:: Customize Products Through The Use of Product Completion CentersGabriela CándanoNo ratings yet

- IGATE Case Study and Industry SolutionsDocument4 pagesIGATE Case Study and Industry SolutionsManish TourasNo ratings yet

- Lean Six Sigma JUNE 2022Document11 pagesLean Six Sigma JUNE 2022Rajni KumariNo ratings yet

- Fabless WhitepaperDocument9 pagesFabless WhitepaperspaulsNo ratings yet

- LogisticsDocument6 pagesLogisticsJosé SalazarNo ratings yet

- Godrej Builds 'Sampark' With Distributors - E-Business - Express Computer IndiaDocument2 pagesGodrej Builds 'Sampark' With Distributors - E-Business - Express Computer IndiaPradeep DubeyNo ratings yet

- Syed Zuahib Waris Registration No 52303 Hourly 2Document2 pagesSyed Zuahib Waris Registration No 52303 Hourly 2Syed Zohaib WarisNo ratings yet

- Supply Chain Innovation Within The FMCG SectorDocument3 pagesSupply Chain Innovation Within The FMCG Sectorquad111No ratings yet

- Gus Sit 2020 05 Piotr Zawada Wlodzimierz Okrasa Jack Warchalowski Flow Management SystemDocument14 pagesGus Sit 2020 05 Piotr Zawada Wlodzimierz Okrasa Jack Warchalowski Flow Management Systemmama123ojoNo ratings yet

- Social Media Marketing StrategyDocument9 pagesSocial Media Marketing StrategySneha Lundia AgrawalNo ratings yet

- ITM7-Group2 PepsiAmericasDocument11 pagesITM7-Group2 PepsiAmericasSneha Lundia AgrawalNo ratings yet

- ITIL Foundation Examination SampleDocument13 pagesITIL Foundation Examination SampleSneha Lundia AgrawalNo ratings yet

- Moneycontrol RatioDocument2 pagesMoneycontrol RatiotwinklechoksiNo ratings yet

- Moneycontrol RatioDocument2 pagesMoneycontrol RatiotwinklechoksiNo ratings yet

- Answer Key Xat 2009Document1 pageAnswer Key Xat 2009Ankit KhuranaNo ratings yet

- Evidencia 4. Fase AnalisisDocument3 pagesEvidencia 4. Fase Analisisel cachi f. fNo ratings yet

- Topic 7 - EOQ and ROPDocument3 pagesTopic 7 - EOQ and ROPMai Mai VarelaNo ratings yet

- Resume Mahendra NewDocument6 pagesResume Mahendra NewhrNo ratings yet

- Small Shops & Departmental ShopsDocument3 pagesSmall Shops & Departmental ShopsRezwan AhmedNo ratings yet

- Place Marketing Channels: Delivering Customer ValueDocument4 pagesPlace Marketing Channels: Delivering Customer ValueDeath StrokeNo ratings yet

- PBM Session 1-8Document49 pagesPBM Session 1-8udi969No ratings yet

- Enterprise Resource Planning: Term Paper OnDocument27 pagesEnterprise Resource Planning: Term Paper OnSharif KhanNo ratings yet

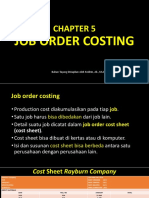

- Cost CH 5 Job Order Costing 2019Document22 pagesCost CH 5 Job Order Costing 2019Shofiyyatul MaulaNo ratings yet

- Information Systems & Supply Chain ManagementDocument25 pagesInformation Systems & Supply Chain ManagementdhivirajNo ratings yet

- An To Retailing: Retail Management: A Strategic ApproachDocument16 pagesAn To Retailing: Retail Management: A Strategic ApproachVishakh0% (1)

- Sinotruk Zimbabwe: Ref: Sinotruk Part Sales Customer VisitsDocument2 pagesSinotruk Zimbabwe: Ref: Sinotruk Part Sales Customer Visitselfigio gwekwerereNo ratings yet

- ch15 MRPDocument37 pagesch15 MRPNaseeb Ullah TareenNo ratings yet

- The Seven Value Stream Mapping Tools Peter Hinesand Nick Rich IJOPM1997Document29 pagesThe Seven Value Stream Mapping Tools Peter Hinesand Nick Rich IJOPM1997Aji Putra PNo ratings yet

- MGT330 Final ReportDocument13 pagesMGT330 Final ReportNadil HaqueNo ratings yet

- Financial Statements ER Problem 2 SolutionDocument11 pagesFinancial Statements ER Problem 2 SolutionSYED ALI SHAH SYED MUKHTIYAR ALINo ratings yet

- The 8 Wastes of Lean Management Aid Memoir A4Document1 pageThe 8 Wastes of Lean Management Aid Memoir A4Hajar RajabNo ratings yet

- Ia Audit Report ExcelDocument5 pagesIa Audit Report ExcelSunil Kumar Gurudutt NanduriNo ratings yet

- Boeing Lean Manufacturing SystemsDocument5 pagesBoeing Lean Manufacturing SystemsAtifNo ratings yet

- Chapter 2-Global E-Business and CollaborationDocument42 pagesChapter 2-Global E-Business and CollaborationSarah Al ZaabiNo ratings yet

- Accounting For Inventories: Chapter OutlinesDocument58 pagesAccounting For Inventories: Chapter Outlinesnarr0% (1)

- PSCM 430 - Additional NotesDocument60 pagesPSCM 430 - Additional NotesJames Gikingo100% (1)

- Tutorial 5 Eco 415Document7 pagesTutorial 5 Eco 415ZhiXNo ratings yet

- Important Documents For Transporting GoodsDocument12 pagesImportant Documents For Transporting GoodsAbhishek TiwariNo ratings yet

- Sourcing Decisions in A Supply ChainDocument23 pagesSourcing Decisions in A Supply ChainsalmanqurashiNo ratings yet