Professional Documents

Culture Documents

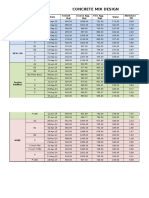

Proportions & Quantities For Ordering: Trial Concrete Mixes

Uploaded by

Graham RobertsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proportions & Quantities For Ordering: Trial Concrete Mixes

Uploaded by

Graham RobertsCopyright:

Available Formats

trial concrete mixes proportions & quantities for ordering

This table was drawn up when only 50 kg bags of cement were available in SA. Mass/bag and Volume/bag quantities are given for 50 kg bags of cement. Concrete strength at 28 days, MPa Mass or volume Mass/50 kg bag 10 Volume/50 kg bag Mass/m

3 3

If bags containing a different mass of cement are used then the per bag quantities should be adjusted proportionately.

9,5 or 13,2 mm stone Cement 50 kg 50 kg 250 kg 5,0 bag 50 kg 50 kg 315 kg

3

19,0 or 26,5 mm stone Stone 128 kg 0,095 m3 640 kg 0,47 m

3

Sand 238 kg 0,175 m3 1 190 kg 0,88 m

3

Cement 50 kg 50 kg 225 kg 4,5 bag 50 kg 50 kg 280 kg 5,6 bag 50 kg 50 kg 340 kg 6,8 bag 50 kg 50 kg 385 kg 7,7 bag 50 kg 50 kg 430 kg 8,6 bag 50 kg 50 kg 475 kg 9,5 bag 50 kg 50 kg 520 kg 10,4 bag

Sand 230 kg 0,170 m3 1 030 kg 0,76 m

3

Stone 196 kg 0,145 m3 890 kg 0,66 m

3

Volume/m

Mass/50 kg bag 15 Volume/50 kg bag Mass/m

3

175 kg 0,130 m3 1 100 kg 0,82 m

3

106 kg 0,080 m3 670 kg 0,50 m

3

170 kg 0,125 m3 950 kg 0,70 m

3

164 kg 0,120 m3 920 kg 0,68 m

3

Volume/m

6,3 bag 50 kg 50 kg 375 kg

Mass/50 kg bag 20 Volume/50 kg bag Mass/m

3 3

138 kg 0,100 m3 1 030 kg 0,76 m

3

92 kg 0,070 m3 690 kg 0,51 m

3

130 kg 0,095 m3 880 kg 0,65 m

3

138 kg 0,100 m3 940 kg 0,70 m

3

Volume/m

7,5 bag 50 kg 50 kg 425 kg

Mass/50 kg bag Volume/50 kg bag 25 Mass/m

3 3

114 kg 0,085 m3 970 kg 0,72 m

3

84 kg 0,060 m3 710 kg 0,53 m

3

106 kg 0,080 m3 820 kg 0,61 m

3

125 kg 0,090 m3 960 kg 0,71 m

3

Volume/m

8,5 bag 50 kg 50 kg 475 kg

Mass/50 kg bag Volume/50 kg bag 30 Mass/m

3 3

95 kg 0,070 m3 910 kg 0,67 m

3

78 kg 0,055 m3 730 kg 0,54 m

3

90 kg 0,065 m3 770 kg 0,57 m

3

114 kg 0,085 m3 980 kg 0,73 m

3

Volume/m

9,5 bag 50 kg 50 kg 525 kg

Mass/50 kg bag Volume/50 kg bag 35 Mass/m

3 3

80 kg 0,060 m3 850 kg 0,63 m

3

72 kg 0,055 m3 750 kg 0,56 m

3

75 kg 0,055 m3 710 kg 0,53 m

3

105 kg 0,080 m3 1 000 kg 0,74 m

3

Volume/m

10,5 bag 50 kg 50 kg 575 kg

Mass/50 kg bag Volume/50 kg bag 40 Mass/m

3 3

68 kg 0,050 m3 780 kg 0,58 m

3

68 kg 0,050 m3 770 kg 0,57 m

3

64 kg 0,045 m3 650 kg 0,49 m

3

98 kg 0,075 m3 1 020 kg 0,76 m

3

Volume/m

11,5 bag

For notes see over.

notes

Recommended concrete strengths for various uses are shown in the table below.

Concrete strength at 28 days, MPa

10 15 20 25 Mass filling

Use

A mix made according to this table, and to the required consistence, should be assessed for stone content before being used on a large scale. This can be done by compacting some of the concrete in a container, e.g. a bucket, by the means (vibration or hand tamping) to be used on the job. If stones protrude from the surface, stone content is too high. If not, scratch the surface of the compacted concrete (before it hardens) with a nail or screwdriver. If the stone content is right, stones should be found two or three millimetres below the surface. If they are deeper than this, the stone content is too low. If stone content is too high, reduce it by 10% and increase sand content by the same amount, i.e. volume or mass. Then reassess. If stone content is too low, increase it by 10% and reduce sand content by the same amount, i.e. volume or mass. Then reassess.

Foundations for houses Floors on the ground (surface beds) for houses Reinforced concrete Home driveways Reinforced concrete Floors on the ground for heavy duty e.g. factories Farm roads Floors on the ground for heavy duty e.g. factories Precast concrete Precast concrete

30

35 40

Mix proportions in the table overleaf are based on the assumption that a CEM II/A 32,5 cement will be used. CEM I 42,5 or higher cements will give a stronger concrete but may be less economical. Cements with higher extender contents (e.g. CEM II/B or CEM III) may develop strength more slowly and will require particular care with curing. Masonry cements complying with SABS ENV 413-1 are not recommended for use in concrete. The amount of water required is not given in the table. The mix should contain enough water to achieve the required consistence. Consistence may be assessed by eye or measured by carrying out the slump test (SABS Method 5862-1:2006). Recommended slumps are: 50100mm for compaction by mechanical vibration 100150mm for compaction by hand 0,001m = 1 litre The capacity of a builders wheelbarrow is 65 litres.

3

The mix proportions given in the table overleaf are conservative. If the quantity of concrete to be made 3 exceeds about 100 m , it is probably possible to save costs by selecting materials and having a mix designed. For information on the choice of materials consult the C&CI. The quantities given overleaf do not include any allowance for wastage.

cement & concrete institute

po box 168, halfway house, 1685 block d, lone creek, waterfall park, bekker road, midrand tel 011 315 0300 fax 011 315 0584 e-mail info@cnci.org.za website http://www.cnci.org.za

published by the cement & concrete institute, midrand, 2010 cement & concrete institute

You might also like

- Method Statement Concrete Coring (ASTM C 142)Document2 pagesMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- Ic 8758Document6 pagesIc 8758Nurali MamenNo ratings yet

- Self Consolidating ConcreteDocument32 pagesSelf Consolidating ConcreteOmar NajmNo ratings yet

- Cement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Document7 pagesCement: A) Brand 2. Aggregates: A) Fine Aggregate B) Coarse Aggregate The Characteristics of Materials Are Given in Table 1 To 3Praneeth KumarNo ratings yet

- Concrete Mix Design Optimized ApproachDocument8 pagesConcrete Mix Design Optimized ApproachHerman MwakoiNo ratings yet

- Conrete Mix Design ACI and JSCE Example. (20+33 Mpa)Document8 pagesConrete Mix Design ACI and JSCE Example. (20+33 Mpa)nirmaljoshi100% (1)

- SoilTestReport - 11611bandra Terminus1Document13 pagesSoilTestReport - 11611bandra Terminus1ShashankSinghNo ratings yet

- Concrete Mix Ratios for 3000, 3500, 4000, 4500 PSIDocument7 pagesConcrete Mix Ratios for 3000, 3500, 4000, 4500 PSINathan AsinasNo ratings yet

- FDT FormDocument3 pagesFDT FormEdison WalitNo ratings yet

- Concrete Mix Design: Plant Class Date Water Cement (KG) Coarse Agg. (KG) Fine Agg. (KG) Admixture (LT)Document6 pagesConcrete Mix Design: Plant Class Date Water Cement (KG) Coarse Agg. (KG) Fine Agg. (KG) Admixture (LT)Suara Jatim PostNo ratings yet

- Aggregate Base CourseDocument5 pagesAggregate Base CoursefauzihidayatNo ratings yet

- Data Required For Concrete Mix DesignDocument9 pagesData Required For Concrete Mix DesignNyan Lin100% (1)

- Evaluation of Rockfill Embankments by Field Tests in Siraf RefineryDocument6 pagesEvaluation of Rockfill Embankments by Field Tests in Siraf RefinerysilongNo ratings yet

- Uxrvsnsrry Tecnxolocy (Buet) or CRVN It 'R: ProjectDocument1 pageUxrvsnsrry Tecnxolocy (Buet) or CRVN It 'R: ProjectMosharaf HossainNo ratings yet

- Concrete Mix DesignDocument24 pagesConcrete Mix Designvishnumani3011No ratings yet

- Properties Concrete Dune SandDocument6 pagesProperties Concrete Dune SandAlanSamNo ratings yet

- Floor Surface Profile Measurement BrochureDocument2 pagesFloor Surface Profile Measurement BrochureErzaNo ratings yet

- Gabion Wall Installation GuideDocument5 pagesGabion Wall Installation GuideJoel KomaNo ratings yet

- Proportioning Concrete Mixtures With Graded AggregatesDocument86 pagesProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (1)

- Table A1.6.3.1 - Recommended Slumps For Various Types of Construction (SI) Slump, MM Types of ConstructionDocument6 pagesTable A1.6.3.1 - Recommended Slumps For Various Types of Construction (SI) Slump, MM Types of Constructiongreat_triskelionNo ratings yet

- 08-Self Consolidating ConcreteDocument22 pages08-Self Consolidating ConcreteAnuja KumariNo ratings yet

- Aashto and astm soil testing standardsDocument4 pagesAashto and astm soil testing standardsmichaella mencero100% (1)

- CDOT Bridge Design ManualDocument216 pagesCDOT Bridge Design ManualAbdul-azeez BelloNo ratings yet

- CBRDocument8 pagesCBRAre-jok MotNo ratings yet

- Comparison Between Marshall MethodDocument57 pagesComparison Between Marshall MethodAbdullah100% (1)

- Maximum Theoritical Specific Gravity at Different Asphalt ContentDocument4 pagesMaximum Theoritical Specific Gravity at Different Asphalt ContentFiras BarrajNo ratings yet

- 749-JMF-BBC-Class-B-2010-Ali & Co - Sep'17-SyDocument18 pages749-JMF-BBC-Class-B-2010-Ali & Co - Sep'17-SySoundar PachiappanNo ratings yet

- Concrete Pipe Deflection LimitsDocument18 pagesConcrete Pipe Deflection LimitsAhmed KarimNo ratings yet

- Base CourseDocument3 pagesBase Courseprobook450_ehsanNo ratings yet

- Installation: Floor TileDocument17 pagesInstallation: Floor TileAli SaifNo ratings yet

- Field Density FDT FormDocument3 pagesField Density FDT FormPedjaNo ratings yet

- Marshall Mix Design Test ProcedureDocument3 pagesMarshall Mix Design Test Procedureshafiqz_4No ratings yet

- Diagnosis and Control of Alkali-Aggregate Reactions in ConcreteDocument26 pagesDiagnosis and Control of Alkali-Aggregate Reactions in ConcreteIrfan OmarNo ratings yet

- QC TESTS ENSURE PRODUCT QUALITYDocument22 pagesQC TESTS ENSURE PRODUCT QUALITYvarma369vinaNo ratings yet

- Methodology For Convreting WorksDocument7 pagesMethodology For Convreting WorksLokesh SaranNo ratings yet

- PCI Recommended Practice for Grouting Post-Tensioned ConcreteDocument8 pagesPCI Recommended Practice for Grouting Post-Tensioned Concretevenkateswara rao PothinaNo ratings yet

- Yield of ConcreteDocument19 pagesYield of ConcreteSuvranil BanerjeeNo ratings yet

- Water Bound Macadam-WbmDocument11 pagesWater Bound Macadam-WbmCheng EngiNo ratings yet

- Cover Block Method StaDocument1 pageCover Block Method StaRavi kumarNo ratings yet

- Marshall Mix Design ProcedureDocument31 pagesMarshall Mix Design Procedurebraackw100% (2)

- Concrete Mix Design (Notes) PDFDocument11 pagesConcrete Mix Design (Notes) PDFMohamad Khaled Nordin100% (1)

- 1195 Specification For Bitumen Mastic For FlooringDocument14 pages1195 Specification For Bitumen Mastic For FlooringRakesh RanjanNo ratings yet

- Concrete Mix Proportioning Using EMMA SoftwareDocument12 pagesConcrete Mix Proportioning Using EMMA SoftwareYuliusRiefAlkhalyNo ratings yet

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocument9 pagesDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedNo ratings yet

- Road Pavements Bituminous MaterialsDocument22 pagesRoad Pavements Bituminous Materialsmayur_lanjewarNo ratings yet

- WSDOT FOP AASHTO T 310 In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Document10 pagesWSDOT FOP AASHTO T 310 In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)fogdartNo ratings yet

- High Slump Concrete Mix Design 2 PDFDocument68 pagesHigh Slump Concrete Mix Design 2 PDFBernie QuepNo ratings yet

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocument75 pagesHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNo ratings yet

- Building Setting Out ChecklistDocument1 pageBuilding Setting Out ChecklistMuhammad Wazim AkramNo ratings yet

- Shotcrete SpecificationsDocument7 pagesShotcrete SpecificationsGEOMAHESHNo ratings yet

- 6 Defects in Brickwork Due To Poor WorkmanshipDocument7 pages6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- Material Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Document1 pageMaterial Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Waqas SadiqNo ratings yet

- Concrete Estimation GuideDocument31 pagesConcrete Estimation GuideErile SergioNo ratings yet

- Chapter 4Document34 pagesChapter 4BlueeeMoonZiahGraceNo ratings yet

- Cost-Estimate (1)Document31 pagesCost-Estimate (1)Way AblogNo ratings yet

- Cost-Estimate (1)Document26 pagesCost-Estimate (1)Xzk MallaboNo ratings yet

- Bulking of Sand Means Increase in ItDocument6 pagesBulking of Sand Means Increase in ItDENCONo ratings yet

- Concrete 3-2Document5 pagesConcrete 3-2alexiegojimenezNo ratings yet

- Mix DesignDocument5 pagesMix Designram6265790No ratings yet

- Building Technology 4 Week 3Document39 pagesBuilding Technology 4 Week 3Xette FajardoNo ratings yet

- Green MaterialsDocument22 pagesGreen MaterialsGraham RobertsNo ratings yet

- Effect of High FA Content On RCCDocument10 pagesEffect of High FA Content On RCCGraham RobertsNo ratings yet

- Back to Elements - Tetrahedra vs Hexahedra FEADocument16 pagesBack to Elements - Tetrahedra vs Hexahedra FEAKomkamol ChongbunwatanaNo ratings yet

- Execution of Durability Index Tests - Bruce Raath PDFDocument4 pagesExecution of Durability Index Tests - Bruce Raath PDFGraham RobertsNo ratings yet

- Hydraulics of Skimming Flows Over Stepped Channels-ChansonDocument17 pagesHydraulics of Skimming Flows Over Stepped Channels-ChansonGraham RobertsNo ratings yet

- Aggregates Crucial for Concrete Strength and PropertiesDocument25 pagesAggregates Crucial for Concrete Strength and Propertiesdatagap100% (2)

- An Introduction To Probabilistic Seismic Hazard Analysis (PSHA) - Jack W. BakerDocument72 pagesAn Introduction To Probabilistic Seismic Hazard Analysis (PSHA) - Jack W. BakerMohaiminul KarimNo ratings yet

- 3D Thermal Analysis-Element Relocating MethodDocument6 pages3D Thermal Analysis-Element Relocating MethodGraham RobertsNo ratings yet

- Modal Time History AnalysisDocument14 pagesModal Time History AnalysisGraham Roberts100% (1)

- NSTAR-Intro ManualDocument501 pagesNSTAR-Intro ManualGraham RobertsNo ratings yet

- Twisting Momentsin Two-Way SlabsDocument6 pagesTwisting Momentsin Two-Way SlabsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- H-P FEMDocument22 pagesH-P FEMGraham RobertsNo ratings yet

- Chemical Process Control A First Course With Matlab - P.C. Chau PDFDocument255 pagesChemical Process Control A First Course With Matlab - P.C. Chau PDFAli NassarNo ratings yet

- Guide To Concrete Repair - US Dep of InteriorDocument168 pagesGuide To Concrete Repair - US Dep of InteriorAllan SchultzNo ratings yet

- Hydraulic Design of Energy DissipatorsDocument286 pagesHydraulic Design of Energy DissipatorsCarlos AndresNo ratings yet

- Ohio Bridge Design Manual OverviewDocument530 pagesOhio Bridge Design Manual OverviewDifa LiuNo ratings yet

- Aggregates Crucial for Concrete Strength and PropertiesDocument25 pagesAggregates Crucial for Concrete Strength and Propertiesdatagap100% (2)

- Tank Analysis Modelling Soil PDFDocument8 pagesTank Analysis Modelling Soil PDFGraham RobertsNo ratings yet

- CFD Simulation in AbaqusDocument34 pagesCFD Simulation in AbaqusGraham RobertsNo ratings yet

- Cathodic Protection of Reinforced Concrete PDFDocument75 pagesCathodic Protection of Reinforced Concrete PDFGraham RobertsNo ratings yet

- Aggregates Crucial for Concrete Strength and PropertiesDocument25 pagesAggregates Crucial for Concrete Strength and Propertiesdatagap100% (2)

- Anchor Bolts - Concrete Capacity Design PDFDocument22 pagesAnchor Bolts - Concrete Capacity Design PDFGraham RobertsNo ratings yet

- Smart Materials 007Document10 pagesSmart Materials 007Graham RobertsNo ratings yet

- Master Civil Engineering Fields with VC-Q&ADocument406 pagesMaster Civil Engineering Fields with VC-Q&AMike Gould100% (2)

- Chemical Process Control A First Course With Matlab - P.C. Chau PDFDocument255 pagesChemical Process Control A First Course With Matlab - P.C. Chau PDFAli NassarNo ratings yet

- Structural DynamicsDocument94 pagesStructural DynamicsGraham RobertsNo ratings yet

- 13 Stormwater, Sewage, Sanitary Wastewater and Environmental ProtectionDocument24 pages13 Stormwater, Sewage, Sanitary Wastewater and Environmental ProtectionGraham RobertsNo ratings yet

- Structural DynamicsDocument94 pagesStructural DynamicsGraham RobertsNo ratings yet

- Structural DynamicsDocument94 pagesStructural DynamicsGraham RobertsNo ratings yet

- PowerOn Fusion PDFDocument16 pagesPowerOn Fusion PDFJagan VanamaNo ratings yet

- Operations and Service 69UG15: Diesel Generator SetDocument64 pagesOperations and Service 69UG15: Diesel Generator SetAnonymous NYymdHgyNo ratings yet

- Parts List CMX1402Document36 pagesParts List CMX1402Jayden BarnesNo ratings yet

- Qtiplot Manual enDocument390 pagesQtiplot Manual enjovita georgeNo ratings yet

- User Home - MoneyEasilyDocument1 pageUser Home - MoneyEasilyEbenezer NyantakyiNo ratings yet

- Wireless DoorbellDocument20 pagesWireless Doorbellmujahed1987No ratings yet

- PDF Ebook Pickle Things by Marc Brown Download BookDocument5 pagesPDF Ebook Pickle Things by Marc Brown Download BookCorissNo ratings yet

- Acp 400020180910102625Document2 pagesAcp 400020180910102625Sofyan Andika YusufNo ratings yet

- Green Finance For Green GrowthDocument24 pagesGreen Finance For Green GrowthSreejith BhattathiriNo ratings yet

- Stepper Motor 57HS8430A4D8 / NEMA 23 3ADocument2 pagesStepper Motor 57HS8430A4D8 / NEMA 23 3AMuhammad Ghiyats MukminNo ratings yet

- Dual-Band Band Pass Filters Using Stub-Loaded ResonatorsDocument3 pagesDual-Band Band Pass Filters Using Stub-Loaded ResonatorsfracosoeNo ratings yet

- Block Out TimeDocument3 pagesBlock Out TimeschumangelNo ratings yet

- Simovert Masterdrives VCDocument16 pagesSimovert Masterdrives VCangeljavier9No ratings yet

- Temporary Revision 12 053: Aircraft Maintenance ManualDocument26 pagesTemporary Revision 12 053: Aircraft Maintenance ManualKentNo ratings yet

- D4. SBS Iran PDFDocument10 pagesD4. SBS Iran PDFMohammed QaderNo ratings yet

- PBV20N2 Service Manual PDFDocument244 pagesPBV20N2 Service Manual PDFJack Norhy100% (1)

- Sustainable Energy and Resource ManagementDocument318 pagesSustainable Energy and Resource ManagementRajdeepSenNo ratings yet

- AIR Intelligence Manual 33 308100 004 RemoteDocument88 pagesAIR Intelligence Manual 33 308100 004 RemoteLeChancheNo ratings yet

- LTE UMTS GSM Network OptimizationDocument44 pagesLTE UMTS GSM Network OptimizationAvi Shetty100% (1)

- Concord IPL Commercial Incline Vertical Platform Lift SearchableDocument92 pagesConcord IPL Commercial Incline Vertical Platform Lift SearchableHongquan SuNo ratings yet

- ACEEE - Best Practices For Data Centres - Lessons LearnedDocument12 pagesACEEE - Best Practices For Data Centres - Lessons LearnedtonybudgeNo ratings yet

- Parts Catalog TT75, TT55 NEW HOLLANDDocument360 pagesParts Catalog TT75, TT55 NEW HOLLANDrogerio97% (35)

- Culata JD 6466Document4 pagesCulata JD 6466TECNOTRAC AldanaNo ratings yet

- Cisco CCIE CCNP RS Study Flashcards Ver 49Document102 pagesCisco CCIE CCNP RS Study Flashcards Ver 49niboozNo ratings yet

- Ordinary Portland Cement, 33 Grade - Specification: Indian StandardDocument12 pagesOrdinary Portland Cement, 33 Grade - Specification: Indian StandardAmbrishNo ratings yet

- Learjet 45 Pilot Traning Manual Volumen 2Document539 pagesLearjet 45 Pilot Traning Manual Volumen 2Agustin Bernales88% (8)

- BNI Vision April 2023 Roster BookDocument16 pagesBNI Vision April 2023 Roster BookTushar MohiteNo ratings yet

- Diffusion of InnovationDocument40 pagesDiffusion of Innovationlali62No ratings yet

- Object-Oriented Programming Lab Manual RDocument63 pagesObject-Oriented Programming Lab Manual RKLR CETNo ratings yet

- Cyclopedia of Architecture Carpentry & Building Vol VIIIDocument422 pagesCyclopedia of Architecture Carpentry & Building Vol VIIIbootsola100% (2)