Professional Documents

Culture Documents

Calculation Sheet: Padeye Calculations Loads

Uploaded by

andi_nuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation Sheet: Padeye Calculations Loads

Uploaded by

andi_nuCopyright:

Available Formats

2

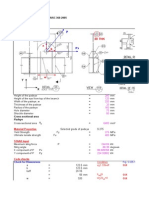

CALCULATION SHEET

Project VALHALL LQ MODULE Discipline

STRUCT By HTCC Room - padeye calculations NKA Date 24/03/09

Job No.

7020 Page

001 Chkd. Date

Title

Padeye calculations Loads Max. Unfactored lifting Load, P Dynamic Amplification factor, DAF Consequence Factor, gc Maximum design vertical load, V Maximum design horizontal load, 50% of vertical load, H Maximum design lateral load, 5% of vertical load, LT

= = = = = =

19.62 1.1 1.25 27.0 13.5 1.35

kN

2 MT

kN kN kN

2.75 MT 1.38 MT 0.138 MT

LT

H

V Shackle Selection : Bow Shackle - Refer EN:13889:2003(E) Static load for shackle selection Working load limit as per EN:13889:2003(E) Shackle pin diameter, Dpin ( D in fig)

= = = = =

19.62 63.8 25 36.5 76

kN kN mm mm mm

2 6.5

MT MT

Inside width of shackle (w, in fig) Inside length of shackle (s, in fig)

Padeye geometry Radius of the main plate, rmp Thickness of the main plate, tmp Width of main plate, W mp Diameter of padeye hole, Dhole Diameter of sling, Dsling

= = = = =

58 20 116 28 10

mm mm mm mm mm

CALCULATION SHEET

Project VALHALL LQ MODULE Discipline

STRUCT By HTCC Room - padeye calculations NKA Date 24/03/09

Job No.

7020 Page

001 Chkd. Date

Title

Check for adequacy Dia. of the padeye hole should be more than shackle pin dia.by 3mm 28 mm Thk. of main plate should be between 0.6 to 0.8times inside width of21.9 - 29.2 mm shackle, Minimum Clearance inside the shackle to be 0.5 times sling dia. 8 mm Padeye Design Young's Modulus, E Material Factor, gM Yield Strength, fy Design Criteria, as per EC3 Axial Tension, 0.6 fy Compression, 0.6 fy Bending, 0.66fy Shear, 0.4fy Bearing, Fb = 0.9fy Combined, 0.66 fy Equivalent stress, 0.75 fy Check for Bearing stress Factored vertical load, V Bearing Thickness, Tbearing Bearing Area, Abearing = Dpin X Tbearing Calculated Bearing Stress, fb Unity Check ratio Check for Shackle-pin shear pull out Factored vertical load, V Area under shear-pull out, A s = (2xrmp - Dhole) x tmp Calculated Shear Stress, fv Unity Check ratio Check for tension and combined stress at section A-A Factored vertical load, V A t = (2xrmp - Dhole) x tmp Tensile area , Calculated Shear Stress, Ft Unity Check ratio Shear stress at section A-A The horizontal component of vertical load, H Shear area, Ashear (same as tensile area) Calculated Shear stress at section A-A, t v Unity Check ratio

Ok Ok Ok

= = =

2 2E+06 N/mm 1.15 2 355 N/mm

= = = = = = =

185 185 204 123 278 204 232

N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 N/mm2 N/mm2

= = = = =

27.0 20.0 500.0 54.0 0.2

kN mm mm2 N/mm2 Ok

= = = =

27.0 kN 2 1760.0 mm 2 15.33 N/mm 0.1 Ok

= = = =

27.0 kN 2 1760.0 mm 2 15.33 N/mm 0.1 Ok

= = = =

13.5 kN 2 1760.0 mm 2 7.66 N/mm 0.1 Ok

CALCULATION SHEET

Project VALHALL LQ MODULE Discipline

STRUCT By HTCC Room - padeye calculations NKA Date 24/03/09

Job No.

7020 Page

001 Chkd. Date

Title

Check for bending At section AA only bending load is due to lateral load, LT Distance taken conservatively from center of pin to the inside length of shackle, (Dpin/2+S) Bending moment Max. bending stress occurs at outer fibre of main plate, tmp/3 Moment of inertia at section A-A, (2xrmpx(tmp)3)/12 LT A A Maximum bending stress, Fb Allowable Bending stress, 0.66fy Unity Check ratio Check for Equivalent Stress, se Equivalent Stres, se = ( Ft2 + Fb2 + 3 t v 2 ) Allowable Equivalent stress, 0.75fy Unity Check ratio

= = = = =

1.35 88.50

kN mm

119375 N-mm 10 mm 77333 mm4

= =

15.44 204 0.1

N/mm2 N/mm2 Ok

= =

25.5 232 0.1

N/mm2 N/mm2 Ok

Tensile and Combined stress at the attachment of padeye to the structure

Tensile stress check Factored vertical load, V Tensile area, Aten = Wmp X Tmp Tensile stress, Ft1 = V/Aten Shear stress check The horizontal component of vertical load, H Shear area, Ashear = Wmp X Tmp Shear stress, tv1= H/Ashear

= = =

27.0 kN 2 2320 mm 2 12 N/mm

= = =

13.5 kN 2 2320 mm 2 6 N/mm

CALCULATION SHEET

Project VALHALL LQ MODULE Discipline

STRUCT By HTCC Room - padeye calculations NKA Date 24/03/09

Job No.

7020 Page

001 Chkd. Date

Title

Check for In-Plane Bending Inplane bending caused by horizontal component, H acting at the padeye hole Inplane Bending Moment, Mipb = 539550 N-mm Maximum Bending stress acts at the outer extremity of padeye plate, point B in the figure Moment of inertia at section A-A, (2xrmp)^3x(tmp))/12 = 3E+06 mm4 H

116 mm C

20 Maximum bending stress, Fb = 12.0 N/mm2

Check for Out-of-Plane Bending The out-of-plane is due to the lateral component of vertical load and it is to be checked at point E Lateral load, LT = 1.35 kN Lateral load acting at the distance from center of padeye hole, = 40 mm Bending moment, = 53955 N-mm Moments of inertia about minor axis = 77333 mm4

150X75 PFC

E 20 100 E 116

40

LT Bending stress at point E, Fb Check for Equivalent Stress, se Equivalent Stres, se = ( Ft2 + Fb2 + 3 t v 2 ) Allowable Equivalent stress, 0.75fy Unity Check ratio Result Hence Padeye passess all the design calculation checks = = 20.7 232 0.1 N/mm2 N/mm2 Ok = 6.98 mm4

CALCULATION SHEET

Project VALHALL LQ MODULE Discipline

STRUCT By HTCC Room - padeye calculations NKA Date 24/03/09

Job No.

7020 Page

001 Chkd. Date

Title

Check for Weld Type 1 : Connecting padeye to the 150X75 PFC facia channel The welds need to be checked for all three forces acting on the padeye Steel Tensile strength (Ft) = 460 N/mm^2 EC3 Material Factor weld = 1.25 EC3 Correlation Factor weld = 0.9

Y 104 3 X

LT r

100

1 Y

assume throat weld = depth no width 6 100 1 6 100 2 104 6 3

6 Area 600 600 624 1824

y 3 113 58

x 50 50 97

Ay Ax 1800 30000 67800 30000 36192 60528 105792 120528

Ay2 5400 8E+06 2E+06

Ax2 Ixx Iyy ###### 500000 1800 ###### 500000 1800 ###### 1872 562432 1E+06 566032

Centroid X = 66.1 mm Y = 58 mm V/2 = 13.5

Ixx Iyy

= = 13

4 2E+06 mm 4 4E+06 mm

Ip = r = 13 kN

4 6E+06 mm 123 mm

V/2 = 13.5

kN

28.9

MT *

1431

MT* = reaction moment

H H= 13.5 V = 27 kN

Force due to vertical load, V/2 Moment due to horizontal load, MT Force on weld due to reaction moment Maximum reaction on weld Shear stress on weld due to max reaction force, tv Allowable shear stress on weld Max weld utilization ratio

= = = = = = =

13.5 1431 13 26 62.46 409 0.15

kN kN-mm kN kN N/mm2 N/mm2 Ok

CALCULATION SHEET

Project VALHALL LQ MODULE Discipline

STRUCT By HTCC Room - padeye calculations NKA Date 24/03/09

Job No.

7020 Page

001 Chkd. Date

Title

Check for Weld

Resultant 150X75 PFC

due to LT H

116

100

MT*

40 E

MT* = reaction moment

LT H

Force due to lateral load, LT Moment due to horizontal load, MT Max force on weld due to reaction moment Resultant force on the weld Shear stress on weld due to max reaction force, tv Hence Resultant shear stress EC3 Allowable shear stress on weld Max weld utilization ratio

= = = = = = = =

1.3 54 4.72 14 29.04 68.88 409 0.17

kN kN-mm kN kN N/mm2 N/mm2 N/mm2 Ok

Type 2 : Connecting padeye to the 254UB146 beam

H LT

LT

Weld Length, W L Force due to Vertical load, V/2 Shear stress on weld due to vertical force, tv

= = =

116 13.5 27.41

mm kN N/mm2

You might also like

- Pad-Eye MainDocument8 pagesPad-Eye MainPradeep ChitluriNo ratings yet

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 page2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNo ratings yet

- Padeye Calculation LatestDocument10 pagesPadeye Calculation LatestPavan RayNo ratings yet

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- Spreader Beam DesignDocument5 pagesSpreader Beam DesigntndeshmukhNo ratings yet

- Load analysis and strength evaluation of vessel lifting lugDocument3 pagesLoad analysis and strength evaluation of vessel lifting lugMudasir MughalNo ratings yet

- Padeye DesignDocument2 pagesPadeye DesignChiedu OkonduNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Lifting TrunionDocument1 pageLifting TrunionRUDHRA DHANASEKAR0% (1)

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDocument3 pages8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshNo ratings yet

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- 6a Padeye Aisc 360 2005Document6 pages6a Padeye Aisc 360 2005mjlazoNo ratings yet

- Spreader Beam (Planning)Document28 pagesSpreader Beam (Planning)AKSHAY BHATKARNo ratings yet

- Calculation PadeyeDocument6 pagesCalculation PadeyeAddy Sumoharjo ST100% (1)

- ASME SpreaderBar DWGDocument1 pageASME SpreaderBar DWGInspetor SoldagemNo ratings yet

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDocument4 pagesLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VNo ratings yet

- 8 Padeye - Spreadsheet Check1Document4 pages8 Padeye - Spreadsheet Check1oluomo1No ratings yet

- Design of Tail LugDocument34 pagesDesign of Tail LugPrajwal Shetty100% (1)

- Gross weight lifting lug dimensionsDocument10 pagesGross weight lifting lug dimensionsReda Elawady100% (1)

- Design Lifting Hook Plate LiftingDocument3 pagesDesign Lifting Hook Plate LiftingSaravan KumarNo ratings yet

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- PADEYE-AISC-360-2005 CalculationDocument6 pagesPADEYE-AISC-360-2005 CalculationsaswattNo ratings yet

- Anchor Bolt Loading Calculation For 101-B-10 29.02.16Document6 pagesAnchor Bolt Loading Calculation For 101-B-10 29.02.16kkaranagNo ratings yet

- Pad Eye StrengthDocument3 pagesPad Eye Strengthhyoung65No ratings yet

- Padeye PATIDocument43 pagesPadeye PATIbayu_23RNo ratings yet

- Lifting Lug CalculationDocument4 pagesLifting Lug CalculationLokesh PatelNo ratings yet

- Cargo acceleration calculation sheetDocument2 pagesCargo acceleration calculation sheetiw2fualNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDocument14 pagesCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiNo ratings yet

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Lifting LugDocument7 pagesLifting LugSajal KulshresthaNo ratings yet

- Lifting LugsDocument2 pagesLifting LugsAdi Cahyoko82% (11)

- Spreader BeamDocument7 pagesSpreader BeamAnonymous sfkedkymNo ratings yet

- Spreader Beam: ASME BTH-1: InputsDocument17 pagesSpreader Beam: ASME BTH-1: InputsGokul AmarnathNo ratings yet

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- Design and Verification of Lifting LugsDocument3 pagesDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- Base Plate CalculationDocument7 pagesBase Plate CalculationLcm TnlNo ratings yet

- Padeye 7Document24 pagesPadeye 7Ramesh SelvarajNo ratings yet

- LIFTING LUG CALCULATIONDocument2 pagesLIFTING LUG CALCULATIONhuangjlNo ratings yet

- Tailing LugDocument12 pagesTailing LuguvarajmecheriNo ratings yet

- ASME Vessel AnalysisDocument17 pagesASME Vessel AnalysiscutefrenzyNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Padeye Calculation For Anchor Block R0 20140722Document3 pagesPadeye Calculation For Anchor Block R0 20140722subucwiNo ratings yet

- Calculation LugDocument20 pagesCalculation LugKartika ZuhraNo ratings yet

- Lift Beam AnalysisDocument2 pagesLift Beam Analysishuangjl100% (2)

- Report SPeaDer BarDocument24 pagesReport SPeaDer BarMochammad Shokeh100% (2)

- Lifting Trunnion Calculations SampleDocument10 pagesLifting Trunnion Calculations SampleshazanNo ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Standard Pad Eye 10T SWL-modifDocument8 pagesStandard Pad Eye 10T SWL-modifrustamriyadiNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument15 pagesCalculation Sheet: Padeye Calculations Loadsshani5573No ratings yet

- Padeye calculations for HTCC RoomDocument28 pagesPadeye calculations for HTCC Roomhyoung65No ratings yet

- Final Design of Angle Members For 4leged Single Angle TowersDocument65 pagesFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerNo ratings yet

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- Indrumator Metal - EGDocument37 pagesIndrumator Metal - EGhooky1100% (1)

- Torsion Validation ShayanDocument10 pagesTorsion Validation ShayanGicuNo ratings yet

- Example: Short Column With Axial Load: General Design ParametersDocument5 pagesExample: Short Column With Axial Load: General Design ParametersCollin Chien Kai KingNo ratings yet

- Offshore Pipelines SaipemDocument78 pagesOffshore Pipelines Saipemrylar999100% (5)

- PIPELINE DESIGN DOCUMENTDocument78 pagesPIPELINE DESIGN DOCUMENTjenbach75% (4)

- PIC001 P&ID Documentation CriteriaDocument79 pagesPIC001 P&ID Documentation Criteriazabiruddin786No ratings yet

- OrificeDocument3 pagesOrificeandi_nuNo ratings yet

- PVElite ManualDocument691 pagesPVElite Manuals.mladin75% (4)

- June 2013Document76 pagesJune 2013andi_nuNo ratings yet

- Of-Pla NF00074 1001D PDFDocument8 pagesOf-Pla NF00074 1001D PDFNigin ParambathNo ratings yet

- Lift Calculation DemoDocument4 pagesLift Calculation Demoa_toups0% (1)

- Boiler Commissioning ProcedureDocument461 pagesBoiler Commissioning ProcedureBambang Setiaji100% (12)

- Pump Control ValveDocument1 pagePump Control Valveandi_nuNo ratings yet

- NPSH Calculations Explained: Net Positive Suction Head and Pump DesignDocument3 pagesNPSH Calculations Explained: Net Positive Suction Head and Pump DesignEdward YanceNo ratings yet

- SAEP 137uuDocument19 pagesSAEP 137uuAnonymous 4IpmN7OnNo ratings yet

- Cold TemperatureDocument15 pagesCold Temperaturehilmy baihaqiNo ratings yet

- Doping Semiconductors to Improve Photocatalytic PropertiesDocument24 pagesDoping Semiconductors to Improve Photocatalytic PropertiesDexhul everythingNo ratings yet

- PSV For Centrifugal PumpsDocument2 pagesPSV For Centrifugal PumpsAnonymous a4Jwz14W100% (3)

- "Green Gas" As SNG (Synthetic Natural Gas) A Renewable Fuel With Conventional QualityDocument17 pages"Green Gas" As SNG (Synthetic Natural Gas) A Renewable Fuel With Conventional QualityRobin ZwartNo ratings yet

- ECSS-E-HB-32-20 - PART-5A - Structural Materials Handbook - New Advanced MaterialsDocument435 pagesECSS-E-HB-32-20 - PART-5A - Structural Materials Handbook - New Advanced Materialsdkleeman4444No ratings yet

- Pharmaceutical Ultrapure Water Systems - : Igor GorskyDocument36 pagesPharmaceutical Ultrapure Water Systems - : Igor GorskyunknownNo ratings yet

- Safety Rules for Chemistry LabDocument2 pagesSafety Rules for Chemistry LabFritz ManyauNo ratings yet

- Lining of Tank Bottoms 3Document5 pagesLining of Tank Bottoms 3pnonnyNo ratings yet

- SDS Unleaded Gasoline RON 95Document19 pagesSDS Unleaded Gasoline RON 95syazani salin71% (7)

- Emergency Response and Spill ControlDocument5 pagesEmergency Response and Spill ControlbaluchakpNo ratings yet

- Msds EthanolDocument5 pagesMsds EthanolVytha MarmoetNo ratings yet

- VLE Systems SAeerDocument8 pagesVLE Systems SAeerGem29No ratings yet

- Welding Procedure SpecificationDocument6 pagesWelding Procedure SpecificationJorge SanchezNo ratings yet

- Relating To Thermophysical Properties: Standard TerminologyDocument7 pagesRelating To Thermophysical Properties: Standard Terminologysabaris ksNo ratings yet

- AVK SVMC Pipe Joints Brochure PDFDocument25 pagesAVK SVMC Pipe Joints Brochure PDFImtiyaz KhanNo ratings yet

- Passive Solar Design 2Document31 pagesPassive Solar Design 2fernandofigueroaNo ratings yet

- PHY4 June 2004Document2 pagesPHY4 June 2004api-3726022No ratings yet

- THS625 Bond Strength Fixtures: All Specifications Subject To Change Without Prior Notice Page 1 of 2Document2 pagesTHS625 Bond Strength Fixtures: All Specifications Subject To Change Without Prior Notice Page 1 of 2Ninh TranNo ratings yet

- Terms Questionnaire Part 6Document5 pagesTerms Questionnaire Part 6Justin MercadoNo ratings yet

- Astm A1017.a1017m 2011 PDFDocument3 pagesAstm A1017.a1017m 2011 PDFjoao carlos protzNo ratings yet

- Transient State Kinetic Measurements 1Document3 pagesTransient State Kinetic Measurements 1OLUWASEGUN K AfolabiNo ratings yet

- 24150Document3 pages24150B.yaswanth KumarNo ratings yet

- Waste ManagementDocument28 pagesWaste Managementkeerthishankar p100% (4)

- Success Criteria: Do I Know This? RAG Start of Do I Now Know This? RAG End of ModuleDocument2 pagesSuccess Criteria: Do I Know This? RAG Start of Do I Now Know This? RAG End of ModuleChris HarrisNo ratings yet

- Homework #1 For Chemical Engineering ThermodynamicsDocument2 pagesHomework #1 For Chemical Engineering Thermodynamicsramesh pokhrelNo ratings yet

- 1840 FullDocument17 pages1840 FullCarlos Garcia GarciaNo ratings yet

- Chemistry 0330 Exam 1 - October 10, 2018: Read Instructions CarefullyDocument7 pagesChemistry 0330 Exam 1 - October 10, 2018: Read Instructions CarefullyBananaNo ratings yet

- D02601880 - Instruction Manual PDFDocument2 pagesD02601880 - Instruction Manual PDFОлег ОрловскийNo ratings yet

- Casp DR - ZakaDocument36 pagesCasp DR - ZakaAsghar AliNo ratings yet