Professional Documents

Culture Documents

Propuesta ORC Capstone

Uploaded by

lafmv90Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Propuesta ORC Capstone

Uploaded by

lafmv90Copyright:

Available Formats

REF.

2013-0005

Bogot D.C., Febrero 12 de 2013 Seores JHM CONSULTORIA Atn.: ANTONIO CUARTAS Bogot

Ref: 2013-0005 Equipos de Generacin ORC (Organic Rankine Cycle)

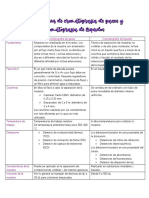

Estimado Ing. Antonio, Adjunto a la presente estamos enviando la informacin tcnica del equipo CC125 producido por nuestro representado Capstone Turbine Corporation para la generacin de energa a partir del calor residual de procesos industriales o de generacin de energa. De acuerdo con la informacin suministrada por ustedes sobre el sistema de generacin de energa que se encuentra instalado y operando en Leticia hemos hecho un anlisis preliminar para establecer cul sera el potencial de generacin a partir de la energa residual disponible con los siguientes parmetros: Altura sobre el nivel del mar Temperatura promedio Temperatura de condensacin 80 metros 30 C 27 C 367 C 23,8 m3/seg (1.428 m3/min)

Temperatura de entrada de los gases de combustin Volumen de gases de combustin

Al hacer una simulacin de operacin con los siguientes parmetros de salida: Temperatura de salida de los gases de combustin Cargas parasticas del sistema 196 C 20 kW

Hemos llegado a la conclusin que se podran instalar dos equipos Ref. CC125 que estaran en capacidad de generar 200 kW netos de entrega. Se estima que el costo por unidad de este equipo (suponiendo algunos costos de instalacin que debern ser confirmados mediante una ingeniera conceptual y luego afinados con una ingeniera de detalle) debe estar en 600.000 dlares americanos por unidad. Para concretar la ingeniera conceptual se requiere hacer una visita al sitio de la instalacin para verificar los parmetros bsicos del modelo y validar los costos estimados y los requerimientos de la instalacin. El costo de realizar esta visita ser cubierto por ustedes en trminos de traslado y alojamiento. Una vez aprobada la ingeniera conceptual se debe proceder con la ingeniera de detalle. El costo de esta ingeniera es de 25.000.000 de pesos mas IVA, que sern abonados al costo de suministro e instalacin del equipo si el proyecto efectivamente se ejecuta. Esperamos contar con su inters y aprobacin para proceder a programar la visita de campo y poder afinar el presupuesto para el suministro del sistema.

REF. 2013-0005

Quedamos a su disposicin para resolver cualquier duda que pueda haber respecto del sistema ofrecido. Cordial saludo,

NESTOR MOSERES DIEPPA Gerente General SUPERNOVA ENERGY SERVICES

Capstone Clean Cycle 125kW Waste Heat to Electricity Generator

The Capstone Clean Cycle waste heat-to-electricity generator uses an Organic Rankine Cycle to capture normally wasted heat from a wide range of sources, turning excess heat into clean-and-green electricity while raising the net efficiency of your system. Advanced power electronics and a sophisticated integrated power module join oil-free, low maintenance magentic bearings and non-ozone depleting refrigerant to achieve highly-efficient thermal energy-to-power output while still respecting the environment.

Capstone Clean Cycle 125kW

The compact, skid systems fundamental components include: Power Electronics: Next-generation design turns high-frequency output into utility-friendly power without the need of expensive capacitors Self-Centering Magnetic Bearings: No oil and low maintenance translates to minimal downtime Integrated Power Module: High speed turbine expander with highly-efficient alternator is sealed in one small unit with only one moving part Environmentally Responsible: Safe, ozone-friendly refrigerant

The Capstone Clean Cycle 125kW waste-heat to electricity generator is one of the components in the Capstone C500 Clean Cycle HE System.

Features and Benefits

Proven Organic Rankine Cycle (ORC) Technology with zero emissions Flexible heat-temperature input from as low as 250F (121C) Ease of synchronization with local utility Ready-to-integrate and efficiently desgined with minimal footprint Highly reliable with only nominal maintanence and ownership costs Only one moving part and no gearbox in the integrated power module avoids expensive upkeep Magnetic bearings need no oil or lubricants The ORC utilizes a PLC-based control system, offering easier integration with customer monitoring and plant management systems Remote Monitoring and diagnostic capabilities with web-based gateway Flexibly designed for both local and remote control Ability to capture heat from many systems including engines, boilers, solar thermal installations, industrial heat stacks, and microturbines

Reliable power when and where you need it. Clean and simple.

Pressurized Hot Water to Power(1) (2)

Waste Heat Conditions Inlet Temperature Outlet Temperature Input Energy Flow Rate 290F (143.3C) 260F (126.7C) 3,340,000 BTU/hr (980kW) 119,555 lbm/hr (54,343 kg/hr)

Condensing @ ISO Ambient: 59F (15C) 60% RH Condensing Temperature Condensing Load 70F (21C) 2,800,000 BTU/hr (821kW)

Saturated Steam to Power(1) (3)

Temperature Pressure Flow 255F (124C) 32 psia (220.6 kPa) 3,692 lbm/hr (1,678 kg/hr)

Hot Gases to Power(1) (2) (4) (5)

Gas temperature needed for power output of 125kWe

Hot Gas Inlet Temperature 400F (204C) 500F (260C) 600F (315.6C) 700F (371.1C) 800F (426.7C) 900F (482.2C)

Hot Gas Flow Rate 150,000 lbm/hr (68,182 kg/hr) 75,000 lbm/hr (34,091 kg/hr) 49,500 lbm/hr (22,500 kg/hr) 36,900 lbm/hr (16,773 kg/hr) 29,250 lbm/hr (13,295 kg/hr) 24,250 lbm/hr (11,023 kg/hr)

Cycle Overview

Power Skid

Heat Input Evaporator

Integrated Power Module Receiver Evaporative Condenser Pump

Economizer

(1) Electrical output gross is 125kWe (2) Waste heat conditions: exhaust gas temperature reduced to 275F (135C) with condensing temperature of 70F (21.1C) (3) Waste heat operating conditions: no superheat in steam included. Condensing temperature of 70F (21C) and heat exchanger 95% efficient (4) Assumed exhaust gas Cp=0.25 BTU/lbm F (1.05kJ/kg C) (5) Heat exchanger 95% efficient Specifications are not warranted and are subject to change without notice.

21211 Nordhoff Street Chatsworth CA 91311 866.422.7786 818.734.5300 www.capstoneturbine.com

2011 Capstone Turbine Corporation. P0411 Capstone Clean Cycle 125kW Data Sheet CAP167 | Capstone P/N 331062A

You might also like

- Informe SueloDocument4 pagesInforme Suelolafmv90No ratings yet

- Sanidad Animal en Ganado de CarneDocument10 pagesSanidad Animal en Ganado de Carnelafmv90No ratings yet

- Presentación 1Document20 pagesPresentación 1lafmv90No ratings yet

- MineriaDocument2 pagesMinerialafmv90No ratings yet

- Destilación Simple y FraccionadaDocument10 pagesDestilación Simple y FraccionadaCindy MuñozNo ratings yet

- 05 FosforoDocument1 page05 FosforocarlosmcdNo ratings yet

- Medidores de TemperaturaDocument4 pagesMedidores de Temperaturamarco antonioNo ratings yet

- Aleaciones Polimeros CeramicosDocument5 pagesAleaciones Polimeros CeramicosEEEDDDOOONo ratings yet

- Examenes FisqmcDocument7 pagesExamenes FisqmcNancy Gabriela Avalos PérezNo ratings yet

- Reacciones químicas: Magnesio, ácido clorhídrico y NaOHDocument12 pagesReacciones químicas: Magnesio, ácido clorhídrico y NaOHBrayan GamboaNo ratings yet

- Determinación de constantes de acididad de H3PO4Document20 pagesDeterminación de constantes de acididad de H3PO4Anonymous 28dbytNo ratings yet

- Biomoléculas y bioelementos esencialesDocument5 pagesBiomoléculas y bioelementos esencialesEugenia MirabalNo ratings yet

- Balotario 3 1Document10 pagesBalotario 3 1Luis AntonioNo ratings yet

- Destilación continua 40Document2 pagesDestilación continua 40Valeria Malca Hernandez100% (1)

- Presion VaporDocument4 pagesPresion VaporHAPINESS28No ratings yet

- VolatilizaciónDocument1 pageVolatilizaciónJhancarlos MartínezNo ratings yet

- Cuestionario de Reversibilidad Jair Castillo 6ADocument3 pagesCuestionario de Reversibilidad Jair Castillo 6AJair CastilloNo ratings yet

- Tratamiento Catalítico de Efluentes GaseososDocument23 pagesTratamiento Catalítico de Efluentes GaseososorlandoaguilarNo ratings yet

- 08 0988 QDocument144 pages08 0988 Q4lvar0No ratings yet

- Aletas Con Extremo AdiabáticoDocument17 pagesAletas Con Extremo AdiabáticoCesarEspinosaLizNo ratings yet

- Ley de Enfriamiento de NewtonDocument4 pagesLey de Enfriamiento de Newtonerika johana VelasquezNo ratings yet

- Cromatografía de gases vs líquidosDocument2 pagesCromatografía de gases vs líquidosJanette Villalpando100% (1)

- Ecuación de BernoulliDocument5 pagesEcuación de Bernoullijalexanderc100% (2)

- 3ra OLIMPIADA CIENTÍFICA ESTUDIANTIL PLURINACIONAL BOLIVIANADocument2 pages3ra OLIMPIADA CIENTÍFICA ESTUDIANTIL PLURINACIONAL BOLIVIANALr FrNo ratings yet

- Practicas de LaboratorioDocument7 pagesPracticas de Laboratoriohector chavezNo ratings yet

- Semiconductor Tipo PDocument2 pagesSemiconductor Tipo PDaniel CumanichoNo ratings yet

- Ladrillos RefrigerantesDocument12 pagesLadrillos Refrigerantesgabriela de la rosa aviñaNo ratings yet

- Control Monitoreo GasesDocument6 pagesControl Monitoreo GasesAmaranteCaqueoLemaNo ratings yet

- RG5410A - EspañolDocument15 pagesRG5410A - EspañoljhonnyNo ratings yet

- Diseño de Una Planta Que Captura CO2Document75 pagesDiseño de Una Planta Que Captura CO2Nidia BatallanosNo ratings yet

- Fabricación anilina nitrobencenoDocument4 pagesFabricación anilina nitrobencenoKimberly Luna NolascoNo ratings yet

- AttachmentDocument16 pagesAttachmentFrancis PalmaNo ratings yet

- Examén U-III Operaciones Transf Masa Ene Jun 2021 ProblemasDocument23 pagesExamén U-III Operaciones Transf Masa Ene Jun 2021 ProblemasAreli HernándezNo ratings yet

- TERMOQUIMICADocument20 pagesTERMOQUIMICAMerinoAlvan75% (8)