Professional Documents

Culture Documents

Construction of the People's Hive with moveable frames

Uploaded by

Jovica VelickovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction of the People's Hive with moveable frames

Uploaded by

Jovica VelickovicCopyright:

Available Formats

Construction of the People's Hive with moveable frames

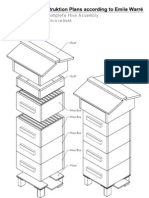

(Translated by David Heaf from pages 60 to 69 L' Apiculture Pour Tous Manuel-Guide Des Fixistes Et Des Mobilistes (Beekeeping For All A manual for fixed comb and mobile frame beekeepers) by Abb Warr, Bureau du 'Travail au Grand Air', 17 Rue Littr, 17 Tours, France, 5th edition, 1923.) On page 46 Warr writes: Nowadays, I recommend without hesitation the People's Hive with fixed combs, even for very large enterprises. [...] However, out of respect for the freedom of my readers, I will describe the People's Hive in its three forms: fixed comb, ordinary frames, open frames* with closed ends.

* no bottom-bar, see page 7

OBSERVATIONS The construction of the People's Hive with moveable frames is very similar to that of the People's Hive with fixed combs. I thus follow the same order of presentation. I will not avoid repetition so that the reader does not have to turn over pages to recall some of my advice. In my presentation of this construction I look to economy. Thus I make the walls 20 mm, the minimum thickness they should have. This thickness is however sufficient if one covers the walls with a mat as I would advise. If you do not want to cover the walls with a mat, you should make them 24 mm thick. If the wood at one's disposal requires it, quite another thickness can be given to the walls but don't forget to enlarge accordingly the external dimensions of all parts of the hive, as the internal dimensions should be retained and that the mat is always useful whatever the thickness of the walls. Constructing it with double walls also gives better results. In this case we use boards from 10 to 15 mm thick and leave between them a void of 15 to 20 mm. It is important to keep stationary air there.

FLOOR The floor comprises one or several boards, of a thickness of one or several centimetres, forming a square 375 x 375 mm (fig. 24). At the extremities two battens of about 20 x 20 mm

strengthen this square (fig. 24, A & A'). On one side of the floor, in the middle, a notch is made to provide an entrance for the bees. This notch is 120 mm wide and 40 mm deep at the bottom, and 50 mm deep at the top. This difference in depth forms a ramp to enable the bees to climb up more easily. Below this notch is placed a board which serves as an alighting board. This board is at least 10 mm thick and 150 mm wide. It must project 70 mm from the edge of the floor. It will thus have a length of 150 mm if one wishes to stop at B, or 445 mm if it is extended to B' to strengthen the floor. At the edge of the floor are placed battens C, C', D, D'. The battens C and C' are 375 mm long. The battens D and D' are 335 mm long. The battens must be 20 mm wide, the width of the walls of the boxes. These battens form a void between the floor and the frames of the lowest box in order to allow passage for the bees under the frames. The battens must thus have a thickness of 10 to 15 mm.

BOXES The boxes we are about to describe rest directly on the floor, or on top of one another, without any nesting. They can be fixed to the floor or each other by some article of ironmongery or simply by two nails linked with wire on two or three sides. Except when moving, these measures are unnecessary. The weight of the boxes does not allow the wind to displace them. Moreover, the bees all to often fix them with propolis. There should be at least three boxes. Two boxes comprise the brood nest in winter as well as in summer. The third box is added only during the main flow. All three boxes have the same dimensions. The inside of the boxes are 207.5 mm high and 335 mm wide and long (fig. 25). At the outside, the dimensions are 207.5 mm high and 375 mm wide and long (fig. 25). We are always assuming that the walls are 20 mm thick. But the walls of the boxes may be made in different ways, or with a single board of 20 mm (fig 25, A) or a board 10 mm thick covered with two boards 10 mm thick placed horizontally (fig 25, B) or a board 10 mm thick covered with several boards 10 mm thick placed crossways vertically (fig 25, C). This system of construction therefore allows small pieces of wood to be used. In the corners of each box we can place battens (fig. 25, D). These battens are the height of the box, 207.5 mm, 5 mm thick and 17.5 mm wide. These battens serve as points of abutment for the spacers that can be put on the frames to keep them the right distance apart, if the spacers are 6 mm and eight are used per frame. If, instead, for separating frames one uses nail spacers of 12 mm, about which we will speak, and numbering four per frame, these battens D no not need to be put in the box. CLOTH On the top box is placed a cloth to stop the bees sticking the frames to the roof, to the quilt, etc. (fig. 25 L). The cloth can be cut from an old sack. It should initially have the dimensions of at least 390 x 390 mm. In case one needs to feed the colony, it is good to cut a square 40 mm x 40 mm in the middle of the cloth. The hole is closed with metal mesh 60 x 60 mm (food safe mesh) fixed in place with thread (fig. 25 I). On top of this metal mesh is fixed a square of cloth 100 x 100 mm (fig. 25 J). To stop the bees fraying the cloth, it is coated with flour paste. To give the cloth the necessary shape and size it is placed still wet on the box. When it is dry it is cut by following the outside edges of the box. If the cloth is finally cut before wetting it will no longer be possible to make it the right size.

FRAMES Each box should have 9 frames. The interior measurements of these frames are 180 x 300 mm. They are made of four pieces of which two are identical: the top-bar (fig 26 A), the two sides B and B', the bottom-bar C. The top-bar A has a thickness of 10 mm, a width of 24 mm and a length of 350 mm. The bottom-bar C has a thickness and width of 10 mm and a length of 330 mm. The two sides, B and B' are 10 mm thick, 24 mm wide and 180 mm long.

The bottom-bar C extends 5 mm beyond the sides B and B'. The square at the two ends of the bottombar is reduced by three cuts to 5 mm (see inset, fig. 26 D). At the ends of both sides B and B' at E, two cuts are made to reduce the width to 10 mm, the same width as the bottom-bar C. The frames rest on their ends in two rebates cut in the upper edges of the boxes (fig 25 E and E'). These rebates are 10 mm wide and 15 mm deep. The rebates can be made either by passing two saw cuts along the upper, inner edge of the walls which have a thickness of 20 mm (fig. 25 F') or by reducing by 15 mm the height of the inner board of a wall made of two boards of 10 mm (fig. 25 F). The frames are positioned 36 mm between centres (fig 25). Between each there is a gap of 12 mm for the bees to pass. There is also a 12 mm gap between the end frames and the adjacent walls. This gap allows the full construction of the end combs. Note that the top-bars of the frames have a groove of about 4 x 4 mm (fig. 26, F). This groove is to hold sheets of wax. This groove can be made with a special joinery tool. It can also be made with a saw, a knife or a chisel. It does not need to be regular, on the contrary. But it is sufficient that this groove is made right in the middle of the top-bar. ROOF The roof comprises two parts, A and B (fig. 27). Part A is made of several boards of at least 10 mm thick forming a square of 380 x 380 mm. This square is surrounded by a batten about 10 mm thick (fig. 27 C & C'). This batten projects 20 mm downwards to enclose the upper box and to better secure the roof during windy weather. On the part A of the roof are placed two battens. One of them (D) should have a minimum thickness of 20 mm and a height of 60 mm. Its length is 380 mm at the bottom and 480 mm at the top. The other batten (E) should be 20 mm thick and 20 mm high. Its length is 480 mm. It is on these two battens that the part B is fixed. In fig. 27, the parts A and B are separated so the details are visible. Moreover, the difference in height between D and E gives the necessary slope to part B which has to receives the rain.

The part B of the roof comprises one or several boards of a minimum thickness of 10 mm. It should be 480 mm square. This part B of the roof can be painted, or covered with zinc or other sheet metal, bitumenised sheet or the joints simply covered with slats (fig. 27, F).

Key to figure 28 A Alighting board projecting 70 mm and extended to the back of the floor. B Floor with a notch sloping 40 to 50 mm for the bees to enter. C Walls formed from two boards 10 mm thick. D Walls formed of one board 20 mm thick. E Frames resting in a rebate. F Roof in which is enclosed the top box. H Roof covering the top box.

Construction of the People's Hive with open frames

(Translated by David Heaf from pages 69 to 71 of L' Apiculture Pour Tous Manuel-Guide Des Fixistes Et Des Mobilistes (Beekeeping For All A manual for fixed comb and mobile frame beekeepers) by Abb Warr, Bureau du 'Travail au Grand Air', 17 Rue Littr, 17 Tours, France, 1923.) The special frame of this hive requires significant modification of the floor and boxes, which moreover are inevitably double walled. The arrangement of the roof and quilt remains the same, but their sizes obviously have to be adjusted to the exterior dimensions of the boxes. FRAME The bottom-bar is eliminated. The top-bar remains the same except that it does not extend beyond the side-bars. The side-bars are totally changed. These side-bars are 207.5 mm high. They should be 36 mm wide. Their thickness should be 24 mm. At the top and over the full thickness a groove is made 10 mm deep and 24 mm wide to receive the end of the top-bar. The end of this top-bar is fixed to the side-bar with two 27 mm nails inserted vertically and two 12 mm nails inserted horizontally on each side in the parts of the side-bar left by the groove. These parts are 6 mm thick and 24 mm wide. At 30 mm from the top of the side-bar, its thickness is reduced to 10 mm to allow it to be supported by a batten and to provide the cavity of a double wall. (see illustration below kindly provided by Paul N)

BOXES The boxes are single-walled made of boards of 13 to 15 mm thick. Their interior measurements are 350 x 350 mm and 210 mm high. They are 2.5 mm deeper than the side bars of the frames. Thus a void is created at the bottom of the boxes. Two battens of 10 mm are placed on two inside surfaces to support the frames. On the two other surfaces, parallel to the frames, two partitions [follower boards Tr.] are fixed to rest against the frames with a spring. I prefer one side of the double wall fixed and the other a partition with a spring. There will of course be only eight frames. FLOOR The floor has to stop the extension of the combs as in the hive with fixed combs. It must also allow the exit of the bees which may occur between, on the one hand, the walls and, on the other hand, the sides of the frames and the partitions. The floor of the hive with fixed combs (fig. 20, see Beekeeping For All, page 44) gives an idea of how the floor of the People's Hive with open frames should be. The notch, 120 mm wide, instead of stopping at 40 mm should be extended to the edge of the floor where it is closed with a batten of the same thickness as the exterior board of the walls of the box. This notch is closed underneath by the alighting board, which is also extended to the edge of the floor. If this board is placed lengthways, it of course has to be strengthened with battens.

You might also like

- Emile - Warre.people - Hive.plans - Engl. .11pDocument0 pagesEmile - Warre.people - Hive.plans - Engl. .11ptewngomNo ratings yet

- Warre Hive Plans MetricDocument11 pagesWarre Hive Plans Metricplc_ratm100% (4)

- Round Warre HivesDocument17 pagesRound Warre HivesVanessa JenningsNo ratings yet

- Warre CoteDocument8 pagesWarre Cotepvm_manuNo ratings yet

- Natural Beekeeping With Warres 1 PDFDocument38 pagesNatural Beekeeping With Warres 1 PDFAnonymous 2Mfw6dCoSlNo ratings yet

- Warre Beekeping - Hexagonal HiveDocument8 pagesWarre Beekeping - Hexagonal HiveboldogasszonylanyaNo ratings yet

- First Year Beekeeping PDFDocument15 pagesFirst Year Beekeeping PDFAnonymous 2Mfw6dCoSlNo ratings yet

- Window Mounted Solar Hot Air FurnaceDocument14 pagesWindow Mounted Solar Hot Air FurnaceEduardo J Villalobos GNo ratings yet

- Geodome PDFDocument26 pagesGeodome PDFTravis JohnsonNo ratings yet

- Sun Hive OverviewDocument4 pagesSun Hive Overview'jd Mora'100% (1)

- P Stipticus Mushroom InstructionsDocument2 pagesP Stipticus Mushroom InstructionsMeoni RiccardoNo ratings yet

- Barrel IncineratorDocument29 pagesBarrel IncineratorEmijo.ANo ratings yet

- Instructions for Setting Up a Sioux TipiDocument31 pagesInstructions for Setting Up a Sioux TipivictorNo ratings yet

- Clay Mix & Process For Building Bread Oven: Construction of Willow BasketDocument4 pagesClay Mix & Process For Building Bread Oven: Construction of Willow BasketJohn MillerNo ratings yet

- Fire by FrictionDocument6 pagesFire by FrictionOtis1964No ratings yet

- Straw Bale Green HomeDocument13 pagesStraw Bale Green Homedanut_docNo ratings yet

- Designing Your Ideal Horizontal Top-Bar HiveDocument15 pagesDesigning Your Ideal Horizontal Top-Bar HiveJohn Vendy100% (7)

- How to Grow Oyster Mushrooms at HomeDocument26 pagesHow to Grow Oyster Mushrooms at HomeMatavi ManoharNo ratings yet

- How to Prevent Bee SwarmingDocument97 pagesHow to Prevent Bee SwarmingrmedinaparedesNo ratings yet

- Capturing Heat 3Document46 pagesCapturing Heat 3AlexandruChivaranNo ratings yet

- DomesDocument14 pagesDomesKarthikeya SarmaNo ratings yet

- Windsor Chair Part 1Document7 pagesWindsor Chair Part 1simon_whittard100% (1)

- Barefoot Beekeeper IntroDocument7 pagesBarefoot Beekeeper Introsant143inNo ratings yet

- Wood Shingle RoofDocument1 pageWood Shingle RoofkamikazewuNo ratings yet

- The Backyard Beekeeper, 4th Edition: An Absolute Beginner's Guide To Keeping Bees in Your Yard and Garden - EngineeringDocument5 pagesThe Backyard Beekeeper, 4th Edition: An Absolute Beginner's Guide To Keeping Bees in Your Yard and Garden - EngineeringbahygomoNo ratings yet

- How To Make Rope: Hickory Withes. Select A Green Branch of Mockernut, Shagbark, or PignutDocument3 pagesHow To Make Rope: Hickory Withes. Select A Green Branch of Mockernut, Shagbark, or PignutnightclownNo ratings yet

- TopBar BeeHive PlansDocument9 pagesTopBar BeeHive Planswtalex378100% (2)

- Growing Oyster Mushrooms On Straw Pellets PDFDocument2 pagesGrowing Oyster Mushrooms On Straw Pellets PDFbravohr98No ratings yet

- Food Forest WorksheetDocument7 pagesFood Forest Worksheetapi-258182324No ratings yet

- Compost Toilet ManualDocument23 pagesCompost Toilet ManualMoreMoseySpeed100% (4)

- Oyster Mushroom Cultivation in Northern ThailandDocument8 pagesOyster Mushroom Cultivation in Northern ThailandAnonymous HXLczq3No ratings yet

- Oyster Mushroom Cultivation - Unidad 2 PDFDocument14 pagesOyster Mushroom Cultivation - Unidad 2 PDFSandra Milena VelandiaNo ratings yet

- Food Forest and Permaculture EnglishDocument6 pagesFood Forest and Permaculture EnglishkakangmasNo ratings yet

- Warre Hive Plans EnglishDocument6 pagesWarre Hive Plans Englishpvm_manuNo ratings yet

- Regenerative Organic Farming: A Solution To Global WarmingDocument13 pagesRegenerative Organic Farming: A Solution To Global WarmingNutrition WonderlandNo ratings yet

- Learn Ancient Basketry SkillsDocument16 pagesLearn Ancient Basketry SkillsLeeNo ratings yet

- Solar-Heated GreenhouseDocument4 pagesSolar-Heated GreenhouseLeontin LeonNo ratings yet

- Greenhouse UndergroundDocument3 pagesGreenhouse Undergroundlydk05No ratings yet

- Ferrocement Biogas DigesterDocument38 pagesFerrocement Biogas DigesterBotár CsabaNo ratings yet

- Jerusalem ArtichokeDocument16 pagesJerusalem ArtichokeceramickurtNo ratings yet

- Soil RestorationDocument126 pagesSoil RestorationManuBeBuNo ratings yet

- Barrel Oven BookDocument98 pagesBarrel Oven BookAlessandroLodovichi100% (1)

- An Introduction To Beekeeping: - Bees - Hives and Equipment - Getting BeesDocument18 pagesAn Introduction To Beekeeping: - Bees - Hives and Equipment - Getting BeesTomboNo ratings yet

- My Bread OvenDocument13 pagesMy Bread OvenGrama TicNo ratings yet

- Food Security Video Guide (19 Oct 2009)Document83 pagesFood Security Video Guide (19 Oct 2009)gramps8142850% (2)

- Worm Composting - Montgomery ExtensionDocument2 pagesWorm Composting - Montgomery ExtensionPennsylvania Association for Sustainable AgricultureNo ratings yet

- The Big Book of the Scythe: User Guidelines for the Versatile ScytheDocument174 pagesThe Big Book of the Scythe: User Guidelines for the Versatile ScytheJason genovaNo ratings yet

- Rice Technology Bulletin Series No. 14: Composting GuideDocument30 pagesRice Technology Bulletin Series No. 14: Composting Guideronalit malintadNo ratings yet

- Cabinet Kitchen IslandDocument2 pagesCabinet Kitchen Islandsvsimo100% (1)

- Tree House Plans GuideDocument10 pagesTree House Plans Guidempendleton100% (1)

- Warre Hive PlansDocument11 pagesWarre Hive PlansGiorgio ZamboniNo ratings yet

- Shed Storage2Document9 pagesShed Storage2Bob Pouliot88% (8)

- Installation Guide For 20/20: Profile Ridge, Rollridge, Roll Hip, Profile Mono Ridge and 20/20 Verge InstallationDocument6 pagesInstallation Guide For 20/20: Profile Ridge, Rollridge, Roll Hip, Profile Mono Ridge and 20/20 Verge Installationslindelft-cool7056No ratings yet

- Wishing WellDocument9 pagesWishing WellKev HawkinsNo ratings yet

- FFFFF Build A GazeboDocument11 pagesFFFFF Build A GazeboGhinea ReluNo ratings yet

- Beginner - Child's BedDocument4 pagesBeginner - Child's BedDillon HartsykerNo ratings yet

- How to build an inexpensive mikvahDocument15 pagesHow to build an inexpensive mikvahserverdigitalNo ratings yet

- Yurt Construction DocumentDocument26 pagesYurt Construction DocumentsepaulsenNo ratings yet

- DIY Birdhouse for Balcony or GardenDocument4 pagesDIY Birdhouse for Balcony or GardenSanjeev ChoudharyNo ratings yet

- Octagonal Gazebo Plans: 2400mm DiameterDocument8 pagesOctagonal Gazebo Plans: 2400mm DiameterrullybandungNo ratings yet

- FSC STD 40 201 V2 0 en FSC On Product Labelling RequirementsDocument16 pagesFSC STD 40 201 V2 0 en FSC On Product Labelling RequirementsDaniel BogleaNo ratings yet

- Analysis of Mending WallDocument2 pagesAnalysis of Mending WallPotgieter Paidi50% (2)

- Viking Ship ConstructionDocument13 pagesViking Ship ConstructionJanne Fredrik100% (2)

- Maximize Honey Yields With Two-Queen Colony ManagementDocument14 pagesMaximize Honey Yields With Two-Queen Colony ManagementAle Biole100% (2)

- Johnny Appleseed: A Legendary American FrontiersmanDocument3 pagesJohnny Appleseed: A Legendary American FrontiersmanArdiyantoNo ratings yet

- Japanese Mnemonics For CharactersDocument15 pagesJapanese Mnemonics For Characterstumblrwush_contactNo ratings yet

- Complete Guide to More Efficient Charcoal Production MethodsDocument1 pageComplete Guide to More Efficient Charcoal Production MethodsHarry SingadilagaNo ratings yet

- Course in Non-Destructive Testing of WoodDocument3 pagesCourse in Non-Destructive Testing of Woodأحمد دعبسNo ratings yet

- Plants Found in Bicol RegionDocument7 pagesPlants Found in Bicol RegionAlyssaNo ratings yet

- Barbara JohnsDocument23 pagesBarbara JohnsJasmina KostadinovićNo ratings yet

- Bamboo Industry Value Chain PresentationDocument39 pagesBamboo Industry Value Chain Presentationapi-19975232No ratings yet

- Wilkinson Dalmatia and Montenegro IIDocument504 pagesWilkinson Dalmatia and Montenegro IIEdin BujakNo ratings yet

- The Egyptian Pyramids Theories of ConstructionDocument22 pagesThe Egyptian Pyramids Theories of Constructionyoma22No ratings yet

- FAQ AgricolaDocument3 pagesFAQ AgricolaAndre Luiz FuzaroNo ratings yet

- Cooperative FarmingDocument14 pagesCooperative FarmingDivesh ChandraNo ratings yet

- Sulfite PulpingDocument4 pagesSulfite PulpingMikaella Manzano0% (1)

- Consolidated Zoning Bylaw No. 871Document142 pagesConsolidated Zoning Bylaw No. 871stevewandlerNo ratings yet

- TapirDocument3 pagesTapirDark_KiroNo ratings yet

- Jenis2 Text Lintas Minat BingDocument16 pagesJenis2 Text Lintas Minat BingSilvara Rifu RinamuNo ratings yet

- Test Series - Forestry: Test Number Date Topic Syllabus Reading Materials 02-11-2020 Paper-1 Section-ADocument4 pagesTest Series - Forestry: Test Number Date Topic Syllabus Reading Materials 02-11-2020 Paper-1 Section-ANikhil AgrawalNo ratings yet

- Deforestation ReportDocument10 pagesDeforestation ReportElina KarshanovaNo ratings yet

- MaltasDocument8 pagesMaltasSebastianNo ratings yet

- Importance of EggplantDocument2 pagesImportance of EggplantKaren Ailene Posada BenavidezNo ratings yet

- Nunes 2008Document6 pagesNunes 2008Lina NunesNo ratings yet

- September 1998 North American Native Orchid JournalDocument109 pagesSeptember 1998 North American Native Orchid JournalNorth American Native Orchid Journal100% (1)

- Tom and The Tomango TreeDocument8 pagesTom and The Tomango TreePei Hwee TanNo ratings yet

- Ansys Usage On PlywoodDocument12 pagesAnsys Usage On Plywoodshivam choudharyNo ratings yet

- Auction Time Magazine 31012013downloadDocument40 pagesAuction Time Magazine 31012013downloadselereakNo ratings yet

- Extensive Le Havre Building Reference and Strategy Guide Draft Version 1Document127 pagesExtensive Le Havre Building Reference and Strategy Guide Draft Version 1Andres TapiaNo ratings yet

- Exploring Land Use Changes and The Role of Palm Oil Production in Indonesia and MalaysiaDocument14 pagesExploring Land Use Changes and The Role of Palm Oil Production in Indonesia and MalaysiaItsuki KamigawaNo ratings yet