Professional Documents

Culture Documents

Solar Screw Jack

Uploaded by

Jeevan Landge PatilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solar Screw Jack

Uploaded by

Jeevan Landge PatilCopyright:

Available Formats

SOLAR SCREW JACK

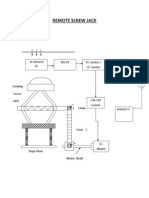

BLOCK DIAGRAM:-

Solar Panel/AC Supply

Rectifier Circuit

DC motor / AC motor

BATTERY

Existing Screw Jack Gear - 1 Chain ON-OFF Switch

Gear - 2

Shop Floor Motor Shaft

DC Motor

Diagram - REMOTE SCREW JACK

Explanation of Components used in REMOTE SCREW JACK:DC BATTERY DC batteries are charged during the day time and store the energy which is utilized during the hours where there are no sun rays and conventional electricity is not utilized. DC batteries are available in different ratings. The battery we utilized in our case is 12v, 10AH capacity. In the applications where appliances are operating on AC supply, the battery supply is converted into AC. For this purpose inverters are required. But in our case the motor used is operated on DC supply. So, there is no need of DC to AC converter. Also, if the polarity is reversed the motor direction is changed. DC Motor:It is permanent magnet type of DC motor. So, no

armature and field winding is there as in conventional DC motor. Only single supply is required. The motor speed can be changed if the voltage is changed. But, in our application the motor has to operate at high torque because, it has lifted the power jack. So, gear box is incorporated with the

existing DC motor. This gear box reduces the speed and increases the torque of the motor.

Mechanical Assembly:The mechanical assembly of the project REMOTE SCREW JACK consists of a DC motor with gear attached a chain and another similar gear at opposite end and which is mounted on a screw jack mechanism. The assembly details are shown in figure. It consists of a threaded screw which travels so as to increases the height of the jack. Hence, it is known as screw jack. The screw jack is used for lifting the auto cars. One of the flat surfaces of the screw jack is placed on ground and another flat surface on top side is used to lift the car. Initially the car is on the ground rested with the helps of wheels. And we require lifting it up for some purpose. We placed the power jack below the car. Then, with the help of threaded screw rotation the assembly lifts up which ultimately lifts the car up. Many accessories like screw, washer, springs etc. are provided. We are about to avoid the human operation for the operation of power jack. So, the screw jack is expected to rotate

automatically when power in ON. Thus, human power is not require and the battery supply is utilized for the same. The battery charging is done with solar energy in the system is more beneficial. The coupling between

screw jack and the rotating motor is done with the help of gear and chain mechanism.

Technical Specifications:1) 2) 3) Basic jack = Screw jack, operated REMOTELY. Energy source = non conventional from solar panel. DC battery = 12v, 10AH for out applications. It can be increased for increased capacity. 4) 5) 6) Gear = with 12 teeth on each side. 2 nos. DC motor = 12v, geared. ON-OFF switch = 16 Ampere toggle.

Machine required for completion of above project:1) ARC Welding Machine, Drilling Machine, Grinder, leath machine for turning purpose. Electro plating setup.

Advantages:1) Being the jack operated on DC supply and dc supply is obtained form solar energy. It helps in minimizing the shortage of

conventional energy. Also, the battery can be charged during the traveling of the car.

2)

The operation is done, by closing a single switch which helps in avoiding the man power, for jack operation.

3)

Being DC motor is suggested NO inversion of DC supply is required.

Disadvantage:1) Solar panel is can not be charge in rainy season. systems are helpless in rainy season. So, these

Future Scope:1) The solar based power jacks so developed have many advantages steel some lacunas are there. These lacunas are over come in further enhancement circuitry project. 2) In rainy season the conventional electricity generation is more, so, the battery charging can be done without solar. For this purpose the required battery charges will be developed in futures. 3) In future enhancements the power required for lifting the car will also, measured by using some transistors and if the load is more than the recommended load of the jack, the system will be stopped. 4) On line charging can be done.

***********

You might also like

- Remote Screw JackDocument5 pagesRemote Screw JackJeevan Landge PatilNo ratings yet

- Chapter III - Electrical Power Generation Using Speed Breaker - Jefferson BeloDocument6 pagesChapter III - Electrical Power Generation Using Speed Breaker - Jefferson BeloJefferson BeloNo ratings yet

- Motorized Four Wheel Nut RemovalDocument44 pagesMotorized Four Wheel Nut RemovalAmrrish S LNo ratings yet

- Project WorkDocument15 pagesProject Workakif akifnaimNo ratings yet

- Solar CarDocument12 pagesSolar Carramanaidu1No ratings yet

- Hev M2Document18 pagesHev M2Anandhu ANo ratings yet

- DCMotor Definition, Working, Types, AndFAQs 1675260129902Document16 pagesDCMotor Definition, Working, Types, AndFAQs 1675260129902Jafar EarlNo ratings yet

- Solar Cycle For Handicaped Person2 FinalDocument16 pagesSolar Cycle For Handicaped Person2 FinalPradeep krNo ratings yet

- Fabrication of Overhead CraneDocument45 pagesFabrication of Overhead CraneWORLD360No ratings yet

- DC @ AC Machines: Construction, Control, and ApplicationsDocument4 pagesDC @ AC Machines: Construction, Control, and ApplicationsMeg CastleNo ratings yet

- 4.1 DC Motor SpecificationDocument6 pages4.1 DC Motor SpecificationAsgher KhattakNo ratings yet

- Hercules M. Biacoraelectrical-MachinesDocument8 pagesHercules M. Biacoraelectrical-MachinesBiacora Manalo HerculesNo ratings yet

- Garbage Cleaning MachineDocument25 pagesGarbage Cleaning MachinesankarNo ratings yet

- Automatic Street Light That Is Powered Through Speed Breaker Chapter - 1Document54 pagesAutomatic Street Light That Is Powered Through Speed Breaker Chapter - 1Anu GraphicsNo ratings yet

- Electric Motor Types & WorkingDocument8 pagesElectric Motor Types & WorkingPlutoNo ratings yet

- Automatic Side StandDocument23 pagesAutomatic Side StandShekhar Sawant0% (1)

- What Is DC MotorDocument38 pagesWhat Is DC Motoralvin dalumpinesNo ratings yet

- Generation of Electricity Through Speed Breaker MechanismDocument7 pagesGeneration of Electricity Through Speed Breaker MechanismDK3002No ratings yet

- Solar Grass Cutter MechanismDocument38 pagesSolar Grass Cutter MechanismAakash DindigulNo ratings yet

- Scotch Yoke MechanismDocument37 pagesScotch Yoke MechanismSaravanan Viswakarma100% (1)

- Multipurpose Machines Using Scotch Yoke MechanismDocument36 pagesMultipurpose Machines Using Scotch Yoke Mechanismnithinkenator88% (16)

- DC MotorDocument8 pagesDC Motorven_avv3382No ratings yet

- Classification of Electric Motors: Electrical Motors Basic ComponentsDocument89 pagesClassification of Electric Motors: Electrical Motors Basic ComponentsSarada Sankar DasNo ratings yet

- 2 Dc-Motors-3Document69 pages2 Dc-Motors-3JheromeNo ratings yet

- Hydraulic Jack Motorised 2015Document57 pagesHydraulic Jack Motorised 2015Chockalingam Athilingam100% (3)

- Classification of MotorSDocument17 pagesClassification of MotorSHumaid Shaikh50% (2)

- Electrical interview questions on motor principles and power electronicsDocument26 pagesElectrical interview questions on motor principles and power electronicsNavdeepNo ratings yet

- Electric Motor Cycle and ScooterDocument9 pagesElectric Motor Cycle and ScooterA A.DevanandhNo ratings yet

- Term Paper On DC MotorDocument4 pagesTerm Paper On DC Motorc5qfb5v5100% (1)

- Double Acting Hacksaw Machine Using Scotch Yoke MechanismDocument32 pagesDouble Acting Hacksaw Machine Using Scotch Yoke Mechanismbalaji67% (12)

- Assignment MachineDocument8 pagesAssignment MachineNur AfiqahNo ratings yet

- DC Shunt Motor: Construction, Working, Speed Control & ApplicationsDocument7 pagesDC Shunt Motor: Construction, Working, Speed Control & ApplicationsGhost ReaconNo ratings yet

- Robotic Trolley DesignDocument46 pagesRobotic Trolley DesignSaggy ChhataniNo ratings yet

- DC Motor - PPTDocument41 pagesDC Motor - PPTali abdel hadiNo ratings yet

- ECEL LAB#3 AngeladaDocument19 pagesECEL LAB#3 AngeladaAlehamarie AngeladaNo ratings yet

- Ee-120 DC MachineDocument6 pagesEe-120 DC Machinesmk30150No ratings yet

- Solar Powered Vehicle: Yogesh Sunil Wamborikar, Abhay SinhaDocument4 pagesSolar Powered Vehicle: Yogesh Sunil Wamborikar, Abhay SinhaPrashant Kumar RaiNo ratings yet

- Advantages and Disadvantages of DC MotorDocument6 pagesAdvantages and Disadvantages of DC MotorMuhd Izwan Ikhmal RosliNo ratings yet

- Assignment # 6Document7 pagesAssignment # 6Jay Ey100% (1)

- Push Button Operated Gear Shifting Mechanism For Two WheelerDocument19 pagesPush Button Operated Gear Shifting Mechanism For Two Wheelersabareesh91mechNo ratings yet

- Motorised JackDocument15 pagesMotorised Jack67 Nikam kunal sanjayNo ratings yet

- 12 - Chapter 6Document23 pages12 - Chapter 6Gunal KuttyNo ratings yet

- Andi Adriani Adiwijaya - 201971048 - 6BB - Modul 2 - Mesin AsDocument11 pagesAndi Adriani Adiwijaya - 201971048 - 6BB - Modul 2 - Mesin AsAndi Adriani AdiwijayaNo ratings yet

- Solar Power Motorized Jack SynopsisDocument6 pagesSolar Power Motorized Jack SynopsisAnonymous j0aO95fgNo ratings yet

- Assignment 2 Ac DCDocument15 pagesAssignment 2 Ac DCVincoy JohnlloydNo ratings yet

- REMOTE CONTROLLED MOTORIZED HYDRAULIC JACKDocument72 pagesREMOTE CONTROLLED MOTORIZED HYDRAULIC JACKSushil KumarNo ratings yet

- Fabrication of Automatic Side Stand Braking Mechanism For Two WheelerDocument28 pagesFabrication of Automatic Side Stand Braking Mechanism For Two Wheelergnana muruganNo ratings yet

- Muhammad Hamza 106report11Document13 pagesMuhammad Hamza 106report11Muhammad Hamza 18-NTU-0106No ratings yet

- Eee-233 R1Document14 pagesEee-233 R1ArifNo ratings yet

- DC Motor - Wikipedia, The Free EncyclopediaDocument2 pagesDC Motor - Wikipedia, The Free Encyclopediadonodoni0008No ratings yet

- Types of Electric MotorDocument6 pagesTypes of Electric Motorfahad pirzadaNo ratings yet

- Advantages Vs DisadvantagesDocument5 pagesAdvantages Vs DisadvantagesAnuar PadeliNo ratings yet

- Assignment 2 Ac DCDocument15 pagesAssignment 2 Ac DCVincoy JohnlloydNo ratings yet

- DC Motor Control Techniques and Speed Control MethodsDocument39 pagesDC Motor Control Techniques and Speed Control Methodsnarendramaharana39No ratings yet

- 2365 02 l2 202 Handout 25Document2 pages2365 02 l2 202 Handout 25dvm4yfptzmNo ratings yet

- Foot Step Power Generation System: SynopsisDocument7 pagesFoot Step Power Generation System: SynopsisviratNo ratings yet

- Automatic Screw Jack Project ReportDocument12 pagesAutomatic Screw Jack Project ReportKaran Bansal67% (3)

- Speed of Cutting Wheel (N)Document3 pagesSpeed of Cutting Wheel (N)Jeevan Landge PatilNo ratings yet

- Reuse of Plastic Waste in Paver BlocksDocument3 pagesReuse of Plastic Waste in Paver BlocksMehran Amin BattNo ratings yet

- Literature Review On Different Plastic Waste Materials Use in ConcreteDocument4 pagesLiterature Review On Different Plastic Waste Materials Use in ConcreteAkshay NivaleNo ratings yet

- Design Calculations:: 5.1 Selection of Material For FrameDocument7 pagesDesign Calculations:: 5.1 Selection of Material For FrameJeevan Landge PatilNo ratings yet

- Drawing1 PDFDocument1 pageDrawing1 PDFJeevan Landge PatilNo ratings yet

- PaverDocument29 pagesPaverJeevan Landge PatilNo ratings yet

- 4.abrasive Belt GrinderDocument63 pages4.abrasive Belt GrinderIyappan Alagappan67% (15)

- Design Calculations:: 5.1 Selection of Material For FrameDocument7 pagesDesign Calculations:: 5.1 Selection of Material For FrameJeevan Landge PatilNo ratings yet

- Maximum Weight of Single Man 100 KGDocument4 pagesMaximum Weight of Single Man 100 KGJeevan Landge PatilNo ratings yet

- E BicycleDocument44 pagesE BicycleJeevan Landge PatilNo ratings yet

- Cutting Forces and Design of a Rice Stalk Cutting SystemDocument7 pagesCutting Forces and Design of a Rice Stalk Cutting SystemJeevan Landge PatilNo ratings yet

- Eight link Bottle shifting conveyor mechanismDocument59 pagesEight link Bottle shifting conveyor mechanismJeevan Landge PatilNo ratings yet

- 4.abrasive Belt GrinderDocument63 pages4.abrasive Belt GrinderIyappan Alagappan67% (15)

- ShaftDocument3 pagesShaftJeevan Landge PatilNo ratings yet

- Drawing 1Document7 pagesDrawing 1Jeevan Landge PatilNo ratings yet

- Design of Mini Compressorless Solar Powered Refrigerator: Project Report ONDocument36 pagesDesign of Mini Compressorless Solar Powered Refrigerator: Project Report ONJeevan Landge PatilNo ratings yet

- ShaftDocument3 pagesShaftJeevan Landge PatilNo ratings yet

- Design Calculations:: 5.1 Selection of Material For FrameDocument2 pagesDesign Calculations:: 5.1 Selection of Material For FrameJeevan Landge PatilNo ratings yet

- Automatic Pneumatic Braking and Bumper SystemDocument46 pagesAutomatic Pneumatic Braking and Bumper SystemJeevan Landge PatilNo ratings yet

- MPC Mechatronics Project Consultancy for College StudentsDocument1 pageMPC Mechatronics Project Consultancy for College StudentsJeevan Landge PatilNo ratings yet

- ShaftDocument48 pagesShaftJeevan Landge PatilNo ratings yet

- IJSART - Design and Fabrication of a Multipurpose Farming MachineDocument14 pagesIJSART - Design and Fabrication of a Multipurpose Farming MachineJeevan Landge Patil100% (1)

- ShaftDocument48 pagesShaftJeevan Landge PatilNo ratings yet

- MouldingDocument5 pagesMouldingJeevan Landge PatilNo ratings yet

- ShaftDocument3 pagesShaftJeevan Landge PatilNo ratings yet

- Rectangular Tapered Hopper VolumeDocument1 pageRectangular Tapered Hopper VolumeJeevan Landge PatilNo ratings yet

- AngleDocument3 pagesAngleJeevan Landge PatilNo ratings yet

- Determining of Your System Specifi Cations and ConditionsDocument1 pageDetermining of Your System Specifi Cations and ConditionsJeevan Landge PatilNo ratings yet

- MouldingDocument5 pagesMouldingJeevan Landge PatilNo ratings yet

- AdsdsasdDocument2 pagesAdsdsasdJeevan Landge PatilNo ratings yet

- MT 6300 AcDocument4 pagesMT 6300 AcFarlan Nag BgfNo ratings yet

- CSA PM Calculation - 07.2019 - FormuleDocument45 pagesCSA PM Calculation - 07.2019 - FormulejogremaurNo ratings yet

- Volvo FMX: Product Guide - Euro 3-5Document24 pagesVolvo FMX: Product Guide - Euro 3-5HiT Dayat100% (2)

- Engine and Peripherals PDFDocument465 pagesEngine and Peripherals PDFE OvidiuNo ratings yet

- Data Summary: Truck, Forklift, Off Pavement, Telescopic Loader, 3 Tonne Merlo P35.9Ev Standard and FlameproofDocument5 pagesData Summary: Truck, Forklift, Off Pavement, Telescopic Loader, 3 Tonne Merlo P35.9Ev Standard and Flameproofslawny770% (1)

- Design Process of A Low Cost Tractor: Christina Popa, and Dorina IonescuDocument5 pagesDesign Process of A Low Cost Tractor: Christina Popa, and Dorina IonescusaddamNo ratings yet

- Motox BevelhDocument218 pagesMotox BevelhJosë RodríguezNo ratings yet

- 1533 Shuttle (34HP) 1538 HST (38HP) : 1500 4WD SeriesDocument6 pages1533 Shuttle (34HP) 1538 HST (38HP) : 1500 4WD SeriesNayaGaadi DavangereNo ratings yet

- Manual Transmission Components and Operation ExplainedDocument38 pagesManual Transmission Components and Operation ExplainedsayedNo ratings yet

- E-CATALOGUE Mini TractorDocument2 pagesE-CATALOGUE Mini TractorAditya BhedasgaonkarNo ratings yet

- Ecodrive Dkc01.1 - dkc11.1 Version Notes Ase 04vrs - Ase04 - fvn1Document24 pagesEcodrive Dkc01.1 - dkc11.1 Version Notes Ase 04vrs - Ase04 - fvn1KrassiNo ratings yet

- FM306 PDFDocument6 pagesFM306 PDFAnonymous gTerattFpQNo ratings yet

- Zetor Crystal 150,160 ManualDocument182 pagesZetor Crystal 150,160 ManualMarija MircevskaNo ratings yet

- Terminal Tractors and Trailers 6.1Document7 pagesTerminal Tractors and Trailers 6.1lephuongdongNo ratings yet

- Ground Verify and Neutral Shifting Details for Manual TransmissionDocument1 pageGround Verify and Neutral Shifting Details for Manual TransmissiontvwrightNo ratings yet

- 33 Ford 3D 4F27E FN4A-EL FNR5 PDFDocument14 pages33 Ford 3D 4F27E FN4A-EL FNR5 PDFCarlos Martinez100% (3)

- Heavy Construction Equipment Seal SolutionsDocument69 pagesHeavy Construction Equipment Seal SolutionsSaif0% (1)

- TEch MaNUalDocument190 pagesTEch MaNUalDavid Chalker82% (22)

- Perencanaan Preventive Maintenance Pada 416F Backhoe Loader CaterpillarDocument20 pagesPerencanaan Preventive Maintenance Pada 416F Backhoe Loader CaterpillarIqbal HamdiNo ratings yet

- MLR DrivetrainStudyGuideDocument74 pagesMLR DrivetrainStudyGuidelonesarah100% (2)

- ALIMAK-Scando 650 Tech Desc 9104228-107 USDocument117 pagesALIMAK-Scando 650 Tech Desc 9104228-107 USramtsanNo ratings yet

- IC 400 ManualDocument102 pagesIC 400 ManualRAFAEL OLIVEIRANo ratings yet

- Rigid Backhoe Loader: 74 KW / 99,2 HP at 2.200 RPM 8.070 KGDocument12 pagesRigid Backhoe Loader: 74 KW / 99,2 HP at 2.200 RPM 8.070 KGvitaliyNo ratings yet

- Volkswagen XL1 - The World's Most Fuel Efficient Car PDFDocument5 pagesVolkswagen XL1 - The World's Most Fuel Efficient Car PDFKarthik SubramanianNo ratings yet

- Course Specifications: Cairo EngineeringDocument3 pagesCourse Specifications: Cairo EngineeringscribNo ratings yet

- SSP 254 - Audi A4 01 - Technical Features Pt2 (Eng)Document18 pagesSSP 254 - Audi A4 01 - Technical Features Pt2 (Eng)Concha SolerNo ratings yet

- Royal Enfield Part NosDocument108 pagesRoyal Enfield Part NosRahul KumarNo ratings yet

- Sistema Control Trans 140hDocument7 pagesSistema Control Trans 140hFernando Ortiz86% (7)

- Dahua PTZ SD56 Series PTZ Camera Installation Manual V1.0.1Document28 pagesDahua PTZ SD56 Series PTZ Camera Installation Manual V1.0.1Serban DanielNo ratings yet

- 1966 1978model Recognition ManualDocument129 pages1966 1978model Recognition ManualChillman100% (1)