Professional Documents

Culture Documents

003 - LICO Light Weight Column Formwork

Uploaded by

smaliscribdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

003 - LICO Light Weight Column Formwork

Uploaded by

smaliscribdCopyright:

Available Formats

D

d

0

4

/

2

0

0

8

5

m

a

A

r

t

.

N

r

.

:

7

9

2

1

6

2

C

o

p

y

r

i

g

h

t

b

y

P

E

R

I

G

m

b

H

LICO

The lightweight column formwork

for forming by hand

LICO EN.indb 2 20.05.2008 13:33:56 Uhr

2

PERI LICO

Crane-independent, exible, inexpensive

LICO, the lightweight column form-

work for cost-effective forming also

without a crane.

The low individual weights of the ele-

ments allow assembly and dismantling

by hand. This means that the formwork

crew is still in a position to effectively

use crane non-availability in a productive

way.

Practical details simplify the use and

lower shuttering times.

The high permissible fresh concrete

pressure of 80 kN/m ensures fast con-

creting cycles and thus contributes to a

very economical utilisation of the equip-

ment.

Height increments of 50 cm

Only three different element heights:

3.00 m, 1.00 m and 0.50 m. These allow

optimal adjustment to the required con-

creting heights.

Column cross-sections

Different cross-section combinations

permit rectangular or square congura-

tions from 20 x 20 to 60 x 60 cm in 5 cm

increments.

3.00 m high LICO column

formwork with RSS I

push-pull-props for con-

struction of an ofce

building.

1

0

0

0

5

0

0

3

0

0

0

EN_LICO_2008_002-003.indd 2 23.05.2008 13:37:36 Uhr

3

Captive column tie bolts

and nuts are permanently

attached to each element.

Eye bolt as load bearing

point for moving as well

as easy and simple ex-

tensions.

LICO chamfer strip,

Item no. 111975, is sim-

ply attached to the front

side of the element.

Column cross-sections from 20 x 20 cm to

60 x 60 cm can be realised both square or

rectangular-shaped in 5 cm increments.

With centrally-positioned ties, cross-sections

up to 60 x 130 cm can be formed. Element

connections are carried out using standard

M20 bolts.

Practice-oriented details

Q

The LICO captive column tie bolts

and nuts are permanently attached

to the elements.

Q

Eye bolts on all elements serve as

load bearing points for moving with

the crane as well as for element con-

nections when extending.

Q

The chamfer strips are easily tted on

the elements this saves on time-

consuming and cost-intensive nailing

of conventional strips.

EN_LICO_2008_002-003.indd 3 23.05.2008 13:37:59 Uhr

4

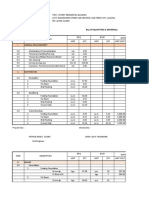

111683 72,400

698

3

0

0

0

5

0

0

2

5

0

7

5

0

7

5

0

7

5

0

88 550 11 x 50 = 60

8

0

111957 29,000

698

1

0

0

0

2

5

0

5

0

0

2

5

0

111964 16,700

698

5

0

0 2

5

0

2

5

0

Item no. Weight kg

LICO column formwork

Column Panel LICO 700 x 3000

Column panel with formlining. For cross-sections

ranging from 20 x 20 tp 60 x 60 cm in 5 cm incre-

ments.

Complete with

4 x 111679 Column Tie Nut LICO DW 15

4 x 111682 Column Tie Bolt LICO DW 15

2 x 710130 Eye Bolt M20x40, galv.

2 x 781053 Hex. Nut ISO 7042 M20-8, galv.

48 x 030290 Plug 20 mm

Column Panel LICO 700 x 1000

Column panel with formlining. For cross-sections

ranging from 20 x 20 tp 60 x 60 cm in 5 cm incre-

ments.

Complete with

2 x 111679 Column Tie Nut LICO DW 15

2 x 111682 Column Tie Bolt LICO DW 15

2 x 710130 Eye Bolt M20x40, galv.

2 x 781053 Hex. Nut ISO 7042 M20-8, galv.

24 x 030290 Plug 20 mm

Column Panel LICO 700 x 500

Column panel with formlining. For cross-sections

ranging from 20 x 20 tp 60 x 60 cm in 5 cm incre-

ments.

Complete with

1 x 111679 Column Tie Nut LICO DW 15

1 x 111682 Column Tie Bolt LICO DW 15

2 x 710130 Eye Bolt M20x40, galv.

2 x 781053 Hex. Nut ISO 7042 M20-8, galv.

12 x 030290 Plug 20 mm

LICO EN.indb 4 20.05.2008 13:34:36 Uhr

5

111975 1,080

28

1

0

0

037530 1,140

1

5

5

24 93

115019 0,335

Q

030290 0,002

028010 18,000

2050 min max 2940

1915

16,5

16,5 7

0

1

0

1

5

32

Item no. Weight kg

LICO column formwork

Chamfer Strip LICO l = 3.00 m

For attaching to the LICO column panels.

Brace Connector QUATTRO QR

For connecting push-pull props and kicker braces

to QUATTRO and LICO column panels.

Complete with

1 x 018060 Cotter Pin 4/1, galv.

1 x 027170 Pin 16 x 42, galv.

Lifting Pin LICO

Plug 20 mm

For closing 20 mm tie holes which are not

required.

Note

Delivery unit of 500 pieces

Push-Pull Prop RSS I

Extension lengths L = 2.05 2.94 m. For aligning

PERI formwork systems.

Note

For permissible loads: see PERI Tables.

LICO EN.indb 5 20.05.2008 13:34:38 Uhr

6

028020 22,100

min 2910 max 3800

16,5

16,5

7

0

2775

32

1

0

1

5

028110 5,180

min 1080 max 1400

980

16x42 16,5

3

8

1

0

1

0

30

108135 13,000

min 1280 max 2100

1171

7

0

16x42 16,5

1

0

1

0

36

106000 1,820 Complete with

1 x 027170 Pin 16 x 42, galv.

1 x 018060 Cotter Pin 4/1, galv.

21

1

0

0

150 12 85

Item no. Weight kg

LICO column formwork

Push-Pull Prop II

Extension lengths L = 2.91 3.80 m.For aligning

PERI formwork systems.

Note

For permissible loads: see PERI Tables.

Kicker Brace AV

Extension Lengths L = 1.08 1.40 m.For aligning

PERI formwork systems.

Complete with

1 x 027170 Pin 16 x 42, galv.

1 x 018060 Cotter Pin 4/1, galv.

Note

For permissible loads: see PERI Tables.

Kicker Brace AV 210

Extension Lengths L = 1.28 2.10 m.For aligning

PERI formwork systems.

Complete with

1 x 027170 Pin 16 x 42, galv.

1 x 018060 Cotter Pin 4/1, galv.

Note

For permissible loads: see PERI Tables.

Base Plate-2 for RSS, galv.

For assembling the RSS push-pull-props.

LICO EN.indb 6 20.05.2008 13:34:39 Uhr

Dokument 1 28.04.2005 12:48 Uhr Seite 1

D

e

0

5

/

2

0

0

8

1

0

m

a

A

r

t

.

N

r

.

:

7

9

2

1

6

3

C

o

p

y

r

i

g

h

t

b

y

P

E

R

I

G

m

b

H

Wall Formwork

Panel Formwork

Girder Formwork

Circular Formwork

Facade Formwork

Brace Frame

Column Formwork

Square

Rectangular

Circular

Slab Formwork

Panel Formwork

Beam Grid Formwork

Girder Formwork

Slab Table

Beam Formwork

Shoring Systems

Steel Slab Props

Aluminium Slab Props

Tower Systems

Heavy-Duty Props

Climbing Systems

Climbing Scaffold

Self-Climbing System

Climbing Protection Panel

Platform Systems

Scaffold, Stairways,

Working Platforms

Facade Scaffold

Working Platform

Weather Protection Roof

Stairway Access

Bridge and Tunnel

Formwork

Cantilevered Parapet Carriage

Cantilevered Parapet Platform

Engineers Construction Kit

Services

Formwork Assembly

Cleaning / Repairs

Formwork Planning

Software

Statics

Special Constructions

Additional Systems

Plywood

Formwork Girders

Stopend Systems

Pallets

Transportation Containers

PERI GmbH

Formwork Scaffolding Engineering

P.O. Box 1264

89259 Weissenhorn

Germany

Tel +49 (0)73 09.9 50- 0

Fax +49 (0)73 09.9 51- 0

info@peri.de

www.peri.de

PERI Product Range

EN_Ruckseite.indd 34 20.05.2008 14:34:02 Uhr

You might also like

- Part 1 of 9 GCC PDFDocument98 pagesPart 1 of 9 GCC PDFsmaliscribdNo ratings yet

- Volume-1-Tender & Conditions of ContractDocument281 pagesVolume-1-Tender & Conditions of ContractsmaliscribdNo ratings yet

- BJP Abridged ManifestoDocument22 pagesBJP Abridged Manifestokane21232874No ratings yet

- Mobile DevGuide 13 - Gulde For Mobile DeveloperDocument258 pagesMobile DevGuide 13 - Gulde For Mobile DevelopersmaliscribdNo ratings yet

- Ariisto - Goregaon - Tender Document - 07 Nov 2013Document571 pagesAriisto - Goregaon - Tender Document - 07 Nov 2013smaliscribdNo ratings yet

- 004CH3Document26 pages004CH3Souvik HalderNo ratings yet

- Special Purpose Simulation Modeling of Tower CranesDocument7 pagesSpecial Purpose Simulation Modeling of Tower CranessmaliscribdNo ratings yet

- Ariisto - Goregaon - Addendum 1Document5 pagesAriisto - Goregaon - Addendum 1smaliscribdNo ratings yet

- Ijesit201302 68 PDFDocument9 pagesIjesit201302 68 PDFSree NivasNo ratings yet

- Ireo8 Very GoodDocument25 pagesIreo8 Very GoodsmaliscribdNo ratings yet

- AIIMS at KalyaniDocument3 pagesAIIMS at KalyanismaliscribdNo ratings yet

- Bartaman Patrika - RASHI FALL - 1421Document10 pagesBartaman Patrika - RASHI FALL - 1421smaliscribdNo ratings yet

- PrefaceDocument27 pagesPrefaceDitsu SomNo ratings yet

- Ëíyíå # Þy S×# Äçþ Î Ä # ÞyDocument24 pagesËíyíå # Þy S×# Äçþ Î Ä # ÞyDhrubajyoti SinghaNo ratings yet

- 4 G NetworkDocument4 pages4 G NetworksmaliscribdNo ratings yet

- 1346 - Water ProofingDocument10 pages1346 - Water ProofingsmaliscribdNo ratings yet

- Course Schedule StatisticsDocument2 pagesCourse Schedule StatisticssmaliscribdNo ratings yet

- Handout Highrise 2Document14 pagesHandout Highrise 2smaliscribdNo ratings yet

- Introduction To Public SpeakingDocument2 pagesIntroduction To Public SpeakingsmaliscribdNo ratings yet

- 14 73 Edx SyllabusDocument5 pages14 73 Edx SyllabussmaliscribdNo ratings yet

- Sector 44 Gurgaon H Frame System Parts ListDocument1 pageSector 44 Gurgaon H Frame System Parts ListsmaliscribdNo ratings yet

- Tamboli 2008 TallBuildingsSustainable.a6b917db A870 4417 8b86 6b19c01f604bDocument0 pagesTamboli 2008 TallBuildingsSustainable.a6b917db A870 4417 8b86 6b19c01f604bsmaliscribdNo ratings yet

- M - 20 OpcDocument1 pageM - 20 OpcsmaliscribdNo ratings yet

- Civil BOQ Gurgaon GreensDocument14 pagesCivil BOQ Gurgaon GreenssmaliscribdNo ratings yet

- Aluminium Formwork Quotes for Lavasa ProjectDocument2 pagesAluminium Formwork Quotes for Lavasa ProjectsmaliscribdNo ratings yet

- Supreme AR2012Document85 pagesSupreme AR2012smaliscribdNo ratings yet

- Civil BOQ Gurgaon GreensDocument14 pagesCivil BOQ Gurgaon GreenssmaliscribdNo ratings yet

- Purtop GBDocument2 pagesPurtop GBsmaliscribdNo ratings yet

- Handrail 3Document24 pagesHandrail 3smaliscribdNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Procurement Methodology Guidelines For Construction: New South Wales GovernmentDocument43 pagesProcurement Methodology Guidelines For Construction: New South Wales GovernmentJames DoolanNo ratings yet

- Home Lift - 02Document1 pageHome Lift - 02Nagarajan SNo ratings yet

- Preparation of Shrinkage Compensating Concrete WitDocument7 pagesPreparation of Shrinkage Compensating Concrete WitPradeep VempadaNo ratings yet

- Course-plan-Eng 2216 Laws, Ethics and ContractsDocument6 pagesCourse-plan-Eng 2216 Laws, Ethics and ContractsGIANNE MARIE AZURINNo ratings yet

- JSRRDA - PMU - 16 JMF Observations PalamuDocument2 pagesJSRRDA - PMU - 16 JMF Observations Palamuprathuri sumanthNo ratings yet

- Product Data Panelboard P1Document33 pagesProduct Data Panelboard P1vvargasNo ratings yet

- Building Materials and ConstructionDocument101 pagesBuilding Materials and ConstructionKarthik A KulalNo ratings yet

- Kohinoor Square Tower - Iconic Mixed-Use SkyscraperDocument23 pagesKohinoor Square Tower - Iconic Mixed-Use SkyscraperPushpak GaikarNo ratings yet

- Extractor de Pasadores de OrugaDocument2 pagesExtractor de Pasadores de OrugaErik MoralesNo ratings yet

- Plastics and Rubbers in BuildingDocument37 pagesPlastics and Rubbers in Buildinghahaamin aminNo ratings yet

- CarpentryDocument9 pagesCarpentryrejeanNo ratings yet

- A Mini Project On Bituminous Road LayersDocument20 pagesA Mini Project On Bituminous Road Layersapi-1988935887% (39)

- CIVIL Engineering ALL IN 1 DATA BOOKDocument212 pagesCIVIL Engineering ALL IN 1 DATA BOOKtataprojectspowergenrationNo ratings yet

- S278 Preliminary Design Submission Checklist: (A1 Size Max)Document4 pagesS278 Preliminary Design Submission Checklist: (A1 Size Max)Rebi HamzaNo ratings yet

- GTCL Foundation TrainingDocument69 pagesGTCL Foundation TrainingMD Shamim Hasan SajibNo ratings yet

- Box Culvert 1+825-1Document1 pageBox Culvert 1+825-1ANKESH SHRIVASTAVANo ratings yet

- Allen Medical Catalog Global General SectionDocument17 pagesAllen Medical Catalog Global General Sectionmohamed hegazyNo ratings yet

- Rolling Shutters and Rolling GrillesDocument43 pagesRolling Shutters and Rolling GrillesM. Murat ErginNo ratings yet

- Iare BMCP Lecture Notes 0Document80 pagesIare BMCP Lecture Notes 0Marjon BazarNo ratings yet

- α-S100iA Mechanical specifications: Clamping unitDocument2 pagesα-S100iA Mechanical specifications: Clamping unitashwin ashokabhavanNo ratings yet

- Owner Involvement in Industrial Building DesignDocument1 pageOwner Involvement in Industrial Building Designaddrien danielNo ratings yet

- Boq & BomDocument20 pagesBoq & Bompat cruzNo ratings yet

- Gas Ban Measure Ballot Title AppealDocument11 pagesGas Ban Measure Ballot Title AppealMegan BantaNo ratings yet

- Kraft Faced Johns Manville InsulationDocument2 pagesKraft Faced Johns Manville InsulationEva MedinaNo ratings yet

- Types of School BuildingsDocument54 pagesTypes of School BuildingsWella WilliamsNo ratings yet

- Hydraulic Cylinder Seal KitsDocument1 pageHydraulic Cylinder Seal KitsSami KahtaniNo ratings yet

- Building Works - Dismantaling & DemolishingDocument4 pagesBuilding Works - Dismantaling & DemolishingArup DebnathNo ratings yet

- KEI - Cable List Price - March 2022Document5 pagesKEI - Cable List Price - March 2022Nagi Reddy0% (1)

- Eurocode 7, Geotechnical Design, Part 3 Design Assisted by FieldtestingDocument150 pagesEurocode 7, Geotechnical Design, Part 3 Design Assisted by FieldtestingAsoka Kumarasiri JayawardanaNo ratings yet

- Rockfall BarrierDocument2 pagesRockfall BarrierAmihan SantosNo ratings yet