Professional Documents

Culture Documents

Large Scale System of Multiple Criteria Decision Making

Uploaded by

Amir MosaviCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Large Scale System of Multiple Criteria Decision Making

Uploaded by

Amir MosaviCopyright:

Available Formats

A.

Mosavi, The Large Scale System of Multiple Criteria Decision Making; Pre-Processing, Large Scale Complex Systems Theory and Applications, Vol. 9, 2010, pp. 354- 359.

The Large Scale System of Multiple Criteria Decision Making; Pre-processing

Amir Mosavi

Faculty of Informatics, University of Debrecen, Hungary

Abstract: Large-scale engineering optimization, including large amounts of variables and objectives requires significant computing power and efficient algorithms. Multiple Criteria Decision Making (MCDM) is a modelling tool for dealing with such complex engineering problems. One approach of MCDM for dealing with complex design evaluation models is to develop meta-models to replace the large scale design space. However there is a lack of research in the large-scale design optimization area applying MCDM to address further approximation using meta-modells. Increasing the number of input variables is one of the sources of complexity. In this situation mining the MCDM data as a preprocessing stage could make a huge difference in terms of reducing the number of input variables and minimizing the design space. This paper aims to introduce the classification task of data mining as an effective option for identifying the most effective variables of the MCDM systems. In order to evaluate the effectiveness of the proposed method an example has been given. Keywords: Design, Variables, Large Scale Systems, Multiple Criteria Decision Making, Classification

1. INTRODUCTION Optimization plays a significant role in the design cycle. Identifying the optimum solution of a real-life problem is often not possible because of the size of the problem and lack of knowledge about the variables. The solution of problems relating to more than one objective in multiple disciplines has been a challenge to engineers for a long time. Engineers are asked to solve problems with several conflicting objective functions. Modelling the problems with multiple objectives and in multiple disciplines is generally known as Multiple Criteria Decision Making (MCDM). It is a modelling tool for dealing with complex engineering problems. As MCDM is very broad most Multiobjective Optimization (MOO) problems can be classified based upon it (Kaisa, 1999). One approach of MCDM in dealing with computationally expensive and complex design evaluation models is to develop metamodells to replace the complex design modells (Egorov et al., 1999). However there is a lack of research in the area of large-scale design optimization applying MCDM to address further approximation using meta-modells. 1.1 Large Scale System of MCDM As the MCDM systems dimensions are so large (Kaisa, 1999; Grauer et al., 2004) the conventional techniques of design, modelling, analysis and optimization fail to give reasonable solutions with reasonable computational efforts; thus, according to Jamshidi, (1989), it could be classified as a Large-Scale System. MCDM has been widely utilized for

dealing with optimization and decision-making problems in different applications such as estimation and control of aerospace engineering (Zhong et al. 2009; Andrs et al. 2009), environmental systems (Andrew et al., 2006), petrochemical and refinery systems (Zhang et al., 2008), marine systems with an emphasis on safety issues (Klanac et al., 2009), power systems and modelling of economic process (Li, 2009), transportation systems (Jan et al., 2008), intelligent design and manufacturing systems (Olcer, 2007), ship design and shipping(Bouazizi et al., 2009), energy policy (Jessica et al., 2008), business system engineering (Vergidis et al., 2007), and management and resolution (Zohar et al., 2008). The complexity of such dynamic systems has many different properties but could be studied in three different parts of data scalability, structure constraints and uncertainty (Rajkumar et al., 2008). However this paper focuses upon the system scalability which is identified as the major challenge for design optimization techniques. According to Aleksandar et al. (2010) one of the most common sources of scalability in modelling the MCDM is the large and prohibitive number of variables which are employed in the design process. 2. META-MODELLING BASED MCDM Meta-modells have wide application in engineering MCDM problems (Rajkumar et al., 2008). Meanwhile Metamodelling based MCDM problems, according to the number of involved variables and objectives can be classified on a small-scale, algorithm dependent and large-scale basis. The scalability is the major challenge for MCDM (Claus, Hillermeier, 1999). As mentioned before one approach to

deal with complicated design evaluation modells of Largescale problems is to develop meta-modells to replace the expensive MCDM modells. Daniel (2006) believes that the meta-modelling approach is actually an approximation of a large scale system. Different MCDM meta-modelling based approaches including Design of Experiment (DOE) (Khoei, 2002), Response Surface (RS) (Daniel, 2006), hybrid models (Olcer, 2007) and IOSO (Egorov, 2009) are used to address different classes of multiple criterion design problems. It is observed that meta-modelling based approaches in largescale MCDM classes require significant research in developing optimization and decision-making fields (Rajkumar et al., 2008). The large number of input variables is the potential reason why designers still cant use the metamodelling approaches in the design of complex mechanical systems as effectively as others. Although meta-modelling has significant potential for optimization, scalability becomes a major weakness, especially because of the computationally expensive design evaluation. Meta-modells are able to reduce the complexity of design systems to some levels (Egorov et al., 1999) but still there is a lack of application for large-scale problems in dealing with large amounts of variables in reallife engineering problems. Large-scale problems require significant computing power and efficient algorithms such as swarm intelligence and self organizing. In order to be still able to apply the meta-modells in large scale MCDM problems there are two options assumed: (1) Grid or distributed computing approach (Grauer et al., 2004) for meta-modells implementation which can well address the complexity issues. This computing approach is able to work with more accurate modells and find ways to deal with the computational costs for large-scale optimization problems (Kere and Lento, 2005). (2)The other option which is the subject of this paper is to utilize some supportive techniques (Esmaeili and Mosavi, 2010) in order to reasonably minimize the number of system input variables in order to fit within the acceptable range of well-known MCDM packages (Egorov, 2009). 3. MCDM AND DATA MINING The field of knowledge discovery in databases, or Data Mining, has evolved in the recent past to address the problem of automatic analysis of larger amounts of data (Katharina, 2009). Data mining refers to a set of methods and techniques that can be used to extract some useful information and patterns hidden within the huge amount of data (Olson and Shi, 2005). MCDM consists of two parts, MOO and Multiple Criteria Decision Analysis (MCDA). Hence the applications of data mining in MCDM could be separately studied within the two different parts of MOO and Decision-Making (Juliang et al., 2009). The involved dataset in both MCDM branches are likely to be huge and complex. Large-scale data of MCDM problems can only be handled with the aid of computers.

Different tasks of data mining have been widely and effectively utilized in the different applications of MCDM using various modelling techniques such as neural network, decision tree and regression analysis (Katharina, 2009; Nakayama, 1995; Nakayama et al., 1984; Zitzler et al., 1999; Morse, 1980). Ehrgott (2010) believes that the Classification and Prediction tasks of data mining can effectively be applied in this regard. Juliang et al. (2009) utilized the data mining task of classification in order to handle the complexity of a huge amount of data in dealing with some real-life MCDM problems. They believe that their study has opened the door for new methods of classification based on their general model. Thus, it is necessary to introduce data mining for successfully performing MCDM projects which face a large volume of data. Data reduction in MCDM has been also widely utilized (Juliang et al. 2009; Morse, 1980) to fulfil objectives such as improving the accuracy of meta-modells, scaling the data mining models, reducing computational cost, and providing a better understanding of data. For this reason data reduction aims to select a subset of attributes which represents the concept of data without losing important information. In the proposed method of this paper (Esmaeili and Mosavi, 2010) data mining techniques are applied to the dataset of problems before the MCDM modelling process, as a preprocessing sequence in order to maintain and reduce the complexity of system in terms of input variables. 4. VARIABLES IN META-MODELLING BASED MCDM Meta-modelling tasks are applied in order to model the design space on the basis of the limited number of numerical analyses. Before any optimization can be done, the problem is supposed to be modelled first. Thus identifying all dimensions of the problem, especially the input variables, is an important task (Daniel, 2006). However in most cases the problem is not clear in terms of right input variables (Andrs, 2009; Andrew, 2006; Bouazizi, 2009). Therefore the attempt is to find the variables which have more effects upon objective functions. This would support the MCDM processes in uncertain sampled records in order to estimate the whole design space. The approach is to mine the problem's dataset including input variables and their effects on objectives. In the next subsections the recent utilized meta-modelling tasks in MCDM and the effects of the large number of variables on each task are reviewed. 4.1 DOE The DOE is an organized method for settling the relationship between variables affecting the performance of that design. The DOE can learn the behaviour of design variables and

afterward tries to deal with the complexity of design systems by approximating the whole design space (Roy, 1997). DOE explores the design space and automatically chooses the minimum set of solutions which contains the maximum amount of information. This ability helps to achieve smaller design space (Khoei, 2002). In business system engineering (Vergidis et al., 2007) and in management (Zohar et al., 2008) DOE has effectively dealt with system complexity. In their analyzing processes or basically in other similar cases the experiments are used to evaluate which inputs have more impact on the objectives, and which target level of experimented inputs might achieve a desired performance. However in large design space where lots of non-organized input variables are involved conducting experiments in all design space involves too much computational costs. In other words ranking, organizing and removing the less important variables in a supporting process framework, before setting up the DOE projects, appear to be very useful in order to reduce the size of the model. 4.2 Response Surface Models There is lots of theoretical and practical literature available in this area (Klanac et al., 2009; Daniel, 2006]. In RSM-based MCDM creating the meta-modells just on the basis of the most important variables rather than all involved variables, leads to more accurate modells of estimation. 4.3 Hybrid Systems A hybrid method tries to exploit the specific advantages of different approaches by combining more than one together. Hybrid methods are a combination of an important group of methods that have significantly contributed to the renewal of MCDM process. But still, such packages need some supports in order to make the design space as small as possible. The pre-processing of the input variables could make a huge difference in terms of computational costs. It has been observed (Olcer, 2007) that hybrid-based tools and packages are very powerful for dealing with MCDM problems. However, ranking the input variables, based on their effects on the design objectives, before utilizing any kind of hybridbased approaches could reduce the complexity and computation costs. 4.4 Indirect Optimization on the basis of Self-Organization (IOSO) IOSO technology is based on the response surface technology utilized widely in MCDM problems (Egorov, 2009). The applied strategy has higher efficiency and provides a wider range of capabilities than standard algorithms. The main advantage of IOSO technology is the ability to approximate very complicated problems, particularly including the cases when the number of points is less than the number of design variables (Egorov. et al., 1999). However because of the limitation of the MCDM packages in accepting a limited

number of input variables, the pre-processing method, presented in this paper, could work with MCDM packages such as IOSO to gain better results in terms of handling the complexity. 4.5 Case Study In an attempt to find the optimal Pareto solutions for the complex and nonlinear mathematical problem of designing the curves by MCDM, including three conflicting objectives, an IOSO-based technique has been utilized (Mosavi and Mikls, 2010). The aim was to incorporate several design objectives into a single optimization process. There were a numerous number of input variables; therefore the problem was modelled several times with a different number and different configuration of input variables. It was concluded that including or excluding some variables of the same class could make a huge difference in the modell. Therefore the preparation phase of selecting the variables should be done with special attention. This fact has motivated current research to try alternative speedy techniques, besides those of DOE tools, in order to manage the design space by classifying, identifying, ranking and removing variables based on the training datasets. 5. METHODOLOGY A data mining classification-based method for effectively and efficiently processing the massive dataset is proposed. This method has been first introduced by Esmaeili and Mosavi, (2010) to address the variable reduction in general MOO problems. Later the similar approach (Mosavi, 2010) was successfully utilized in pre-processing of an airfoil shape optimization. In this method the same prepared dataset for meta-modelling is mined right before modelling the MCDM problem. Pre-processing the dataset of MCDM makes understanding the problem easier, because it becomes possible to focus on the most important data. Applied data mining in pre-processing tries to bring together all the variables available and examine them. The proposed classification-based method studies the effect value of each design variable on the objectives. The target categorical variables which are design objectives would be defined by the numerical analysis performed by any of the Computer Aided Engineering (CAE) packages. First of all the target categorical variables according to their values and expected accuracy are partitioned into different classes. Then the classification algorithm examines the dataset which contains both the input variables and the classified target variables. Afterwards the algorithm would learn which combinations of input variables are associated with which class of target categorical variable. The achieved knowledge will deliver the training set. As the numerical simulations by most of the engineering packages are very expensive, the dataset of most Meta-

modelling based MCDM problems doesnt include the information of the whole design space. In this situation classification can work efficiently to estimate the entire design space. The workflow of proposed methodology is described in Fig.1 where the classification method is utilized in order to create several classifiers or decision trees. In the next steps the most important variables which have more effects on the objectives are selected. Regressions and model trees are constructed by a decision tree in order to build an initial tree. The splitting criterion is used to determine which variable is the better to split the portion T of the training set. Based on the treating of the standard deviation of the objective values in T, as a measure of the error, the expected reduction in error as a result of testing each variable is calculated. The variables which maximize the expected error reduction are chosen for splitting. The splitting process terminates when the objective values of the instances vary very slightly, that is, when their standard deviation has only a small fraction of the standard deviation of the original instance set. The Mean Absolute Error (MAE) and Root Mean Squared Error (RMSE) of the class probability are estimated by the algorithm output. The RMSE is the square root of the average quadratic loss and the MAE is calculated in a similar way using the absolute differences.

Fig.2. Shape of the given example Fig.2 (b) shows the thirty basic points of the surface supplied by a digitizer. The Z coordinate of the points is identified as input variables. An optimal configuration of thirty variables is supposed to satisfy the two described design objectives. In the described MCDM pre-processing the number of variables is subjected to minimization before any process takes place. Table 1. Dataset including five calculations' results

Variables Configuration : V1-V30

0,0.84,0.99,0.84,0.62,0. 26,0,-0.20,-0.40,-0.36,0.70,-0.58, 0,0.59,0.78,0.56,0.30,0, -0.21,-0.24,-0.38, 0,1,1.2,1,0.8,0.4,0.2,0,0.4,-0.48, 0.6,-0.8,-0.72,

Training set

Effective Variables Variable Selection

Dataset

Classification

CAD Model

Displacement Distribution

Fig. 1. Workflow of the proposed methodology 6. GIVEN EXAMPLE

1

Objective / target variable

O1=c O2=c

The example has been given in shape optimization with defined objectives in displacements distribution. In the similar case (YIN et al., 2008; Zhong et al., 2009) there is an attempt to utilize the MCDM approaches. In their approaches the geometry are actually input variables. However all possible variables have been involved in the optimization process ignoring the value of effects on objectives. The above MCDM modells could be more effective, accurate and less complicated if they were just created upon effective variables. In shape optimization problems input variables are naturaly in high quantity, with many of them possibly not even having any effect on system behaviour but still being included in the workflow. This fact has dramaticaly increased the meta-modell size. The shape Fig.2 part (a) is subjected to optimization. The shape needs to be optimized in order to deliver minimum displacement in terms of applied pressure on the surface according to the following objectives. Objective 1 (O1): Minimizing the displacements distribution on the shape for the constant pressure value of . Objective 2 (O2): Minimizing the displacements distribution on the shape for the constant pressure value of 2.

0.62,-0.81,-0.70, 0,0.86,0.1,0.82,0.60,0.2 5,0.01,-0.20,-0.39,0.39,-0.70,-0.58, 0,0.58,0.76,0.57,0.32,0, . -0.21,-0.23,-0.37, 2 0,1.1,1.21,.9,0.82,0.42,0 .18,.1,-0.41,-0.46,-

O1=b O2=c

0.72, 0,.88,0.99,0.84,0.62,0.2 6,0,-0.23,-0.35,-0.37,3 0.70,-0.54, 0,0.58,0.76,0.58,0.31,0, -0.23,-0.23,-0.37, 0,1,1.2,1,0.8,0.4,0.2,0,0.4,-0.48,-0.6,-0.8,0.6,-0.8,0.78,0,0.84,.92,0.84,0.6 2,0.26,0,-0.23,-0.39,0.37,-0.70,0.54,0,0.58,0.76,0.58,0. 4 31,0,-0.24,-0.22,-0.36, 0,1.3,1.23,1.06,0.83,0.4 1,0.28,0.07,-0.41,-0.48, 0.59,-0.79,-0.69, 0,0.80,1.01,0.86,0.64,0. 26,-0.01,-0.20,-0.40,0.40,-0.72,-0.56, 0,0.58,0.76,0.58,0.31,0, -0.23,-0.23,-0.37, 0,1.01,1.21,1,0.8,0.4,0.2 1,0-0.41,-0.47,

O1=b O2=c

O1= c O2= d

O1=c O2=a

In the given example the target categorical variable is the value of Displacements Distribution calculated according to numerical analyses done by ANSYS. It is classified according to the four classes of a, b, c and, d. The dataset including the five sets of geometrical and numerical analyses are given in table.1. The data mining classifier package of Weka (Esmaeili and Mosavi, 2010) has provided dataset implementations, training sets and learning algorithms. Note that Weka includes methods for all the standard data mining problems such as regression and classification which are necessary for the proposed approach. Weka also includes many data visualization facilities and data pre-processing tools. One algorithm of WEKA, the BFTree, is chosen to search the whole design space for the input variables where there is no record of target categorical variables. Based on the classifications in the training set, the algorithm would be able to classify these records as well. The intention in Metamodelling based optimization problems due to costly numerical analyses is to run minimum simulation runs as much as possible in order to obtain a less complicated system. Thus in the given example there was an attempt to minimize the number of simulations to five calculations. 6.1 Results

classification pre-processing the expected number of variables could be arranged. For the given example we were expecting more than a 50% reduction in design space for the errors available in table.2. 7. CONCLUSIONS In this paper, we performed the MCDM project based on data mining task classification for pre-processing in order to reduce the complexity of the system. Data mining increased the project performance as a supportive system in MCDM problems. With the aid of data mining the complexity in terms of the number of input variables has been reduced by more than 50%. The classification task of data mining has been introduced as an effective option for identifying the most effective variables involved in the MCDM systems. The classification algorithm of BFTree was utilized analyzing the effect of each design variable on the identified objectives. The number of optimization variables has been effectively managed and reduced in the given example. The modified methodology has been successfully demonstrated in this framework. The author believes that the process is simple and fast. It is evident that the growing complexity of MCDM systems could be handled by a preprocessing step utilizing data mining classification tools. For future work, studying the effectiveness of the introduced data reduction process in different applications is suggested. Also trying to use the other tasks of data mining such as clustering and association could produce beneficial results. Acknowledgments Author would like to thank his supervisors; Professor Nagy Pter Tibor, Professor Mikls Hoffmann. The language of this paper was reviewed by Daniel Haitas.

The obtained results from pre-processing are available in table.2. Six variables out of thirty have been selected having more effects upon O1 and seven variables that have more effects upon O2. Two types of classification error (MAE, RMSE) are shown for the utilized algorithm corresponding to different classes of objectives. Experiments show that the obtained results are not very sensitive to the exact choice of these thresholds.

Table 2. Identified effective variables

MAE RMSE Effective Variables Objectives

Classification Algorithm

REFERENCES Andrs, Sz., Miroslav md and Jaroslav Hjek. (2009). Aerodynamic Optimization via multi-objective microgenetic algorithm with range adaptation, knowledgebased reinitialization, Advances in Engineering Software 40 P.419430 Andrew, Higgins, J., Stefan Hajkowicz and Elisabeth Bui, (2006). A multiobjective model for environmental investment decision making,Computers & Operations Research 35 P.253 266 Aleksandar, I. Zecevic, Dragoslav, D. and iljak. (2010). Control of Complex Systems Structural Constraints and Uncertainty, Springer New York Dordrecht Heidelberg London. Bouazizi, M.-L., Ghanmi, S. and N.Bouhaddi, (2009). Multiobjective optimization in dynamics of the structures with nonlinear behavior: Contributions of the

BFTree

0.277 0.604

0.500 0.769

15,24,2,32,41,39, 23,22,18,15,42,2, 4

O1 O2

The whole pre-processing was done within two minutes on a Pentium IV 2.4 MHZ Processor. The variables were reduced by more than 50%. The dataset for the given MCDM problem have been pre-processed and effective variables have been identified. With the results of the pre-processing analyses presented in table.2 the problem has became much clear in terms of variable and objective interactions. The new created design space based on the new sets of variables listed in table.2 is much smaller, which would make the further Meta-modelling based MCDM much easier in terms of complexity. By adjusting the MAE and RMSE in each

metamodels, Finite Elements in Analysis and Design 45 P. 612 623. Claus, Hillermeier. (1999). nonlinear multiobjective optimization: a generalized homotopy approach, Birkhuser Verlag, 2001. Kaisa Miettinen, Nonlinear multiobjective optimization, Springer-Verlag, Berlin. Daniel, B. Marjavaara (2006). CFD Driven Optimization of Hydraulic Turbine Draft Tubes using Surrogate Models, doctoral thesis, Lulea University of TechnologyDepartment of Applied Physics and Mechanical EngineeringDivision of Fluid Mechanics, Lulea, Sweden. Esmaeili, M.and Mosavi, A. (2010). Variable Reduction for MultiObjective Optimization Using Data Mining Techniques; Application to Aerospace Structures, IEEE Proc. of international conf. on Mechanical and Aerospace Engineering. Egorov, N., Kretinin, G. V Leshchenko, I. A. and Babiy, Y. I. (1999). Optimization of complex engineering systems using variable-fidelity models, MCB University Press, ISBN: 0-86176-650-4, Proceedings of the 1st ASMO UK/ISSMO conference on Engineering Design Optimization, pp.143-149. Ehrgott, M. (2010) Multiple Criteria Decision Making for Sustainable Energy and Transportation Systems, Lecture Notes in Economics and Mathematical Systems 634, Springer Physica-Verlag Berlin Heidelberg. Egorov, N. Indirect Optimization on the Basis of SelfOrganization (IOSO), http://www.iosotech.com/ioso_tech.htm, (accessed Nov 7, 2009. Grauer, M. Barth, T. and Thilo, F. (2004). Grid-based Computing for Multidisciplinary Analysis and Optimization, in: Collection of Technical Papers-10th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, August 30September 1, American Institute of Aeronautics and Astronautics Inc., Reston, VA, USA: pp. 17441753. Jamshidi, M. (1989). Introduction to Large-Scale Systems, Chapter 6 in Simulation of Dynamic Systems. N. Kheir (ed.) Marcel Dekker, New York. Juliang, Zhang., Yong Shi and Peng Zhang. (2009). several multi-criteria programming methods for classification, Computers & Operations Research 36 823 836. Kaisa, M. Miettinen. (1999) Nonlinear Multiobjective Optimization, Kluwer Academic Publishers. Kere, P. and Lento, J. (2005). Design Optimization of Laminated Composite Structures Using Distributed Grid Resources. Composite Structures 71(34):435 438. Klanac, Alan., Ehlers, Soren. and Jasmin, Jelovica.(2009). Optimization of Crashworthy marine structures", Marine Structures, Vol.22, No.5, p. 670690. Katharina, witkowski. (2009) Data mining and visualization of Pareto", 7th European LS-DYNA conference proceeding. Khoei, AR. Masters. I. and Gethin, DT. (2002). Design Optimization of Aluminum Recycling Processes Using Taguchi Technique. Journal of Materials Processing Technology 127(1):96106.

Morse, N. (1980). Reducing the size of the nondominated set: Pruning by clustering. Computers and Operations Research, Vol.7, No.12, pp.5566. Mosavi, A. (2010). Multiple Criteria Decision-Making Preprocessing; Using Data Mining Tools, IJCSI

International Journal of Computer Science Issues, Vol. 7, Issue 2. P.143-151.

Mosavi, A. and Mikls, Hoffmann. (2010). Design of curves by multicriteria optimization; Utilizing IOSO packages, a technical report, university of Debrecen faculty of informatics, Debrecen, Hungary. Nakayama, H. (1995). Aspiration level approach to interactive multiobjective programming and its applications". In P. M. Pardalos, Y. Siskos, and C. Zopounidis, editors, Advances in Multicriteria Analysis, Kluwer Academic Publishers, Dordrecht. Nakayama, H. and Y. Sawaragi. (1984)."Satisficing trade-off method for multiobjective programming". In M. Grauer and A. P. Wierzbicki, editors, Interactive Decision Analysis, Springer- Verlag, Berlin. Olcer, A.I. (2007). A hybrid approach for multi-objective combinatorial optimization problems in ship design and shipping, Computers & Operations Research 35 P.2760 277. Olson, D. and Shi, Y. (2005).Introduction to business data mining, New York: McGraw-Hill/Irwin. Roy, R. (1997). Adaptive Search and the Preliminary Design of Gas Turbine Blade Cooling System, PhD Thesis, University of Plymouth. Rajkumar. Roy. Srichand, Hinduja. and Roberto Teti. (2008). recent advances in engineering design optimisation: Challenges and future trends, CIRP Annals Manufacturing Technology 57 p.697715. Vergidis, K. Tiwari, A. Majeed, B. and Roy, R. (2007). Optimisation of business process designs: An algorithmic approach with multiple objectives, Int. J. Production Economics 109 105121. YIN Bo, XUD. and ANY. (2008). Aerodynamic optimization of 3D wing based on iSIGHT, Appl. Math. Mech. Engl. Ed, Vol.5 ,pp. 603610. Zitzler, E. and Thiele, L. (1999). Multiobjective evolutionary algorithms: A comparative case study and the strength Pareto approach. IEEE Transactions on Evolutionary Computation, Vol.3, No4, pp.257271. Zhang, J.D. and Rong, G. (2008). An MILP model for multiperiod optimization of fuel gas system scheduling in refinery and its marginal value analysis, chemical engineering research and design 86 p. 141 151. Zhong Xiaopinga, Ding Jifengb, Li Weijia and Zhang Yongc, (2009). Robust Airfoil Optimization with Multiobjective Estimation of Distribution Algorithm Chinese Journal of Aeronautics 21 p. 289-295. Zohar Laslo, Albert, I. and Goldberg. (2008). Resource allocation under uncertainty in a multi-project matrix environment: Is organizational conflict inevitable? International Journal of Project Management 26 P. 773 788.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

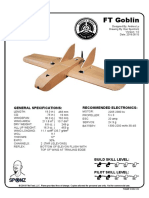

- FT Goblin Full SizeDocument7 pagesFT Goblin Full SizeDeakon Frost100% (1)

- Calc Fields Networking and Sharing: Welcome ToDocument42 pagesCalc Fields Networking and Sharing: Welcome Toprashant adhikariNo ratings yet

- Digital Booklet - Bach ConcertosDocument14 pagesDigital Booklet - Bach Concertosppopgod33% (3)

- Individual Differences: Mental Ability, Personality and DemographicsDocument22 pagesIndividual Differences: Mental Ability, Personality and DemographicsAlera Kim100% (2)

- Overhead Door Closers and Hardware GuideDocument2 pagesOverhead Door Closers and Hardware GuideAndrea Joyce AngelesNo ratings yet

- ContactsDocument10 pagesContactsSana Pewekar0% (1)

- Trinath Chigurupati, A095 576 649 (BIA Oct. 26, 2011)Document13 pagesTrinath Chigurupati, A095 576 649 (BIA Oct. 26, 2011)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Identifying Most Suitable Priority Areas For Soil-Water Conservation Using Coupling Mechanism in Guwahati Urban WatershedDocument35 pagesIdentifying Most Suitable Priority Areas For Soil-Water Conservation Using Coupling Mechanism in Guwahati Urban WatershedAmir MosaviNo ratings yet

- Comparative Analysis of Artificial Intelligence Models For Accurate Estimation of Groundwater Nitrate ConcentrationDocument23 pagesComparative Analysis of Artificial Intelligence Models For Accurate Estimation of Groundwater Nitrate ConcentrationAmir MosaviNo ratings yet

- Algorithms: COVID-19 Outbreak Prediction With Machine LearningDocument36 pagesAlgorithms: COVID-19 Outbreak Prediction With Machine LearningAradhana MehraNo ratings yet

- Large Electromagnetic Field Enhancement in Plasmonic Nanoellipse For Tunable Spaser Based ApplicationsDocument23 pagesLarge Electromagnetic Field Enhancement in Plasmonic Nanoellipse For Tunable Spaser Based ApplicationsAmir MosaviNo ratings yet

- Principal Component Analysis To Study The Relations Between The Spread Rates of COVID-19 in High Risks CountriesDocument8 pagesPrincipal Component Analysis To Study The Relations Between The Spread Rates of COVID-19 in High Risks CountriesAmir MosaviNo ratings yet

- International Journal of Sediment ResearchDocument12 pagesInternational Journal of Sediment ResearchAmir MosaviNo ratings yet

- Fuzzy Logic Model To Assess Desertification Intensity Based On Vulnerability IndicesDocument18 pagesFuzzy Logic Model To Assess Desertification Intensity Based On Vulnerability IndicesAmir MosaviNo ratings yet

- A Non-Singleton Type-3 Fuzzy Modeling: Optimized by Square-Root Cubature Kalman FilterDocument33 pagesA Non-Singleton Type-3 Fuzzy Modeling: Optimized by Square-Root Cubature Kalman FilterAmir MosaviNo ratings yet

- Machine Learning Information Fusion in Earth Observation: A Comprehensive Review of Methods, Applications and Data SourcesDocument17 pagesMachine Learning Information Fusion in Earth Observation: A Comprehensive Review of Methods, Applications and Data SourcesAmir MosaviNo ratings yet

- Voltage Regulation For Photovoltaics-Battery-Fuel Systems Using Adaptive Group Method of Data Handling Neural Networks (GMDH-NN)Document10 pagesVoltage Regulation For Photovoltaics-Battery-Fuel Systems Using Adaptive Group Method of Data Handling Neural Networks (GMDH-NN)Amir MosaviNo ratings yet

- Fractional-Order Fuzzy Control Approach For Photovoltaic/Battery Systems Under Unknown Dynamics, Variable Irradiation and TemperatureDocument19 pagesFractional-Order Fuzzy Control Approach For Photovoltaic/Battery Systems Under Unknown Dynamics, Variable Irradiation and TemperatureAmir MosaviNo ratings yet

- Develop Lattice Boltzmann Method and Its Related Boundary Conditions Models For The Benchmark Oscillating Walls by Modifying Hydrodynamic and Thermal Distribution FunctionsDocument18 pagesDevelop Lattice Boltzmann Method and Its Related Boundary Conditions Models For The Benchmark Oscillating Walls by Modifying Hydrodynamic and Thermal Distribution FunctionsAmir MosaviNo ratings yet

- Machine Learning For Modeling The Singular Multi-Pantograph EquationsDocument18 pagesMachine Learning For Modeling The Singular Multi-Pantograph EquationsAmir MosaviNo ratings yet

- Yicheng Li Iman Moradi Mahdi Kalantar Elmira Babadi Omid Malekahmadi Amirhosein MosaviDocument17 pagesYicheng Li Iman Moradi Mahdi Kalantar Elmira Babadi Omid Malekahmadi Amirhosein MosaviAmir MosaviNo ratings yet

- Incorporation of Horizontal Fins Into A PCM-Based Heat Sink To Enhance The Safe Operation Time: Applicable in Electronic Device CoolingDocument15 pagesIncorporation of Horizontal Fins Into A PCM-Based Heat Sink To Enhance The Safe Operation Time: Applicable in Electronic Device CoolingAmir MosaviNo ratings yet

- SensorsDocument27 pagesSensorsAmir MosaviNo ratings yet

- Nonlinear Model Identification of Dissimilar Laser Joining of S.S 304 and ABS Using The Hammerstein-Wiener MethodDocument9 pagesNonlinear Model Identification of Dissimilar Laser Joining of S.S 304 and ABS Using The Hammerstein-Wiener MethodAmir MosaviNo ratings yet

- Evaluating The E Decision Tree, and Bayesian Machine Learning Algorithms in Spatial Piping Erosion Susceptibility Using ALOSDocument22 pagesEvaluating The E Decision Tree, and Bayesian Machine Learning Algorithms in Spatial Piping Erosion Susceptibility Using ALOSAmir MosaviNo ratings yet

- Fuzzy Clustering To Classify Several Time Series Models With Fractional Brownian Motion ErrorsDocument9 pagesFuzzy Clustering To Classify Several Time Series Models With Fractional Brownian Motion ErrorsAmir MosaviNo ratings yet

- Boiling of Argon Flow in A Microchannel by Considering The Spherical Geometry For Roughness Barriers Using Molecular Dynamics SimulationDocument12 pagesBoiling of Argon Flow in A Microchannel by Considering The Spherical Geometry For Roughness Barriers Using Molecular Dynamics SimulationAmir MosaviNo ratings yet

- Predicting Soil Electrical Conductivity Using Multi-Layer Perceptron Integrated With Grey Wolf OptimizerDocument10 pagesPredicting Soil Electrical Conductivity Using Multi-Layer Perceptron Integrated With Grey Wolf OptimizerAmir MosaviNo ratings yet

- The Molecular Dynamics Simulation of Thermal Manner of Ar/Cu Nanofluid Flow: The Effects of Spherical Barriers SizeDocument9 pagesThe Molecular Dynamics Simulation of Thermal Manner of Ar/Cu Nanofluid Flow: The Effects of Spherical Barriers SizeAmir MosaviNo ratings yet

- The Molecular Dynamics Simulation of Thermal Manner of Ar/Cu Nanofluid Flow: The Effects of Spherical Barriers SizeDocument8 pagesThe Molecular Dynamics Simulation of Thermal Manner of Ar/Cu Nanofluid Flow: The Effects of Spherical Barriers SizeAmir MosaviNo ratings yet

- Powder Technology: Amirhosein Mosavi, Shahab Naghdi Sedeh, Davood Toghraie, Aliakbar KarimipourDocument9 pagesPowder Technology: Amirhosein Mosavi, Shahab Naghdi Sedeh, Davood Toghraie, Aliakbar KarimipourAmir MosaviNo ratings yet

- Atomic Interactions Between Rock Substrate and Water-Sand Mixture With and Without Graphene Nanosheets Via Molecular Dynamics SimulationDocument8 pagesAtomic Interactions Between Rock Substrate and Water-Sand Mixture With and Without Graphene Nanosheets Via Molecular Dynamics SimulationAmir MosaviNo ratings yet

- Detection and Prediction of Lake Degradation Using Landscape Metrics and Remote Sensing DatasetDocument17 pagesDetection and Prediction of Lake Degradation Using Landscape Metrics and Remote Sensing DatasetAmir MosaviNo ratings yet

- Detection and Prediction of Lake Degradation UsingDocument1 pageDetection and Prediction of Lake Degradation UsingAmir MosaviNo ratings yet

- Comprehensive Review of Deep ReinforcementLearning Methods and Applications in EconomicsDocument42 pagesComprehensive Review of Deep ReinforcementLearning Methods and Applications in EconomicsAmir MosaviNo ratings yet

- Groundwater Salinity Susceptibility Mapping Using Classifier Ensemble and Bayesian Machine Learning ModelsDocument13 pagesGroundwater Salinity Susceptibility Mapping Using Classifier Ensemble and Bayesian Machine Learning ModelsAmir MosaviNo ratings yet

- Water 12 01995 v3 PDFDocument17 pagesWater 12 01995 v3 PDFIrland FardaniNo ratings yet

- Chapter 3: Elements of Demand and SupplyDocument19 pagesChapter 3: Elements of Demand and SupplySerrano EUNo ratings yet

- Distribution of Laptop (Ha-Meem Textiles Zone)Document3 pagesDistribution of Laptop (Ha-Meem Textiles Zone)Begum Nazmun Nahar Juthi MozumderNo ratings yet

- Green Management: Nestlé's Approach To Green Management 1. Research and DevelopmentDocument6 pagesGreen Management: Nestlé's Approach To Green Management 1. Research and DevelopmentAbaidullah TanveerNo ratings yet

- Credentials List with Multiple Usernames, Passwords and Expiration DatesDocument1 pageCredentials List with Multiple Usernames, Passwords and Expiration DatesJOHN VEGANo ratings yet

- Gary Mole and Glacial Energy FraudDocument18 pagesGary Mole and Glacial Energy Fraudskyy22990% (1)

- ABBBADocument151 pagesABBBAJeremy MaraveNo ratings yet

- Sapkale Sandspit 2020Document5 pagesSapkale Sandspit 2020jbs_geoNo ratings yet

- Keya PandeyDocument15 pagesKeya Pandeykeya pandeyNo ratings yet

- As 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsDocument6 pagesAs 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsSAI Global - APACNo ratings yet

- De Thi Chuyen Hai Duong 2014 2015 Tieng AnhDocument4 pagesDe Thi Chuyen Hai Duong 2014 2015 Tieng AnhHuong NguyenNo ratings yet

- Yamaha Nmax 155 - To Turn The Vehicle Power OffDocument1 pageYamaha Nmax 155 - To Turn The Vehicle Power Offmotley crewzNo ratings yet

- Nature and Effects of ObligationsDocument5 pagesNature and Effects of ObligationsIan RanilopaNo ratings yet

- Debentures Issued Are SecuritiesDocument8 pagesDebentures Issued Are Securitiesarthimalla priyankaNo ratings yet

- Emperger's pioneering composite columnsDocument11 pagesEmperger's pioneering composite columnsDishant PrajapatiNo ratings yet

- Philippine Architecture, Film Industry EvolutionDocument4 pagesPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelNo ratings yet

- Impact of Coronavirus On Livelihoods of RMG Workers in Urban DhakaDocument11 pagesImpact of Coronavirus On Livelihoods of RMG Workers in Urban Dhakaanon_4822610110% (1)

- Abb Drives: User'S Manual Flashdrop Mfdt-01Document62 pagesAbb Drives: User'S Manual Flashdrop Mfdt-01Сергей СалтыковNo ratings yet

- Max 761 CsaDocument12 pagesMax 761 CsabmhoangtmaNo ratings yet

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarDocument2 pagesOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossNo ratings yet

- Module 5Document10 pagesModule 5kero keropiNo ratings yet

- Applicants at Huye Campus SiteDocument4 pagesApplicants at Huye Campus SiteHIRWA Cyuzuzo CedricNo ratings yet

- An Overview of National Ai Strategies and Policies © Oecd 2021Document26 pagesAn Overview of National Ai Strategies and Policies © Oecd 2021wanyama DenisNo ratings yet

- 7th Kannada Science 01Document160 pages7th Kannada Science 01Edit O Pics StatusNo ratings yet