Professional Documents

Culture Documents

5 Flexible Saddle Support of A Horizontal Cylindrical Pressure Vessel by Magnucki

Uploaded by

Antonio Perez ZornozaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 Flexible Saddle Support of A Horizontal Cylindrical Pressure Vessel by Magnucki

Uploaded by

Antonio Perez ZornozaCopyright:

Available Formats

International Journal of Pressure Vessels and Piping 80 (2003) 205210 www.elsevier.

com/locate/ijpvp

Flexible saddle support of a horizontal cylindrical pressure vessel

K. Magnuckia,b,*, P. Stasiewicza, W. Szyca

a

Institute of Applied Mechanics, Poznan University of Technology, ul. Piotrowo 3, Poznan 60-965, Poland b Institute of Rail Vehicles TABOR, ul. Warszawska 181, Poznan 61-055, Poland Received 29 January 2002; revised 16 December 2002; accepted 16 January 2003

Abstract The subject of this paper is the supporting saddle of a horizontal cylindrical pressure vessel lled with liquid. A parametric model of the saddle support has been developed; the effect of the geometrical parameters on the stress values arising in the structure has been examined by means of the Finite Element Method. The shape and location of the supporting saddle have been determined with a view to minimizing the concentration of stresses. Results of numerical analysis allow determination of the effective proportions of the geometrical parameters of the vessel. q 2003 Elsevier Science Ltd. All rights reserved.

Keywords: Numerical analysis; Finite element method; Parametric shaping; Circular cylindrical vessel

1. Introduction Stationary horizontal cylindrical vessels supported on two supporting saddles (Fig. 1) are usually loaded with uniform internal pressure and hydrostatic pressure. Such a vessel is subject to a non-uniform stress distribution. The stiffness of the supporting saddles and the distance between them have a considerable effect on the maximum stresses occurring in the structure. The problem has been the subject of many research works. El-Abbasi, Meguid and Czekanski [1] performed a 3D analysis of a pressure vessel freely supported on two deformable supports by means of FEM. They developed a seven-parameter thick shell nite element taking into account friction between the support and the vessel, as well as the changes of stresses and strains across the shell thickness. They investigated the effect of geometric parameters of the vessel and support on the state of stress and calculated optimal proportions between these quantities. They showed that in the case of a supporting saddle with a radius 1 2 percent greater than that of the vessel the stresses occurring in the structure are reduced by 50%. Boutros [2] discussed the results of parametric analysis of deformable saddle supports of circular cylindrical vessels of

* Corresponding author. Address: Institute of Applied Mechanics, Poznan University of Technology, ul. Piotrowo 3, Poznan 60-965, Poland. Fax: 48-61-665-2307. E-mail address: krzysztof.magnucki@put.poznan.pl (K. Magnucki).

large diameter. He indicated the inuence of proportions between vessel dimensions and support location on the stresses occurring in the structure. He took into account the guidelines provided by British Standards, Australian Standards, and ASME. He also compared stiff and deformable supports, with regard to stress concentration at the saddle horn. Magnucki et al. [3] developed a parametric FEM-model of the vessel and its support. The support and vessel of the structure considered were joined by welding. The stiffness of the support was smaller than that recommended by European standards. They investigated the effect of the geometric parameters of the vessel and support on the stresses in characteristic regions of the structure. Magnucki and Szyc [4] proposed a method of determining the thickness of a cylindrical vessel resting upon two supports. They effected a numerical FEM analysis of a family of vessels and developed corrections for determining the thickness of the walls of pressure vessels. The British Standard BS5500 [5] provides guidelines for designing pressure vessels and their supports. The proposed methods are based on the theory of beams and the results of experimental research published by Zick in 1951. The standard recommends welded connection between the vessel and support; however, the saddle supports have excessive stiffness resulting in increased stresses. Ong and Lu [6] determined the optimal radius of the support with a preliminary clearance between the vessel and saddle. In

0308-0161/03/$ - see front matter q 2003 Elsevier Science Ltd. All rights reserved. doi:10.1016/S0308-0161(03)00023-1

206

K. Magnucki et al. / International Journal of Pressure Vessels and Piping 80 (2003) 205210

Fig. 1. Geometric model of a horizontal pressure vessel.

the area of the vessel saddle contact they assumed a constant distribution of the contact pressure along the vessel, but varying circumferentially. They performed a parametric analysis aimed at reducing the stress concentration at the saddle horn. Tooth et al. [7] analytically and experimentally determined the stresses in real supports of multi-layered Glass Reinforced Plastic (GRP) vessels. They divided the region of the vessel-support contact into small areas, assuming uniform radial and tangent pressure distributions in each. Variable distributions of contact pressure were assumed in the direction of support width. In the experimental part, they presented strain gauge results for three vessels with equal overall dimensions but different laminate layers. They investigated two types of saddle with

radii exceeding the external radius of the vessel and proposed a useful method for calculating the maximum strain, particularly in the absence of computer software. Banks et al. [8], presented an approximate solution of the strain state of a horizontal cylindrical vessel, making use of the earlier paper [7].

2. Structure of the horizontal vessel The structure considered in this paper is a typical thinwalled horizontal cylindrical vessel, supported on two deformable supports, welded to the vessel and located symmetrically near its ends at a distance s from the middle

Fig. 2. Structure of the saddle support.

K. Magnucki et al. / International Journal of Pressure Vessels and Piping 80 (2003) 205210

207

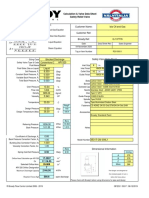

symmetry plane. The length 2L of the cylindrical part of the vessel and its radius r are variable parameters, while the capacity of the vessel is constant and equal to V0 300 m3 (Fig. 1). The vessel is closed with two ellipsoidal heads of convexity b0 equal to a half of the radius b0 r=2: Moreover, it is assumed that the vessel is made of steel of density rs 7:85 103 kg m23 ; lled with a liquid of density rl 103 kg m23 ; and additionally loaded with uniform internal pressure p0 2:5 MPa: It is assumed that the structure is described by 10 parameters: vessel radius r; length L; spacing between supports s; height of vessel axis H above support base, characteristic dimensions of the support b; c; and e; thicknesses h1 of the heads, h2 of cylindrical shell, and h3 of the supports. A simple design of the support is adopted with the shape shown in Fig. 2. It is a welded support made of steel plate, formed to avoid excessive deformation of the vessel, with an angle of contact with the vessel by its load carrying structure of ws 1208 and by its support cover plate of wc 1408: The cover plate width cn depends on vessel length and is cn 2L=45: Initial values of particular geometrical parameters of the vessel are taken as r 1:8 m, L 14:1 m, s 12L=15; H 1:15r; b r=2; c 300 mm, e 210 mm, h1 16 mm, h2 14 mm, h3 8 mm.

3. Numerical analysis A parametric model of 1=4 of the vessel structure with the supports has been developed. The model was used to carry

out static nite element analysis by means of the COSMOS/M system. It included 2374 shell elements and enabled easy changing of the ten geometric parameters of the structure. Results of each have been produced in the form of contour maps of equivalent Huber Mises stresses. Their values have been analyzed in eight characteristic regions shown in Fig. 1 with the symbols A1 ; A2 ; B; C1 ; C2 ; C3 ; D; and E: Regions A1 ; A2 and B surround the saddle support of the vessel, more precisely they touch edges of the support cover plate. Those are the places where local stress concentration occurs, as an effect of the support and the vessel skin interaction. The maximum equivalent stress values in these regions are selected. Regions C1 ; C2 ; C3 are located in the middle cross-section of the vessel at upper, medial and lower generatrix, and the stress values calculated in these points are taken into account. Region D is located in the ellipsoidal head near the joint with the cylindrical shell where maximum equivalent stresses occur. Region E includes the whole saddle support and from this area the maximum stresses are selected. Maximum values of the equivalent stresses in each area are presented in Fig. 3 6. There are not greater stress values elsewhere. In Fig. 3 the examples of the results obtained for calculations with different values of the parameter b (width of support bed) in the range 0:39r # b # 0:83r are presented. The value of b has little effect in the areas D (the head) and C (the middle of the vessel). Effects are also relatively small in the areas A1 (next to the support) and B (above the support). However, in the area E (the support) a

Fig. 3. Inuence of width of the saddle support bed b on stress level.

208

K. Magnucki et al. / International Journal of Pressure Vessels and Piping 80 (2003) 205210

Fig. 4. Inuence of the saddle support tip height e on stress level.

distinct minimum in stress is observed as the value of b increases beyond r=2: The height of the end of the support arm, e; also inuences the stiffness of the support. Changes in equivalent stress in particular parts of the structure with e in the range 0:094r # e # 0:28r are shown in Fig. 4. The most signicant effects are observed in the areas A1 and E: In

particular, near the support A1 ; a clear increase of stress with increase of the dimension e is observed. This means that an elastic support of relatively low stiffness is the most advantageous solution for a vessel to give low stresses in the area of the support. However, stress in the support E will increase if the value of e is too small. Hence, a reasonable recommendation in this case would be to use supports

Fig. 5. Inuence of the saddle support base s on stress level.

K. Magnucki et al. / International Journal of Pressure Vessels and Piping 80 (2003) 205210

209

Fig. 6. Inuence of the vessel slenderness ratio L=r on stress level.

having a tip dimension e 0:1 0:12r: Fig. 5 shows how the equivalent stress values change with increase of the ratio s=L; i.e. with moving the location of the saddle supports. The gure suggests that the most favourable location of the supports would be near the ends of the vessel. For increasing s=L; the stresses decrease in almost all areas, including the middle part of the vessel, C1 : In the area C3 maximal equivalent stresses have the similar values as in the area C1 : However, the stresses in the head (D area) increase slightly at larger s=L: Therefore, a reasonable compromise would consist of the use of a slightly thicker head (the model assumes the head thickness h1 16 mm and the cylindrical shell thickness h2 14 mm) and positioning the supports near the ends of the vessel, at about s=L 14=15: Considering the vessel as a beam subject to uniform load and supported at two points, as sometimes found in the literature, is inappropriate. The set of curves in Fig. 6 shows the changes in stress level in the same areas of vessels having different proportions but the same capacity V0 300 m3 : The stresses are indicated for outer and inner surfaces of the cylindrical shell. The run of the curves show that reasonable proportions are for L=r in the range 6 8, corresponding to L 11:8 14:3 m or r 2:0 1:8 m. in this case. In practice, vessels with radius exceeding 2 m are often avoided because of problems with possible road transport. With increasing L=r; higher stresses occur in the area B closest to the support and in the middle section of the vessel C3 :

Analyses were also made to assess the effects of support height H; the dimension c; and the width cn of the cover plate. The results indicate that preliminary values for these parameters, specied in the end of Section 2, are reasonable.

4. Conclusions The results enable selection of the most favourable values of basic structural parameters of a thin-walled cylindrical pressure vessel. The vessel is treated as an integral system, including the deformable supports with stiffness adjusted to minimize the stress concentration in the vessel shell. The support should be of appropriate shape, simple design, and suitable thickness relative to the thickness of the vessel shell (the results suggest h3 =h2 0:6 2 0:7). The use of supports of high stiffness (e.g. concrete, in the form of a bed) is certainly unfavourable taking into account the strength of the vessel. The supports should be located near the vessel ends, thus taking full advantage of the increased stiffness of the head, due both to its shape and increased thickness relative to the vessel shell. Calculations have shown that the thickness of the ellipsoidal head should equal 1.15 1.25 of the thickness of the cylindrical shell. A ratio of support to vessel lengths equal to s=L 14=15 is most favourable, although a beam model of the vessel would suggest location of the supports nearer the middle, to reduce the bending moment at the middle

210

K. Magnucki et al. / International Journal of Pressure Vessels and Piping 80 (2003) 205210 [2] Boutros YA. Flexible saddle support for large diameter cylindrical vessels. Proc Ninth Int Conf Pressure Vessel Technol, Sydney 2000;1: 918. [3] Magnucki K, Szyc W, Stasiewicz P. Selection of design parameters of a cylindrical pressure vessel together with its support. 36th Symposium Modelling in Mechanics, Silesian Technical University, Gliwice 1997;4:2116. in Polish. [4] Magnucki K, Szyc W. Shell thickness of a horizontal cylindrical vessel lled with liquid. 37th Symposium Modelling in Mechanics, Silesian Technical University, Gliwice 1998;7:20712. In Polish. [5] British Standard BS5500, Specication for unred fusion welded pressure vessels. 1. Supports and mountings for horizontal vessels. Brit Std Inst 1997;G3.3:6477. [6] Ong LS, Lu G. Optimal support radius of loose-tting saddle support. Int J Pressure Vessel Piping 1993;54:46579. [7] Tooth AS, Banks WM, Seah CP, Tolson BA. The twin-saddle support of horizontal multi-layered GRP vesselstheoretical analysis, experimental work and a design approach. Proc Inst Mech Engng, Part E: Process Mech Engng 1994;208:59 74. [8] Banks WM, Nash DH, Flaherty AE, Fok WC, Tooth AS. The derivation of a best t equation for maximum strains in a GRP vessel supported on twin saddles. Proc Ninth Int Conf Pressure Vessel Technol, Sydney 2000;1:10919.

cross-section. The geometrical slenderness of the vessel, dened as the length to radius ratio, should be in the range 2L=r 12 16: Similar proportions would apply to vessels of smaller capacity. Similar calculations have been carried out for vessels of capacities 200, 100 m3, and smaller. Conclusions are very similar and the main proportions should be maintained even for capacities down to 15 m3. However, other rules for the shapes of vessels and their supports may be required for smaller internal pressure, when the contribution of hydrostatic pressure is more important relative to the pressure inside the vessel.

References

[1] El-Abbasi N, Meguid SA, Czekanski A. Three-dimensional nite element analysis of saddle supported pressure vessels. Int J Mech Sci 2001;43:1229 42.

You might also like

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocument12 pagesStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackNo ratings yet

- Solution: WE1 12 Nov 2008Document9 pagesSolution: WE1 12 Nov 2008aauppalNo ratings yet

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringFrom EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillRating: 3.5 out of 5 stars3.5/5 (3)

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Saddle Stress CalculationsDocument8 pagesSaddle Stress CalculationsMuthuNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- 3 Saddle SupportsDocument15 pages3 Saddle Supportswasif78No ratings yet

- WRC Load AnalysisDocument5 pagesWRC Load Analysisyogacruise100% (1)

- Finite Element Analysis of Skirt To Dished Junction in A Pressure VesselDocument4 pagesFinite Element Analysis of Skirt To Dished Junction in A Pressure VesselIJMERNo ratings yet

- Design, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselDocument7 pagesDesign, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselGRD JournalsNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Comparitive Study of Design of Piping SupportDocument18 pagesComparitive Study of Design of Piping SupportbkguptazNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- How To Use Code Case in PV EliteDocument2 pagesHow To Use Code Case in PV EliteMukeshChopraNo ratings yet

- ASME DIV 2 Class 1 Vs Class 2Document3 pagesASME DIV 2 Class 1 Vs Class 2Idris SiddiquiNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- PV Elite Webinar 001Document23 pagesPV Elite Webinar 001MEC_GuiNo ratings yet

- Ansi B16.9-16.28-MSS SP-43Document3 pagesAnsi B16.9-16.28-MSS SP-43vangie3339515No ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- Wind Seismic Calculation DataDocument8 pagesWind Seismic Calculation Dataaknauriyal2013No ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- Asme A-2 Reverse Flange CalculationDocument1 pageAsme A-2 Reverse Flange CalculationpastylNo ratings yet

- External Pressure Calculation ResultsDocument8 pagesExternal Pressure Calculation ResultsAndika DearsonNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- Expanded and WeldedDocument9 pagesExpanded and Weldedmasaminathan100% (1)

- BN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerDocument1 pageBN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerAlexDdd123No ratings yet

- ASME Formula DerivationDocument1 pageASME Formula Derivationvm153748763No ratings yet

- Zick Analysis For Saddle SupportDocument8 pagesZick Analysis For Saddle Supportfuransu777100% (1)

- Ccopps WebinarDocument36 pagesCcopps WebinarAkenathon71No ratings yet

- PTB E4.18.5 Fixed TubesheetDocument83 pagesPTB E4.18.5 Fixed TubesheetNicolaSaviliNo ratings yet

- Sample21 SpreadsheetDocument20 pagesSample21 SpreadsheetSivateja NallamothuNo ratings yet

- WRC107Document6 pagesWRC107Guru MoorthiNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- FlangeCalculationASMEVIII Version5Document3 pagesFlangeCalculationASMEVIII Version5alvinchuan100% (1)

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- Ejma7r2 Bellows Worksheet-1Document11 pagesEjma7r2 Bellows Worksheet-1odormicchiNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- Chibro Press Fit Piping Data SheetDocument5 pagesChibro Press Fit Piping Data SheetBoyd JohnstonNo ratings yet

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- Calculo Brida Ejemplo PV - EliteDocument8 pagesCalculo Brida Ejemplo PV - ElitePedro Montes MarinNo ratings yet

- 003-Heat ExchangerDocument299 pages003-Heat ExchangerVijayshanker GuptaNo ratings yet

- Stress Distributions in A Horizontal Pressure Vessel and The Saddle SupportsDocument6 pagesStress Distributions in A Horizontal Pressure Vessel and The Saddle SupportspadalakirankumarNo ratings yet

- Nagi Pressure VesselDocument15 pagesNagi Pressure Vesselmohammed alaa eldinNo ratings yet

- Effective Length Factors For Gusset Plate BucklingDocument12 pagesEffective Length Factors For Gusset Plate Bucklingkaranderohan100% (2)

- Gusset PlatesDocument12 pagesGusset PlatesJason GarnerNo ratings yet

- Elastic Strength of High Pressure Vessels With A Radial Circular Cross BoreDocument10 pagesElastic Strength of High Pressure Vessels With A Radial Circular Cross BoreTJPRC PublicationsNo ratings yet

- Design of Saddle Support For Horizontal Pressure VesselDocument5 pagesDesign of Saddle Support For Horizontal Pressure Vesselsebastian9033100% (1)

- State of Stress in The Plate With Slot at Biaxial Load: Articles You May Be Interested inDocument10 pagesState of Stress in The Plate With Slot at Biaxial Load: Articles You May Be Interested inArun KumarNo ratings yet

- Horizontal Saddle Supported Storage Vessels: A Parametric Study of Plastic Collapse LoadsDocument27 pagesHorizontal Saddle Supported Storage Vessels: A Parametric Study of Plastic Collapse LoadsBimaNo ratings yet

- Plastic Collapse of Horizontal Saddle Supported Storage VesselsDocument6 pagesPlastic Collapse of Horizontal Saddle Supported Storage Vesselsapatil_491421No ratings yet

- Calculation of The Collapse Load of An ADocument13 pagesCalculation of The Collapse Load of An ALuminita GeorgetaNo ratings yet

- The Effect of ManholeDocument10 pagesThe Effect of ManholeCarlos CarmonaNo ratings yet

- The Effect of ManholeDocument10 pagesThe Effect of ManholeCarlos CarmonaNo ratings yet

- Objective Type Questions With AnswersDocument29 pagesObjective Type Questions With AnswersNikka LopezNo ratings yet

- Problem 2.50 PDFDocument2 pagesProblem 2.50 PDFKauê BrittoNo ratings yet

- RacDocument36 pagesRacm_er100No ratings yet

- Course: Applied Thermodynamics Course Code: 10ME43 Course Type: Core Sem: 4Document3 pagesCourse: Applied Thermodynamics Course Code: 10ME43 Course Type: Core Sem: 4Prashanth JagadeeshNo ratings yet

- Shoring System (Tie Back Wall) 2DDocument10 pagesShoring System (Tie Back Wall) 2DAndiNo ratings yet

- CPE 722 Applied Fluid Mechanics: Republic of The Philippines Central Luzon State University College of EngineeringDocument13 pagesCPE 722 Applied Fluid Mechanics: Republic of The Philippines Central Luzon State University College of EngineeringNikka Briones Domingo100% (1)

- DCS BeamDesign Lect3Document14 pagesDCS BeamDesign Lect3Rahul ChaudharyNo ratings yet

- EtaNorm Curva SDocument174 pagesEtaNorm Curva Sseht94No ratings yet

- الإجابة النموذجية لامتحان نصف الفصل مارس 20152015 - 5 - 9!8!27Document6 pagesالإجابة النموذجية لامتحان نصف الفصل مارس 20152015 - 5 - 9!8!27Amr RaghebNo ratings yet

- Alfred Aimé Flamant: Hydraulician and Textbook Author: ForumDocument10 pagesAlfred Aimé Flamant: Hydraulician and Textbook Author: ForumJoelCasasNo ratings yet

- Uplift Pressures by Khosla MethodDocument8 pagesUplift Pressures by Khosla MethodsamoonibrahimNo ratings yet

- Normal StrainDocument16 pagesNormal StrainMohsin Islam RifatNo ratings yet

- Model Answer: Winter 2015Document23 pagesModel Answer: Winter 2015Kapil MoreNo ratings yet

- Ch.1-Matter in Our Surroundings 9th SolvedDocument50 pagesCh.1-Matter in Our Surroundings 9th SolvedVikash SharmaNo ratings yet

- Sound Energy and Doppler EffectDocument2 pagesSound Energy and Doppler EffectVera MaureenNo ratings yet

- 1 s2.0 S2214157X23005579 MainDocument11 pages1 s2.0 S2214157X23005579 Main007 Karim khan mechNo ratings yet

- Group # 3: 4cheaDocument16 pagesGroup # 3: 4cheaNishant ChughNo ratings yet

- Molecular Dynamics SiCDocument15 pagesMolecular Dynamics SiCAnoushka GuptaNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- PT 2023 Past QuestionDocument7 pagesPT 2023 Past QuestionTSOG MHNo ratings yet

- Brizzolara CFD Planing HullsV5 LibreDocument9 pagesBrizzolara CFD Planing HullsV5 LibrehiguelNo ratings yet

- Theory Questions Asked in Mid Sem and CVMU QP - 07072023Document26 pagesTheory Questions Asked in Mid Sem and CVMU QP - 07072023a9157272235No ratings yet

- Tests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperDocument9 pagesTests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperpicottNo ratings yet

- Heatex 01Document2 pagesHeatex 01sumitNo ratings yet

- Lab 8Document3 pagesLab 8Nadia NasirNo ratings yet

- Steam Pipe Failure Investigation ReportDocument21 pagesSteam Pipe Failure Investigation ReportMohd Saiful Izwan100% (1)

- Bottom Failure - Annex K - en 14015 - Rev 3Document3 pagesBottom Failure - Annex K - en 14015 - Rev 3KP SahuNo ratings yet

- Intake DesignDocument1 pageIntake Designpushkar078No ratings yet

- Experiment Number 2 Coffee Cup CalorimetryDocument7 pagesExperiment Number 2 Coffee Cup Calorimetryapi-529605052No ratings yet