Professional Documents

Culture Documents

6.6 Onshore and Offshore Pipeline Design Philosophy

Uploaded by

ifechuuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6.6 Onshore and Offshore Pipeline Design Philosophy

Uploaded by

ifechuuCopyright:

Available Formats

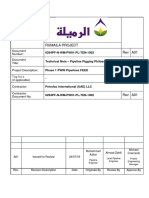

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 1 of 3

Onshore and Offshore Pipeline Design Philosophy

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 2 of 3

TableofContents

1. Scope and Functional Requirement ................................................................................................ 4 1.1. Scope of Document ................................................................................................................. 4 1.2. Definitions................................................................................................................................ 4 1.3. Abbreviations........................................................................................................................... 5 1.4. System of Units ....................................................................................................................... 6 2. Assumptions .................................................................................................................................... 7 2.1. General.................................................................................................................................... 7 3. Design Requirements ...................................................................................................................... 8 3.1. Design Life .............................................................................................................................. 8 3.2. Operating Philosophy .............................................................................................................. 8 3.3. Operating Data ........................................................................................................................ 8 3.3.1. Product Composition ....................................................................................................... 8 3.3.2. Design and Operating Pressures .................................................................................... 9 3.4. Design Codes ....................................................................................................................... 10 3.5. Pipeline Hydrotest Parameters ............................................................................................. 10 3.6. Onshore Pipeline Location Class .......................................................................................... 10 3.7. Materials ................................................................................................................................ 11 3.7.1. Linepipe Materials ......................................................................................................... 11 3.7.2. Corrosion Resistant Alloys ............................................................................................ 11 3.7.3. External Corrosion Protection ....................................................................................... 11 3.7.4. Concrete Weight Coating .............................................................................................. 11 3.8. Onshore Pipeline Routing .................................................................................................... 11 3.8.1. General.......................................................................................................................... 11 3.8.2. Description of Proposed Route ..................................................................................... 12 3.8.3. Routing Constraints ....................................................................................................... 13 3.9. Offshore Pipeline Routing .................................................................................................... 14 3.9.1. General.......................................................................................................................... 14 3.9.2. Routing Constraints ....................................................................................................... 14 3.9.3. Additional Routing Considerations ................................................................................ 16 3.10. Onshore Pipeline Installation and Construction .................................................................... 17 3.10.1. General.......................................................................................................................... 17 3.10.2. Landfall .......................................................................................................................... 18 3.10.3. Onshore Pipeline Construction in Near Shore/Landfall Areas ...................................... 19 3.11. Offshore Pipeline Installation and Construction .................................................................... 19 3.11.1. General.......................................................................................................................... 19 3.11.2. Outline Installation Methodology ................................................................................... 19 3.11.3. Trenching and Burial ..................................................................................................... 20 3.11.4. Crossings and Third Party Ownership Considerations ................................................. 20 3.11.5. Landfall Design.............................................................................................................. 20 3.12. Offshore Pipeline Protection Design ..................................................................................... 20 3.13. Connections Design .............................................................................................................. 21 3.14. Risk Assessment ................................................................................................................... 21 3.15. Pigging .................................................................................................................................. 21 3.16. Future Expansion of System ................................................................................................. 22 3.17. Environmental Design Data .................................................................................................. 22 3.18. Pipeline Safety and Control Systems .................................................................................... 22 3.19. Condition Monitoring ............................................................................................................. 23 3.20. Onshore Pipeline Sectional Valves ....................................................................................... 23 3.21. Offshore Pipeline SSIVs ....................................................................................................... 24 3.22. Pre-Commissioning and Commissioning .............................................................................. 24 3.23. Pipeline Surveillance and Maintenance ................................................................................ 24

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 3 of 3

4. Mandatory References................................................................................................................... 26 4.1. Regulations and Statutes ...................................................................................................... 26 4.2. Project Documentation .......................................................................................................... 27 4.3. Design Codes ........................................................................................................................ 27 5. Supporting References .................................................................................................................. 28 5.1. Project Documentation .......................................................................................................... 28 5.2. Design Codes ........................................................................................................................ 28

TableofFigures

Figure 1.1: Outline Pipeline System Schematic ...................................................................................... 4 Figure 3-1: Proposed Onshore Pipeline Route ..................................................................................... 13 Figure 3-2: Offshore Pipeline Outline Route ........................................................................................ 16

TableofHolds

HOLD No. 1 2 3 4 5 6 7 8 9 10 11 12 13 Description Cleared Maximum Allowable Pressure Cleared Cleared Cleared Minimum Flow Rate (Injection) Cleared Bend radii Straight route length Cleared Cleared. Cleared Cleared 3.9.2 3.9.2 Table 3.3.2-a Table 3.3.2-a Section

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 4 of 4

1. Scope and Functional Requirement

1.1. Scope of Document This document presents the design philosophy, assumptions and design guidelines for the onshore and offshore sections of the CO2 pipeline from the Kingsnorth Power Station to the Hewett field. Error! Reference source not fo und. is an outline schematic of the overall system.

Figure 1.1: Outline Pipeline System Schematic

1.2. Definitions COMPANY CONTRACTOR E.ON UK or its nominated representative. The companies designated on the purchase order form as being the selected Contractor of materials and services. The task, process or operation being conducted by the CONTRACTOR on any tier on behalf of COMPANY. Indicates mandatory requirement Indicates preferred course of action Indicates optional course of action

WORK Shall Should May

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 5 of 5

1.3. Abbreviations 3LPP ALARP ASME BLEVE BS CCS COS CP DCS DNV DP EIA ESD(V) FJC FEED GHS HAZID HAZOP HSE ID IID ISO KP MAOP MAPD MCA MMscmd Mt N/A NPS PEXA PSR ppb ppmv PWHT

3 Layer Polypropylene As Low as Reasonably Practicable American Society of Mechanical Engineers Boiling Liquid Expanding Vapour Explosion British Standard Carbon Capture and Storage Carbonyl Sulphide Cathodic Protection Distributed Control System Det Norske Veritas Dynamic Positioning Environmental Impact Assessment Emergency Shut Down (Valve) Field Joint Coating Front End Engineering Design Globally Harmonised System Hazard Identification Hazard and Operability Health and Safety Executive Internal Diameter Intelligent Inspection Device International Standardisation Organisation Kilometre Point Maximum Allowable Operating Pressure Major Accident Prevention Document Maritime and Coastguard Agency Million Standard Cubic Metre per Day Million tonnes Not Applicable Nominal Pipe Size Practice and Exercise Areas Pipeline Safety Regulations parts per billion Parts Per Million by Volume Post-Weld Heat Treatment

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy Route Corridor Investigation Study Specified Minimum Yield Strength System International Special Protection Area Special Area of Conservation Sub Sea Isolation Valve Site of Special Scientific Interest Supervisory Control and Data Acquisition Wellhead Platform.

Project Title: Document Title: RCIS SMYS SI SPA SAC SSIV SSSI SCADA WHP

Page 6 of 6

1.4. System of Units Units to be used throughout the FEED design are defined in ref. [M34], Overall Project Units. During the injection and production regimes, the CO2 may exist in the gas, liquid or dense phases with varying densities. As a result, the flow rate in this report is given in tonne/day and Mt/year (as opposed to MMscmd). Specific assumptions made to adapt this mass flow rate to its equivalent volume flow rate will be clearly stated in the relevant reports.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 7 of 7

2. Assumptions

2.1. General The following assumptions have been made: Pipeline will be required to cater for both gas and dense phase flow; The dryness spec is 100 ppmv or better to ensure that liquid water will not exist in the line. This figure is the minimum requirement and may change during FEED 1a. However, the specification delivered to the pipeline will ensure that no free water or hydrate potential will exist in the pipeline or CO2 transport system; Standard conditions that will govern the design flowrate are assumed as 1.01325 bara, and 15 C.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 8 of 8

3. Design Requirements

3.1. Design Life It is assumed that the pipeline system will have a design life of 40 years.

3.2. Operating Philosophy The pipeline will be designed for CO2 transportation for injection at the Hewett field. The Hewett field has been in production for 40years, and it is anticipated that during the initial injection years, the reservoir pressure will be as low as 3bara. Current preferred choice is to start injecting gaseous CO2 into the reservoir until reservoir pressure has increased to approximately 40barg and change to dense phase thereafter. Consequently, the pipeline transportation will be in gaseous phase in the early years and dense phase in later years. The maximum and mean CO2 flow capacity will vary over time as the reservoir pressure rises. Under initial (gaseous) flowing conditions it is anticipated that the maximum flow rate in the gaseous phase is 9470 tonnes per day at startup and 13380 tonnes per day at 40 bar, after which the system will be switched to dense phase operation. To operate in dense phase, and to avoid problems with two-phase flow in the pipeline, requires the arrival pressure to rise to 80 barg. As the reservoir pressure rises further the required arrival pressure gradually increases to approximately 90 barg, corresponding to approximately 120 barg pipeline inlet pressure. The CO2 from Kingsnorth CCS Plant will need to be dehydrated prior to export to avoid free water drop out and increased likelihood of corrosion and hydrate formation. Whether in gaseous or liquid phase, pipeline design will be based on a single phase fluid being transported, refer to E.ON Kingsnorth Project Scope of Work Dispersion Experiments and Modelling for static and dynamic modelling of the system, ref.[S5]. However further work on 2phase operations is planned and this will be analysed to determine any potential problems.

3.3. Operating Data 3.3.1.Product Composition The CO2 is captured using an amine capture process, and is compressed and dried prior to reaching the export pipeline. The Basis of Design for Studies (ref. [M33] contains typical post compressor i.e. pipeline inlet composition of the gas. Significant deviations from the given composition over time are not expected, although the burning of different coals may give rise to minor variations. During normal operations, it is not anticipated than anything will be added to the CO2 stream at any point in the capture, compression, transportation or injection process. Odourisation of the gas may be considered, however, and other (as yet unknown) chemical injection may also be required. Under upset and shutdown conditions oxygen scavenger may be added to the CO2 stream to prevent corrosion; this shall be confirmed during the FEED 2 study. It is a design requirement that the CO2 will be dried at the dehydration plant to a water content less than the values listed in Section 2 (the dryness spec is 100 ppmv or better to ensure that liquid water will not exist in the line). If assumed then dryness sensitivities will be required unless it can be stated as a design requirement.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 9 of 9

3.3.2.Design and Operating Pressures A normal operating pressure of approximately 50 barg would be suitable for gas phase transportation, but as the pipeline is to be capable of dense phase transportation as well then a significantly higher MAOP is required. It should be noted that the compression plant at Kingsnorth must be designed such that it cannot exceed the MAOP of the pipeline i.e. so that the pipeline is fully rated. The maximum allowable operating pressure of the pipeline and the inlet to the platform is estimated to lie in the range 150 to 200 barg. This includes an allowance for future increases in capacity, plus allowance for a degree of linepack, due to diurnal swings in CO2 production for example. The finalised design pressure of the pipeline system shall not be less than the maximum allowable operating pressure, and shall take into consideration transient effects in the system, as well as linepack and potential future expansion of the system. Finalisation of the design pressure will be undertaken during FEED 2 and shall take into consideration the cost of providing additional steel to withstand the higher pressure vs the operational flexibility that this additional material would provide. Pipeline operating parameters used during this phase are summarised in Table 3.3.1-a. Description. Design Pressure Maximum Allowable Operating Pressure Maximum Design Temperature Inlet Temperature (Injection) Inlet Temperature Range to Pipeline (at Compressor after cooling - Kingsnorth end) Minimum Design Temperature Minimum Design Temperature (Materials) Minimum Flow Rate (Injection) Unit barg barg C C C C C tonne/day 150 HOLD 2 70 3) Seabed ambient 30-50 HOLD 4 -20oC offshore -85oC onshore HOLD 6 28000 Value

Design Flow Rate (Kingsnorth tonne/day Only) Table 3.3.2-a Overall Pipeline Operating Parameters

During gas phase operation of the pipeline, no pressure control valve or heating is required on the platform. A fired heater is provided to mitigate the low temperature produced across the valve due to Joules-Thomson cooling, during start-up, dense phase operation of the pipeline or any other condition which results in a situation where the pressure in the pipeline is significantly greater than that in the wellbore. It should be noted that during line pack operations (i.e. where the Hewett choke is either partially or completely closed and the pressure in the pipeline allowed to rise) then this may also need heating duty or limits set on the degree of choking at Hewett to ensure that the downstream temperature does not fall below design limits.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 10 of 10

3.4. Design Codes The design code for the pipeline will be BS EN 14161, supplemented by the code of practice PD 8010. DNV OS F101 shall be used for design of the offshore section. To date there have been no pipelines constructed for the transport of CO2 in the UK, and therefore PD 8010 does not specifically address CO2 transport, in particular the transport of dense phase CO2. The DNV OS F101 code does refer to CO2 (but as a non-flammable non-toxic gas, thus falling into Category C). ASME B31.4 code makes provision for CO2 pipelines, including dense phase CO2. Whilst mixing of codes is generally not accepted, the approach of ASME B31.4 if appropriately applied could assist the infilling of areas not specifically addressed by the UK/European codes. For 2 design purposes the dense phase CO2 anticipated to be produced from the Kingsnorth power station will be classified as Category E substance under BS PD 8010-1 (toxic fluids that are gases at ambient temperature and atmospheric pressure conditions and are conveyed as gases and/or liquids). This classification and treatment of CO2 is subject to confirmation by 3rd parties. It is expected that there will be ongoing discussions with the HSE on this aspect and on issues concerning design code selection and code compliance generally. It is also expected that there will be particular issues relating to the pipeline system, in particular the transport of the dense phase CO2, that will require further research and development, and the results of this research incorporated in the pipeline Design Philosophy/Data during FEED 2. A list of Mandatory and Supporting References, including Design Codes, are listed in Sections 4 and 5, respectively. The new DNV code for pipeline transport of CO2, ref. [M40], is expected to be available during this phase of the project.

3.5. Pipeline Hydrotest Parameters Mill hydrotest pressure for the linepipe shall be determined in accordance with ISO 3183. System hydrotest strength and leak test pressures for the onshore and offshore pipeline shall be determined in accordance with the appropriate design codes. It is anticipated that a golden weld i.e. 100% radiographically tested, will be performed at the landfall location (onshore / offshore tie-in weld) in lieu of an overall onshore/offshore leak test. Refer also to Pipeline Testing and Drying Philosophy, ref. [M30].

3.6. Onshore Pipeline Location Class Location classes will be confirmed during FEED 2, after completion of the route surveys and assessment of the population densities. Preliminary location classes, in accordance with PD 8010-1, will be adopted to estimate pipeline wall thickness requirements and proximities. The following general pipeline location classes shall be considered as a starting point: Class 2 (Areas with a population density greater than or equal to 2.5 persons per hectare) to be adopted for a distance of 800m (as a minimum) from High Water Tide Level towards offshore; Class 1 (Areas with a population density less than 2.5 persons per hectare) where applicable for other sections along the onshore pipeline route.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title: 3.7. Materials

Page 11 of 11

3.7.1.Linepipe Materials Carbon steel linepipe is the economical choice for CO2 transport. Subject to any additional requirements such as those discussed in the Pipeline Material Selection, Corrosion Protection and Monitoring Philosophy ref. [M32] with respect to low temperature capability/toughness and internal corrosion mitigation, ISO 3183 L450M (API 5L X65 equivalent) linepipe steel is expected to be generally suitable for construction of the onshore pipeline. Direct depressurisation of dense phase CO2 could lead to temperatures lower than the minimum design temperature of the carbon steel, hence this issue will need to be addressed as part of the pipeline depressurisation/blowdown studies. Final linepipe material selection will be made during FEED 2. 3.7.2.Corrosion Resistant Alloys Although the main pipeline is expected to be fabricated from carbon steel, there is likely to be a requirement for corrosion resistant alloys (CRAs) at particular locations in the system, for example valve materials, or spoolpieces subject to particularly low temperatures. Selection of suitable CRAs shall take into consideration all relevant aspects of the service environment, including the pre-commissioning and commissioning phases. 3.7.3.External Corrosion Protection The pipeline shall be protected against external corrosion using a standard anti-corrosion coating and cathodic protection. Where the linepipe is to be subsequently concrete coated for hydrodynamic stability and/or protection, the anti-corrosion coating shall be compatible with the application of the concrete weight coating. 3.7.4.Concrete Weight Coating The onshore section of the pipeline route may cross areas of ground which may be subject to periodic flooding and may require the installation of anti-buoyancy. This may be undertaken with the installation of concrete weight coating or other measures, which will be reviewed during the FEED 2 design phase.

3.8. Onshore Pipeline Routing 3.8.1.General Above 73 barg and 31C carbon dioxide is supercritical, and its physical properties are intermediate between gas and liquid. It exhibits high solvency characteristics, and if released would quickly form a cloud and solid CO2 particles whilst causing extreme freezing around the point of release. In high concentrations, for example above 30 per cent, the gas can quickly kill as it displaces oxygen. The onshore pipeline poses a potential threat to the general public, therefore further work needs to be conducted in the modelling of releases of CO2 in its dense phase to satisfy and address risks concerned with potential releases from the pipeline. Onshore pipeline route selection is, in general, a balance between availability of a viable, unimpeded route, proximity of the route to population accumulations and individual dwellings, and the stress levels within the pipeline material. In accordance with BS PD 8010-1, a pipeline carrying a Class E substance may not be routed through high populations density areas i.e. towns and cities. Provided that the stress

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 12 of 12

level in the pipe material remains less than 0.3 x SMYS, pipelines conveying Class E substances may be routed through Class 2 population density areas (above 2.5 persons per hectare but excluding towns and cities). The Code provides guidance on proximity distances to buildings for Class 1 areas. 3.8.2.Description of Proposed Route The pipeline starts within the confines of the proposed Kingsnorth Power Station. The preferred pipeline route heads in a northenly direction from the Power Station towards the landfall location and landfall valve in the vicinity of St. Marys Marshes where it will cross the intertidal mud flats and continue eastwards down the Thames Estuary. The landfall valve site shall include provision for future tie-ins from other CO2 capture sources. Such provision shall enable connections to be made without interruption to the flow from Kingsnorth to Hewett. The following lists the main features and principal crossings en route including: Small watercourses; Industrial access roads; Access tracks; A rail line; A gas pipeline An A road; Lower class roads.

The onshore route is outlined in Figure 3-1.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Key Knowledge Sch 7 item 6.42 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy Page 13 of 13

Figure 3-1: Proposed Onshore Pipeline Route

3.8.3.Routing Constraints A single onshore route shall be defined as early as possible in the FEED process. This will permit release of the topographical and geotechnical survey workscopes, and the commencement of the full EIA, which is anticipated to take a year to fully complete. In parallel with the onshore pipeline route selection, a suitable landfall location will be confirmed. This is dependent on agreement of a suitable offshore pipeline route, and clarification of outstanding near shore routing issues. Routing constraints which will be considered during overall route selection for the onshore pipeline will include the following: Proximity distances to inhabited areas to be maximised; CO2 dispersion issues; Ease of installation and construction of the pipeline - shortest route length to be maintained where possible; Project stakeholder preferences, including Local Authority, Environment Agency, Natural England; Landowner issues;

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 14 of 14

Environmental impact, including impact on ecology, archaeology and landscape. to be minimised; Impact on existing and on any proposed future infrastructure, including pipeline, cables and other utilities to be minimised; Impact on any future developments e.g.in local plans, to be minimised; Local community issues, particularly during construction, to be taken into consideration; Interaction with any known areas of landfill or contaminated ground to be minimised.

3.9. Offshore Pipeline Routing 3.9.1.General The offshore section starts at the proposed landfall, then runs east towards deeper water before deviating northwards towards Hewett. Further details of the various routing options considered during pre-FEED are contained in ref. S2. An offshore route survey, will be performed at an early stage during FEED 2, and on completion, and on obtaining agreement with stakeholders, the route selection will be confirmed. The offshore routing is currently being modified as part of an ongoing RCIS. 3.9.2.Routing Constraints The following considerations and constraints shall be taken into consideration in defining the route of the offshore pipeline: The shortest route length to be maintained where possible; Pipelay will likely be initiated from the landfall to enable the laybarge to lay into deeper water. Laydown will likely be performed adjacent to the Hewett field WHP; Bend radii of 3000m (HOLD 8) to be maintained at route deviations; Straight route lengths of 500m (HOLD 9) to be maintained preceding and following any route deviations; The pipeline to be routed in such a way that it maintains a minimum clearance of approximately 500m from wind farm structures, to allow for maintenance operations; Routing to deeper water where possible, to minimise routing through the shallower water zones; Clearances to be maintained to munitions dump sites; Military Practice and exercise areas (PEXA) to be taken into account; Clearances to be maintained to disposal dump sites; Dredge sites to be avoided; Pipeline, umbilical and cable (telecoms and power) crossings to be minimized; Licensed block holders (some in the Thames Estuary); Disturbance of fishing breeding grounds to be minimized ; Areas of reef forming organisms to be avoided;

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 15 of 15

Clearance to shipping access channels, future channels and consideration of future dredging requirements for these channels to be taken into account as per ongoing RCIS; Shipping separation zones to be avoided; Anchoring zones to be avoided ; High intensity of shipping to be avoided ; High intensity of fishing to be avoided; Areas of mobile seabed to be avoided; Seabed sand banks to be avoided; Seabed sandwaves and megaripples to be avoided; Ship wrecks to be avoided ; and plane wrecks; Clearance of 500m to wells and installations to be maintained; Clearance to drill rigs to be maintained subject to anchor patterns; Consideration to be given to the routing of the pipeline past the major ports of Great Yarmouth and Lowestoft so as to minimise any disruption to marine activity during construction, and minimise risks to the pipeline throughout its operating life.

The outline offshore pipeline route is shown on Figure 3-2.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Key Knowledge Sch 7 item 6.42 Project Title: Document Title: Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy Page 16 of 16

Figure 3-2: Offshore Pipeline Outline Route 3.9.3.Additional Routing Considerations There is a significant constraint just offshore from the Isle of Grain in the wrecked SS Richard Montgomery, a Second World War munitions ship left partly submerged on a shallow sandbar. The ship still contains significant quantities of explosives. The route shall be chosen so as to pass a safe distance from this constraint, but the precise distance will be considered as part of the RCIS.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 17 of 17

The route also crosses busy shipping lanes. Shipping lanes can be crossed though consideration needs to be given to safety during construction and the potential for the pipeline to limit future use of the lane. Trenching/burial depths shall be established in conjunction with the MCA and other relevant parties in order to allow for future maintenance dredging. Further potential and actual obstacles are present including: Wind farm concession areas Round 1, Round 2 plus latest Round 3; Dredging licence areas and dredging application areas; Disposal sites; UK mineral rights extent; Existing cables and pipelines; and near future cables (Britned) and pipelines including Baird and ENI future pipeline routes; Military practice exercise area (PEXA). The number of pipeline and cables crossings should be minimised. The crossings are estimated to be 6 pipelines and at least 12 cables, depending on the finalised routing. There is a large MOD practice area, which the most logical pipeline route crosses. This may be feasible and is being investigated as part of the ongoing RCIS work. The northern section of the pipeline route is known for its predominance of sandwaves and a highly mobile seabed. For a large diameter pipeline this implies seabed preparation by dredging and post-lay trenching of the pipeline. This is a high cost activity, which will require further study to optimise. Sandwaves may also occur in the southern part of the route. Drawings of the offshore routing detailing the locations of wind farm concession areas and PEXA shall be issued during FEED 2.

3.10. Onshore Pipeline Installation and Construction 3.10.1. General The proposed construction methodology to be fully developed during FEED 2 and set out in a Construction Philosophy which shall comply with all relevant Health and Safety, and Environmental legislation. Construction techniques shall minimise the overall environmental impact of the onshore pipeline. Consents will be required for certain construction activities e.g. planning permission from local planning authorities for any buildings, fences or bunds along the pipeline route. An Environmental Impact Assessment (EIA) will be required, in accordance with European Directives. The onshore pipeline will be buried along its entire length, with a minimum depth of cover of 1.1m, and with increased cover at crossings. All items of infrastructure on the proposed onshore pipeline route shall be identified and 3rd party owners confirmed. These shall be documented in the routing report. Construction specifications will be prepared covering all aspects of design and construction including: Fencing and right of way preparation to ensure delineation of the working area and to minimise unauthorised access; Top soil strip, soil management and reinstatement on completion of the works;

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 18 of 18

Excavation and general open trench safe working; Pipe handling and stacking to control storage and to minimise damage prior to installation; Stringing and storage of the pipe alongside the pipeline route; Field bending of the pipe to accommodate changes in alignment and elevation; Welding, including any necessary weld or welder qualifications associated with pipelines for the conveyance of CO2 and possible PWHT depending on WT; Radiography and weld inspection; External coating of welded joints; Lift and lay to avoid pipe damage and to safely control site lifting operations; Backfill of the pipe trench with suitably graded material and bedding layer; Reinstatement of the working width to ensure minimal long term environmental impact. Backfilling and reinstatement requirements will be developed during FEED 2 to minimise any adverse effects of the proposed routing on natural drainage; Quality control/inspection records and handover documentation; Corrosion protection philosophy; Weight coating at water courses and areas prone to flooding, taking into consideration predicted sea level elevation changes; Crossing construction where roads, railways, river or other services are to be crossed; It should be noted that the following items are discussed in the relevant commissioning philosophies (Ref. M29 and M30); Hydro testing of the pipeline to demonstrate overall integrity; Cleaning and dewatering of the pipe line prior to performing tie-in weld to the offshore pipeline; Air or vacuum drying of the pipeline system and filling with air or possibly nitrogen; Dewatering of groundwater where required; Commissioning of the pipeline system and introduction of CO2. 3.10.2. Landfall The landfall area is a key aspect of the proposed pipeline route, and will be subject to considerable interest from third parties and regulatory bodies. Early engagement and discussion of the precise design solution (including other options considered) with these bodies shall be undertaken. For the St. Marys Marshes shore approach the provisions of the Habitats Regulations to Ramsar sites, would require that the development proposals be subject to appropriate assessment'. This assessment requires taking into consideration the site's conservation objectives, including ensuring that the full range of Ramsar interests has been designated and their vulnerabilities to any effects of the proposed development determined. Designated sites are to a greater or lesser degree affected by activities which occur away from or adjacent to those sites, as well as those on the construction site which is the case for the shore approach for the offshore pipeline. Wetland sites are especially vulnerable to factors such as hydrological change within or adjacent to the site. To meet the obligations for Ramsar, a full environmental assessment will be required which would include benthic

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 19 of 19

sampling and biology, water quality, wild life monitoring, marine mammal survey, and a video survey, inter tidal biology, commercial fishery activity etc. 3.10.3. Onshore Pipeline Construction in Near Shore/Landfall Areas The selection of the precise method of construction and sequence of activities to be followed during near shore/landfall construction will depend upon factors such as line diameter, water depth along the pipeline route, and environmental considerations (the objective is to minimise damage and environmental impact in a RAMSAR site) and other conditions at the landfall. The final choice of method would be made after consultations with all the interested third parties and a review with E.ON concerning cost and schedule implications.

3.11. Offshore Pipeline Installation and Construction 3.11.1. General The proposed construction methodology shall comply with all relevant Health and Safety, and Environmental legislation. Pipeline routes and construction techniques shall also be developed during FEED 2 to minimise the overall environmental impact of the offshore pipeline, for instance by avoiding environmentally sensitive areas wherever possible. The pipeline design work to be performed during FEED 2 shall include consideration of the following: Stability design (concrete weight coating limits); Pipeline installation assessment and analyses; Span analysis and bottom roughness analysis to determine if pre-sweeping is required, e.g. sandwaves; Trenching design and burial requirements (if any); Pipeline and cable crossing designs; Shore approach and landfall design; Riser tie-in design; Pre-commissioning and commissioning update. 3.11.2. Outline Installation Methodology The offshore pipeline will be require to be installed using conventional S-lay techniques employing anchor and dynamic positioning (DP) laybarges. An anchor barge may be used for the shallow water depths from the landfall out to a water depth of approximately 18 to 20m, which corresponds to approximately the first 60km. The pipeline will be laid down at this water depth then recovered by the DP laybarge which will then continue the pipelay towards the offshore storage site. Alternatively the DP laybarge may initiate lay at the offshore storage site and then use a midline tie-in at the 18 to 20m water depth using davit lifts. Some areas of the seabed, e.g. sand waves may require pre-sweeping prior to pipelay to prevent over-stressing of the pipeline. Pre-sweeping operations may be subject to environmental constraints. Following pipelay and trenching, the pipeline will be pre-commissioned, including flooding, cleaning, gauging and hydrostatic pressure strength testing. The pipeline will then be tied into the riser at the offshore storage site using a conventional flanged spool piece; the flanged connections will then be subject to a pressure leak test. Finally the pipeline will be dewatered

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 20 of 20

and dried to a level to prevent corrosion and hydrate formation during commissioning (gassing-up). The offshore pipeline will be tied into the onshore pipeline via a golden weld before vacuum or air drying operations. 3.11.3. Trenching and Burial Trenching and burial of the offshore pipeline will be minimised wherever possible, subject to practical levels of concrete weight coating requirements and pipeline protection from thirdparty interaction. The level and limit of pre-trenching/burial that will be required in the shore approach, shipping access channels and landfall regions shall be defined in both the onbottom stability and routing reports. 3.11.4. Crossings and Third Party Ownership Considerations All pipelines and cables or other items of infrastructure on the proposed offshore pipeline route shall be identified and 3rd party owners confirmed. The locations of these items shall be confirmed by the offshore route survey. Future pipelines and cables that could be installed before the CO2 pipeline shall also be identified. The FEED 2 work shall include preliminary designs for construction of the required crossings. It is critical that all consents, including those for the offshore pipeline and the storage of CO2, are obtained in a timely manner, as failure to achieve this will have an impact on the projects programme to deliver the project on schedule. 3.11.5. Landfall Design The scope of the work to be carried out during FEED 2 for design of the landfall shall include: Performing shore approach design for the pipeline up to landfall tie-in; Determine pulling loads and potential requirements for temporary flotation aids; Determination of pipeline profile in the shore approach and intertidal zones; Determination of governing minimum cover depth requirements; Determination of pipeline weight coating requirements for nearshore and landfall zones; CP (cathodic protection) requirements for nearshore and landfall areas; Spoil and rockdump volumes determination; Production of Shore Approach and Landfall Design Report; Preparation of General Arrangement drawings of the Shore Approach and Landfall.

3.12. Offshore Pipeline Protection Design A detailed pipeline protection system design shall be performed during FEED 2. The protection system design shall include consideration of the following: Dropped objects; Vessel anchoring (snagging and cable/anchor dragging); Fishing activities (trawlboard and beam impact and pullover and hooking).

A dropped object study shall be performed during FEED 2 to determine the risk of dropped objects from activities at the WHP.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 21 of 21

Security / protection of the land fall valve will require a security cage and intruder alarm or similar. Southern North Sea shipping activities are very dense especially within the vicinity of Thames Estuary. An assessment of shipping within the region of interest for this project shall be contained in the routing report. A low to medium fishing intensity, with both Beam and Otter trawl efforts, exists along most of the proposed pipeline route. Fishing interaction studies shall be carried out during FEED 2 to evaluate risks from fishing and determine appropriate protection measures for the pipeline.

3.13. Connections Design Pipeline connections shall be weld-neck flanges in accordance with the appropriate design codes. Offshore pipeline spool piece flanges shall include swivel ring type to ease bolting. The number of flanged connections will be minimized wherever possible. Consideration may be given to hyperbaric welded tie-ins and possible stalking subject to water depth.

3.14. Risk Assessment A hazard identification and risk evaluation will be undertaken to provide input to a major accident prevention document (MAPD) as part of the Pipeline Safety Regulations (PSR) 1996 requirements (Regulation 23). This is based on defining the CO2 pipeline as conveying a dangerous fluid in accordance with Regulation 18 and Schedule 2 of PSR 1996. Dangerous fluids can be flammable and/or toxic. PSR 1996 defines a toxic fluid as classified by The Chemicals (Hazard Information and Packaging for Supply) Regulations 1994 (SI 1994 No. 3247) as follows: Toxic - Substances and preparations which in low quantities cause death or acute or chronic damage to health when inhaled, swallowed or absorbed via the skin. This definition would suggest CO2 is not classed as toxic, however, there are no definitions of a dangerous fluid for high concentrations such as that which would be released from a dense-phase CO2 pipeline. CO2 at elevated concentrations is known to have toxicological effects on the human body. Within the Globally Harmonised System (GHS) Acute Toxicity criteria, any substance that has a median lethal concentration (LC50) of less than 5000 parts per million (ppm) (0.5% v/v in air) is classified within one of the five defined Hazard Categories. A substance such as CO2 with a LC50 concentration greater than 5000 ppm is defined as Not Classified. Clarification on the definition of CO2 pipeline transport will be obtained during FEED 2.

3.15. Pigging The pipeline system will be equipped with a pig launcher at the Kingsnorth pipeline inlet and a receiver at the offshore platform. These vessels will be specified to accommodate intelligent pipeline inspection devices (IID) that will need to be designed specifically for use in the flowing CO2 pipeline. There also may be a requirement to provide pigging heads at the landfall location. Studies shall be carried out during FEED 2 to develop tools that will be compatible with and reliable in the CO2 environment. The devices will be equipped with an ultrasonic inspection tool (non liquid interface type) along with other equipment and will be run as required. The device will be designed to seek any evidence of localised or general internal/external

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 22 of 22

corrosion or damage to the pipe wall. An operating strategy will be agreed in consultation with the suppler of the IID inspection services during product development and this will generate recommendations for the frequency of IID use. The geometry of the pipeline system shall be compatible with frequent running of IIDs, with bend radii of a minimum of 5 x outside diameter included in the tie-in spool pieces and pipework. The pipeline shall have a constant ID to allow smooth transit of pigs. At branched connections, guide bars shall be incorporated where the branched connection diameters exceeds 25% of the pipeline diameter to ensure effective and safe pigging. Refer to Full System Commissioning Philosophy (ref. M29) and Pipeline Testing and Drying Philosophy (ref. M30) for more details on pipeline pigging philosophies.

3.16. Future Expansion of System Consideration shall be given during FEED 2 to the future expansion of the CCS system i.e. preparation for feeding in of the Thames cluster of power stations to the pipeline. This shall include consideration of tie-in locations and layouts, flow assurance considerations arising from mixing of the fluids, and pigging requirements for the system.

3.17. Environmental Design Data Preliminary environmental data are contained in the document Onshore Pipeline Design Data (ref. M28) and Offshore Pipeline Design Data (ref. M31). These data will be developed during FEED 2. In order to ensure the availability of comprehensive environmental data the following project-specific studies and surveys (as applicable) should be commissioned and carried out during early FEED 2: Metocean Study; Fishing and Shipping Study; Pipeline Bathymetric Survey; Pipeline Route Geophysical/Geotechnical Survey, to include environmental survey; Environmental Impact Assessment; Morphology Study (to determine extent of coastal and channel erosion & extent of scour).

3.18. Pipeline Safety and Control Systems Specific concepts and strategies for providing the pipeline Control and Safety Systems will be developed through FEED 2 by consultation across design contributors/disciplines and by enquiry with potential specialist suppliers. In some instances it may be necessary to engage with suppliers early to identify where focussed product development work will be necessary as the project develops. System design will take into account HAZOP and HAZID studies, different available control system types (SCADA, DCS etc) and technologies such as fieldbus, profibus etc, as well as focus on the environment and the locations where the parts of the control system could be installed. These will also be in compliance with internationally recognised standards such as IEC 61511 Functional Safety, Safety Instrumented Systems for the process industry and IEC 61508 - Functional safety of electrical/electronic/programmable electronic safety-related systems.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 23 of 23

Monitoring by the SCADA system will include the following: Pressure switches; Flow switches; Temperature switches; Position switches.

Safety management systems that will be considered include: Continuous leak detection (acoustic); Cathodic protection monitoring; Internal Inspection devices (intelligent pigs); Corrosion monitoring potentially including the use of probes and inline corrosion spools; Coupons to provide monitored information on any reactivity between the flowing fluid and representative material samples; Automatic ESD systems (pipeline shutdown to safe condition may include some valves that move to a fail-safe condition of open rather than closed). Leak detection e.g. Pipeline Management System incorporating modelling of pipeline operation, monitoring and control elements; Sacrificial anode cathodic protection monitoring.

3.19. Condition Monitoring The main focus of monitoring will be to identify conditions that could give rise to internal and external corrosion and to confirm that the operating conditions are being maintained in a way that corrosion is being successfully inhibited. Condition monitoring is discussed further in ref.M32.

3.20. Onshore Pipeline Sectional Valves Section isolating valves shall be installed at the beginning and end of the onshore pipeline, with consideration to further isolating valves at a spacing along the pipeline appropriate to the substance being conveyed to limit the extent of a possible leak. The location and spacing of valves shall be justified to the statutory authorities as part of the safety evaluation of the pipeline. The spacing of sectional isolating valves should reflect the conclusions of any safety evaluation prepared for the pipeline, and should preferably be installed below ground. In the locating of section isolating valves, account should be taken of topography, ease of access for operation and maintenance, protection from vandalism and proximity to normally occupied buildings.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 24 of 24

3.21. Offshore Pipeline SSIVs Currently it is not anticipated to require SSIV's and sectional barrier valves for the offshore pipeline, however, such requirements shall be identified and discussed with the HSE during the course of the FEED 2.

3.22. Pre-Commissioning and Commissioning The following philosophy documents address offshore pipeline pre-commissioning and full system commissioning, respectively: Offshore Pipeline Testing and Drying Philosophy (ref. M30); Full System Commissioning Philosophy (ref. M29). Pre-commissioning and commissioning plans shall be further developed during the FEED 2 study to include the following aspects: CCS Plant start-up requirements; Offshore platform start-up requirements, initial and after shutdown; Hydrotest and dewatering philosophy (with alternatives); Pre-commissioning methodology (including drying); Dryness level feasibility; Depressurisation/Blowdown Philosophy. The agreed commissioning plan shall map out clearly the key activities and responsibilities required to fully understand the commissioning requirements from the start of FEED 2 through to implementation. During FEED 2 studies, focussing on pipeline and CO2 conditions, studies shall also be carried out to understand the reality of pipeline condition once it has been commissioned. Comprehensive investigations and multiple scenario modelling shall be performed to fully appreciate the commissioning scope of the project, both the individual components of the CCS chain and the whole chain. In order to establish the baseline parameters for commissioning the pipeline, a deviations study shall be conducted during the FEED 2 stage to investigate targets and limitations for pipeline drying, and to understand the emergency shutdown requirements of the pipeline. Requirements for dense phase operation of the pipeline and for the transition from gas to dense phase operation shall also be investigated, and any impacts of this phase of operations on commissioning requirements identified.

3.23. Pipeline Surveillance and Maintenance During operation, the onshore pipeline right-of-way will be monitored weekly to inspect for any indications of leaks or external damage. Typically 2 individuals would be assigned to this activity, an Operator / Mechanic and an Operator / I&E Technician. Their basic responsibilities would entail daily surveillance and daily routine maintenance of the onshore pipeline and compressor unit. It is anticipated that the pipeline system will be shut-in for at least one day per year for internal inspection and annual compressor maintenance services, along with a more thorough inspection of the cathodic protection system. If major maintenance is required on the compressors or drivers it is anticipated that an outside manufacturer / certified service

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 25 of 25

company would be utilized. Additionally, it is anticipated that onshore right-of-way maintenance will be accomplished by an outside service company. Further details will be provided in the Inspection and Maintenance Philosophy.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 26 of 26

4. Mandatory References

4.1. Regulations and Statutes Pipeline construction and burial requirements shall comply with all related directives from the appropriate Port Authorities and Councils. In addition, the following acts and regulations shall be complied with: [M1] [M2] [M3] [M4] [M5] [M2] [M3] [M4] [M5] [M6] [M7] [M8] [M9] [M10] [M11] [M12] [M13] [M14] Construction (Design & Management) Regulations 2007; Construction (Design & Management) Regulations 2007; Health and Safety at Work Act 1974; Offshore Installations (Safety Case) Regulations 2005; Pipeline Safety Regulations 1996; Construction (Design & Management) Regulations 2007; Coast Protection Act 1974; Construction (Design & Management) Regulations 2007; Continental Shelf Act 1964; Environmental Protection Act 1990; Health and Safety at Work Act 1974; Offshore Installations (Safety Case) Regulations 2005; Offshore Installations and Wells (Design and Construction, etc.) Regulations 1996; Offshore Petroleum Production and Pipelines (Assessment of Environmental Effects) Regulations 1999; Pipeline Safety Regulations 1996; The Chemicals (Hazard Information and Packaging for Supply) Regulations 1994 (SI 1994 No. 3247); Pressure Equipment Regulations 1996; Town and Country Planning Act 1990; Town and Country Planning (Environmental Impact Assessment, England and Wales) Regulations 1999.

Pipeline Works Authorisation shall comply with all related Pipeline Inspectorate (Department of Energy) directives. In addition, the following guidelines and regulations shall be complied with: [M15] Department for Business Enterprise and Regulatory Reform (BERR), Petroleum Act 1998: Offshore Pipelines, Guidelines for the completion of pipeline works authorisations (PWA's); EIA Offshore Petroleum Production and Pipe-lines (Assessment of Environmental Effects) (Amendment) Regulations; EPC 2002 The Offshore Installations (Emergency Pollution Control) Regulations; EU ETS 2005 Greenhouse Gas Emissions Trading Scheme Regulations 2005 (as amended); FEPA Part II (as amended) 1985 Food and Environmental Protection Act 1985, Part II Deposits in the Sea (as amended);

[M16] [M17] [M18] [M19]

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title: [M20] [M21] [M22] [M23] [M24] [M25] [M26]

Page 27 of 27

Habitats 2001 Offshore Petroleum Activities (Conservation of Habitats) Regulations; OCR 2002 Offshore Chemicals Regulation; OPRC 1998 The Merchant Shipping (Oil Pollution Preparedness, Response Cooperation Convention) Regulations; PPC Offshore Combustions Installations (Prevention and Control of Pollution) (Amendment) Regulations 2007; OPPC-2005 Offshore Petroleum Activities (Oil Pollution Prevention and Control) Regulations; ODS 2008 The Environmental Protection (Controls on Ozone-Depleting Substances) (Amendment) Regulations; F-Gases 2008 The Fluorinated Greenhouse Gases Regulations 2008.

4.2. Project Documentation [M27] FEED Health and Safety Plan, KCP-GNS-SHE-PRO-0001; [M28] [M29] [M30] [M31] [M32] [M33] [M34] FEED Onshore Pipeline Design Data, KCP-GNS-PLD-DPR-0005; Platform and Pipeline Commissioining Philosophy, KCP-GNS-PCD-DPR-0011.; FEED Pipeline Testing and Drying Philosophy, KCP-GNS-PLD-DPR-0003; FEED Offshore Pipeline Design Data, KCP-GNS-PLD-DPR-0004; FEED Pipeline Material Selection, Corrosion Protection and Monitoring Philosophy, KCP-GNS-PLD-DPR-0002. FEED Basis of Design for Studies, KCP-GNS-PCD-STU-0001; FEED Overall Project Units, KCP-EEN-PCD-DPR-0001 [M6] and Safety Plan, KCP-GNS-SHE-PRO-0001; Pre-FEED Health

4.3. Design Codes [M35] BS PD 8010:2004 Code of Practice for Pipelines Part 1: Steel Pipelines on Land and Part 2: Subsea Pipelines; [M36] [M37] [M38] [M39] [M40] [M41] ISO 3183 Petroleum and Natural Gas Industries, Steel Pipe for Pipeline Transportation Systems; DNV OS F101 Submarine Pipeline Systems; ASME B31.4: Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids; ASME B31.8: Gas Transmission & Distribution Piping Systems; DNV CO2 Pipeline Transmission Guidelines (CO2PIPETRANS) (In preparation); BS EN 14161 Petroleum and Natural Gas Industries Pipeline Transportation Systems.

Kingsnorth CCS Demonstration Project The information contained in this document (the Information) is provided in good faith. E.ON UK plc, its subcontractors, subsidiaries, affiliates, employees, advisers, and the Department of Energy and Climate Change (DECC) make no representation or warranty as to the accuracy, reliability or completeness of the Information and neither E.ON UK plc nor any of its subcontractors, subsidiaries, affiliates, employees, advisers or DECC shall have any liability whatsoever for any direct or indirect loss howsoever arising from the use of the Information by any party.

KCP-GNS-PLD-DPR-0001 Revision: 04 Kingsnorth Carbon Capture & Storage Project Onshore and Offshore Pipeline Design Philosophy

Project Title: Document Title:

Page 28 of 28

5. Supporting References

5.1. Project Documentation [S1] Kingsnorth Phase II CO2 Pipeline Project, Pipeline Design Basis, 80011-BOD-PL001; [S2] [S3] [S4] [S5] [S6] [S7] Kingsnorth Phase II CO2 Pipeline Project, Transport of CO2 by Pipeline, 80011-RPTEN-001; Kingsnorth Phase II CO2 Pipeline Project, Offshore Pipeline Routing Report, 80011-RPT-PL-001; Kingsnorth Phase II CO2 Pipeline Project, Project Summary Report, 80011-RPT-PM003; E.ON Kingsnorth Project Scope of Work Dispersion Experiments and Modelling; Submission D168,Basis of Design for the Offshore Installation; BS PD 8010-1:2004 Code of Practice for Pipelines Part 1 Steel Pipelines on Land.