Professional Documents

Culture Documents

Moog D633

Uploaded by

Balu MOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moog D633

Uploaded by

Balu MCopyright:

Available Formats

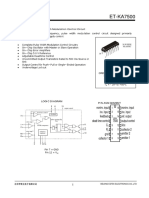

D633 and D634 Series Direct Drive Servo-Proportional Control Valves with integrated 24 V Electronics ISO 4401 Size

03 and 05

GENERAL

D!""#D!"$

PAGE

2 3 4 5 7 13

SECTION

General Benefits and Function General technical data, Symbols General technical data, Electronics Technical Data Ordering Information

MOOG SERVO- AND PROPORTIONAL CONTROL VALVES

For over 25 years Moog has manufactured proportional control valves with integrated electronics. During this time more than 150,000 valves have been delivered. These servo control valves have been proven to provide reliable control including injection and blow molding equipment, die casting machines, presses, heavy industry equipment, paper and lumber processing and other applications.

D633 AND D634 SERIES SERVO CONTROL VALVES

The D633 and D634 Series are Direct Drive Valves (DDV) with electric closed loop spool position control. These valves are throttle valves for 3-, 4-, and 2x2-way applications. They are suitable for electrohydraulic position, velocity, pressure or force control systems including those with high dynamic response requirements. The spool drive device is a permanent magnet linear force motor which can actively stroke the spool from its spring centered position in both directions. This is an advantage compared with proportional solenoids with one force direction only. The closed loop spool position electronics and pulse width modulated (PWM) drive electronics are integrated into the valve. The integrated electronics of the valves is a new development featuring SMD technology with pulse width modulated (PWM) current output stage and requires a 24 VDC power supply.

The valve series described in this catalog have successfully passed EMC tests required by EC Directive. Please refer to the respective references in the electronics section.

Valves available with explosion protection to EN 50018 and 55019, class II 2G EExde B+H2 T4, DMT 00 ATEX E 037, CE 0470 for D633 series and II 2G EExde B+H2 T3, DMT 00 ATEX E 037, CE 0470 for D634 series. Note: Installation dimensions and electrical connection altered. Special data sheet on request.

NOTICE

Before installation of the valve into the system, the complete hydraulic system must be flushed. Please read the notes in section Electronics, page 6.

This catalog is for users with technical knowledge. To ensure that all necessary characteristics for function and safety of the system are given, the user has to check the suitability of the products described herein. In case of doubt, please contact Moog.

Our quality management system conforms to DIN EN ISO 9001.

MOOG D633/634 Series

BENEFITS AND FUNCTION

D!""#D!"$

Standardized spool position monitoring signal with low residual ripple Electric null adjust With loss of supply voltage or broken cable or emergency stop, the spool returns to its spring centered position without passing a load move position.

OPERATIONAL BENEFITS OF DIRECT DRIVE SERVO VALVES (DDV)

Directly driven by a permanent magnet linear force motor with high force level No pilot oil flow required Pressure independent dynamic performance Low hysteresis and low threshold Low current consumption at and near hydraulic null

DIRECT DRIVE VALVE (DDV) OPERATION

The position control loop for the spool with position transducer and linear force motor is closed by the integrated electronics. An electric signal corresponding to the desired spool position is applied to the integrated electronics and produces a pulse width modulated (PWM) current to drive the linear force motor. An oscillator excites the spool position transducer (LVDT) producing an electric signal proportional to spool position. D633 Series single stage Servo Control Valve The demodulated spool position signal is compared with the command signal, and the resulting spool position error causes current in the force motor coil until the spool has moved to its commanded position and the spool position error is reduced to zero. The resulting spool position is thus proportional to the command signal.

Null adjust cover plug Valve connector

Spool

Bushing

Hydraulic symbol: Symbol shown with electric supply on and zero command signal.

Integrated electronics

Position transducer

Linear force motor

Centering spring

PERMANENT MAGNET LINEAR FORCE MOTOR OPERATION

The linear force motor is a permanent magnet differential motor. The permanent magnets provide part of the required magnetic force. For the linear force motor the current needed is considerably lower than would be required for a comparable proportional solenoid.The linear force motor has a neutral midposition from which it generates force and stroke in both directions. Force and stroke are proportional to current. High spring stiffness and resulting centering force plus external forces (i.e. flow forces, friction forces due to contamination) must be overcome during out-stroking. During backstroking to center position, the spring force adds to the motor force and provides additional spool driving force which makes the valve much less contamination sensitive. The linear force motor needs very low current in the spring centered position. Proportional solenoid systems require two solenoids with more cabling for the same function. Another solution uses a single solenoid, working against a spring. In case of current loss in the solenoid, the spring drives the spool to the end position by passing through a fully open position. This can lead to uncontrolled load movements.

Cable hole

Permanent magnets

Centering springs

Bearing

Coil

Armature

Plug

MOOG D633/634 Series

GENERAL TECHNICAL DATA, SYMBOLS

D!""#D!"$

4-WAY FUNCTION

PERFORMANCE SPECIFICATIONS FOR STANDARD MODELS

Operating pressure range Ports P, A and B up to 350 bar (5000 psi) Port T see data for individual series Temperature range Ambient Fluid Seal material Operating fluid

Viscosity recommended allowed System filtration High pressure filter (without bypass, but with dirt alarm) mounted in the main flow and if possible directly upstream of the valve. Class of cleanliness The cleanliness of the hydraulic fluid particularly effects the performance (spool positioning, high resolution) and wear (metering edges, pressure gain, leakage) of the servo valve. Recommended cleanliness class For normal operation ISO 4406 < 15 / 12 For longer life (wear) ISO 4406 < 14 / 11 Filter rating recommended For normal operation 10 75 (10 m absolute) For longer life (wear) 6 75 ( 6 m absolute) Installation options any position, fixed or movable Vibration 30 g, 3 axes Degree of protection EN60529: class IP 65 with mating connector mounted Shipping plate Delivered with an oil sealed shipping plate

20 C to +60 C (-4F to +140F) 20 C to +80 C (-4F to +170F) NBR, FPM, others on request mineral oil based hydraulic fluid (DIN 51524, part 1 to 3), others on request 15 to 100 mm2/s 5 to 400 mm2/s

4-way version spring centred Flow control (throttle valve) in port A and port B Port Y required if pressure pT > 50 bar (715 psi) in port T for 3-way function close port A or port B of the manifold Spools with exact axis cut, 1,5 to 3 % or 10 % overlap available

2X2-WAY FUNCTION

2x2-way version (Y-Port required) Flow control (throttle valve) in port A Port Y required Connect externally port P with port B, and port A with port T

MOOG D633/634 Series

GENERAL TECHNICAL DATA, ELECTRONICS

D!""#D!"$

Flow rate Q [l/min] pmax = 350 bar (5000 psi) Valve pressure drop p [bar]

VALVE FLOW CALCULATIONS

The actual valve flow is dependent on the spool position and the pressure drop across the spool lands. At 100% command signal (i.e. +10 VDC = 100% valve opening), the valve flow at rated pressure drop pN = 35 bar per metering land is the rated flow QN. For other than rated pressure drop, the valve flow changes at constant command signal according to the square root function for sharp edged orifices.

Q QN p pN

[l/min] [l/min] [bar] [bar]

= = = =

calculated flow rated flow actual valve pressure drop rated valve pressure drop

The real valve flow Q calculated in this way should result in an average flow velocity in ports P, A, B or T of less than 30 m/s.

GENERAL REQUIREMENTS FOR VALVE ELECTRONICS

Supply 24 VDC, min. 19 VDC, max. 32 VDC for D633 1.2 A Current consumption IAmax for D634 2.2 A External fuse per valve for D633 1.6 A (slow) for D634 2.5 A (slow) All signal lines, also those of external transducers, shielded. Shielding connected radially to (0 V), power supply side, and connected to the mating connector housing (EMC). EMC: Meets the requirements of emission: EN55011:1998+A1:1999 (limit class: B) and immunity: EN61000-6-2:1999 Minimum cross-section of all leads 0.75 mm2 (0.001 in2). Consider voltage losses between cabinet and valve. Note: When making electric connections to the valve (shield, protective earth), appropriate measures must be taken to ensure that locally different earth potentials do not result in excessive ground currents. See also Moog Application Note TN 353.

MOOG D633/634 Series

ELECTRONICS

D!""#D!"$

Actual value 4 to 20 mA The actual spool position value can be measured at pin F (see diagram below). This signal can be used for monitoring and fault detection purposes. The spool stroke range corresponds to 4 to 20 mA. The centered position is at 12 mA. 20 mA corresponds to 100% valve opening P A and B T . The position signal output 4 to 20 mA allows detecting a cable break when IF = 0 mA. Circuit diagram for measurement of actual value IF (position of spool) for valves with 6+PE pole connector

Valve side Iout 4-20 mA RL=500 (0,25 W) Uout Actual value UOut: 2-10 V

VALVE ELECTRONICS WITH 24 VOLT SUPPLY VOLTAGE AND 6+PE POLE CONNECTOR

Command signal 0 to 10 mA floating, Valves with current command input The spool stroke of the valve is proportional to ID = IE. 100 % valve opening P A and B T is achieved at ID = +10 mA. At 0 mA command the spool is in centered position. The input pins D and E are inverting. Either pin D or E is used according to the required operating direction. The other pin is connected to signal ground at cabinet side. Command signal 0 to 10 V, Valves with voltage command input The spool stroke of the valve is proportional to (UD UE). 100% valve opening P A and B T is achieved at (UD UE) = +10 V. At 0 V command the spool is in centered position. The input stage is a differential amplifier. If only one command signal is available, pin D or E is connected to signal ground at cabinet side according to the required operating direction.

For failure detection purposes, it is advised to connect pin F of the mating connector and route this signal to the control cabinet.

WIRING FOR VALVES WITH 6+PE CONNECTOR

to EN 175201 Part 8041) and mating connector (type R and S, metal shell) with leading protective earth connection ( ). See also Application Note AM 426 E.

Valve Connector Mating connector Cabinet side

Function

Supply Supply / Signal Ground Not used

CurrentCommand

24 VDC (19 t0 32 VDC) (0 V)

Voltage Command

Input rated command (differential)

Input command ID = -IE: 0 to 10 mA Input command (inv.) IE = -ID: 0 to 10 mA (Re=200 )

UD-E = 0 to 10 V Re = 10 k

Input voltage for UD-B and UE-B for both signal types is limited to min. -15 V and max. +24 V Output actual value spool position IF-B: = 4 to 20 mA. At 12 mA spool is in centered position. RL =300 to 500

Protective earth

1)

formerly DIN 43563

MOOG D633/634 Series

TECHNICAL DATA

D!""

mm (in) D633 ISO 4401-03-03-0-94 7.9 (0.31) Single stage, spool in bushing 3-way, 4-way, 2x2-way directly, with permanent magnet linear force motor none 2.5 (5.5) 5 / 10 / 20 / 40 (1.3 / 2.6 / 5.3 / 10.6) 75 (19.8) 350 (5000) 50 (715) 350 (5000) directly to tank 12 < 0.1 < 0.2 < 1.5 0.15 / 0.3 / 0.6 / 1.2 (0.04 / 0.08 / 0.16 / 0.32)

PERFORMANCE SPECIFICATIONS FOR STANDARD MODELS

Model . . . Type Mounting pattern with or without leakage port Y 3) Port diameter Valve version 2) Spool actuation Pilot supply Mass Rated flow (10%) at pN= 35 bar [500 psi] per land Max. valve flow Operating pressure max. Ports P,A,B Port T without Y Port T with Y Port Y Response time for 0 to 100% stroke, typical Threshold 1) Hysteresis 1) Null shift 1) with T = 55 K Null leakage flow 1) max. (axis cut)

1) 2) 3)

kg (Ib) l/min (gpm) l/min (gpm) bar (psi) bar (psi) bar (psi) bar (psi) ms % % % l/min (gpm)

At operating pressure pp = 140 bar (2000psi), fluid viscosity of 32 mm2/s (0.05 in2/s) and fluid temperature of 40 C (104 F) See symbols page 4 Leakage port Y must be used with 3- and 4-way function and pT > 50 bar (715psi) with 2x2-way function

MOOG D633/634 Series

TECHNICAL DATA

D!""

CHARACTERISTIC CURVES (TYPICAL)

Flow rate Q l/min [gpm]

200 [52.8] 150 [39.6] 100 [26.3] 80 [21.1] 60 [15.8] 40 [10.6] 30 [7.9] 20 [5.3] 15 [4.0] 10 [2.6] 8 [2.1] 6 [1.6] 4 [1.1] 3 [.79] 2 [.53]

6 [.26] 10 [145] 20 30 50 70 100 150 200 350 [290] [435] [725][1015][1450][2175][2900][5076] Valve pressure p bar [psi]

MOOG D633/634 Series

TECHNICAL DATA

D!""

INSTALLATION DRAWING

Mounting pattern ISO 4401-03-03-0-94, without X port

mm

P A B T 7,5 7,5 7,5 7,5 x y

inch

X1)

Y F1 3,3 M5 40,5 9 0 0

F2 M5

F3 M5

F4 M5 0

G 4 33

21,5 12,7 30,2 21,5 25,9 15,5 15,5 5,1

40,5 40,5

-0,75 31,75 31 31,75

P A B T X1) Y F1 0.30 0.30 0.30 0.30 0.13 M5 x y

1)

F2 M5

F3 M5

F4 G M5 0.16 0 1.30

0.85 0.50 1.19 0.85 1.02 0.61 0.61 0.20

1.60 0.35

0 0

1.60 1.60

-0.03 1.25 1.22 1.25

Port X must not be drilled, not sealed at valve base.

Mounting surface needs flat within 0,01 mm (0.0004 in) over a distance of 100 mm (3.94 in). Average surface finish value, Ra = 0.8 m. Spare parts and Accessories

MOOG D633/634 Series

TECHNICAL DATA

D!"$

mm (in) D634 ISO 4401-05-05-0-94 11.5 (0.45) Single stage, spool in bushing 3-way, 4-way, 2x2-way directly, with permanent magnet linear force motor none 6.3 (13.9) 60 / 100 (15.8 / 26.3) 185 (48.8) 350 (5000) 50 (715) 350 (5000) directly to tank 20 < 0.1 < 0.2 < 1.5 1.2 / 2.0 (0.26 / 0.43)

PERFORMANCE SPECIFICATIONS FOR STANDARD MODELS

Model . . . Type Mounting pattern with or without leakage port Y 3) Port diameter Valve version 2) Spool actuation Pilot supply Mass Rated flow (10%) at pN= 35 [500 psi] bar per land Max. valve flow Operating pressure max. Ports P,A,B Port T without Y Port T with Y Port Y Response time for 0 to 100% stroke, typical Threshold 1) Hysteresis 1) Null shift 1) with T = 55 K Null leakage flow 1) max. (axis cut)

1) 2) 3)

kg (Ib) l/min (gpm) l/min (gpm) bar (psi) bar (psi) bar (psi) bar (psi) ms % % % l/min (gpm)

At operating pressure pp = 140 bar (2000 psi), fluid viscosity of 32 mm2/s (0.05 in2/s) and fluid temperature of 40 C (104 F) See symbols page 4 Leakage port Y must be used with 3- and 4-way function and pT > 50 bar (715 psi) with 2x2-way function

10

MOOG D633/634 Series

TECHNICAL DATA

D!"$

CHARACTERISTIC CURVES (TYPICAL)

Flow rate Q l/min [gpm]

200 [52.8] 150 [39.6] 100 [26.3] 80 [21.1] 60 [15.8] 40 [10.6] 30 [7.9] 20 [5.3] 15 [4.0] 10 [2.6] 8 [2.1] 6 [1.6] 4 [1.1] 3 [.79] 2 [.53]

6 [.26] 10 [145] 20 30 50 70 100 150 200 350 [290] [435] [725][1015][1450][2175][2900][5076] Valve pressure p bar [psi]

MOOG D633/634 Series

11

TECHNICAL DATA

D!"$

INSTALLATION DRAWING

Mounting pattern ISO 4401-05-05-0-94, without X port

mm

P A B T T2 X1) Y F1 11,2 11,2 11,2 11,2 11,2 6,3 M6 x y

inch

F2 M6 54 0

F3 M6 54 46

F4 M6 0 46

27 6,3

16,7 21,4

37,3

3,2

50,8

62 11

0 0

21,4 32,5 32,5

P A B T T2 X1) Y F1 0.44 0.44 0.44 0.44 0.44 0.25 M6 x y

1)

F2 M6 0

F3 M6

F4 M6 0

1.06 0.25

0.66 0.84

1.47 0.13 2.00 0.84 1.28 1.28

2.44 0.43

0 0

2.13 2.13

1.81 1.81

Port X must not be drilled, not sealed at valve base.

Mounting surface needs flat within 0,01 mm (0.0004 in) over a distance of 100 mm (3.94 in). Average surface finish value, Ra = 0.8 m. Spare parts and Accessories

12

MOOG D633/634 Series

ORDERING INFORMATION

D!""#D!"$

Type designation

ORDERING INFORMATION

Model-Number

D 63 .

. . .

. . . .

Series 3 Size 03 4 Size 05 Specification-Status Series specification E Preseries specification K explosion proof version upon request Z Special specification Model designation assigned at the factory Seal material Factory identification Valve version R with integrated electronics N V S

Supply voltage 2 24 VDC (19 to 32 VDC)

Signals for 100% spool stroke* Command Output +4 to +20 mA M 10 VDC X 10 mA, floating +4 to +20 mA deadband compensation on request Valve connector 6+PE pole EN 175201 Part 804

NBR (Buna) FPM (Viton) others on request

Rated flow QN[l/min] at pN = 35 bar (QN[gpm] at pN = 500 psi) 02 04 08 16 24 40 5 (1.3) 10 (2.6) 20 (5.3) 40 (10.6) 60 (15.8) 100 (26.3) pN = 5 bar per land 2 4 8 16 24 40 Series D633 D633 D633 D633 D634 D634

Y- port 0 closed with plug 3 open, with filter insert

pTmax = 50 bar (715 psi) p > 50 bar (715 psi)

Spool position without electric supply M mid position F P B, A T connected (10% open) D P A, B T connected (10% open) other openings on request Linear motor 1 Standard 2 Standard Bushing / Spool type 0 A D Z X 4-way: axis cut, linear characteristic 4-way: 1,5 to 3% overlap, linear characteristic 4-way: 10% overlap, linear characteristic 2x2-way: P A, B T, with Y-port only Special spool on request Series D633 D634

Maximum operating pressure K 350 bar (5000 psi)

Options may increase price and delivery. All combinations may not be available. Preferred configurations are highlighted. Technical changes are reserved.

*(input voltage limited, see page 6)

MOOG D633/634 Series

13

NOTES

D!""#D!"$

14

MOOG D633/634 Series

NOTES

D!""#D!"$

MOOG D633/634 Series

15

Argentina Australia Austria Brazil China Finland France Germany India

Ireland Italy Japan Korea Luxembourg Norway Russia Singapore Spain Sweden United Kingdom USA

Industrial Controls Division

Moog Inc., East Aurora, NY 14052-0018 Telephone: 716 /655-3000 Fax: 716 /655-1803 Toll Free: 1-800-272-MOOG www.moog.com

CDL6581 Rev F 500-189 103

You might also like

- D 633 Series Valves eDocument16 pagesD 633 Series Valves ehaggNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Proportional Control Valves with Integrated 24 Volt ElectronicsDocument24 pagesProportional Control Valves with Integrated 24 Volt ElectronicsLuis Alberto RamosNo ratings yet

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- 3-En2200-B - 4VP01Document15 pages3-En2200-B - 4VP01najafali1No ratings yet

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- Proportional Control Valves ISO 4401 Size 05Document8 pagesProportional Control Valves ISO 4401 Size 05Devendra BangarNo ratings yet

- Closed Loop Control Systems ExplainedDocument33 pagesClosed Loop Control Systems ExplainedSgsksbskxvxk100% (1)

- Electrohydraulic ValvesDocument9 pagesElectrohydraulic Valves1sympatyagaNo ratings yet

- Moog ServoValves Techn Look Overview enDocument36 pagesMoog ServoValves Techn Look Overview enGonzalo Gutierrez100% (1)

- MV99 - Load Sensing VVDocument46 pagesMV99 - Load Sensing VVthailanNo ratings yet

- Solenoid Directional Valves DHI: Direct Operated, ISO 4401 Size 06Document4 pagesSolenoid Directional Valves DHI: Direct Operated, ISO 4401 Size 06EBNo ratings yet

- Lecture 1 ElectrohydraulicsDocument62 pagesLecture 1 ElectrohydraulicsAhmedNo ratings yet

- Report No (1) Haydrulic MachinesDocument15 pagesReport No (1) Haydrulic MachinesWesame Shnoda100% (1)

- Shuttle Valves: Catalog HY15-3502/USDocument17 pagesShuttle Valves: Catalog HY15-3502/USPartsGopher.comNo ratings yet

- SpeDocument12 pagesSpeseaqu3stNo ratings yet

- Unit 3 Control Components in Hydraulic SystemDocument16 pagesUnit 3 Control Components in Hydraulic SystemAbhishek KumbalurNo ratings yet

- Salami Catalog Group3 Zupcaste PumpeDocument32 pagesSalami Catalog Group3 Zupcaste Pumpeado_22No ratings yet

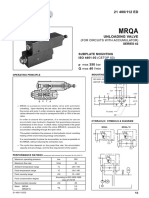

- Accumulator Unloading Valve, Type MRQADocument2 pagesAccumulator Unloading Valve, Type MRQALibinNo ratings yet

- Linear Hydraulic CircuitsDocument11 pagesLinear Hydraulic CircuitsBetileno QuadAlexNo ratings yet

- MOOG - JRA1 Actuation at MoogDocument32 pagesMOOG - JRA1 Actuation at MoogBazlur Rahman SohelNo ratings yet

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Document12 pages2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Sujeet KumarNo ratings yet

- Hydraulics ValvesDocument17 pagesHydraulics Valveslingot123@yahoo.com100% (1)

- V80647 Parker Series 15-30P High Pressure FiltersDocument12 pagesV80647 Parker Series 15-30P High Pressure FiltersPaulPaucarCamposNo ratings yet

- Moog New Tb117Document24 pagesMoog New Tb117Hammad Ali Zaman100% (1)

- Iocci Strozzi GaltechDocument14 pagesIocci Strozzi GaltechmagzigioNo ratings yet

- Moog AnimationDocument14 pagesMoog AnimationBouazzaNo ratings yet

- Servo Solenoid ValvesDocument204 pagesServo Solenoid Valveschandushar1604100% (1)

- External Gear Pumps Technical SpecificationsDocument4 pagesExternal Gear Pumps Technical SpecificationsAnton Feny SaputraNo ratings yet

- Electro Hydraulic Servo ValveDocument8 pagesElectro Hydraulic Servo ValveabyzenNo ratings yet

- High Precision Position Control of Electro-Hydraulic Servo SystemDocument10 pagesHigh Precision Position Control of Electro-Hydraulic Servo Systemamin342No ratings yet

- ME4803 Motion Control: The Strengths and Design of Fluid Power SystemsDocument36 pagesME4803 Motion Control: The Strengths and Design of Fluid Power SystemssayproNo ratings yet

- 3 Handout Pilot-Controls enDocument14 pages3 Handout Pilot-Controls enluisNo ratings yet

- Fast Forw Ard, Manual Op Manual Op - Feed ValveDocument3 pagesFast Forw Ard, Manual Op Manual Op - Feed ValveA Ramos GabyNo ratings yet

- Deal With The Function of The Pressure Control Valves in Hydraulic Power SystemsDocument6 pagesDeal With The Function of The Pressure Control Valves in Hydraulic Power Systems666667No ratings yet

- Moog Technical Bulletin 103Document11 pagesMoog Technical Bulletin 103William PetersNo ratings yet

- Atos - Modular Relief Valve - HMP HM KMDocument4 pagesAtos - Modular Relief Valve - HMP HM KMClaudecir PereiraNo ratings yet

- Flushing ProcedureDocument3 pagesFlushing ProcedureRex ValenciaNo ratings yet

- Summary of Schematic IdentificationDocument23 pagesSummary of Schematic IdentificationLeunamezNo ratings yet

- Hyd TrainingDocument72 pagesHyd TrainingJuned Hamid KhanNo ratings yet

- Servo ValveDocument7 pagesServo Valveapi-348629909No ratings yet

- Modeling Intro to EH SystemsDocument62 pagesModeling Intro to EH SystemsAhmedNo ratings yet

- ISO 9001 Flexible Couplings CatalogDocument16 pagesISO 9001 Flexible Couplings CatalogAnonymous 4MwmDaNbNo ratings yet

- Feedbacks in Hydraulic Servo Systems RydbergDocument21 pagesFeedbacks in Hydraulic Servo Systems Rydbergc1ronNo ratings yet

- PLC Stepper Motor ControllerDocument12 pagesPLC Stepper Motor ControllerSibtain Ul Hassan100% (1)

- Unbalanced Vane Pump Design ExplainedDocument5 pagesUnbalanced Vane Pump Design ExplainedRaghu KrishnanNo ratings yet

- TG 73-200 - en PDFDocument7 pagesTG 73-200 - en PDFSheril ChandraboseNo ratings yet

- Hydraulic Power Units Vertical Mount Fixed DisplacementDocument32 pagesHydraulic Power Units Vertical Mount Fixed DisplacementSujata Roy100% (1)

- Difinition of Load SensingDocument16 pagesDifinition of Load SensingMahmmod Al-QawasmehNo ratings yet

- Industrial (Steam) : 26 © 2004 The Trustees of The University of IllinoisDocument21 pagesIndustrial (Steam) : 26 © 2004 The Trustees of The University of IllinoisArini Rizal100% (1)

- Industrial Hydraulic CircuitsDocument16 pagesIndustrial Hydraulic CircuitskingkakingNo ratings yet

- Electro - Proportional ValvesDocument47 pagesElectro - Proportional Valveshamidouhou100% (1)

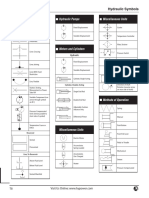

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFsanisah1245100% (1)

- WalvoilDocument64 pagesWalvoilSamad A BakarNo ratings yet

- PGP030 031 SeriesDocument28 pagesPGP030 031 SeriesWesame ShnodaNo ratings yet

- How Moog servo valves operate and differences between simplex and TMR controllersDocument5 pagesHow Moog servo valves operate and differences between simplex and TMR controllersMikoto Rifky100% (1)

- Thrust BearingDocument8 pagesThrust Bearingsonu_saurabh100% (1)

- D631 Series Servo Control Valves ISO 4401 Size 05Document12 pagesD631 Series Servo Control Valves ISO 4401 Size 05José OlaveNo ratings yet

- 62 Series Servovalves Technical OverviewDocument8 pages62 Series Servovalves Technical OverviewDevendra BangarNo ratings yet

- Pneumatic and Apm Liquid Level ControlDocument12 pagesPneumatic and Apm Liquid Level Controlyuri0527No ratings yet

- Research On Inverter Integrated Reactive Power Control Strategy in The Grid-Connected PV SystemsDocument22 pagesResearch On Inverter Integrated Reactive Power Control Strategy in The Grid-Connected PV SystemsBalu MNo ratings yet

- Back Up Protection SystemsDocument21 pagesBack Up Protection SystemsBalu MNo ratings yet

- Capability chart of a Doubly Fed Induction Generation based on its ratings and stability marginDocument6 pagesCapability chart of a Doubly Fed Induction Generation based on its ratings and stability marginBalu MNo ratings yet

- N 2 XcyDocument4 pagesN 2 XcyBalu MNo ratings yet

- Hawker Batteries: HandbookDocument0 pagesHawker Batteries: Handbookrajpre1213No ratings yet

- Capability chart of a Doubly Fed Induction Generation based on its ratings and stability marginDocument6 pagesCapability chart of a Doubly Fed Induction Generation based on its ratings and stability marginBalu MNo ratings yet

- Numerical and Experimental Investigation of The 4-Quadrant Behavior of Different Mixed Flow Diffuser PumpsDocument18 pagesNumerical and Experimental Investigation of The 4-Quadrant Behavior of Different Mixed Flow Diffuser PumpsBalu MNo ratings yet

- N 2 XfgbyDocument3 pagesN 2 XfgbyBalu MNo ratings yet

- New JSME Standard S008 Performance Conversion MethDocument11 pagesNew JSME Standard S008 Performance Conversion MethBalu MNo ratings yet

- Generator Protection - CalculationDocument4 pagesGenerator Protection - CalculationBalu MNo ratings yet

- Ocpem 2019 20 BDocument7 pagesOcpem 2019 20 BBalu MNo ratings yet

- Sensors 17 00872Document16 pagesSensors 17 00872Waris KhanNo ratings yet

- Internal 2013Document246 pagesInternal 2013eekamalesh100% (1)

- Generator Hipot TestingDocument30 pagesGenerator Hipot TestingBalu MNo ratings yet

- HITACHIDocument8 pagesHITACHIBalu MNo ratings yet

- Hydro NasselqvistDocument19 pagesHydro NasselqvistBalu MNo ratings yet

- Research On The Automatic Generation Control (AGC) Coordinated Control Modes Between Provincial Dispatching and Regional Dispatching in Yunnan Power GridDocument7 pagesResearch On The Automatic Generation Control (AGC) Coordinated Control Modes Between Provincial Dispatching and Regional Dispatching in Yunnan Power GridBalu MNo ratings yet

- Top Five Causes of Switchgear FailureDocument3 pagesTop Five Causes of Switchgear FailureGlenn Adalia Bonita75% (4)

- Paper 1Document33 pagesPaper 1Balu MNo ratings yet

- Energies: Directional Overcurrent Relays Coordination Problems in Distributed Generation SystemsDocument17 pagesEnergies: Directional Overcurrent Relays Coordination Problems in Distributed Generation SystemsBalu MNo ratings yet

- Motor ClasstyDocument128 pagesMotor Classtywatep_08No ratings yet

- Distance Protection Testing in An IEC 61850 Environment: Jan Ciechanowicz, Waldemar RebizantDocument5 pagesDistance Protection Testing in An IEC 61850 Environment: Jan Ciechanowicz, Waldemar RebizantBalu MNo ratings yet

- IEC Motor Insulation Classes B, F, H Temperature LimitsDocument1 pageIEC Motor Insulation Classes B, F, H Temperature Limitsmr_badihiNo ratings yet

- Pumped Storage Hydro-Plant Models For System Transient and Long-Term Dynamic StudiesDocument8 pagesPumped Storage Hydro-Plant Models For System Transient and Long-Term Dynamic Studiesmunagala balasubramanyamNo ratings yet

- Top Five Causes of Switchgear FailureDocument3 pagesTop Five Causes of Switchgear FailureGlenn Adalia Bonita75% (4)

- Last 50 Years of Hydro Energy-A Bibliographic Survey: KeywordsDocument7 pagesLast 50 Years of Hydro Energy-A Bibliographic Survey: KeywordsBalu MNo ratings yet

- Transient Behavior of Variable Speed Pump-Turbine UnitsDocument14 pagesTransient Behavior of Variable Speed Pump-Turbine UnitsSuresh CNo ratings yet

- C - Connecting Water To WireDocument24 pagesC - Connecting Water To WireBalu MNo ratings yet

- Ten Breadboard Projects For BeginnersDocument27 pagesTen Breadboard Projects For BeginnersMarius Danila100% (1)

- Electronic Control Module (Power Train) : Operación de SistemasDocument4 pagesElectronic Control Module (Power Train) : Operación de Sistemasgalvis1020100% (2)

- Power Electronics (CT318)Document3 pagesPower Electronics (CT318)Timothy FieldsNo ratings yet

- EV2000Document129 pagesEV2000Vladimir Colombiano de Souza100% (1)

- Trofazni Invertor SPWMDocument6 pagesTrofazni Invertor SPWMBorislav BrnjadaNo ratings yet

- Advanced Electromechanical Systems Course Manual PDFDocument44 pagesAdvanced Electromechanical Systems Course Manual PDFAhmed M H Al-YousifNo ratings yet

- Password Protects Circuit BreakerDocument40 pagesPassword Protects Circuit BreakerInnovation 4uNo ratings yet

- Electronic Slot Car Controller Mysteries Revealed - JayGee RacingDocument13 pagesElectronic Slot Car Controller Mysteries Revealed - JayGee RacingBeen DeeNo ratings yet

- Burkert Ds8611 Standard Eu enDocument16 pagesBurkert Ds8611 Standard Eu enJebran FarazNo ratings yet

- Flowmeter Endress+HauserDocument70 pagesFlowmeter Endress+Hausersanach100% (1)

- ATV1200 CatalogDocument32 pagesATV1200 CatalogahilsergeyNo ratings yet

- Ldp-105m150 Moso Test ReportDocument17 pagesLdp-105m150 Moso Test ReportzecyberNo ratings yet

- Tda8929t PDFDocument36 pagesTda8929t PDFtecniloco80No ratings yet

- Un04 t05 enDocument101 pagesUn04 t05 enStephan LewisNo ratings yet

- CMMP AS 3A HW - 2007 08 - 557326g1Document110 pagesCMMP AS 3A HW - 2007 08 - 557326g1LucianoNo ratings yet

- MCQ Pe 162Document162 pagesMCQ Pe 162rajuNo ratings yet

- How To Select Digital Power ICsDocument13 pagesHow To Select Digital Power ICsDucSyHoNo ratings yet

- Technical Data: 1. GeneralDocument12 pagesTechnical Data: 1. GeneraltecnicomanelNo ratings yet

- Migration s7-200 To s7-1200 Tech enDocument20 pagesMigration s7-200 To s7-1200 Tech enBin MulyadinNo ratings yet

- Lab 2, Part B: Robot DC Motor: Speed Measurement Circuit DesignDocument31 pagesLab 2, Part B: Robot DC Motor: Speed Measurement Circuit DesignNunjaNo ratings yet

- Fauji Cement Company Limited (FCCL) : ElectricalDocument25 pagesFauji Cement Company Limited (FCCL) : Electricalrahim khanzadaNo ratings yet

- Pulse Width Modulation Control Circuit Technical SpecificationsDocument4 pagesPulse Width Modulation Control Circuit Technical SpecificationsManutenção FNNo ratings yet

- EeeDocument13 pagesEeesiddharthNo ratings yet

- Analog & Digital Communication Lab ManualDocument78 pagesAnalog & Digital Communication Lab ManualELECTRONICS COMMUNICATION ENGINEERING BRANCHNo ratings yet

- Pic Microcontroller Projects List (800 Projects)Document14 pagesPic Microcontroller Projects List (800 Projects)duino4projects83% (6)

- Hyperloop Transportation System: Analysis, Design, Control and ImplementationDocument9 pagesHyperloop Transportation System: Analysis, Design, Control and Implementationkumar pranavNo ratings yet

- Tektronix A6303 070390504Document34 pagesTektronix A6303 070390504hieuhuech1No ratings yet

- PDF Sanken 882276Document13 pagesPDF Sanken 882276Moises CelosoNo ratings yet

- Energy Efficient Elevator and EscalatorDocument122 pagesEnergy Efficient Elevator and EscalatorherrtammNo ratings yet

- Power Pro Delta DS300Document83 pagesPower Pro Delta DS300Khách Sạn Hoàng Phố100% (2)