Professional Documents

Culture Documents

61 105 1 PB

Uploaded by

slv_prasaadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

61 105 1 PB

Uploaded by

slv_prasaadCopyright:

Available Formats

ISSN: 2278 7798 International Journal of Science, Engineering and Technology Research (IJSETR) Volume 1, Issue 5, November 2012

Emission and Performance of Diesel Engine Using Karanja BioDiesel A Critical Review

1

. S.C.V.Ramana Murty Naidu*

. G.Raju

.D.Srinivasulu

1,2,3-Department of Mechanical Engineering, Kallam Haranadha Reddy Institute of Technology, Guntur, Andhra Pradesh.

Abstract

This paper presents a brief review on the Karanja (Pongamia Pinnata) biodiesel emission and its performance characteristics as Diesel engine fuel. Biodiesel is the name of a clean burning alternative fuel produced from domestic, renewable resources. It contains no petroleum, but it can be blended at any level with Diesel to create a biodiesel blend. It can be used in Diesel engines with no modifications. It is simple to use biodegradable, non toxic and essentially free of sulphur and aromatics. Based on the research reports, it is concluded that vegetable oils, either chemically altered or blended with Diesel to prevent the engine failure. It was reported that the combustion characteristics of biodiesel are similar to Diesel. Power out put of engine was found to be equivalent to that of Diesel fuel. CO, NOx and HC are with in maximum limits that safer use as an alternative fuel. Key words: Karanja biodiesel, Diesel engine, emissions and performance. 1. Introduction: During last decade India has maintained a high growth rate in accepting the improved technological challenges in global scenario. India ranks 6th in the world in terms of energy demand accounting for 3.5% of world commercial energy demand in 2001. The energy demand is expected to grow at 4.8%. The demand of Diesel is projected to grow from 39.81 million metric tons in 2001-02 to 52.32 million metric tons in 2006-07 at 5.5%

per annum. Also due to gradual depletion of the world petroleum reserve, rising petroleum prices, increasing threat to the environment from exhaust emission and global warming have generated an intense international intrest in developing alternative non petroleum fuels [1].The purpose of transesterification process is to decrease the oil viscosity. Major problems of vegetable oil as biodiesel are their high viscosity and low volatility, which causes improper combustion in C.I.engines. The conversion of the vegetable oil as a C.I.engine fuel can be done by transesterification process. This process reduces the viscosity to a value comparable to that of Diesel and hence improves combustion.

All Rights Reserved 2012 IJSETR

102

ISSN: 2278 7798 International Journal of Science, Engineering and Technology Research (IJSETR) Volume 1, Issue 5, November 2012 g/KW-hr).It is an indication of the complete combustion of biodiesel being an oxygenated fuel. The shorter ignition delay associated with biodiesel higher Cetane number could also reduce the over mixed fuel which is the primary source of UBHC. For B20 the maximum & minimum HC produced is 0.02 g/KW-hr & 0.004 g/KW-hr, which is around same as that is mentioned in EURO-IV norms (Maximum 0.02 g/KW-hr).For B20 blend the percentage increase of CO2 for maximum & minimum load is 3.8& 3.75. This increase in percentage is may be due to complete combustion of the fuel. For Diesel engine the minimum & maximum exhaust temperature is 1200 C & 2600 C, where as for B20, it is found to be 810 C & 2160 C. The injection timing advancement associated with these effects could be partially responsible for the increase in NOx emissions. For B20 blend the maximum & minimum NOx produced is 0.04 g/KW-hr & 0.002 g/KW-hr, which is much less than mentioned in EURO-IV norms (Maximum 3.5 g/KW-hr). Raheman and Phadatare [3] tested Karanja Methyl Ester (KME) and its blends with Diesel from 20% to 80% by volume in a single cylinder D.I. Diesel engine and found that an effective reduction of smoke density,CO & NOx emissions. Also the B20 blend shows the similar result with narrow range of variation with respect to mineral Diesel. There is no such variation of exhaust gas temperature using Diesel & KME because of heat loss to the exhaust is nearer to be same. Suryawanshi & Deshpande [4] studied the effect of EGR and retardation injection timing on C.I. engine fuelled with KME. It is reported that NOx emissions were reduced with injection timing retardation and EGR compared to standard conditions. Nagarhalli M.V, Nandedkar V.M. et.al [5] have been carried out experimental work on emission & performance characteristics of Karanja biodiesel and its blends in a C.I. engine. The results of experimental investigation with biodiesel blends were compared with mineral Diesel. The results indicate that the CO emissions

Figure-1: Bio diesel Process Untreated Karanja oil is mixed with a mixture of anhydrous methanol in the presence of NaOH as catalyst. The mixture is maintained at a temperature little below 650C, the B.P. of methanol and continuously stirred the mixture for around 3 hours. After completion of stirring, the mixture is allowed to settle down for 24 hours. The layer of glycerol settled at the bottom is carefully taken out and the upper layer is the ester of Karanja oil which is collected separately [1].Karmee and Chada [2] prepared biodiesel from Pongamia Pinnata by transesterification in the presence of Potassium Hydroxide as catalyst. 2. Emissions from Karanja BioDiesel: Biodiesel mainly emits Carbon monoxide, Carbon dioxide, Oxides of Nitrogen, Sulphur oxides and Smoke. A brief review has made about these pollutants emitted from bioDiesel. Sudipta Choudhury, Dr.P.K.Bose[1] carried experiments on Kirloskar make vertical single cylinder, D.I.Diesel engine. The emissions as well as engine performance were studied at different engine load at maximum power. It is noticed that for B20 blend the maximum & minimum CO produced is 0.42 g/KW-hr & 0.05 g/KW-hr, which is much less than mentioned in EURO-IV norms (Maximum 1.5

All Rights Reserved 2012 IJSETR

103

ISSN: 2278 7798 International Journal of Science, Engineering and Technology Research (IJSETR) Volume 1, Issue 5, November 2012 were slightly higher for B20 & B40 blends. HC emissions decreased from 12.8 % for B20 & 2.85% for B40 compared to Diesel at full load. Depending on load, the NOx emissions decreased by 39% for B20 & 28% for B40 at full load. Baiju et.al [6] studied a comparative evaluation of Diesel engine characteristics using KOME. It is reported that smoke formation is lesser. The reason is the complete combustion of KOME due to the presence of more oxygen in the biodiesel for all loads. Smoke emission from ethyl ester is more than that of methyl ester. At lower loads, CO emissions not much varied for all fuels. At full load, B20 KOEE emits more CO than methyl esters due to enrichment of oxygen which results in better combustion with biodiesel. NOx emissions of biodiesel blends and pure biodiesel are higher than Diesel at part loads. At higher loads, Diesel is emitting more NOx than biodiesel fuels. Ethyl esters are emitting more NOx than methyl esters. Chennakesava Reddy et.al [7] have been performed an experimental work on Potential of a Low Heat Rejection (LHR) Diesel engine with crude Pongamia oil. It is reported that in LHR engine preheating of vegetable oils decreased smoke levels & NOx levels with the advancing of the injection timing and increase of injection pressure. Anand Kumar Pande et.al [8], the effects of pure Karanja biodiesel fuel on performance, emission & engine wear of a 118 KW,6 cylinder, CIDI engine have been investigated & compared with the base line Diesel fuel. The observations are CO emission decreased by 80% when Diesel fuel is replaced with pure Karanja oil biodiesel fuel at full load condition. The UHC decreases by 42% at full load condition with pure Karanja oil biodiesel fuel & NOx emission increase by 10% with pure Karanja oil biodiesel fuel in comparison with Diesel fuel at full load condition. Kamal Kishore Khatri et.al [9], on the basis of the observations & results of the experimental investigations on a single cylinder, 4 stroke constant speed stationary, water cooled C.I. engine run on KaranjaDiesel blend and Diesel oil at different injection timings, reported that slightly more smoke emissions are observed with KaranjaDiesel blend compared to Diesel over entire load range mainly due to poor atomization of Karanja oil. However the smoke level for K40 at optimum timing is less than the smoke level of K40 at standard timing. Nagarhalli et.al [10] studied the emission and performance characteristics of the blend of Karanja biodiesel and Diesel by varying three injection pressure of 190 bar, 200 bar and 210 bar and concluded that the HC emissions decreased for B20 & B40 blends by 15-25% at an injection pressure of 190 bar. NOx emissions showed a drop of 24% for B20 blend & 16% for B40 blend. HC emissions at 200 bar injection pressure decreased by up to 3% for B20 & B40 where as NOx decreased by 3039% in comparison with Diesel. At an injection pressure of 210 bar, HC emissions were unchanged for B20 blend and decreased by 18 % for B40 blend where as NOx showed an increasing trend (8-18%). B.K.Venkanna et.al [11] investigated Pongamia Pinnata linn oil Diesel blend on the single cylinder, DI Diesel engine and tests were conducted for the entire load range(0 to 100%)i.e.0 to 5 H.P.) at constant speed of 1500 RPM. and reported that least CO & HC emissions were observed at 275 bar & 250 bar respectively and this is better than neat Diesel at standard injection pressure of 200 bar. Nanthagopal K et.al [12] on the basis of the experimental investigations on a single cylinder, 4 stroke, DI, bowl in piston combustion chamber Diesel engine run on KOME. It is noticed that CO, HC & Smoke emissions are lower for biodiesel blends as compared to Diesel. However emissions of NOx are found to be higher for biodiesel blends. 3. Performance of Karanja BioDiesel: The performance parameters such as Power out put, Specific fuel consumption, Brake thermal efficiency of Karanja Biodiesel had been evaluated by different researchers after experimental studies are reported in this section.

All Rights Reserved 2012 IJSETR

104

ISSN: 2278 7798 International Journal of Science, Engineering and Technology Research (IJSETR) Volume 1, Issue 5, November 2012 Sudipta Choudhury, Dr.P.K.Bose [1] reported that the break thermal efficiency is increased due to reduced heat loss with increased in load. The maximum efficiency obtained is 33.74% (B25) & 33.54 %(B20).BSFC reduces with increase in load. The reverse trend in the BSFC may be due to increase in bioDiesel percentage ensuring lower calorific value of fuel. Raheman and Phadatare [3] reported that both Torque & Brake power increased with increase in load. This is due to increase in fuel consumption with increase in load. The torque & B.P. produced in case of B20 & B40 is 0.8 to 7.4% lower than Diesel. The maximum brake thermal efficiency obtained as 26.79%& 26.19% for of B20 & B40 respectively, which were more than that of Diesel (24.62%). Nagarhalli M.V, Nandedkar V.M. et.al [5] reported that the brake specific energy consumption value increased by 7% for B20 & 1.9% for B40 at full load. Hence a blend of 40% biodiesel and 60% Diesel (B40) is recommended. There is no significant change in efficiency. Chennakesava Reddy et. al [7] observed that preheating of the vegetable oils improved performance when compared with normal vegetable oils in both versions of the engine. Improvement in the performance is observed with the advancing of the injection timing and with the increase of injection pressure with the vegetable oil operation on both versions of the engine. Anand Kumar Pande et.al [8] reported that the Brake power of the engine slightly decreases when Diesel engine is fueled with pure Karanja oil biodiesel fuel. Kamal Kishore Khatri et.al [9] experimentally found that, for Karanja Diesel blend (K40) injection timing of 190 BTDC is found to be the optimum injection timing, as highest brake thermal efficiency, lowest BSFC are observed over the entire load range at this injection timing.Dipak Patil, Dr.Rachayya, et.al [13] studied the performance analysis of 4 cylinder, 4 stroke Diesel engine using Karanja biodiesel & reported that Brake power, Brake thermal efficiency, Mechanical efficiency and time for fuel consumption is higher at constant speed & also at variable speed & load condition for 20% & 40% biodiesel blends with Diesel fuel. Sagar Pramodrao Kadu et.al [14],on the basis of the observations & the results of the experimental investigations on a computerized single cylinder 4 stroke CI engine powered by neat Karanja oil at different fuel inlet temperatures, reported that at higher speed there is no significant difference in BSFC when the engine is operated with preheated and unheated vegetable oil fuels. The Karanja oil fuel produced the same brake thermal efficiency at high speed & low speed of the engine and slightly deviating in the mid of the speed range studied. The heated fuel showed a marginal decrease in brake thermal efficiency as compared to Diesel fuel operation. Engine power increases with speed to a maximum value at an engine speed of 3500 RPM. At speeds more than 3500 RPM the power produced is slightly higher than that of Diesel fuel. N.Stalinn& H.J.Prabhu [15] concluded that Brake power is higher for the dual fuel combustions from B5 to B30 than Diesel. In case of B40, the B.P. is more or les equal to that of Diesel. For the dual fuel combinations from B50 to B100, the B.P. is less than that of Diesel. As the load increases, BSFC decreases to the minimum of at 70% load and then increases for all the fuel samples tested. This can be correlated that B.P. increases as the load increases. As the load increases, brake thermal efficiency increases up to 70% load and then decreases for all the fuel samples tested. The low brake thermal efficiency for B60, B80 and B100 may be due to the lower HHV and the increase in fuel consumption. Y.C.Bhatt & M.K.Verma[16] concluded that the fuel temperature and injection pressure has significant role on engine performance parameters. Power out put and brake thermal efficiency decrease with the increase in concentration of KME in Diesel & increased with the increase in the injection pressure and fuel temperature. The BSFC & BSEC increased with the increase in concentration of KME in Diesel & decreased with the increase

All Rights Reserved 2012 IJSETR

105

ISSN: 2278 7798 International Journal of Science, Engineering and Technology Research (IJSETR) Volume 1, Issue 5, November 2012 in injection pressure and fuel temperature. S.S.Karhale et al.[17] tested the blend of Karanja biodiesel & Diesel with two variable injection pressure of 180 & 245 Kgf/cm2 and temperature of 30,50 & 700C and concluded that engine starting is normal with KME and its blend with Diesel. Injection pressure & fuel temperature were found to be significant effects on engine performance parameters. The power out put decreases with increase in the concentration of KME in Diesel and increased with increase in injection pressure and fuel temperature. R.K. Singh & Saswat Rath [18] have been carried out experimental work on 4 stroke, single cylinder DI Diesel engine for performance analysis of blends of KME. It is noticed that the brake thermal efficiency of the engine with KME-Diesel blend is marginally better than with neat Diesel fuel. BSEC is lower for KME-Diesel blends than Diesel at all loading. Conclusions: Biodiesel is an alternative to Diesel as a fuel in Diesel engine. The engine performance of Karanja bio-diesel has been compared to that of Diesel. It is found from the literature review that the emission characteristics of biodiesel are better than Diesel except NOx emission. CO, UBHC and particulate matter emissions were found to significantly decrease with bio diesel and its blends due to more complete combustion caused by higher oxygen content. Hence based on engine emission studies i.e., CO, NOx & HC, it is concluded that the parameters studied were with in the maximum limits and are safe to use as an alternate fuel. References: [1] Sudipta Choudhury, Dr.P.K.BoseKaranja oil-its potential and suitability as Biodiesel. [2] Karmee Sanjib Kumar, Chadha AnjuPreparation of biodiesel from crude oil of Pongamia Pinnata. Bioresource Technology 2005,96: 1425-9. [3] Raheman H and Phadatare A G-Diesel engine emissions and performance from blends of Karanja Methyl Ester and Diesel. Bio-mass & Bio-energy 2004;27: pp:393-397. [4] Suryawanshi J G & Deshpande N V-Over view of EGR, Injection Timing and pressure on emissions and performance of CI engine with Pongamia Methyl Ester. SAE paper 2005, 26-346. [5]Nagarhalli M V,Nandedkar V M and Mohit K C.-Emission & performance characteristics of Karanja biodiesel and its blends in a CI engine and its economics. ARPN Journal of engineering & Applied Sciences-Vol.5.No.2, February 2010. [6] B.Baiju,M K Naik,L M Das-A Comparative evaluation of Compression Ignition engine characteristics using methyl and ethyl esters of Karanja oil Renewable energy Vol.34,pp 1616- 1621,2009. [7]Chennakesava Reddy,M V S Murali Krishna et al.-Potential of a low Heat Rejection Diesel engine with crude Pongamia oil. IJMERVol.1 issue 1, pp-210-224. [8]Ananda Kumar Pande & M R Nandgaonkar.-Experimental Investigation of the Effect of Estirified Karanja oil biodiesel on performance, emission & engine wear of a Military 160HP turbo charged CIDI engine. Proceedings of the world congress on engineering 2011, vol.III. [9]Kamal Kishore Khatri/Dilip Sharma et al.Investigations of optimum fuel injection timing of Direct Injection CI engine operated on preheated Karanja Diesel blend. JJMIE, Vol 4,No-5,Nov- 2010, pp:629-640. [10] Nagarhalli M V,Nandedkar V M- Effect of injection pressure on emission & performance characteristics of Karanja biodiesel & its blends in CI engine. IJAER, Dindigul, vol 1,No.4,2011. [11] B.K.Venkanna,Swati.B,et.al-Effect of injection pressure, emissions and combustion characteristics of Direct injection Diesel engine running on blends os Pongamia Pinnata linn oil and direct fuel.Agricultural Engineering International: The CIGR E Journal.No 1316,vol XI,May 2009. [12] Nanthagopal K, Thundil Karuppa Raj R & Vijaykumar T.-Performance & Emission

All Rights Reserved 2012 IJSETR

106

ISSN: 2278 7798 International Journal of Science, Engineering and Technology Research (IJSETR) Volume 1, Issue 5, November 2012 characteristics of Karanja methyl esters, Diesel blends in a direct injection compression ignition (CI) engine. Journal of petroleum Technology & Alternative fuels. vol.3(4)pp:3641,April 2012. [13]Dipak patil,Dr.Rachayya R et al.Performance analysis of Multi cylinder CI engine by using Karanja biodiesel. IJERA, vol.1, issue 4, pp:1755-1763. [14]Sagar Pramodrao Kadu, Rajendra H.Sarda.-Experimental Investigations on the use of preheated neat Karanja oil as fuel in a Compression Ignition engine. [15]N Stalin & H J Prabhu-Performance test of I C engine using Karanja biodiesel blending with Diesel. ARPN Journal of engineering & Applied Sciences-Vol.2.No.5, October 2007. [16]Y C Bhatt & MK Verma. Effect of fuel temperature & injection pressure on engine performance with Karanja (Pongamia Glabra) Methyl ester oil & Blends with Diesel. [17] S S Karhale,R G Nadre,DK Das & S K Das-Studies on comparative performance of compression ignition engine with different blends of biodiesel and Diesel under varying operating conditions. Karnataka J.Agric.Sci21 (2),246-249,2008 [18] R.K.Singh & Saswat Rath-Performance Analysis of blends of Karanja Methyl Ester in a Compression Ignition Engine. International Conference on Biomedical Engineering& Technology.vol.11(2011).

All Rights Reserved 2012 IJSETR

107

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Dry Hands MinecraftDocument1 pageDry Hands MinecraftBrandon RotzankNo ratings yet

- Stock Register StoreDocument1,218 pagesStock Register StoreSantanu Kumar SahuNo ratings yet

- Dont CryDocument8 pagesDont CryIolanda Dolcet Ibars100% (1)

- Timeline of Programming Languages PDFDocument11 pagesTimeline of Programming Languages PDFMohd Khir ZainunNo ratings yet

- Answers About HubSpotDocument1 pageAnswers About HubSpotPrasetyaNo ratings yet

- Aashto T19-Bulk Density (Unit Weight)Document7 pagesAashto T19-Bulk Density (Unit Weight)Marc Anthony de Villa100% (1)

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadNo ratings yet

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadNo ratings yet

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadNo ratings yet

- Smart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsDocument5 pagesSmart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsEko Hadi Susanto100% (1)

- Services Marketing: Consumer Behavior in Services Unit 2Document78 pagesServices Marketing: Consumer Behavior in Services Unit 2mpsrishaNo ratings yet

- JNTUA Mechanical Engineering (R09) Syllabus BookDocument147 pagesJNTUA Mechanical Engineering (R09) Syllabus Bookslv_prasaad0% (1)

- R7310305-Design of Machine Members-IDocument1 pageR7310305-Design of Machine Members-Islv_prasaadNo ratings yet

- 9A03504 Design of Machine Elements IDocument4 pages9A03504 Design of Machine Elements Islv_prasaadNo ratings yet

- Curved BeamsDocument8 pagesCurved BeamsAnonymous EKqkRJsJNNo ratings yet

- ME2303Document7 pagesME2303slv_prasaadNo ratings yet

- Worm GearsDocument4 pagesWorm Gearsnitesh_n2840No ratings yet

- 9A03504 Design of Machine ElementsDocument2 pages9A03504 Design of Machine Elementsslv_prasaadNo ratings yet

- R7310305-Design of Machine Members-I2Document4 pagesR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- 9A03504 Design of Machine Elements I 1Document2 pages9A03504 Design of Machine Elements I 1slv_prasaadNo ratings yet

- Performance and emission characteristics of Karanja biodiesel and its blends in a variable compression ignition engineDocument52 pagesPerformance and emission characteristics of Karanja biodiesel and its blends in a variable compression ignition engineslv_prasaadNo ratings yet

- Me1302 LP ADocument3 pagesMe1302 LP ACKDinakarrajNo ratings yet

- r7320101 Geotechnical Engineering IDocument1 pager7320101 Geotechnical Engineering Iprasaad08No ratings yet

- r7320102 Environmental EngineeringDocument4 pagesr7320102 Environmental Engineeringslv_prasaadNo ratings yet

- Lecture 26aDocument12 pagesLecture 26aslv_prasaadNo ratings yet

- RCC Slab Estimation and Bending ScheduleDocument4 pagesRCC Slab Estimation and Bending Scheduleslv_prasaadNo ratings yet

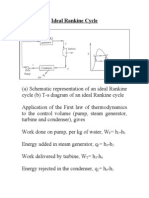

- Ideal Rankine CycleDocument27 pagesIdeal Rankine Cycleslv_prasaadNo ratings yet

- .. TenthClass BitBanks MathsEM 7geomentryDocument4 pages.. TenthClass BitBanks MathsEM 7geomentryslv_prasaadNo ratings yet

- CH 9 1 2Document46 pagesCH 9 1 2slv_prasaadNo ratings yet

- The Z Engine - A New Type of Low Emission Diesel EngineDocument9 pagesThe Z Engine - A New Type of Low Emission Diesel Engineslv_prasaadNo ratings yet

- CFD Optimization With Altair Hyperworks: in This Issue July 2006Document6 pagesCFD Optimization With Altair Hyperworks: in This Issue July 2006slv_prasaadNo ratings yet

- Ajas53189 196Document8 pagesAjas53189 196slv_prasaadNo ratings yet

- CH 4 1Document48 pagesCH 4 1slv_prasaadNo ratings yet

- Extraction and Visualization of Swirl and Tumble Motion From Engine Simulation DataDocument15 pagesExtraction and Visualization of Swirl and Tumble Motion From Engine Simulation Dataslv_prasaadNo ratings yet

- Extraction and Visualization of Swirl and Tumble Motion From Engine Simulation DataDocument15 pagesExtraction and Visualization of Swirl and Tumble Motion From Engine Simulation Dataslv_prasaadNo ratings yet

- Engineering Optimization Ch 1 IntroductionDocument21 pagesEngineering Optimization Ch 1 Introductionslv_prasaadNo ratings yet

- CFD Optimization With Altair Hyperworks: in This Issue July 2006Document6 pagesCFD Optimization With Altair Hyperworks: in This Issue July 2006slv_prasaadNo ratings yet

- 1zzfe Technical DataDocument13 pages1zzfe Technical Datacris5001100% (1)

- Advances in Remediation-eBookDocument88 pagesAdvances in Remediation-eBookalinerlfNo ratings yet

- Module 8 SAHITA ConcreteDocument11 pagesModule 8 SAHITA ConcreteHarrybfnNo ratings yet

- Geo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterDocument5 pagesGeo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterVinod Vincy67% (3)

- CHEST Workout Structure and Training Log PREVIEWDocument3 pagesCHEST Workout Structure and Training Log PREVIEWgaurav singhNo ratings yet

- SI Units in Geotechnical EngineeringDocument7 pagesSI Units in Geotechnical EngineeringfaroeldrNo ratings yet

- Msds Thinner 21-06Document8 pagesMsds Thinner 21-06ridhowibiiNo ratings yet

- UFED Solutions Brochure WebDocument4 pagesUFED Solutions Brochure Webwilly irawanNo ratings yet

- MC 8051Document85 pagesMC 8051Sonu SatishNo ratings yet

- Zhao PeiDocument153 pagesZhao PeiMuhammad Haris HamayunNo ratings yet

- PLCDocument16 pagesPLCMohit Kinger100% (1)

- QUICK GUIDE ON WRITING PATENT SPECIFICATION v1Document37 pagesQUICK GUIDE ON WRITING PATENT SPECIFICATION v1Muhammad Azuan TukiarNo ratings yet

- Transient and Random VibrationDocument19 pagesTransient and Random VibrationAman SharmaNo ratings yet

- Artikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsDocument9 pagesArtikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsJohny DoelNo ratings yet

- Sheet #6Document2 pagesSheet #6AHMED BAKRNo ratings yet

- 0 EDEM Applications MeDocument16 pages0 EDEM Applications MeRuben PurcaNo ratings yet

- Assign 1Document5 pagesAssign 1Aubrey Camille Cabrera100% (1)

- Analytic DeviceDocument4 pagesAnalytic DeviceuiuiuiuNo ratings yet

- RELAY SEEDER PROTECTION GUIDE (P40 Agile CompactDocument23 pagesRELAY SEEDER PROTECTION GUIDE (P40 Agile CompactvinodlifeNo ratings yet

- Testing concrete and brick strengthDocument2 pagesTesting concrete and brick strengthlolenlennNo ratings yet

- OFFICE 365 PROXY GUIDEDocument4 pagesOFFICE 365 PROXY GUIDErossloveladyNo ratings yet

- 7.qad-Dpr-11 ImteDocument4 pages7.qad-Dpr-11 ImteDhinakaranNo ratings yet