Professional Documents

Culture Documents

Environmental Impact and Treatment of Produced Water PDF

Uploaded by

Francis AbuludeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Impact and Treatment of Produced Water PDF

Uploaded by

Francis AbuludeCopyright:

Available Formats

Continental J.

Water, Air and Soil Pollution 3 (1): 21 24, 2012 ISSN: 2251 0508 Wilolud Journals, 2012 http://www.wiloludjournal.com Printed in Nigeria doi:10.5707/cjwasp.2012.3.1.21.24 ENVIRONMENTAL IMPACT AND TREATMENT OF PRODUCED WATER P.N. Onwuachi-Iheagwara Department of Petroleum and Gas Engineering, Delta State University, Abraka, Oleh campus, Oleh, Nigeria. pniheagwara@gmail.com ABSTRACT This paper reviews the effect of produced water from oil and conventional natural gas production on the environment. The many chemical constituents found in produced water, when present individually or collectively in a high enough concentrations, can present a threat to aquatic life when discharged into marine environments or to crops when the water is used for irrigation. Jacobs et al. (1992) report that, in the North Sea, ambient pH is 8.1 and chlorides are about 19 g/L. Some of these chemical were observed to be formed by the precipitation from the water due to temperature change (Utvik 2003). The different potential impacts are dependent on concentration and discharged point. The constituents of produced water affect the environment into which it is discharged and operations. As the well ages, the volume of produced water increases and this present challenges which calls for finesse and some degree of understanding of the constituents of produced water and their effects on the environment of discharge. Because of its sheer volume and its high handling cost management of produced water is a key issue in any hydrocarbon recovery program; its potential environmental impacts if not properly managed, could be substantial. KEYWORDS: environmental impact, produced water, pollution, oil and gas production, produced water treatment INTRODUCTION When hydrocarbons are produced, they are brought to the surface as a produced fluid mixture. The composition of this produced fluid generally includes a mixture of either liquid or gaseous hydrocarbons, produced water. The produced water contains dissolved or suspended solids, produced solids (sand or silt), injected fluids and additives that may have been placed in the formation during exploration and production activities. Lee et al (2002) report that U.S. wells produce an average of more than 7 bbl of water for each barrel of oil where as wells elsewhere in the world average 3 bbl of water for each barrel of oil It has been estimated that for 1999, an average of 210 million bbl of water was produced each day worldwide (Khatib and Verbeek, 2003). Produced water is an inextricable part of the hydrocarbon recovery process and the need to optimize water management cannot be over stated .Produced water must be adequately handled, at a considerable cost to operator, to prevent and/or minimize environmental degradation AIM OF STUDY This paper aims to highlight the danger posed by the millions of barrels of water produced daily from oil and gas fields in different parts of the world. Study from several sources shows that this water contaminates the environment into which they are discharged. Important factors that determine the magnitude of the hazard includes The concentration of dispersed oil in produced water , oil density, interfacial tension between oil and water phases, type and efficiency of chemical treatment, and type, size, and efficiency of the physical separation equipment (Ali et al. 1999). WHAT IS PRODUCED WATER? During oil and gas production water trapped in underground formations are brought to the surface, this water is known as Produced water . Management of produced water presents challenges that should not

21

P.N. Onwuachi-Iheagwara: Continental J. Water, Air and Soil Pollution 3 (1): 21 24, 2012

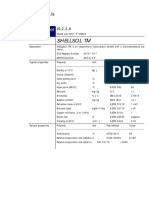

be ignored. This paper is intended to throw more light on the how produced water is generated and its potential impacts on the environment and on oil and gas operations. The characteristics and physical properties of produced water differ considerably depending on the geographic location of the field, the geological formation with which it has been in contact for thousands of years, and the type of hydrocarbon product produced. Its properties and volume also vary during the lifetime of the reservoir. Table 1 Constituents of Produced water Water Hydrocarbons Dispersed Dissolved (BTEX) Precipitated ( waxes and asphaltenes) These 3 Solid Suspended (sands, scales, corrosion products) Dissolved (salts n, carbon , iron) Gases (oxygen, carbon dioxides, hydrogen sulphides) 4 Production Chemicals 5 Metals 6 NORM( normally occurring radioactive minerals) contaminants have to be removed before the water can be re-used or disposed. Treatment of produced water involves all processes used to remove these contaminants from the produced water. 1 2 These processes used include: 1. De-oiling 2. De-sanding After treatment these water can be used in several capacities. Namely: 1. Surface disposal into sea or evaporation ponds. This is subject to local environmental regulations 2. Injection into a disposal well which may be a watered down part of the reservoir 3. Re-injection for pressure maintenance thereby replacing sea/aquifer water as a source of water for this activity 4. Reuse for agricultural purposes and in irrigation or as an industrial process water Treatment of produced water is important for several reasons including the under listed. ACUTE TOXICITY Works by Frost et al 1998 showed that the main culprits are the aromatics and the phenol. The impact of these on in the short term depends to a large extent to the concentration and the point of discharge. Effects are minimal in area of rapid dilution. (Cline 1998) CHRONIC TOXICITY Studies by US DOE 2004 indicate that the produced waters discharged from gas/condensate platforms are about 10 times more toxic than the produced waters discharged from oil platforms However, for produced water discharged offshore, the volumes from gas production are much lower, so the total impact may be less. Most countries adopt one form of control or the other. In Norway Johnsen (2003) and Johnsen et al (2000) reports on a detail methodology that involves employs a risk-based approach to compare the predicted

22

P.N. Onwuachi-Iheagwara: Continental J. Water, Air and Soil Pollution 3 (1): 21 24, 2012

environmental concentration for each constituent with the predicted no-effect concentration. This approach varies from the US EPA method whereby offshore oil and gas operations require chronic toxicity testing. EFFECT ON THE ENVIRONMENT AND OPERATIONS The ratio of produced water to oil is expected to increase as the wells age this is expected to adversely affect the environment as the actual impacts of produced water constituents is a function of the concentration. The variety of potential additive, synergistic, and antagonistic effects of multiple constituents can affect actual impacts. The danger from cross-media impacts must also be acknowledged (whereby a technology designed to address a problem in environment creates problem for another.) it is known that at the surface dispersed oil may spread and increased biological oxygen demand near the mixing zone which have an adverse effect on aquatic life. (Stephenson, 1992) FACTORS AFFECTING PRODUCED WATER PRODUCTION AND VOLUME The importance of an analysis of the factors affecting produced water production cannot be overemphasized. Optimization in the production and handling of produced water not only translate into lower operational cost for the lease operator but also a conservation of a natural resource that may otherwise be wasted or diminished. Reynolds and Kiker 2003 in their study considered factors can affect the volume of produced water during the life cycle of a well. Their study considered: 1. Completion Type 2. Well type, the Type of well drilled 3. Water separation and treatment facilities WELL COMPLETION A perforated completion offers a greater degree of well control than is absence in open-hole completion. Specific intervals in the hydrocarbon-producing zone can either be targeted for plugged to minimize water production when necessary. TYPE OF WELL DRILLED AND ITS LOCATION With similar drawdown horizontal well produce at higher rates than a vertical well thus delaying the entry of water into the well bore in a bottom water drive reservoir , the location of well within reservoir structure is important in the anticipated time for commencement of water production. WATER SEPARATION AND TREATMENT FACILITIES When surface separation and treatment facilities are in the produced water management of produced water, an additional expense is cost incurred in lifting the water to the surface as well. Once at the surface other expenses are the cost of equipment and chemical for treatment of the water. A more appealing method should be the down-hole separation with equipment that allows the produced water to remain down-hole. CONCLUSION With today level of technology produced water is an inextricable part of the hydrocarbon recovery process. It therefore behoves us to establish an unambiguous policy worldwide on its production and deposal. The hazard posed by this often overlook by-product of oil and gas exploitation may be a time bomb waiting to go off in the near future.

23

P.N. Onwuachi-Iheagwara: Continental J. Water, Air and Soil Pollution 3 (1): 21 24, 2012

REFERENCE Lee, R., R. Seright, M. Hightower, A. Sattler, M. Cather, B. McPherson, L. Wrotenbery, D. Martin, and M. Whitworth, 2002, Strategies for Produced Water Handling in New Mexico, presented at the 2002 Ground Water Protection Council Produced Water Conference, Colorado Springs, CO, Oct. 16-17. (Paper available at: http://www.gwpc.org/Meetings/ PW2002/Papers-Abstracts.htm.) Khatib, Z. and P. Verbeek, 2003, Water to Value Produced Water Management for Sustainable Field Development of Mature and Green Fields, Journal of Petroleum, Technology, Jan., pp. 26-28. Frost T.K., S. Johnsen, and T.I. Utvik, 1998, Environmental Effects of Produced Water Discharges to the Marine Environment, OLF, Norway (Available at http://www.olf.no/static/ en/rapporter/producedwater/summary.html) Cline, J.T., 1998, Treatment and Discharge of Produced Water for Deep Offshore Disposal, presented at the API Produced Water Management Technical Forum and Exhibition, Lafayette, LA, Nov. 17-18. Johnsen, S., T.K. Frost, M. Hjelsvold, and T.R. Utvik, 2000, The Environmental Impact Factor A Proposed Tool for Produced Water Impact Reduction, Management and Regulation, SPE 61178, SPE International Conference on Health Safety and the Environment in Oil and Gas Exploration and Production, Stavanger, Norway, June 26-28. Johnsen, S., 2003, Risk Assessment Based Environmental Management of Produced Water from Offshore Oil and Gas Fields, presented at the Produced Water Workshop, Aberdeen, Scotland, March 26-27 U.S. Department of Energy, 2004 A white paper on produced water from oil and gas production and coal bed methane, National Energy Technology Laboratory Stephenson, M.T., 1992, A Survey of Produced Water Studies, in Produced Water, J.P. Ray and F.R. Englehart (eds.), Plenum Press, New York. Ali, S.A., L.R. Henry, J.W. Darlington, and J. Occapinti, 1999, Novel Filtration Process Removes Dissolved Organics from Produced Water and Meets Federal Oil and Grease Guidelines, 9th Produced Water Seminar, Houston, TX, January 21-22. Jacobs, R.P.W.M., R.O.H. Grant, J. Kwant, J.M. Marqueine, and E. Mentzer, 1992, The Composition of Produced Water from Shell Operated Oil and Gas Production in the North Sea, Produced Water, J.P. Ray and F.R. Englehart (eds.), Plenum Press, New York. Utvik, T.I., 2003 Composition and Characteristics of Produced Water in the North Sea, Produced Water Workshop, Aberdeen, Scotland, March 26-27. Received for Publication: 24/02/2012 Accepted for Publication: 02/05/2012

24

You might also like

- Produced Water Volume Estimates and Management PracticesDocument6 pagesProduced Water Volume Estimates and Management PracticesEmmanuel Gomez GalvisNo ratings yet

- Thesis - Characterization of Produced Water From Two Offshore Oil Fileds in Qatar PDFDocument169 pagesThesis - Characterization of Produced Water From Two Offshore Oil Fileds in Qatar PDFSudNo ratings yet

- Report of ThesisDocument109 pagesReport of Thesisvinay10356No ratings yet

- Assignment 1Document9 pagesAssignment 1TejasNo ratings yet

- Produced Water Research Paper Verygood PDFDocument132 pagesProduced Water Research Paper Verygood PDFSatish KumarNo ratings yet

- How to rejoin the CQI membershipDocument1 pageHow to rejoin the CQI membershipR JNo ratings yet

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- Quality Surveillance Checklist/Report: ProjectDocument2 pagesQuality Surveillance Checklist/Report: Projectdeltz0706No ratings yet

- Evaluation of The Indoor Air Quality of Beato Angelico Building of The University of Santo TomasDocument43 pagesEvaluation of The Indoor Air Quality of Beato Angelico Building of The University of Santo TomasCrisencio M. PanerNo ratings yet

- Wet H2S CorrosionDocument12 pagesWet H2S CorrosionMedina EldesNo ratings yet

- Eco15 150519 1755 EtheraDocument17 pagesEco15 150519 1755 EtheraondonumosmanNo ratings yet

- World Quality Day - WikipediaDocument3 pagesWorld Quality Day - Wikipediabala subramanyam0% (1)

- Paraffin Wax Deposition Challenges and Mitigation ReviewDocument8 pagesParaffin Wax Deposition Challenges and Mitigation ReviewJit MukherheeNo ratings yet

- The Management of NORM Esidues & NORM Waste TechnologiesDocument49 pagesThe Management of NORM Esidues & NORM Waste TechnologiesBob SmithNo ratings yet

- Dow ASPDocument25 pagesDow ASPAndres GomezNo ratings yet

- Improving River Quality in KarachiDocument18 pagesImproving River Quality in KarachiJabran KhanNo ratings yet

- Gas Dehydration Process With GlycolDocument6 pagesGas Dehydration Process With GlycolAstrid Carolina Lizcano AriasNo ratings yet

- Dead Leg Rupture HSE 20190829Document3 pagesDead Leg Rupture HSE 20190829kuraimundNo ratings yet

- Westfield Company Profile Rev3 May2017 (Web)Document29 pagesWestfield Company Profile Rev3 May2017 (Web)ifiokdomNo ratings yet

- Shelsol Shoc CardDocument3 pagesShelsol Shoc Cardvinil radhakrishnaNo ratings yet

- Water Monitoring SystemDocument10 pagesWater Monitoring SystemMylene PallonesNo ratings yet

- Chapter 1 (Introduction To Quality)Document24 pagesChapter 1 (Introduction To Quality)AsjadNo ratings yet

- Anti FoamDocument20 pagesAnti FoamNduong NguyenNo ratings yet

- HSE Annual ReportDocument12 pagesHSE Annual ReportKashifPervez1No ratings yet

- UN Pipelines 2014Document24 pagesUN Pipelines 2014omissam2No ratings yet

- Bha RaluDocument10 pagesBha RalujituNo ratings yet

- Guide To Water ManagementDocument84 pagesGuide To Water ManagementYajuvendra JhalaNo ratings yet

- 1-Pit To Crack Transition and Corrosion Fatigue Lifetime Reduction Estimations by Means of A Short Crack Microstrutural ModelDocument12 pages1-Pit To Crack Transition and Corrosion Fatigue Lifetime Reduction Estimations by Means of A Short Crack Microstrutural ModelGilmar Menegotto100% (1)

- Formation DamageDocument26 pagesFormation DamagerajneeshgogoiNo ratings yet

- Masters ThesisDocument92 pagesMasters Thesispetsedia clovisNo ratings yet

- On Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitDocument17 pagesOn Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitAzmi Mohammed NorNo ratings yet

- HAZID Table Parameters Effects HazardsDocument6 pagesHAZID Table Parameters Effects HazardsAnifahNo ratings yet

- 430 Pipeline SecurityDocument39 pages430 Pipeline SecuritydmansoorNo ratings yet

- 4.2 - Ali - MoosaviDocument23 pages4.2 - Ali - MoosaviRavie OuditNo ratings yet

- Techno-Economic Assessment About Propylene OxideDocument5 pagesTechno-Economic Assessment About Propylene OxideIntratec SolutionsNo ratings yet

- Lesson From Seveso ItalyDocument48 pagesLesson From Seveso ItalyBilal ZamanNo ratings yet

- Suvidya Institute Piping Engineering TrainingDocument2 pagesSuvidya Institute Piping Engineering TrainingMohammedBujairNo ratings yet

- Produced Water Management & Treatment: Dr. Yasmeen Al LawatiDocument26 pagesProduced Water Management & Treatment: Dr. Yasmeen Al Lawatiسعيد الهاديNo ratings yet

- KOC Tender for Scale and Corrosion InhibitorsDocument5 pagesKOC Tender for Scale and Corrosion InhibitorsmelvinkuriNo ratings yet

- Produced Water CharacterizationDocument136 pagesProduced Water Characterizationmahaza88100% (1)

- Gas Treating Products and Services PDFDocument16 pagesGas Treating Products and Services PDFProcess EngineerNo ratings yet

- MMC Oil & Gas Engineering Cover LetterDocument2 pagesMMC Oil & Gas Engineering Cover LetterMunis RaoNo ratings yet

- Basics To Corrosion at Petrochemical Plants: by Shahid Razzaq Inspection Unit - MMDocument314 pagesBasics To Corrosion at Petrochemical Plants: by Shahid Razzaq Inspection Unit - MMMuhammad Abdullah Khan100% (1)

- Wax Removal in Pipeline PDFDocument291 pagesWax Removal in Pipeline PDFKhwanas LuqmanNo ratings yet

- Emc1 Sample Eng Obe QP v1Document5 pagesEmc1 Sample Eng Obe QP v1haitham aliNo ratings yet

- DNV RP-G101 - 2010Document74 pagesDNV RP-G101 - 2010Mohammad TaherNo ratings yet

- Corrosion Accident in PetroleumDocument101 pagesCorrosion Accident in PetroleumnertNo ratings yet

- Pakistan 2005 Earthquake: Prepared by Asian Development Bank and World Bank Islamabad, Pakistan November 12, 2005Document26 pagesPakistan 2005 Earthquake: Prepared by Asian Development Bank and World Bank Islamabad, Pakistan November 12, 2005Aslam KyonNo ratings yet

- Measurement of Oil in Produced WaterDocument38 pagesMeasurement of Oil in Produced WaterharlyakbarNo ratings yet

- Seminar Objectives: Offshore Facility Process Safety OverviewDocument11 pagesSeminar Objectives: Offshore Facility Process Safety OverviewCarlos Domingo Roland CheekNo ratings yet

- A. Major Causes of Construction Site AccidentsDocument6 pagesA. Major Causes of Construction Site AccidentsAlyzza Mae AngkahanNo ratings yet

- PSBR 1 TemplateDocument2 pagesPSBR 1 TemplatesathishNo ratings yet

- Selecting A Corrosion Inhibitor PDFDocument3 pagesSelecting A Corrosion Inhibitor PDFTariqNo ratings yet

- Thesis On Okavango Water QualityDocument74 pagesThesis On Okavango Water QualityValmik SoniNo ratings yet

- MSDS - Xylar - 2 - 2022Document14 pagesMSDS - Xylar - 2 - 2022SYED MAZHAR100% (2)

- 41-187.0 Natural Gas Processing 0Document12 pages41-187.0 Natural Gas Processing 0Thameem AnsariNo ratings yet

- Safety at Construction Project A ReviewDocument5 pagesSafety at Construction Project A ReviewIJRASETPublicationsNo ratings yet

- Hazardous Substances and Human Health: Exposure, Impact and External Cost Assessment at the European ScaleFrom EverandHazardous Substances and Human Health: Exposure, Impact and External Cost Assessment at the European ScaleNo ratings yet

- PHYSICOCHEMICAL PROERTIES OF GELATIN THAT ENHANCE SUGAR CRAFT EXPRESSIONS - Onyemize U.CDocument4 pagesPHYSICOCHEMICAL PROERTIES OF GELATIN THAT ENHANCE SUGAR CRAFT EXPRESSIONS - Onyemize U.CFrancis Abulude100% (1)

- ADVANCING EDUCATION IN THE CARIBBEAN AND AFRICA - Edited by Cynthia Onyefulu, PHDDocument176 pagesADVANCING EDUCATION IN THE CARIBBEAN AND AFRICA - Edited by Cynthia Onyefulu, PHDFrancis AbuludeNo ratings yet

- THE RELEVANCE OF FRENCH LANGUAGE TO THE NIGERIAN FIFA GRADED REFEREES IN THEIR INTERNATIONAL ASSIGNMENTS Agbagbatu Samuel OghenekaroDocument7 pagesTHE RELEVANCE OF FRENCH LANGUAGE TO THE NIGERIAN FIFA GRADED REFEREES IN THEIR INTERNATIONAL ASSIGNMENTS Agbagbatu Samuel OghenekaroFrancis AbuludeNo ratings yet

- Counselling For Educational Reform and Sustainability: A 21ST Century ApproachDocument119 pagesCounselling For Educational Reform and Sustainability: A 21ST Century ApproachFrancis AbuludeNo ratings yet

- MONTHLY AIR TEMPERATURE VARIABILITY IN ILORIN AND LAGOS, NIGERIA - Adejumo I. A and Ojo J. F.Document10 pagesMONTHLY AIR TEMPERATURE VARIABILITY IN ILORIN AND LAGOS, NIGERIA - Adejumo I. A and Ojo J. F.Francis AbuludeNo ratings yet

- TRANSIENT HYDROMAGNETIC NATURAL CONVECTION FLOW OF REACTIVE VISCOUS FLUID WITH VARIABLE THERMAL CONDUCTIVITY IN A VERTICAL CHANNEL - M.M. Hamza and I.G. UsmanDocument13 pagesTRANSIENT HYDROMAGNETIC NATURAL CONVECTION FLOW OF REACTIVE VISCOUS FLUID WITH VARIABLE THERMAL CONDUCTIVITY IN A VERTICAL CHANNEL - M.M. Hamza and I.G. UsmanFrancis AbuludeNo ratings yet

- EFFICIENCY OF STANDARD GERMINATION AND VIGOUR TESTS IN PREDICTING FIELD EMERGENCE OF SESAME Sesamum Indicum L. SEEDS - Aghimien, E.V., Ekaun, A.A, Geply, O.A., Aghimien, O.G., Aremu, O.T.Document7 pagesEFFICIENCY OF STANDARD GERMINATION AND VIGOUR TESTS IN PREDICTING FIELD EMERGENCE OF SESAME Sesamum Indicum L. SEEDS - Aghimien, E.V., Ekaun, A.A, Geply, O.A., Aghimien, O.G., Aremu, O.T.Francis AbuludeNo ratings yet

- FOODS OF THE BRACKISH RIVER PRAWN, Macrobrachium Macrobrachion (HERKLOTS, 1851) FROM EKOLE CREEK, BAYELSA STATE, NIGERIA - Deekae, Suanu Nanee, Ansa, Ebinimi J., Davidson, Edubamo BinaebiDocument16 pagesFOODS OF THE BRACKISH RIVER PRAWN, Macrobrachium Macrobrachion (HERKLOTS, 1851) FROM EKOLE CREEK, BAYELSA STATE, NIGERIA - Deekae, Suanu Nanee, Ansa, Ebinimi J., Davidson, Edubamo BinaebiFrancis AbuludeNo ratings yet

- PRINCIPAL COMPONENT ANALYSIS USING MULTIVARIATE METHOD FOR ANALYSING INVENTORY FIELD DATA IN FEDERAL COLLEGE OF FORESTRY, IBADAN, NIGERIA - Aghimien, E.V., Chenge, I.B., Ekaun, A.A., Geply, O.ADocument6 pagesPRINCIPAL COMPONENT ANALYSIS USING MULTIVARIATE METHOD FOR ANALYSING INVENTORY FIELD DATA IN FEDERAL COLLEGE OF FORESTRY, IBADAN, NIGERIA - Aghimien, E.V., Chenge, I.B., Ekaun, A.A., Geply, O.AFrancis AbuludeNo ratings yet

- LIBRARY AND EDUCATIONAL REFORMS IN THE 21ST CENTURY Edited by Olu Olat Lawal (Editor - in - Chief) and Kwaghga Beetsh (Associate Editor)Document133 pagesLIBRARY AND EDUCATIONAL REFORMS IN THE 21ST CENTURY Edited by Olu Olat Lawal (Editor - in - Chief) and Kwaghga Beetsh (Associate Editor)Francis AbuludeNo ratings yet

- HEAT AND MASS TRANSFER OVER A VERTICAL PLATE WITH RADIATION - J. AbdullahiDocument14 pagesHEAT AND MASS TRANSFER OVER A VERTICAL PLATE WITH RADIATION - J. AbdullahiFrancis AbuludeNo ratings yet

- PERFORMANCE EVALUATION OF SOLAR FISH DRYER - Oluwole, F. A., A. M. El-Jummah, M. Ben Oumarou and Kabir M. A. WanoriDocument6 pagesPERFORMANCE EVALUATION OF SOLAR FISH DRYER - Oluwole, F. A., A. M. El-Jummah, M. Ben Oumarou and Kabir M. A. WanoriFrancis AbuludeNo ratings yet

- LEARNING FRENCH AS A SECOND LANGUAGE: CHALLENGES FOR A NATIVE ENGLISH SPEAKER - Adigwe Joseph Chinedu and Anukwu Anthonia .UDocument9 pagesLEARNING FRENCH AS A SECOND LANGUAGE: CHALLENGES FOR A NATIVE ENGLISH SPEAKER - Adigwe Joseph Chinedu and Anukwu Anthonia .UFrancis AbuludeNo ratings yet

- The Pathway For African Development in The 21ST CenturyDocument10 pagesThe Pathway For African Development in The 21ST CenturyFrancis AbuludeNo ratings yet

- NATIONAL SUSTAINABLE DEVELOPMENT: THE ROLES OF THE CHURCH (VOLUME 1) - Edited by E. A. AdewaleDocument118 pagesNATIONAL SUSTAINABLE DEVELOPMENT: THE ROLES OF THE CHURCH (VOLUME 1) - Edited by E. A. AdewaleFrancis AbuludeNo ratings yet

- NATIONAL SUSTAINABLE DEVELOPMENT: THE ROLES OF THE CHURCH (VOLUME 2) - Edited by Donald A. Odeleye, PHDDocument110 pagesNATIONAL SUSTAINABLE DEVELOPMENT: THE ROLES OF THE CHURCH (VOLUME 2) - Edited by Donald A. Odeleye, PHDFrancis Abulude100% (1)

- GENDER EQUALITY: RECOGNIZING THE CONTRIBUTIONS OF WOMEN TO SCIENCE AND EDUCATION - Edited by Eunice O. Osakinle and Juliet C. Alex-NmechaDocument102 pagesGENDER EQUALITY: RECOGNIZING THE CONTRIBUTIONS OF WOMEN TO SCIENCE AND EDUCATION - Edited by Eunice O. Osakinle and Juliet C. Alex-NmechaFrancis AbuludeNo ratings yet

- Isolation of Diarrhoeagenic Bacteria in ChildrenDocument6 pagesIsolation of Diarrhoeagenic Bacteria in ChildrenFrancis AbuludeNo ratings yet

- Counselling For Educational Reform and Sustainability: A 21ST Century ApproachDocument119 pagesCounselling For Educational Reform and Sustainability: A 21ST Century ApproachFrancis AbuludeNo ratings yet

- Toxicological Effects of Extracts of The Leaves of Scoparia Dulcis On The Brain ofDocument5 pagesToxicological Effects of Extracts of The Leaves of Scoparia Dulcis On The Brain ofFrancis AbuludeNo ratings yet

- ADVANCING EDUCATION IN THE CARIBBEAN AND AFRICA - Edited by Cynthia Onyefulu, PHDDocument176 pagesADVANCING EDUCATION IN THE CARIBBEAN AND AFRICA - Edited by Cynthia Onyefulu, PHDFrancis AbuludeNo ratings yet

- GLOBAL ISSUES ON RURAL AND URBAN CONFLICT VIOLENCE IN THE 21ST CENTURY - Beetseh, Kwaghga (Editor) GedDocument106 pagesGLOBAL ISSUES ON RURAL AND URBAN CONFLICT VIOLENCE IN THE 21ST CENTURY - Beetseh, Kwaghga (Editor) GedFrancis AbuludeNo ratings yet

- Haematological Responses of Clarias Gariepinus Exposed To AnaestheticsDocument12 pagesHaematological Responses of Clarias Gariepinus Exposed To AnaestheticsFrancis AbuludeNo ratings yet

- MARKETING STRUCTURE and PERFORMANCE of Ocimum Gratissimum in Selected Markets in Ibadan MetropolisDocument6 pagesMARKETING STRUCTURE and PERFORMANCE of Ocimum Gratissimum in Selected Markets in Ibadan MetropolisFrancis AbuludeNo ratings yet

- Full Page Photo PDFDocument1 pageFull Page Photo PDFFrancis AbuludeNo ratings yet

- Vol 4 - 1 - Cont. J. Biol. Sci - MACROINVERTEBRATE FAUNA OF A TROPICAL SOUTHERN RESERVOIR, EKITI STATE, NIGERIA.Document11 pagesVol 4 - 1 - Cont. J. Biol. Sci - MACROINVERTEBRATE FAUNA OF A TROPICAL SOUTHERN RESERVOIR, EKITI STATE, NIGERIA.Francis AbuludeNo ratings yet

- Leadership For Quality Decision Making in The University System TheDocument5 pagesLeadership For Quality Decision Making in The University System TheFrancis AbuludeNo ratings yet

- Globilization and Educational Development in Nigeria Which Way ForwardDocument7 pagesGlobilization and Educational Development in Nigeria Which Way ForwardFrancis AbuludeNo ratings yet

- TRAFFIC MODELING FOR CAPACITY ANALYSIS OF GSM NETWORKS IN NIGERIA Biebuma J.J.,Orakwe S.I and Igbekele O.JDocument11 pagesTRAFFIC MODELING FOR CAPACITY ANALYSIS OF GSM NETWORKS IN NIGERIA Biebuma J.J.,Orakwe S.I and Igbekele O.JSteven JonesNo ratings yet

- QUALITY CHARACTERISTICS OF INDIGENOUS FERMENTED BEVERAGE PITO USING Lactobacillus Sake AS A STARTER CULTURE - Okoro, I A, Ojimelukwe, P C, Ekwenye, U N, Akaerue, B, And, Atuonwu, A C.Document6 pagesQUALITY CHARACTERISTICS OF INDIGENOUS FERMENTED BEVERAGE PITO USING Lactobacillus Sake AS A STARTER CULTURE - Okoro, I A, Ojimelukwe, P C, Ekwenye, U N, Akaerue, B, And, Atuonwu, A C.Francis AbuludeNo ratings yet

- Regional Emp Based On Environmental Carrying Capacity: Implementation IssuesDocument19 pagesRegional Emp Based On Environmental Carrying Capacity: Implementation IssuesJayti MoitraNo ratings yet

- Ongc Project ReportDocument16 pagesOngc Project ReportChitraParialNo ratings yet

- Multiple-Choice Test Chapter 22: Humans and The Environment: 1 A B C D 2 A B C D 3 A B C D 4 A B C D 5 A B C DDocument2 pagesMultiple-Choice Test Chapter 22: Humans and The Environment: 1 A B C D 2 A B C D 3 A B C D 4 A B C D 5 A B C DsybejoboNo ratings yet

- Modeling of Conventional Water Supply Treatment PlantDocument22 pagesModeling of Conventional Water Supply Treatment PlantMamoon RiazNo ratings yet

- Health COTDocument24 pagesHealth COTSarah A. DavidNo ratings yet

- C 16 Firebox Wet ScrubDocument1 pageC 16 Firebox Wet Scrubjohn_serafica7104No ratings yet

- Msds DibenzalasetonDocument5 pagesMsds DibenzalasetonFedi Rahman TaraNo ratings yet

- Water Quality Management in India: E-Mail: SCRMB - Cpcb@nic - In, Rmbdelhi@yahoo - Co.inDocument30 pagesWater Quality Management in India: E-Mail: SCRMB - Cpcb@nic - In, Rmbdelhi@yahoo - Co.inHarsh WaliaNo ratings yet

- Advantages of Steam Car WashingDocument2 pagesAdvantages of Steam Car WashingPc HealerNo ratings yet

- Technical Writing Guidebook PDFDocument106 pagesTechnical Writing Guidebook PDFaliomairNo ratings yet

- Final Environmental Impact Assessment Report: Prepared ForDocument129 pagesFinal Environmental Impact Assessment Report: Prepared ForfosterbalaNo ratings yet

- GEOGRAPHY PROJECT ON 5 TYPES OF POLLUTIONDocument12 pagesGEOGRAPHY PROJECT ON 5 TYPES OF POLLUTIONKelly MerieNo ratings yet

- ETRATA, CHRISTIAN ANGELO (Part 1,2,3 and Related Appendices)Document62 pagesETRATA, CHRISTIAN ANGELO (Part 1,2,3 and Related Appendices)AngeloEtrataNo ratings yet

- 2M Old PCs for Disposal in IndiaDocument25 pages2M Old PCs for Disposal in India9915622484No ratings yet

- Portable Purifi Cation Systems: Models PVS 185, 600, 1200, 1800, 2700Document12 pagesPortable Purifi Cation Systems: Models PVS 185, 600, 1200, 1800, 2700Hebert Dacorrégio HeidenreichNo ratings yet

- RRL (Pollutants)Document3 pagesRRL (Pollutants)Rhea MambaNo ratings yet

- Environmental Engineering at CornellDocument2 pagesEnvironmental Engineering at CornellyardleyNo ratings yet

- SSW#1 Basics of Industrial EcologyDocument8 pagesSSW#1 Basics of Industrial EcologyAisara AmanovaNo ratings yet

- Sika MiniPack WaterplugDocument6 pagesSika MiniPack WaterplugJoslyn Cachia BantickNo ratings yet

- Waste DisposalDocument18 pagesWaste DisposalYasser Arfat100% (2)

- Story Telling The Very Ugly BugDocument6 pagesStory Telling The Very Ugly BugjuddylajatyNo ratings yet

- Porirua Stream - Ecological Restoration Priorities For The Porirua Stream and Its CatchmentDocument62 pagesPorirua Stream - Ecological Restoration Priorities For The Porirua Stream and Its CatchmentPaul MarlowNo ratings yet

- MSDS Concentrated Molasses SolidsDocument5 pagesMSDS Concentrated Molasses SolidsTimbo SibaraniNo ratings yet

- ĐỀ 1 PTMH_TADocument7 pagesĐỀ 1 PTMH_TAMai PhạmNo ratings yet

- HS 1220 Material Safety Data SheetDocument5 pagesHS 1220 Material Safety Data SheetDewiNo ratings yet

- Introduction To Groundwater ModelingDocument119 pagesIntroduction To Groundwater ModelingAdi SusantoNo ratings yet

- Glossary of Terms Marine PaintingDocument2 pagesGlossary of Terms Marine PaintingRENGANATHAN PNo ratings yet

- Passive-Voice-Environment - 14654 (1) (6.8.2021)Document2 pagesPassive-Voice-Environment - 14654 (1) (6.8.2021)Phương Nguyễn HàNo ratings yet

- Environmental Protection and Management of Volos Sea-PortDocument97 pagesEnvironmental Protection and Management of Volos Sea-PortValerie Masita HariadiNo ratings yet