Professional Documents

Culture Documents

Aficio 500 Technical Manual

Uploaded by

Jeremy YoungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aficio 500 Technical Manual

Uploaded by

Jeremy YoungCopyright:

Available Formats

3-BIN SORTER (Machine Code: A566) Service Manual

25 April 1997

SPECIFICATIONS

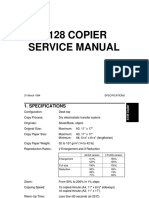

1. SPECIFICATIONS

Paper Size for Bins: Sort/Stack Modes: Maximum: A3, 11 x 17" Minimum: A6 lengthwise, 51/2 x 81/2" Face up: 1st bin: 52 ~ 157 g/m2 (14 ~ 42 lb) 2nd/3rd bins: 52 ~ 105 g/m2 (14 ~ 28 lb) Face down: All bins: 64 ~ 105 g/m2 (17 ~ 28 lb) 1st bin: A4, 81/2 x 11" : 500 copies A3, 11 x 17" : 250 copies 2nd/3rd bins: A4, 81/2 x 11" : 250 copies A3, 11 x 17" : 125 copies 3 copy trays 1 inverter tray DC 24 V, 5 V (from the main machine) Average: Less than 30 W 13 kg (28.7 lb) 361 x 483 x 427 mm (14.2" x 19.0" x 16.8")

Paper Weight for Bins:

Bin Capacity:

Number of Bins: Power Source: Power Consumption: Weight: Dimensions (W x D x H):

A566-1

Options

COMPONENT LAYOUT

25 April 1997

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENT LAYOUT

1 15

14 13

2 3 4

12 5 11 10 9 8

A566V001.wmf

1. Tray Lift Belt 2. 2nd Bin Gate 3. 2nd Exit Sensor 4. 3rd Bin Gate 5. Entry Sensor 6. Junction Gate 7. Feed Roller 8. Return Pinch Roller

9. Inverter Sensor 10. 3rd Exit Sensor 11. Inverter Bin 12. 3rd Bin 13. 2nd Bin 14. Tray Lower Limit Sensor 15. 1st Bin

A566-2

25 April 1997

COMPONENT LAYOUT

2.2 DRIVE LAYOUT

1 4

6 9 3 2

A566V002.wmf

7

A566V003.wmf

1. Entry Roller 2. Feed Roller 3. Entrance Motor 4. 1st Exit Roller 5. 2nd Exit Roller

6. 3rd Exit Roller 7. Inverter Roller 8. Return Pinch Roller 9. Exit Motor

A566-3

Options

COMPONENT LAYOUT

25 April 1997

2.3 ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the point-topoint diagram (on waterproof paper).

Symbol Motors M1 M2 M3 M4 Solenoids SOL1 Index No. 13 14 18 16 Description Entrance Exit Tray Shift Tray Lift 2nd Bin Gate 4 3rd Bin Gate SOL2 5 Junction Gate SOL3 6 Pinch Roller SOL4 Sensors Stack Height S1 2 Tray Half-turn 1st Exit 2nd Exit 3rd Exit Inverter Entry Tray Lower Limit Detects when the copy paper stack is at the correct height, and detects when the 1st bin is at its upper limit position. Detects complete side-to-side movement of the 1st bin. Detects paper jams at the 1st bin. Detects paper jams at the 2nd bin. Detects paper jams at the 3rd bin. Detects misfeeds and synchronizes the inverter gate. Detects misfeeds and copy paper entry. Detects when the 1st bin is at its lower limit position. Detects when the sorter is attached to the main machine. Controls all sorter functions. 7 Note Drives the feed roller and the entry roller. Drives the inverter roller and the exit rollers. Moves the 1st bin from side to side. Moves the 1st bin up or down. Opens and closes the 2nd bin gate to direct the copies into either the 2nd bin or 1st bin. Opens and closes the 3rd bin gate to direct the copies into either the 3rd bin or the other bins. Opens and closes the junction gate to direct copies into either the inverter area or other exits. In face down mode, contacts the return pinch roller with the copy to deliver the copy to bin 1, 2, or 3.

S2 S3 S4 S5 S6 S7 S8 Switches SW1 Circuit Board PCB1

17 1 8 9 10 11 15

3 12

Sorter Set

Control

A566-4

25 April 1997

DETAILED SECTION DESCRIPTIONS

3. DETAILED SECTION DESCRIPTIONS

3.1 BASIC OPERATION

3.1.1 Face-up Mode

[D] [C] [E]

[A] [B]

A566D001.wmf

A566D002.wmf

Copies exiting the copier pass through the entrance guide plate [A]. The entry roller will send copies either to the inverter bin or to each bin, depending on the selected mode. When the sorter receives the feed-out signal from the main machine, the entrance motor and exit motor energize to rotate the all rollers in the sorter. During copying, all rollers transport the paper at a speed which depends on the copier. When the leading edge of the copy passes the entry sensor [B], the speed of the rollers changes to 550 mm/s. - 1st, 2nd and 3rd bins When the junction gate [C] is closed as shown above, the copies pass through the upper part of the junction gate. For 1st bin output mode, the copy goes straight up from the junction gate directly to the bin. For the 2nd and 3rd bins, the copies from the junction gate are delivered to these bins, as directed by the 2nd bin gate [D] and 3rd bin gate [E].

A566-5

Options

DETAILED SECTION DESCRIPTIONS

25 April 1997

3.1.2 Face-down mode

[A]

[B]

[C]

[D]

A566D003.wmf

A566D004.wmf

When the junction gate [A] is opened, the copy goes to the inverter bin [B] through the lower part of the junction. When the trailing edge of the copy passes through the inverter sensor [C], the return pinch rollers [D] lower to contact the copy, then the copy is fed back in by the rollers. The copy is fed out to any output bin and it arrives face down.

A566-6

25 April 1997

DETAILED SECTION DESCRIPTIONS

3.2 1ST BIN UP/DOWN MECHANISM

[C] [D] [B]

[E]

[A]

A566D005.wmf

The tray lift motor (a dc motor) [A] controls the vertical position of the 1st bin [B] through gears. When the main switch is turned on, the 1st bin is initialized at the upper position. The bins upper position is detected by the stack height sensor [C]. The 1st bin activates the stack height sensor, then the 1st bin lowers until it is at the correct height to receive the copy. This initialization is performed before every copy job. During coping, when the stack height sensor is activated by the stack of paper, the 1st bin lowers until the stack height sensor is deactivated.

Options

When the 1st bin reaches its lower limit, actuator [D] enters the lower limit sensor [E], and copying stops. After copying ends, the machine stops.

A566-7

DETAILED SECTION DESCRIPTIONS

25 April 1997

3.3 1ST BIN SIDE-TO-SIDE SHIFT MECHANISM

[A] [B] [B] [D] [E]

[H] [E]

A566D006.wmf

[G]

[F]

[C]

A566D007.wmf

In the sort/stack mode, the 1st bin [A] moves from side-to-side to stagger and separate the sets of copies. The horizontal position of the shift tray is controlled by the tray shift motor (a dc motor) [B] and the shift cam [C]. After one set of copies is delivered to the bin, the tray shift motor starts rotating, driving the shift cam through gears. The link [D] connected between the shift cam and the tray shift plate [E] is creating the side-to-side movement required to stagger the copies. When the shift cam has rotated 180 degrees (when the tray is fully shifted across), the tray half-turn sensor [F] is activated by the slot [G] in the actuator plate [H], which is fixed to the shift cam, and the tray shift motor stops. The next set of copies is then delivered. The motor rotates, repeating the same process and moving the bin back to the previous position.

A566-8

25 April 1997

Normal Mode [A4 sideways, 3 pages, 40 CPM (200 mm/s)]

1 2 3 4 5 6

Normal Mode

0 (Sec.)

Feed Out Signal

550 mm/s *1

Entrance Motor

J1

J2

Entry Sensor

*1: This speed depends on the copier.

J4

Junction Gate Sol.

3.4 PAPER FEED AND MISFEED DETECTION TIMING

A566-9

J4 J3 J4

550 mm/s *1

J3

3rd Exit Sensor

J3

2nd Exit Sensor

1st Exit Sensor

Exit Motor

DETAILED SECTION DESCRIPTIONS

Options

A566D008.wmf

300 mm/s

Inverter Mode [A4 sideways, 3 pages, 40 CPM (200 mm/s)]

1 2 3 4 5 6

0 (Sec.)

Feed Out Signal

Inverter Mode

550 mm/s *1

Entrance Motor

DETAILED SECTION DESCRIPTIONS

Entry Sensor

Junction Gate Sol.

*1: This speed depends on the copier.

J5 J6 J7

A566-10

J8 J9 J8 J9

300 mm/s

Inverter Sensor

Pinch Roller Sol.

1st Exit Sensor

Exit Motor

550 mm/s

2nd Exit Sensor

J8

J9

A566D009.wmf

25 April 1997

3rd Exit Sensor

25 April 1997

DETAILED SECTION DESCRIPTIONS

3.5 JAM DETECTION

Paper Jams J1: The entry sensor does not turn on within 2 s after the feed out signal has turned on. J2: The entry sensor does not turn off within 610 ms after the feed out signal has turned off or the entry sensor stays on over 2.8 s. J3: The following exit sensors do not turn on within the specified time after the entry sensor has turned on. 1st exit sensor: 2.4 s 2nd exit sensor: 1.4 s 3rd exit sensor: 740 ms J4: The following exit sensors do not turn off within the specified time after the entry sensor has turned off. 1st exit sensor: 870 ms 2nd exit sensor: 500 ms 3rd exit sensor: 270 ms J5: The inverter sensor does not turn off within 4.56 s after the inverter senosr has turned on. J6: The inverter sensor does not turn on again within 380 ms after the inverter sensor has turned off. J7: The inverter sensor does not turn off within 1.14 s after the inverter sensor has turned on again. J8: The following exit sensors do not turn on within the specified time after the inverter sensor has turned on again. 1st exit sensor: 770 ms 2nd exit sensor: 430 ms 3rd exit sensor: 250 ms J9: The following exit sensors do not turn off within the specified time after the inverter sensor turned off again.

Options

A566-11

1st exit sensor: 770 ms 2nd exit sensor: 430 ms 3rd exit sensor: 250 ms

INSTALLATION PROCEDURE

25 April 1997

4. INSTALLATION PROCEDURE

4.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following list. 1. New Equipment Condition Report ........................... 1 2. Installation Procedure.............................................. 1 3. Front Connecting Bracket........................................ 1 4. Rear Connecting Bracket ........................................ 1 5. Bottem Bracket ........................................................ 1 6. Copy Tray ................................................................ 4 7. Decal - Paper Size Detector .................................... 1 7. Philips Screw - M4X12 ............................................ 6 9. Tapping Screw - M4X10 .......................................... 2 10. Snap Ring .............................................................. 2

A566-12

25 April 1997

INSTALLATION PROCEDURE

4.2 INSTALLATION PROCEDURE

A566I500.wmf A566I501.wmf

[F]

[A]

[E]

[C]

[B]

A566I502.wmf

[D]

A566I503.wmf

Unplug the copier power cord before starting the following procedure. 1. Remove the strips of tape. 2. Install the front connecting bracket [A] (2 screws) and the rear connecting bracket [B] (2 screws). 3. Install the bottom bracket [C]. 4. Remove the front cover [D] (3 screws) and rear cover [E] (3 screws). 5. Install the tray [F] with 2 tapping screws - M4 x 10.

Options

+ CAUTION

A566-13

INSTALLATION PROCEDURE

25 April 1997

[A]

[B]

[G]

[E] [C] [D]

A566I504.wmf

[I]

[H]

[F]

A566I505.wmf

A566I506.wmf

6. Install the sorter unit [A] on the frame with 1 clip [B]. 7. Mount the arm bracket [C] with 1 clip [D]. 8. Install the trays [E]. 9. Reinstall the front and rear covers. 10. Connect the cable [F] and the optic cable [G]. NOTE: If the main machine is 115V version, perform the following. In other case, skip step 11. 11. Remove the slider [H] from the copiers paper tray and attach the paper size detection decal [I]. 12. Reinstall the slider. 13. Turn the copiers main switch on and check the sorter operation.

A566-14

25 April 1997

REPLACEMENT AND ADJUSTMENT

5. REPLACEMENT AND ADJUSTMENT

5.1 EXTERIOR COVER AND BIN REMOVAL

[C]

[A]

[B]

[D]

A566R006.wmf

1. Rear Cover [A] (3 screws) 2. Front Cover [B] (3 screws) 3. Top Cover [C] (2 screws) 4. Bins [D] (1st bin: 2 screws)

A566-15

Options

REPLACEMENT AND ADJUSTMENT

25 April 1997

5.2 TRAY LIFT/TRAY SHIFT MOTOR ASSEMBLY REMOVAL

[A]

[B]

A566R007.wmf

1. Remove the rear cover (see Exterior Cover and Bin Removal). 2. Remove the clip [A]. 3. Remove the motor assembly [B] (3 screws, 3 connectors).

A566-16

25 April 1997

REPLACEMENT AND ADJUSTMENT

5.3 ENTRANCE MOTOR REPLACEMENT

[A] [B]

A566R008.wmf

[C]

A566R009.wmf

1. Remove the rear cover (see Exterior Cover and Bin Removal). 2. Remove the control board [A] (9 connectors, 4 clamps). 3. Remove the motor bracket [B] (2 screws). 4. Remove the exit motor [C] (2 screws).

A566-17

Options

REPLACEMENT AND ADJUSTMENT

25 April 1997

5.4 EXIT MOTOR REPLACEMENT

[B]

[A]

A566R010.wmf

1. Remove the rear cover (see Exterior Cover and Bin Removal). 2. Remove the motor bracket [A] (2 screws, 1 connector). 3. Remove the exit motor [B] (2 screws, 1 connector).

A566-18

25 April 1997

REPLACEMENT AND ADJUSTMENT

5.5 STACK HEIGHT SENSOR AND 1ST EXIT SENSOR REPLACEMENT

[C] [B]

A566R001.wmf

[A]

A566R002.wmf

1. Remove the front, rear, and top covers (see Exterior Cover and Bin Removal). 2. Remove all bins (see Exterior Cover and Bin Removal). 3. Remove the 3-bin sorter. 4. Remove the middle guide plate [A] (1 clip). 5. Remove the motor assembly [B] (see Tray Lift/Tray Shift Motor Assembly Removal). 6. Remove the upper guide plate [C] (4 screws).

Options

A566-19

REPLACEMENT AND ADJUSTMENT

25 April 1997

[D] [E]

[F]

A566R003.wmf

7. Remove the middle shift guide plate [D] (3 screws). 8. Remove the stack height sensor [E] (1 connector). 9. Remove the 1st exit sensor [F] (1 screw, 1 connector).

A566-20

25 April 1997

REPLACEMENT AND ADJUSTMENT

5.6 2ND / 3RD EXIT SENSOR AND INVERTER SENSOR REPLACEMENT

[A] [B] [D] [E]

[G] [F] [C]

A566R004.wmf

[H]

A566R005.wmf

1. Remove the front cover and rear cover (see Exterior Cover Removal). 2. Remove all bins. 3. Remove four tray brackets [A] (1 screw each). 4. Remove the upper exit cover [B] (2 screws). 5. Remove the lower exit cover [C] (2 screws). 6. Remove the sensor bracket [D] (1 screw) and replace the 2nd exit sensor [E] (1 screw, 1 connector).

Options

7. Remove the sensor bracket [F] (1 screw) and replace the 3rd exit sensor [G] (1 screw, 1 connector). 8. Replace the inverter sensor [H] (1 screw, 1 connector).

A566-21

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Overhead Water Tank Structural AnalysisDocument28 pagesOverhead Water Tank Structural Analysiscollins unanka100% (3)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFdiego diaz100% (1)

- SEM 3037E Tower Piping.Document52 pagesSEM 3037E Tower Piping.Kodali Naveen KumarNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- D31!37!39x21a Testing & Adjusting Procedure (WM)Document6 pagesD31!37!39x21a Testing & Adjusting Procedure (WM)words2zhigang_612545100% (1)

- MSZ Msy Ge06 24na - Service - Obh548a - 9 10Document44 pagesMSZ Msy Ge06 24na - Service - Obh548a - 9 10tm5u2rNo ratings yet

- Multi Zone Outdoors Service ManualDocument56 pagesMulti Zone Outdoors Service Manualcmorley505775% (4)

- Astra v10Document9 pagesAstra v10toni100% (4)

- What Is A Lecher AntennaDocument4 pagesWhat Is A Lecher AntennaPt AkaashNo ratings yet

- VVVF 4+manual (English)Document16 pagesVVVF 4+manual (English)Felix Romero67% (3)

- FR Se 2 65 K A C FR Se Falownik Inverter Freqrol Mitsubishi ManualDocument161 pagesFR Se 2 65 K A C FR Se Falownik Inverter Freqrol Mitsubishi ManualgrebogryzarkaNo ratings yet

- 34-15-59a.pdf Component Maintenance ManualDocument110 pages34-15-59a.pdf Component Maintenance Manualescribedecr100% (2)

- Movement Joints (NHBC)Document5 pagesMovement Joints (NHBC)hemendraengNo ratings yet

- Fermator vvvf-4+Document20 pagesFermator vvvf-4+paul100% (3)

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- Start Up Routine: Field Component ManualDocument12 pagesStart Up Routine: Field Component Manualihwisso100% (5)

- YARN MANUFACTURING STEPSDocument62 pagesYARN MANUFACTURING STEPSPranav Sharma100% (2)

- 20-Bin Sorter Stapler MachineDocument55 pages20-Bin Sorter Stapler MachineAnonymous MCh53tENo ratings yet

- Pneumatic LogicDocument27 pagesPneumatic LogicEliasNo ratings yet

- 20-BIN SORTER STAPLER SPECIFICATIONSDocument53 pages20-BIN SORTER STAPLER SPECIFICATIONSAnonymous MCh53tENo ratings yet

- Auto Reverse Document Feeder: (Machine Code: B379)Document30 pagesAuto Reverse Document Feeder: (Machine Code: B379)Cristian BobaruNo ratings yet

- Auto Reverse Document Feeder (Machine Code: A548)Document29 pagesAuto Reverse Document Feeder (Machine Code: A548)servicerNo ratings yet

- A084/A083 Service Training ManualDocument259 pagesA084/A083 Service Training ManualsafwatNo ratings yet

- Room Air ZQ08-10 CP08!10!12 SVC Parts Manual 5-06Document24 pagesRoom Air ZQ08-10 CP08!10!12 SVC Parts Manual 5-06Alex M-endoza'No ratings yet

- FT4015 (A219) Service ManualDocument262 pagesFT4015 (A219) Service ManualRaúl Lerma VallesNo ratings yet

- Akai GX-C730DDocument57 pagesAkai GX-C730Dlpy21No ratings yet

- PF-2D/AD-5: Service ManualDocument51 pagesPF-2D/AD-5: Service ManualMauricio Yamamoto PNo ratings yet

- Dual Job Feeder: (Machine Code: A610)Document62 pagesDual Job Feeder: (Machine Code: A610)Anonymous MCh53tENo ratings yet

- Service Training Manual A095/A096/A097: Ricoh Group CompaniesDocument282 pagesService Training Manual A095/A096/A097: Ricoh Group Companiespedrocc72100% (1)

- Akai GX65Document20 pagesAkai GX65sedder100% (1)

- S fw870Document206 pagesS fw870dieubimatNo ratings yet

- Manual Service Ricoh FW770 A0Document206 pagesManual Service Ricoh FW770 A0Andreea Iliescu100% (1)

- Manual Servicio Ricoh Fenix 4527-4127-4027-5035-5135-5535 PDFDocument368 pagesManual Servicio Ricoh Fenix 4527-4127-4027-5035-5135-5535 PDFDockmax CopierNo ratings yet

- Technical Bulletin No. RTB-001: Item Parts No. SpecificationDocument18 pagesTechnical Bulletin No. RTB-001: Item Parts No. SpecificationUlmanu ValentinNo ratings yet

- VT1730 PDFDocument161 pagesVT1730 PDFCristian BobaruNo ratings yet

- Ricoh FT 4215 A128 Service ManualDocument45 pagesRicoh FT 4215 A128 Service ManualJaime Rios100% (1)

- Mitsubishi Evaporadora MSH A18 A24NDDocument28 pagesMitsubishi Evaporadora MSH A18 A24NDfrigotecniaNo ratings yet

- MitsubishiDocument35 pagesMitsubishiAlfredoJoseRayaNo ratings yet

- Inspecting and Cleaning DiaphragmsDocument4 pagesInspecting and Cleaning DiaphragmsAnonymous zdCUbW8HfNo ratings yet

- Duplex: (Machine Code: A896)Document12 pagesDuplex: (Machine Code: A896)Cristian BobaruNo ratings yet

- TE-2000P Air Sampler ManualDocument13 pagesTE-2000P Air Sampler Manualsuko winartiNo ratings yet

- TB 6560Document23 pagesTB 6560marekNo ratings yet

- CHM-18XX Service Manual RevA 2Document30 pagesCHM-18XX Service Manual RevA 2stereojos86No ratings yet

- DC-8000 MK1 InstructionDocument63 pagesDC-8000 MK1 Instructioniceman1977No ratings yet

- 2030 3eDocument6 pages2030 3eJaikishan KumaraswamyNo ratings yet

- 1000-Sheet Finisher: (Machine Code: B408)Document25 pages1000-Sheet Finisher: (Machine Code: B408)Cristian BobaruNo ratings yet

- Wadkin BER 2 Spindle Moulder Manual & Parts ListDocument18 pagesWadkin BER 2 Spindle Moulder Manual & Parts Listmkmk15793No ratings yet

- Manual Trident Klasik 200Document12 pagesManual Trident Klasik 200DanielMachadopovoa100% (1)

- Service Manual: Electronic Cash RegisterDocument16 pagesService Manual: Electronic Cash RegisterDoru RazvanNo ratings yet

- Operation Manual KH-212Document63 pagesOperation Manual KH-212Jorge Centeno Ramos100% (2)

- B-Sa4T Series: Maintenance ManualDocument45 pagesB-Sa4T Series: Maintenance ManualTonyandAnthonyNo ratings yet

- Service Manual Sharp Ghettoblaster Gf4646Document16 pagesService Manual Sharp Ghettoblaster Gf4646stephanNo ratings yet

- Hydraulic 4 Roll Bending Machine Instruction ManualDocument79 pagesHydraulic 4 Roll Bending Machine Instruction ManualGeLoRa66No ratings yet

- Large Grilles Multiple SectionsDocument46 pagesLarge Grilles Multiple SectionsFaquruddin AliNo ratings yet

- PF-1D/AD-3: Service ManualDocument48 pagesPF-1D/AD-3: Service ManualMauricio Yamamoto PNo ratings yet

- How to Use and Service a High Pressure Air CompressorDocument12 pagesHow to Use and Service a High Pressure Air CompressorAleš FejglNo ratings yet

- Product Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 TonsDocument26 pagesProduct Data: 38CKE 50Hz Air Conditioner With R - 410a Refrigerant Single and Three Phase 1 - 1/2 To 5 Tonsalmig200No ratings yet

- Bridge Unit: (Machine Code: A897)Document9 pagesBridge Unit: (Machine Code: A897)Cristian BobaruNo ratings yet

- 1 Health, Safety and Environment 3Document24 pages1 Health, Safety and Environment 3gunasekaranveluNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Mayan Calendar End Date Sparks Doomsday SpeculationDocument16 pagesMayan Calendar End Date Sparks Doomsday SpeculationElfen RoxanneNo ratings yet

- Transformer Oil Testing: Dissolved Gas AnalysisDocument18 pagesTransformer Oil Testing: Dissolved Gas AnalysisIkhsan LyNo ratings yet

- HRM Assignment Final - Case StudyDocument7 pagesHRM Assignment Final - Case StudyPulkit_Bansal_2818100% (3)

- Writing A Spooky Setting DescriptionDocument4 pagesWriting A Spooky Setting DescriptionAayan AnjumNo ratings yet

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- 21st Century Literature Exam SpecsDocument2 pages21st Century Literature Exam SpecsRachel Anne Valois LptNo ratings yet

- Calculating Molar MassDocument5 pagesCalculating Molar MassTracy LingNo ratings yet

- PMMAEE Application FormDocument2 pagesPMMAEE Application Formshiero501100% (15)

- Margin Philosophy For Science Assessment Studies: EstecDocument11 pagesMargin Philosophy For Science Assessment Studies: EstecFeyippNo ratings yet

- CSE (With SPL)Document65 pagesCSE (With SPL)parthasarathycseNo ratings yet

- Hyd Schematic 2658487205 - 005Document3 pagesHyd Schematic 2658487205 - 005Angelo Solorzano100% (2)

- The Influence of Teleworking On Performance and Employees Counterproductive BehaviourDocument20 pagesThe Influence of Teleworking On Performance and Employees Counterproductive BehaviourCHIZELUNo ratings yet

- Managerial Performance Evaluation ProceduresDocument3 pagesManagerial Performance Evaluation Procedures1robcortesNo ratings yet

- DAFTAR PUSTAKA Generik vs Branded Drug ReferencesDocument4 pagesDAFTAR PUSTAKA Generik vs Branded Drug ReferencesRika MardiahNo ratings yet

- Symbiosis Skills and Professional UniversityDocument3 pagesSymbiosis Skills and Professional UniversityAakash TiwariNo ratings yet

- Catalogue: Product Offering 51Document56 pagesCatalogue: Product Offering 51Bruno MartinsNo ratings yet

- Manufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaDocument28 pagesManufacturing Processes (ME361) Lecture 13: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- Naaqs 2009Document2 pagesNaaqs 2009sreenNo ratings yet

- Main Sulci & Fissures: Cerebral FissureDocument17 pagesMain Sulci & Fissures: Cerebral FissureNagbhushan BmNo ratings yet

- SEW Motor Brake BMGDocument52 pagesSEW Motor Brake BMGPruthvi ModiNo ratings yet

- Syllabus Agri 2015Document248 pagesSyllabus Agri 2015parvathivignesh279No ratings yet

- Lecture 6-Design For ShearDocument14 pagesLecture 6-Design For ShearMarkos DanielNo ratings yet

- 4.3 Structural Analysis 4.3.1 ModellingDocument8 pages4.3 Structural Analysis 4.3.1 Modellingdavid ROBALINONo ratings yet

- The Eukaryotic Replication Machine: D. Zhang, M. O'DonnellDocument39 pagesThe Eukaryotic Replication Machine: D. Zhang, M. O'DonnellÁgnes TóthNo ratings yet