Professional Documents

Culture Documents

Flexcut Tools

Uploaded by

eternal_harpyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexcut Tools

Uploaded by

eternal_harpyCopyright:

Available Formats

Carvin Jack by Flexcut is a complete carving kit in your pocket!

Great for camping! Includes its own Flexcut Sliptrop and Flexcut Gold polishing compound. Complete instructions for operating and maintaining the sharpest edge possible. Each razor edge is honed and locks securely in both the opened and closed positions. All blades are made of Flexcuts high-carbon steel, which made their tools famous.

A complete carving kit in your pocket!

I c u e aF e c tS i s r p , nlds lxu lpto Flexcut Gold polishing compound a dc m l t i s r c i n f rm i t i i g n opee ntutos o anann t es a p s e g p s i l . h hret de osbe

Detail Knife

Straight Gouge

Its fine point can be used for detailing delicate areas or quickly removing wood from a convex surface as you would with any whittling knife.

Gouges are used for modeling surfaces or creating different textures. It can also be used for carving printmaking woodcuts.

k Knife

Made in USA

Hook Knife

V- Scorp

The hook knife is designed for carving in hollow areas where a straight blade cant reach. Its ideal for hollowing spoons or roughing out larger amounts of waste wood.

The V-Scorps sharp corners leave a clean line of demarcation between two adjacent surfaces, much the same as outlining with a pencil.

el

Instructions and Sharpening Manual

Gouge Scorp

Chisel

Scorps, by their nature, are right-angled gouges. Their very short turning radius allows them to carve very narrow, deep recesses, similar to spoon gouges, only better.

This handy carpenters tool is great for setting a hinge, carving lettering or smoothing off hardto-reach convex surfaces.

www.flexcut.com

Flexcut Tool Company Inc., 8105 Hawthorne Drive, Erie, PA 16509, 800-524-9077 Made in USA

www.flexcut.com

Thank you for your purchase of Carvin Jack, the worlds first multiple-blade jackknife designed specifically for woodcarvers. We put great effort into manufacturing innovative, quality carving tools designed to give you a lifetime of enjoyment. Our reputation for long-lasting, razor-sharp edges is well known throughout the world. The information contained in this manual is designed to provide you with the basic knowledge for operating the different blades contained in your new knife. We also provide routine maintenance tips. Reading over this material will ensure that you know how to keep your knife in top working order. Performing this maintenance will keep the blades working at their maximum efficiency. More detailed information can be found at your authorized Flexcut dealer, flexcut.com or local library.

spotting of rust. Wiping the blades with a thin coat of oil or wax can also be very good preventive maintenance. The edge of each blade has been designed specifically for carving wood. Using them on other materials can dull the tool prematurely or even damage the edge. It is highly recommended that you use the SlipStrop and polishing compound included with your knife for routine stropping which will maintain the sharpest possible edge. The highly polished bevel on the blade is what creates its razor edge. Conventional sharpening stones can remove this polish and dull the tool prematurely. Only use sharpening stones for reshaping the edge and only when needed. Always repolish the bevel to bring it to its original sharpness. Please review the following stropping instructions. Always avoid prying with any blade. Push the tool through the entire cut. Prying can damage the blade and void the warranty. Stropping and keeping your tools sharp. Your Flexcut Carvin Jack has been pre-sharpened at the factory to a highly polished razors edge. This creates an efficient, long-lasting cutting tool. Keeping each blade sharp requires some routine maintenance. This can most easily be done by periodically stropping both sides of the edge (outside and inside) with the SlipStrop and Flexcut Gold polishing compound. Sharpening stones should not be used for this routine maintenance. They are too coarse and will put scratches in the polish, reducing the sharpness. Edge tools have two converging surfaces joined at an apex. This apex is the cutting edge. Both of these surfaces need to be smooth and as polished as possible for the edge to be truly sharp. The more highly polished they are, the sharper the tool and the longer it will stay sharp. These microscopic views show an edge before and after being polished.

The coarse texture left from a hard Arkansas stone creates fragile peaks on the edge that tend to break down more quickly as the tool is being used.

A smoother, polished edge is not only sharper, but will last longer due to its more uniform surface.

When to use the strop. A few moments taken to maintain the edge will save time and frustration and keep your tools in top working order. When carving in softer woods, a few strokes should be given to both the inside and outside edge every 20 to 30 minutes. For carving harder materials, the frequency or number of strokes should be increased. When the tool begins to feel as if dragging through a cut, the tool should be stropped a number of times until the sharpness is restored. Waiting until the tool is actually dull will take much more time than doing this routinely as you carve. Using the SlipStrop To strop the outside edge, apply the gold compound to the matching blade shape molded into the strop. Flexcut Gold polishing compound has been specially formulated to apply to the strop like a crayon and quickly polish hardened steels. The bevel of the tool should be placed as flat against the strop as possible. The tool is then pulled away from the edge to avoid digging into the strop. If the angle of the bevel against the strop is too high, it will round prematurely. If it is too low, the edge will not be properly abraded. To strop the inside edge, once again, apply gold compound to the matching blade shape molded into the strop. The tool should be tilted up slightly as shown above, and once again, pulled away from the edge. Tilting the tool while it is stropped creates a slight secondary bevel on the inside of the tool to give the edge more durability and remove any burr. Due to the softer nature of the material for stropping, each time the tool is polished the edge

becomes slightly rounded. Over a long period of time it will become so rounded that it no longer has an efficient cutting angle. The blade will then need to be reshaped using a sharpening stone or abrasive wheel to flatten the bevel back to its original angle. The edge should always be repolished to restore its sharpness and longevity. Flexcut Tool Co. Inc. offers a sharpening service for those who would like a factory edge restored to the knife. Flexcut Limited Lifetime Warranty We warrant products manufactured by Flexcut Tool Co. Inc., to be free of defects in material and workmanship for the life of the owner, and we will repair or replace with a new Flexcut carving tool, at our option, any Flexcut carving tool that is defective. If you feel any Flexcut tool has failed due to a manufacturing defect, mail the tool with a written explanation of the problem to the address below. Please include your name, address, email address (if available), and daytime telephone number to: Flexcut Tool Co. Inc. Tool Return 8105 Hawthorne Drive Erie, PA 16509 Flexcut Tool Co. Inc., does not warrant its product against normal wear and misuse. Flexcut carving tools are not intended to be used for prying, or as screwdrivers. If your carving tool is damaged due to misuse, our repair department can analyze the tool for factory specifications and type of damage. Repairs can be made for a reasonable fee. This warranty gives you specific legal rights and you may have other rights that vary from state to state. Consumer Awareness Statement Flexcut Tool Co. Inc., manufactures edge tools for wood carving and each is tested to be razor sharp. Consumers should practice extreme caution when opening, using or sharpening any of our tools. Flexcut carving tools are intended to be used for carving wood and should not be used on other materials. They are not weapons and should not be used as such. If an injury occurs during use (or misuse) of any Flexcut carving tool, this is a risk that our customers assume and Flexcut Tool Co. Inc., can in no way be held accountable. Our customers should always exercise good safety practices and use our products wisely.

Operating the locking device Always use great caution when opening or closing any blade in the knife. They are extremely sharp! After making your blade choice, use the embossed nail nick to pull it out until the blade locks into place. Note: The V-scorp does not have a nail nick, and can be pulled out by inserting your nail under the shank of the tool itself. If any of the adjacent blades rotate out along with the blade you wish to use, push them back into the handle. The blade will only lock in place if the others are completely closed. For added safety, test the blade to ensure it is securely locked in position. To unlock and close the blade into the handle, push down on the thumb recess on the back of the knife. When the blade releases, fold the blade completely back into the handle until its edge is safely covered. While the lock is depressed, be careful not to push the blades that are already closed any deeper into the handle . This can jam the locking mechanism. Maintenance The Carvin Jack blades are made from high-carbon steel to offer the best possible edge for carving wood. The black oxide finish is added to make the blades rust-resistant, not rustproof. Keeping the knife in a dry environment will help prevent

You might also like

- Takamura Knives PDFDocument2 pagesTakamura Knives PDFeternal_harpyNo ratings yet

- J. Mutz Knives Catalog 2011Document10 pagesJ. Mutz Knives Catalog 2011eternal_harpyNo ratings yet

- Timmerfold EngDocument4 pagesTimmerfold Engeternal_harpyNo ratings yet

- Chroma KnivesDocument2 pagesChroma Kniveseternal_harpyNo ratings yet

- Chroma Okishiba CnivesDocument0 pagesChroma Okishiba Cniveseternal_harpyNo ratings yet

- MIL TAC BrochureDocument2 pagesMIL TAC Brochureeternal_harpyNo ratings yet

- Chroma Tradition CnivesDocument4 pagesChroma Tradition Cniveseternal_harpyNo ratings yet

- Chroma Japan Chef CnivesDocument4 pagesChroma Japan Chef Cniveseternal_harpyNo ratings yet

- Pay Star 5900 Sba Spec CardDocument2 pagesPay Star 5900 Sba Spec Cardeternal_harpyNo ratings yet

- Lyon-Healy HarpsDocument2 pagesLyon-Healy Harpseternal_harpyNo ratings yet

- Chroma Haiku Yakitori CnivesDocument2 pagesChroma Haiku Yakitori Cniveseternal_harpyNo ratings yet

- qx56 EbrochureDocument8 pagesqx56 Ebrochureeternal_harpyNo ratings yet

- Godin MultiOud modernizes the ancient OudDocument2 pagesGodin MultiOud modernizes the ancient Oudeternal_harpyNo ratings yet

- 888 Pro Generic PartDocument2 pages888 Pro Generic Parteternal_harpyNo ratings yet

- Freund Product BroschDocument24 pagesFreund Product Broscheternal_harpyNo ratings yet

- Aston Martin V12 Vantage Misc Documents-BrochureDocument12 pagesAston Martin V12 Vantage Misc Documents-BrochureMusaHamzicNo ratings yet

- Olympic and Regular Weight Plates, Bars, and DumbbellsDocument6 pagesOlympic and Regular Weight Plates, Bars, and Dumbbellseternal_harpyNo ratings yet

- MediumDuty CatalogDocument14 pagesMediumDuty Catalogeternal_harpy0% (1)

- Chroma Okishiba CnivesDocument0 pagesChroma Okishiba Cniveseternal_harpyNo ratings yet

- Infiniti G Coupe: Why Be Convinced, When You Can Be Seduced?Document12 pagesInfiniti G Coupe: Why Be Convinced, When You Can Be Seduced?eternal_harpyNo ratings yet

- Compound Bow SpecsDocument1 pageCompound Bow Specseternal_harpyNo ratings yet

- REEVES PaintingDocument28 pagesREEVES Paintingeternal_harpy100% (1)

- Doral Marine document features sport boats and cruisers specificationsDocument6 pagesDoral Marine document features sport boats and cruisers specificationseternal_harpyNo ratings yet

- Gcoupe EspecsDocument11 pagesGcoupe Especseternal_harpyNo ratings yet

- KnifeBook12 WebDocument28 pagesKnifeBook12 Webvictorhs258No ratings yet

- For WomenDocument18 pagesFor Womeneternal_harpyNo ratings yet

- Genzbenz Catalog2012Document15 pagesGenzbenz Catalog2012eternal_harpyNo ratings yet

- Panasonic AG HVX200APDocument16 pagesPanasonic AG HVX200APeternal_harpyNo ratings yet

- Broncolor Studio Light Monolights Minicomrfs enDocument12 pagesBroncolor Studio Light Monolights Minicomrfs eneternal_harpyNo ratings yet

- Chevrolet Camaro Catalog WebDocument20 pagesChevrolet Camaro Catalog Webeternal_harpyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GM's Crib SheetDocument7 pagesGM's Crib SheetSteve WilbyNo ratings yet

- Armour in England - J Starkie Gardner (1897)Document120 pagesArmour in England - J Starkie Gardner (1897)Captain_GlenNo ratings yet

- Armour of The Goths IDocument6 pagesArmour of The Goths ITeuccio Di RenzoNo ratings yet

- (1910) Cavalry Tactics As Illustrated by The War of The RebellionDocument210 pages(1910) Cavalry Tactics As Illustrated by The War of The RebellionHerbert Hillary Booker 2nd100% (1)

- Magic Items of Myths and LegendsDocument5 pagesMagic Items of Myths and LegendsAlexandre CrowNo ratings yet

- Cuadro AevDocument12 pagesCuadro AevCristiam BOBADILLA LLONTOPNo ratings yet

- 6 LVL ClericDocument3 pages6 LVL ClericBob MerrittNo ratings yet

- PatchDocument363 pagesPatchMabrajoch WiccaNo ratings yet

- LacerDocument12 pagesLacerBolareNo ratings yet

- Atlas Copco RH 656 PartsDocument16 pagesAtlas Copco RH 656 PartsTiago HenriquesNo ratings yet

- Masseinheiten LDocument4 pagesMasseinheiten LbdbauerNo ratings yet

- Prologue Battle in Herbery of Small StoneDocument182 pagesPrologue Battle in Herbery of Small StoneJames SpencerNo ratings yet

- Muskets Tomahawks Scribd - Szukaj W GoogleDocument2 pagesMuskets Tomahawks Scribd - Szukaj W GoogleRafał KalinowskiNo ratings yet

- ASLSK3 Summary: Intensive FireDocument4 pagesASLSK3 Summary: Intensive FireasejuaNo ratings yet

- 6e AvalonDocument31 pages6e AvalonFatih KerseNo ratings yet

- Lesson 1 Terminology and History - Forensic BallisticsDocument27 pagesLesson 1 Terminology and History - Forensic BallisticsEve LynnNo ratings yet

- Forum New Vegas Character BuildsDocument7 pagesForum New Vegas Character BuildsLucius LunáticusNo ratings yet

- S&W M&P 15Document40 pagesS&W M&P 15txpatriot66No ratings yet

- Chamber of The Crimson DrakeDocument25 pagesChamber of The Crimson DrakeAdrián Sánchez-Alarcos BlanesNo ratings yet

- Listado de Archivos Afectados de QwinnDocument26 pagesListado de Archivos Afectados de QwinnDr. Andrés Eduardo Maldonado SuarezNo ratings yet

- Digital Dual-Axis Line-Of-sight Los DefensetechsDocument2 pagesDigital Dual-Axis Line-Of-sight Los DefensetechsdefensetechsNo ratings yet

- Knives Illustrated - November 2016Document84 pagesKnives Illustrated - November 2016João Gilberto Araújo Pontes100% (2)

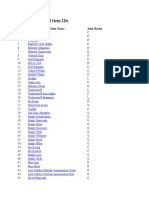

- List For Unturned Item IDsDocument33 pagesList For Unturned Item IDsAldy audiwan0% (1)

- D&D 5e Archer (EMIYA) ClassDocument4 pagesD&D 5e Archer (EMIYA) ClassRobert83% (6)

- Zombie's Retreat Guide (0.9.3)Document44 pagesZombie's Retreat Guide (0.9.3)Ankit updateNo ratings yet

- Airborne SolutionsDocument8 pagesAirborne SolutionsMauro CantanheideNo ratings yet

- Night ThrasherDocument3 pagesNight Thrasherapi-254598709No ratings yet

- Fuze InfoDocument41 pagesFuze InfoQualityOffice100% (2)

- FOWW Battle Mode v10 DownloadDocument9 pagesFOWW Battle Mode v10 DownloadMeriadec ValyNo ratings yet

- Winchester 77XS Operations ManualDocument15 pagesWinchester 77XS Operations ManualYesenia BastidasNo ratings yet