Professional Documents

Culture Documents

Predicting Friction Factors in Non-Circular Channels Using Geometry Factors

Uploaded by

limin zhangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Predicting Friction Factors in Non-Circular Channels Using Geometry Factors

Uploaded by

limin zhangCopyright:

Available Formats

Int. J. Heat Mass Transfer. Vol. 16, pp. 933-950. Pergamon Press 1973.

Printed in Great Britain

SIMPLE METHOD OF PREDICTING FRICTION FACTORS

OF TURBULENT FLOW IN NON-CIRCULAR CHANNELS

K. REHME

Institut fr Neutronenphysik und Reaktortechnik, Karlsruhe Nuclear Research Centre, D-7500 Karlsruhe 1,

P.O. Box 3640, Germany

(Received 17 July 1972)

Abstract-On the basis of friction factor relationships of a simple model a method is developed which

allows the prediction of friction factors for turbulent flow in non-circular channels if only the geometry

factor of the pressure drop relationship for laminar flow is known. The proposed method of calculation

is tested with numerous experimental results from the literature with respect to non-circular channels

such as triangular shaped ducts, eccentric annuli and rod bundles in hexagonal and square arrays in

circular tubes, hexagonal and square channels. It turns out that the proposed method provides an excellent

description of all the experimental data at hand.

channel wall and rods;

annular zone parameter;

wall distance;

dimensionless wall distance y+ =

YU*/v;

friction factor ;

friction factor of the circular tube;

density;

wall shear stress;

kinematic viscosity.

x,

y,

y+

,

NOMENCLATURE

geometry factor ;

rod and tube diameter, respectively;

hydraulic diameter;

flow cross section;

geometry factor (turbulent flow);

geometry factor (turbulent flow) ;

geometry factor (laminar flow);

geometry factor for circular tube;

geometry factor for annular zone;

characteristic length;

length in flowdirection ; 1. INTRODUCTION

distance between rod centres ;

RESULTS of pressure drop measurements have

pressure;

radius; been known for a number of years for turbulent

flowin various non-circular channels which can-

} radii of annular zone; not be described in terms of the friction factors of

velocity; the circular tube when using the hydraulic

velocity averaged over the cross diameter as the characteristic length. Non-

circular tubes, i.e. rod bundles, are used especi-

section F;

ally in reactor technology.

maximum velocity;

/ Both in theoretical and experimental studies

friction velocity U* = y(nv/p);

of the friction factors of rod bundles the strong

dimensionless velocity U+ = U/U*; influence ofthe type and arrangement of channel

wall distance in rod bundles = rod wall upon the friction factor was soon dis-

diameter + closest distance between covered, however, without there being a general

933

U

max

,

U*,

A,

D,

o;

F,

G,

G*,

K,

KR'

K

Rz

,

L,

1,

P,

p,

T,

T

O'

Tz,

U,

Um'

934 K. REHME

2. GEOMETRY FACTORS OF THE PRESSURE

DROP RELATIONSHIPS

The pressure drop relationship for laminar

flow is

with the maximum velocity Umaxs the velocity

averaged over the flow cross section U,,,, and

the friction velocity U* = J(7;wlp).

Maubach was able to show that this geometry

parameter G has a characteristic value for each

where the constant K is a geometry factor,

because it is determined solely by the geometry.

It is the eigenvalue of Poisson's equation.

For turbulent flow there is also a geometry

factor, as has been proved by Maubach [5]

for circular tubes, annular zones, and parallel

plates. This geometry factor G of turbulent flow

turns out to be

solution to the dependence on geometry of the

friction factors.

Below, a method is developed and tested for

various non-circular channels by means of

numerous measured results which allows the

friction factor for turbulent flow to be indicated

in a simple way. The only condition on which the

method can be applied is the required knowledge

of the geometry factor of laminar flow. How-

ever, geometry factors of laminar flow are

known for a variety of non-circular channels or

else can be determined quickly and rather

accurately by numerical calculation procedures.

A fewmethods are mentioned in the literature

which can be used to calculate the friction factor

for turbulent flow on the basis of laminar solu-

tions [1-4]. These methods will not be mentioned

in more detail in this paper because the method

outlined here is basically different and refers only

to the geometry factors of the pressure drop

relationships. For this purpose, the geometry

factors will be explained very briefly.

u+ = 25 In y+ + 55 (3)

the pressure drop relationships are written as

follows [5] :

J0) = 2'5 In ~ U * + 55 - G (4)

where L is the length characterizing the flow

cross section, which is the thickness of the flow

layer in the geometries studied by Maubach.

As is evident, the following questions arise

in the light of these facts:

(1) Can a relationship be established between

the two geometry parameters K and G

for laminar and turbulent flow, respectively?

(2) What must be the structure of the pressure

drop relationships for channels with the wall

shear stress variable on the circumference

in order to fully take into account both

experimental and theoretical results?

shape of channel, which value is independent of,

for instance, the roughness of the channel or

the Reynolds number, if, in case of small Rey-

nolds numbers, the factor is left out of account

that the sublayer close to the wall gives rise to

a minor correction.

Of course, this geometry parameter occurs

also in the pressure drop relationships of the

geometries studied by Maubach. Under the

condition of a universal velocity profile existing

for the channels investigated, such as Nikuradse's

profile,

3. MULTICHANNEL EFFECT

For more detailed studies ofthe pressure drop

behaviour of channels with wall shear stresses

variable on the circumference it is necessary to

visualize the characteristics of such channels.

One characteristic all these channels have in

common is a different curvature of the walls

either, as in the case of annuli, there are different

radii of curvature of the walls or, as in triangular

shaped ducts, discontinuities in the curvature

of the wall in the corners. Now, it has been

proved in a large number of experiments that

the velocity profile obviously is not influenced by

(2)

(1) ).Re=K

G = Umax - Um

U*

PREDICTION OF FRICTION FACTORS 935

or

In this way the wanted friction factor Aof the

entire channel has been found.

Gi = U;:;ax - U;;, = 3966. (8)

The equation defining the friction factor

(7)

(6)

(9)

(11)

(10)

(12)

11

v.r.: 1.

i =1

=

From (10) it is found that

and (5) result in

AP;

-- = const. = --.

o, DIJ

Finally, the continuity equation furnishes

which turns (11) into

= (14)

i =1

where Pi is the pressure in the ith channel of the

diameter Di:

Now, according to Maubach [5], the follow-

ing friction law (4) applies for smooth circular

tubes with L = DJ2 and

11

Ij&,YJ = 1 (13)

j=l

U* = umJ(D

[D

i

U

j

li(k)J

,tI; = 25 In 2:-----;;'.j'i +5'5-G

i

with the geometry parameter for Reynolds

numbers Re < 10

6

the curvature of the wall (7-11]. Results

obtained on annuli by Brighton and Jones [12]

showing a dependence of the velocity profile on

the curvature of the wall do not agree with

measurements by Quarmby [18]. Quarmby

concludes that the results by Brighton and

Jones are wrong. However, we believe the

results by Brighton and Jones have been mis-

interpreted because of the assumption that the

line of maximum velocity was identical with the

line of zero shear stress [14], which results in a

dependence on wall curvature of the velocity

profile in the results of Brighton and Jones.

Another characteristic of the channels with

a wall shear stress variable on the circumference

is the existence of zero shear stress lines in the

flow area. Such flow channels can be sub-

divided along these lines because, averaged over

time, there is no momentum transport across

these lines. Such subdivision gives rise to

parallel subchannels which are independent of

each other. Since these subchannels in general

have different flow cross sections and wall

fractions, the way in which the individual

parallel channels interact and the relationships

that can be derived from such interaction must

be investigated.

Parallel circular tubes

These relationships will be derived by a

simple example which can be described un-

ambiguously in terms of the solutions available.

For this purpose, the model of parallel circular

tubes suggested by Maubach will be used.

We look for the friction factor of a number of

smooth, parallel connected circular tubes of

various diameters with inner flow, that is a

flow channel with several sub-channels.

An incompressible, isothermal, fully

developed turbulent flow is assumed. In ad-

dition, the tubes are assumed to be long enough

to make the inlet and outIet losses small

relative to the friction pressure drop. Hence, it

applies for all the parallel channels that

apo

af = const. (5)

936 K. REHME

and the hydraulic diameter of the entire channel From (7) it follows with (12)

J(f) = 25 In JGi)

X Um + 5'5 - Gi

(15)

n

4 I: r,

D _ i=l

11 - n

I: Pi

i = 1

(22)

x + 5'5 - G}

(17)

and for the entire channe1

Since the quantities of A and G* defined in (19)

and (20) depend only on the diameter and area

relationships and the geometry parameter Gi'

A and G* are two new geometry parameters

which are independent of the flow condition,

i.e. the Reynolds number.

For laminar flowin the sub-channels it applies

for each tube that

(24)

(23)

1- Re,

(16)

JO) =I

i=l

+ 55 - Gi'

Substituting (16) in (14) yie1ds

or

j(f) = 25 In [Re

Now, the pressure drop relationship of the entire

channel can be written as

JG) = A 5'5]-G*.

The continuity equation (11) and (10) can be

used to find for the geometry factor of the entire

channe1 in the case of laminar flow

(18)

A comparison of coefficients makes (17) and

(18) into

n

A=

i =1

G* = - [2'5 In D

i

J(D

i

) - Gi]

2D

'I

D

'I

i=l

x

with the entire area

n

F= L F

i

i =1

(19)

(20)

(21)

(25)

For calculation ofthe friction factors for laminar

and turbulent flowit is assumed that a tube of the

diameter D1 with n tubes of the diameter Dz

make up a channel. Hence, the channe1 is

determined by D

z/D1

and n.

Table 1 is a compilation of the K gese A and G*

determined for various parameters investigated.

Moreover, the friction coefficient referred to the

circular tube value is indicated for Re = 10

4

and Re = 10

5

.

In Figs. 1 and 2, the relative friction factors

are plotted over the diameter ratio with the

number of parallel tubes as a parameter for

laminar and turbulent flow, respectively. It is

PREDICTION OF FRICTION FACTORS 937

evident that the friction factor is decreased with

irregular flowdistribution. Depending upon the

number of tubes the minimum of the overall

friction factor is shifted towards the other

D

2/D1

. For a large number of tubes the friction

factor is decreased significantly below the value

of the single tube. This behaviour is typical of

friction factors in the case of parallel connection

of channe1s of different cross sections and shapes

of cross sections. The effect is called the multi-

channel eifect.

O

2/0,

FIG. 2. Tubes in parallel: turbulent flow.

D

2/D,

FIG. 1. Tubes in parallel: laminar flow.

4. NEW METHOD OF CALCULATING FRICTION

FACTORS

Acomparison of Figs, 1and 2 clearly indicates

that the friction factor in turbulent and laminar

tlows show a similar behaviour. In laminar flow,

the dependencies are more marked than in

turbulent flow, but the basic shape of curves is

the same. The same results are found by com-

paring the measured results obtained from tri-

angular shaped ducts, eccentric annuli, and rod

bundles for laminar and turbulent flows. It

turns out that if, for a specific geometry, the

friction factor for laminar flowdrops below the

circular tube value, also the friction factors for

turbulent flow are lower than the circular tube

values, and vice versa.

If this effect can be ascribed mainly to the

geometry factors of the pressure drop relation-

ships, it must be possible to establish a relation-

ship between the geometry factors. Since, in

'----....J..--------L---'-----....J..-------J1.0 laminar flow, only one geometry factor K is

needed to describe the pressure drop relation-

ships, whereas it takes two, namely A and G*,

in the case of turbulent flow, as we have seen,

the geometry factors A and G* are plotted over K.

Figure 3 is a plot of the magnitudes of G*

obtained from the multi-tube model. It appears

that for K > 20 the points can be arranged on

a curve with only a small amount of scatter.

Geometries so far investigated experimentally

and applied in practice always have values in

excess of K = 20. For geometry factors K > 64,

1.0 the respective G* values were determined from

the annular zone solution. In this case, the

0.5 I-----+_

Table 1. Results for parallel circular tubes

(G = 3'966)

dl/dz

005 001 03 0'5 09

n = 1

K

ges

58'59 54'49 4865 5229 63-48

A 1'021 1037 1051 1031 1001

G* 5-650 5603 5520 5575 5-694

A/AR Re = 10

4

0947 0911 0'874 0'919 0997

A/A

R

Re = 10

5

0950 0915 0881 0'923 0998

n.= 2

~ g e s

53069 4H6 4042 48'00 6350

A 1042 1070 1084 1'042 1001

G* 5599 5504 5-380 5'521 5-695

A/AR Re = 10

4

0899 0'838 0804 0892 0998

A/AR Re = 10

5

0'904 0'846 0814 0898 0998

n=5

K

ges

4251 3291 3000 45'34 63066

A 1101 1-156 1-129 1044 1001

G* 5436 5198 5-135 50494 5-696

A/AR Re = 10

4

0'781 0'684 0717 0885 0998

A/AR Re = 10

5

0'791 0'697 0731 0892 0999

n = 10

K

ges

3063 2127 2538 46'91 63-78

A 1187 1265 1-140 1035 1000

G* 5.143 4'706 5'014 5'527 5-697

A/A

R

Re = 10

4

0643 0540 0'694 0'906 0999

A/A

R

Re = 10

5

0657 0557 0709 0912 0999

1.0

K

~

0.5

D

938 K. REHME

JG) = 25 In Re \/G) + 55

- [G + 25 In2(1 + x)]. (31)

A comparison with (18) results in

G ~ z = G + 25 In 2(1 + x) (32)

and with (28) in

3966 + l'25x

. G ~ z = + 2'5 In 2(1 + x). (33)

, + x

laminar solution of the annular zone turns out

to be [15]

64(x

2

- 1?

K

RZ

= 3x

4

_ 4x

2

_ 4x

2

In x + 1 (26)

with the annular zone parameter (cf. Fig. 4)

r

o

x = -. (27)

r.

The values of the parameter G* for the annular

zone in a turbulent flow are obtained from

Maubach [5] as

3966 + 125x

G = (28)

l+x

for smooth walls and in an analogous way as

in (7)

and with (6) and

L (r

o

- r

z)2rz

DIJ (r6 - r;)4

to be

1

2(1 + x)

(30)

I;

/

/

/

/

V

l/

V

/

I

n

)

1

A 2

0 5

0 Jj

~ anrill<Ir zone

10

)(

8) L U*

I = 2'5 In -v- + 55 - G

10' K

Fm. 3. Geometry parameter G*.

(29)

1: = (i)

i----r

z

- - -

Fm. 4. Annular zone.

Table 2 lists the values of the geometry factors

K and G* for various values of x. In addition, it

is seen that A = 1 for annular zones, which is

no surprise because there is a constant wall

shear stress on the circumference and no sub-

channe1s can be generated.

The parameters A in Fig. 5 obtained from the

multitube calculation also can be represented

in a curve in good approximation which, in this

case, is a straight line.

The geometry factors A and G* represented

above for turbulent flow in channe1s can now

be used to establish pressure drop relationships

also for other geometries, if the geometry para-

meter K for laminar flow is known.

For a number of flow channels, the laminar

PREDICTION OF FRICTION FACTORS 939

Table 2. Values of the geometry parameters of the annular

zone in laminar (K) and turbulent (G*)jlOlVS

X

K G*

0 64000 56988

01 64'604 5'6902

02 66217 5'7020

03 68574 57280

05 74836 5,8072

09 91200 60170

10 96-000 60737

1-1 100'912 6'1310

15 122-183 63600

20 152'091 6,6327

50 393-638 7'9149

100 993546 92245

solution is known from the literature. For

triangular shaped ducts, an approximative solu-

tion is found with Carlson and Irvine [16],

theoretical data are also given by Sparrow [17]

and SparrowandHaji-Sheikh [18]. For eccentric

annuli Tiedt [19] has compiled the laminar

solutions for all diameter ratios and eccentrici-

ties. For rod bundles there are solutions by

Sparrow and Loeffler [20] and Sholokhov,

Buleev and Gribanov [21] for rod bundles of

infinite extension. For rod bundles with seven

rods in circular tubes laminar solutions are

indicated by Courtaud, Ricque and Martinet

[22], Axford [23, 24] and Min, Hoffman,

Tucker and Peebles [25]. For rod bundles in

hexagonal and square channels, the author has

elaborated laminar solutions by numerical

integration of Poisson's equation for the sub-

channe1s in such rod bundles (centre, wall and

corner channe1sfor a wide range of rod distance

ratios P/D and wall distance ratios W/D [15, 26].

With these sub-channel geometry factors, the

geometry factors for laminar flow can be cal-

culated in a very simple way for all rod bundles

so far investigated experimentally, For ducts

with arbitrary cross-section Pendergast, Cobble

and Smith [27] reported analytical solutions of

Poisson's equation.

The method suggested for calculation of the

pressure drop relationships for turbulent flow

from the laminar solutions, called the G*-

method below, can be justified only by saying

that the measured results available for various

channe1s with non-circular cross sections are

described sufficiently well by the pressure drop

relationships obtained in this way.

Influences of anisotropy of the turbulent

transport quantities .or by secondary flows

100

K

40 20

, @

@ ~

~

0

@

0

n 0

~

@

11>

.. 1

Ii> 2

011>.

0 5

@

~ 10

~

1.1

1.0

10

1.3

1.2

A

Fm. 5. Geometry parameter A.

940 K. REHME

observed in non-circular channeIs of course are

not taken into account in a method like this.

In the same way, a momentum exchange

between the individual sub-channels of a rod

bundle is neglected because the lines for which

the momentum transport disappears are selected

in the calculations to be the lines resulting if the

rods proper and rod and channel wall, res-

pectively, are subdividedat their closest distances.

However, in general these simplifications

have but a negligible effect on the friction factors,

as has been proved by various authors.

5. COMPARISON BETWEEN CALCULATED AND

AND MEASURED DATA

The method suggested above will be tested

with triangular shaped ducts, eccentric annuli,

and rod bundles.

Figure 6 shows the data measured by Carlson

[28], which were reported also by Eckert and

Irvine [16,29], obtained from triangular shaped

ducts. Agreement between the measured values

and the calculated ones is good. For small

angles, the transition from laminar to fully

developed turbulent flow obviously is 'not yet

complete, hence, the slightly greater deviation.

For eccentric annuli, Fig. 7 contains the data

measured by Johnson [30] for a diameter ratio

of dt/d

2

= 0'75 and dt/d

2

= 0,281, respectively.

In the case of the lower diameter ratio there is

excellent agreement between measured and

predicted values; this is not the case for the

higher diameter ratio. The data measured by

Tiedt [19] show the same behaviour (Fig. 8).

For low diameter ratios, again, experiment and

theory are in excellent agreement; for high

diameter ratios agreement is excellent for the

concentric case only. Figure 9 shows the

measured data by Bourne, Figueiredo and

Charles [31] for a diameter ratio of'd.yd, = 0813

(top). In the turbulent region, the predicted line

fits the data excellently, even for a high diameter

ratio. Data by Lee [32] are shown in Fig, 9

(bottom) for a diameter ratio of d

t/d2

= 0387.

In this case, there would be excellent agreement

with the predicted values if all the data were

shifted by about 10 per cent, a margin which is

necessary also for good agreement between the

predicted and the measured values for other

10'

m=4

"

ft2a

'\;

rne S -,

-, ;"

o ClI

- me z

f\,"

"'-

."

-,

-,

,

'0&"",

0::.-:

m=l

1"--.'

1'0, , . :<i.

-,

"\

''<iI 0 0

--

r:::::.

m=O ."

tt>-:;

", -,

-,

I'" "

"'-<>-

--

'\. -, "\,,'

vco 0 0

-

--f-

-,

'('"

--

"'" 0 0

-

--f-

-,

r-

.::::::..--

--

---ClrciJlar rbOI --

r-t--

-Th.ory

1

1.0

0.1

0.0

2'10' 10' 10'

Re

2a =38.8

2a =22.3

2a =12

2a =7.96

2a =4.01

Fm. 6. Triangular shaped duct: Carlson.

PREDICTION OF FRICTION FACTORS 941

0.04

e

o

0.

0.9

1.0

d, /d,= 0.75

- Ihecry

Re

0.01

1

'-o 0, - - - - - ---'- - - - - - --'--- - - '---- ---'-- ---J

10'

0.02

e

o 0

0.6

A 0.8

'" 1.0

d,/d, =0.281

-Thoorr

Re

FIG. 7. Eccentric annuli: Jonsson.

diameter ratios tested byLee and not shown here.

The assumption that the data by Lee are too

high is reasonable, if one considers the excellent

agreement between theory and experiments of

different authors in the case of concentric

annuli [33].

To illustrate the difference between the pre-

dicted values and the measurements for high

diameter ratios, Fig. 10shows all measurements

known to the author which are related to the

concentric values for maximum eccentricity

(e = 1,0) and different diameter ratios.

The values measured by Jonsson [30] and

Tiedt [19] are the lowest for high diameter

ratios; they are correlatedrather well-especially

with respect to the dependence on the diameter

ratio-by the calculations of Eifler and Nijsing

[34]. The experimental results of Bourne et al.

[31], Lee [32], Denton [35], and Dodge [36]

are higher and well correlated by the method

suggested above. It is impossible to decide at

this time which experimental values are best,

even in the light of the data measured by Diskind

[37] for eccentricities between e = 09 and

e = 0'97 tending to the higher values, and the

investigation of Stampa [38] who reported "the

influence of eccentricity measured by Tiedt

could not be verified by OUf experimental

studies".

Now for the rod bundles. For seven rods in a

942 K. REHME

Re

0.0' 1":I:,....j:---I-+----+----+--+-j--j

10'

0.01 L----.JL.--'----'-__---'--__----'_---l-_L-J

10'

Re

e

00

'" 0.6

o 1.0

- Theory

0.01 L----.JL.--'---'--__---'--__----'_---l-_L-J

10'

0.0'

Re'

Fm. 8. Eccentric annuli: Tiedt.

Re

I I

0

0

"

cl, /<1, =0.813

00<,

t

" G

-,

"

0

-,

-,

0.

-,

r-,

00-

----

,0 l'l

-.

.

--I---

--

-----

(a)

10....

"'-G

--- Circular tube

- Thoory

I

0.01 2

2'10

0.1

0.04 ,--------,--------,-----,---.---c::-----,

(b l

0.0'10'

Fm. 9. Eccentric annuli.

PREDICTION OF FRICTION FACTORS

943

j= 1

j= 9

j= 4

j =3

j =10

j= 12

j=11

) =12.5

j= 2

j= 6

j=O,5

... )=0

- f-- ---- -L ,I.

-- --f----

....::::-- -

-"""t;--

-i=;;::::f::::=. ::::::

f-

r

t--f=;::::

..;::::;;:::.: ---.

-

--------

t--..

I

."...

I--

--0--.

>---.,.

-

--

-0--

r--.

.........

H-

i--

t--

---

-.,..",.,

I-"-

..-.

r---

r-

--

.......

-

-.........

"-

---------

........

r--

f-.

v--...

-0-

:>--

:r----"......

-----

t-->

--

f":

---

r--::::::

r=:--

..:::.:::.

c-=:t---

-

1---_ .

-".....

;;- ---

r-----=::

<::

p-,;.::.

..:::.:: -

-

---Ci,eulor &.t..

....... ;:--

r;=;:

-Tholory

--

Re

FIG. 11. Rod bundles : Courtaud et al.

O.Olyt

m=9

m=11

10

m=8

m=5

m=7

m=10

m=3

m=4

m=2

m=O

by extreme shapes of channels such as those

occurring for rod bundles with P/D = 1 and

W/D = 1, respectively.

Fr the square array, Gunn and Darling

[1, 43] have performed measurements on one

centre, side and corner channel each. Figure 17

shows the results. Agreement with calculated

data is good. The theoretical geometry factors

for laminar flow [15] were used for calculation.

The values measured in the laminar area are

slightlyhigher than the theoretical solution. The

agreement would be perfect if the values

measured by Darling were used for K. For

P/D = 1 in a square array, measured results

have been communicated also by Ushakov et al.

[44]. Agreement is good (Fig. 18).

For P/D = 1in a hexagonal pin array, Fig. 19

0.8

8

a G

"<,

Symbol Author

80URNE et 01.

... LEE

DODOE

TIEDT

B JONSSON

DENTON

0.6 0.' 0.2

FIG. 10. Eccentric annuli: e = 10.

-._.- Tbecry:EIFLER,

-- Theory: 0.- molhod

0.61-----+----+---+---+-----j

0.5 '--__-'---__----'--__--'- .1-_---'

o

0.8

1.0,-----,--------,---------------,

circular tube Courtaud et al. [22] performed

experiments with a largenumber ofrod distances.

The results are shown in Fig. 11. Except for

the extreme position, in which the rods contact

each other, there is excellent agreement between

the calculated and the experimental data. The

same applies to the studies conducted by the

author on rod bundles in hexagonal channels

with rod distance ratios P/D equal to the wall

distance ratios W/D [39, 40] for different rod

distance ratios and rod numbers, as is shown in

Figs. 12-14. Also for other wall distances there

is good agreement between experiment and

theory. This is shown by the measured data of

Galloway and Epstein [41, 42] for 19-rod

bundles with half the rod distance as the wall

distance (Fig. 15). The results measured by Gunn

and Darling [1,43] for rod bundles in a square

array could well be described also by the curve

determined by the G*-method (Fig. 16). The

excellent description of the experimental results

by the theoretical method is shown especially

.x,

hconc.

944

0.1

0.01

K. REHME

z ,,37

I-

p/O" 1.075

W/O" 1.095 0C)OOOOOOOOC?

00000

0000

0

0

'"I'"

0

<,

0

-,

"1>-

,

-,

-,

""-,

''''''f-.:

i',

-,

-,

Z = 61

I.

o p'

p/o" 1.025

w/rh 1.060

,0,

'<,

-

-

" 0

-----

-

-

-

-

-F::

---Ci'cular tube

--I-

-Theory T

Z

"19

r-,

p/o"1.756

0000

00000

wlo =1.754

0000

-,

00

0

0

-,

-,

-,

-,

-

- 0...<

-,

-,

.0

G

<,

,;;;r,......

-,

-,

"'",

-,

",

b:::::-

:-:::--1::-

<,

-,

Z =37

I.

-,

p10 =2.315 000500

'tfo=

0000000

-,

I"'"

000000

-, 00000

-, 0000

-, -,

-

-

-,

-.

""'-

<,

-,

--- Circular -,

I'"

--

- Theory

-,

1'-...

<-:::-

-,

f::-.

0.1

0.01

0.01

10'

10'

FIG. 12. Rod bund1es: Author.

10'

FIG. 13. Rod bund1es: Author.

Re

Re

10'

PREDICTION OF FRICTION FACTORS 945

0.1

Z 168

P/,ID = 1.3117

Wt/D = 1.2'85

---Cireular ti.P

-- Theory

0.01

1 O ~

FIG. 14. Rod bundles: Author.

Re

10'

Re

tl'

le

-,

" ~

000

0

~ '

~

m p/o wjo

0 1.105 1.008

I 1.266 1.C112

-,

~ '

~

2 1.510 1.1!J. -

~ -,

~ 0

3 2055 1./04.1

-, -,

"

-, 0

, ~

-, "'"

-,

0

~ , ' ~ , -.

~ 0

0

~

-,

~

-, 0

- ~

~ -, -,

0",

"""

~

~ , " r-,

0

~ ~

~

'0-

---

---

~

~ ,

0

........

r--

f-",.,,,,,,,

r--

-,

0 ............

--

.......

-, 00t>0

r--<>..

!'b

-"

~ r:::::""e..

- ~

t.lt:.

- ~

-.::::::.::...-

--

---Clrcular tube

r--:

-Theory

0.1

O.OlJl2

m=3

rne Z

rne O

FIG. 15. Rod bundles: Galloway.

946 K. REHME

1.'

z 4

U

P!0.1.3'O

":, W!0.1.157

I"

.......

,"'"

"""

-,

oe

,

t-,

-

-,

'\

r-

-, -,

-,

,

,

-,

Z

.g

m

-,

<, P!0.1.439

-,

-,

-,

-, ->.

---Clrcular lube

-

-Theory

0.0

0.1

0.01

10'

FIG. 16. Rod bundles: Gunn and Darling.

Re

10'

L

1'Z

-,

-,

-,

",

-,

-,

-,

-,

-

-

<, t'..

---

r-,

---

-

""

-, -,

--=

""'". -,

-,

"-'"

r-,

"

-,

-,

1 : I

-,

o<\l'",

-

-

r-,

-,

,,,,,,,-

---

-,

---

-,

-, -,

-......

-

-,

F-o:t--

'"

51

,

-,

-

-

'"

----

---Ci"' ...... _

--

-lhwry 1

1--1-

0.01

0.1

0.01

0.01

10'

FIG. 17. Rod bundles: Darling.

PREDICTION OF FRICTION FACTORS

0.Cl4

--- Circular tube

- Theory

Re

FIG. 18. Rod bundles: Ushakov et al.

947

A

.

--

........

t--

----........

..

r-___

r--...

----

--

"

--

--

---

I-- .

Data of SUBBOTIN el al,

A Data 0' LfVCHENKOet al.

---- Clrcular lub.

- Theory

0.1

0.01

0.004

10

3

10'

FIG. 19. Rod bundles.

10'

Re

10'

shows the results measured by Subbotin et al.

[45], and Levcheko et al. [8]. All measured

values are excellently described by the curve of

the friction factor by the G*-method.

6. CONCLUSIONS

In summary it can be said that the friction

factors calculated by the method outlined for

turbulent flow in channels with non-circular

cross sections very "well describe the experi-

mental data at hand.

The method is very simple because it requires

only knowledge of the geometry factor for

laminar flow, which is a condition that can be

fulfilled as a rule for the channels occurring in

practice.

In that case, the geometry factors A and G*

can be taken from two diagrams in which the

pressure drop relationship

= A [2.5 In Re + 5'5] - G*

for turbulent flow is determined.

Because of its easy application and yet high

accuracy, this method of calculation of friction

factors in turbulent flows is superior to all the

methods of calculation previously suggested.

Hence, it can be used also for other .shapes of

948

K. REHME

channe1s to predict friction factors for turbulent

flow with sufficient accuracy and in a simple way.

ACKNOWLEDGEMENTS

The author wishes to express his gratitude to Dr. K.

Maubach for numerous useful discussions and to Mr. A.

Roth for the careful preparation of the diagrams.

REFERENCES

I. D. J. GUNN and C. W. W. DARLING, Fluid flow and

energy losses in non-circular conduits, Trans. Instn

Chem. Engrs 41, 163-173 (1963).

2. V. S. OSMACHKIN, Some problems of heat transfer in

liquid cooled reactors A/Conf. 28/P/326 UdSSR (1964)

Third United Nations International Conf. on the

Peaceful Uses of Atomic Energy.

3. Yu. P. SHLYKOV and S. N. TSAREVSKIIDYAKIN, Tur

bulent flow and heat exchange in smooth straight

channe1s of any cross-section, Thermal Engineering

13 (12), 90--96 (1966).

4. E. ARANOVITCH, A method for the determination of the

local turbulent friction factor and heat transfer co-

efficient in generalized geometries, J. Heat Transfer

93,61--68 (1971).

5. K. MAUBACH, Reibungsgesetze turbulenter Strmungen

Chemie-Ing, Technik 42 (15), 995-1004 (1970).

6. J. NIKURADSE, Gesetzmssigkeiten der turbulenten

Strmung in glatten Rohren, Forschs-Arb-LngWesen,

VDl-Forschungsheft No. 356 (1932)

7. W. EIFLER and R. NUSING, Fundamental studies of

fluid flow and heat transfer in fuel element geometries.

Pt 11. Experimental investigation of velocity distribution

and flow resistance in a triangular array of parallel rods,

Report EUR 2193 e of the European Atomic Energy

Community (1965); Nucl. Engng Design 5, 22-42 (1967).

8. Yu. D. LEVCHENKO, V. I. SUBBOTIN, P. A. USHAKOV

and A. V. SHEYNINA, Geschwindigkeitsverteilung in der

Zelle eines dicht gepackten Stabbndels, Liquid Metals,

pp. 223-34. Atomizdat, Moskau (1967); cf. KFKtr371.

9. Yu. D. LEVCHENKO, V. I. SUBBOTIN and P. A. USHAKOV,

The distribution of coolant velocity and wall stresses in

closely packed rods, Atomnaya Energiya 22 (3), 262

(1968).

10. M. KH. IBRAGIMOV, I. A. Isurov and V. I. SUBBOTIN,

Calculation and experimental study of velocity fields

in a complicated channel, Liquid Metals, pp. 234--250.

Atomizdat, Moscow (1967); cf. KFKtr379 (1971).

11. V. I. SUBBOTIN, P. A. USHAKOV, Yu. D. LEVCHENKO

and A. M. ALEKSANDROV, Velocity fields in turbulent

flow past rod bundles, Heat Transfer-Sooiet Research

3 (2), 9-35 (1971).

12. J. A. BRIGHTON and J. B. JoNES, Fully developed tur-

bulent flow in annuli, J. Basic Engng 86D, 835-844

(1964).

13. A. QUARMBY, An experimental study of turbulent flow

through concentric annuli, Int. J. Mech. Sei. 9, 205-221

(1967).

14. K. MAUBACH and K. REHME, Negative eddy diffusivities

for asymmetrie turbulent velocity profiles? Int. J. Heat

Mass Transfer 15, 425-432 (1972).

15. K. REHME, Laminarstrmung in Stabbndeln, Chemie-

TngsTechnik: 43,962-966 (1971).

16. L. W. CARLSON and T. F. IRVlNE JR., Fully developed

pressure drop in triangular shaped ducts. J. Heat

Transfer 83C, 441-444 (1961).

17. E. M. SPARROW, Laminar flow in isoseeles triangular

ducts, A.I.Ch.E. Jl8 (5), 599--604(1962).

18. E. M. SPARROW and A. HAJI-SHEIKH, Laminar heat

transfer and pressure drop in isoseeles triangular,

right triangular, and circular sector ducts, J. Heat

Transfer 87, 426-428 (1965).

19. W. TIEDT, Berechnung des laminaren und turbulenten

Reibungswiderstandes konzentrischer und exzen-

trischer Ringspalte, Chemiker-Ztg.l Chem. Apparatur

90,813-821 (1966); 91,17-25,149-155,299-311,569-

576,968-975 (1967); 92, 76-89 (1968).

20. E. M. SPARROW and A. L. LOEFFLER, Longitudinal

laminar flow between cylinders arranged in regular

array, s.t.ci. J/5, 325-330 (1959).

21. A. A. SHOLOKOV, N. I. BULEEV, Yu. I. GRIBANOV and

V. E. MINASHIN, Longitudinal laminar fluid flow in a

bundle of rods, Inz, Fiz. Zh. 14 (3), 389-394 (1968)

(in Russian).

22. M. COURTAUD, R. RICQUE and B. MARTINET, Etude des

pertes de charge dans des conduites circulaires con-

tenant un faisceau de barreaux, Chem. Engng Sei. 21,

881-893 (1966).

23. R. A. AXFORD, Longitudinal laminar flow of an in-

compressible fluid in finite tube bundles with m + Itubes,

Report LA3418, Los Alamos Scientific Laboratory

(1966).

24. R. A. AXFORD. Summary of theoretical aspects of heat

transfer performance in clustered rod geometries,

Report LADC-9786, Los Alamos Scientific Laboratory

(1968).

25. T. C. MIN, H. W. HOFFMANN, T. C. TUCKER and F. N.

PEEBLES, An analysis ofaxial flow through a circular

channel containing rod clusters, W. A. SHAW,

Developments in Theoretical and Applied Mechanics,

Bd, 3, p. 667. Pergamon Press, Oxford (1967).

26. K. REHME, Laminarstrmung in Stabbndeln, Paper

presented at the 1971 Reaktortagung des Deutschen

Atomforums, Bonn, March 30--April 2, pp. 130--133

(1971).

27. D. PENDERGAST, M. COBBLE and P. SMITH, Laminar

flow through ducts of arbitrary cross-section, Int. J.

Mech, Sei. 12,695-703 (1970).

28. L. W. CARLSON, Experimental friction factors for fully

developed turbulent flow in smooth triangular ducts,

MS thesis, Mechanical Engineering Dept., University of

Minnesota, Minneapolis (1959).

29. E. R. G. ECKERT and T. F. IRVINE, JR., Pressure drop and

heat transfer in oa duct with triangular cross section,

J. Heat Transfer 82C, 125-138 (1960).

30. V. K. JONSSON, Experimental studies of turbulent flow

phenomena in eccentric annuli, Ph.D. Thesis, Univer-

sity of Minnesota, Minneapolis (1965).

31. D. E. BOURNE, D. FIGUEIREDO and M. E. CHARLES,

PREDICTION OF FRICTION FACTORS 949

Laminar and turbulent flow in annuli of unit eccentri-

city, Can. J. Chem. Engng 46, 289-293 (1968).

32. Y. LEE, Turbulent flow and heat transfer in concentric

and eccentric annuli, Ph.DiThesis, University of Liver-

pool (1964).

33. W. EIFLER, ber die turbulente Geschwindigkeits-

verteilung und Wandreibung in Strmungskanlen

verschiedener Querschnitte, Dissertation Technische

Hochschule Darmstadt (1968).

34. W. EIFLER and R. NIJSING, Berechnung der turbulenten

Geschwindigkeitsverteilung und Wandreibung in ex-

zentrischen Ringspalten, ATKE 18 (2), 133-142 (1971).

35. J. D. DENTON, Turbulent flow in concentric and

eccentric annuli, University of British Columbia, MS

Thesis (1963).

36. N. A. DODGE, Friction losses in annular flow, ASME

paper No. 63-WA-ll (1963).

37. T. DISKIND, Heat transfer and pressure drop in

eccentric annuli, Report NYO-9649 of Columbia

Univ., Department ofChemical Eng., NewYork (1961).

38. B. STAMPA, Experimentelle Untersuchung an axial

durchstrmten Ringspalten, Ph.D.Thesis, University of

Braunschweig, Germany, Pfleiderer-Institut fr Str-

mungsmaschinen (1971).

39. K. REHME, Pressure drop performance ofrod bundles in

hexagonal arrangements, Int. J. Heat Mass Transfer

15, 2499 (1972).

40. K. REHME, Widerstandsbeiwerte von Gitterabstands-

haltern fr Reaktorbrennelemente, ATKE 15 (2),

127-130 (1970).

41. L. R. GALLOWAY and N. EpSTEIN, Longitudinal flow

between cylinders in square and triangular arrays and

in a tube with square-edged entrance, A.I.Ch.E.-I.

Chem. E. Symposium Series No. 6, London (1965).

42. L. R. GALLOWAY, Longitudinal flow between cylinders

in square and triangular arrays, University of British

Columbia, Ph.D.Thesis (1964).

43. C. W. W. DARLING, Fluid flow and energy losses in

irregular conduits of constant flow area, M.Sc.Thesis,

Department of Chemical Engineering, Queen's Univer-

sity Kingston, Ontario (1961).

44. P. A. USHAKOV, V. I. SUBBOTIN, B. N. GABRIANOVICH,

V. D. TALANOV and I. P. SVIRIDENKO, Heat transfer and

hydraulic resistance in tightly packed corridor bundle of

rods, Atomnaya Energiya 13 (2), 162-169 (1962).

45. V. I. SUBBOTIN, P. A. USHAKOV and B. N. GABRIANO-

VICH, Hydraulischer Widerstand bei durch Flssigkeiten

lngsumstrmten Stabbndeln, Kernenergie 4, 658-660

(1961); cf. Atomnaya Energiya 9,308, (1960).

METHODE SIMPLE DE CALCUL DES FACTEURS DE FROTTEMENT POUR

L'ECOULEMENT TURBULENT DANS DES CANAUX NON-CIRCULAIRES

Resume-i-A l'aide des lois regissant la perte de charge dans un modele simple une methode est mise au

point qui permet de calculer le coefficient de perte de charge d'un ecoulement turbulent dans les canaux

non-circulaires, supposant seulement la connaissance du facteur de geometrie de la loi regissant la perte

de charge de l'ecoulement laminaire. La methode de calcul proposee est verifiee sur de nombreux resultats

experimentaux derives de la litterature et portant sur des canaux non-circulaires, p.ex. des triangles

acutangles, des fentes annulaires excentriques et des faisceaux de barres disposes de facon hexagonale et

carree dans des tubes circulaires et des canaux hexagonaux et carres, 11 apparait que l'ensemble du

materiel experimental peut tre tres bien decrit I'aide de la methode mise au point.

EINFACHE METHODE ZUR BESTIMMUNG VON REIBUNGSKOEFFIZIENTEN FR

TURBULENTE STRMUNG IN NICHT-KREISFRMIGEN KANLEN

Zusammenfassuug-Anhand der Druckverlustgesetzmssigkeiten eines einfachen Modells wird eine

Berechnungsmethode fr den Druckverlustbeiwert bei turbulenter Strmung in nicht-kreisfrmigen

Kanlen entwickelt, wobei nur die Kenntnis des Geometriefaktors des Druckverlustgesetzes fr die

laminare Strmung vorausgesetzt wird. An zahlreichen Versuchsergebnissen aus der Literatur bezglich

nicht-kreisfrmiger Kanle wie spitzwinklige Dreiecke, exzentrische Ringspalte und Stabbndel in

hexagonaler und quadratischer Anordnung in Kreisrohren, Sechskant- und Vierkantkanlen wird das

vorgeschlagene Berechnungsverfahren geprft. Es zeigt sich, dass das gesamte Versuchsmaterial mit

dem entwickelten Verfahren sehr gut beschrieben werden kann.

950 K. REHME

IlPOCTO:0. METO,n, PACQETA K08l!>l!>I1IJ)!IEHTOB TPEHI1H TVPRYJIEHTHOrO

TEQEHI1H B HEKPVrJIbIX KAHAJIAX

OCHOBe saKOHOMepHOCTeil conpOTHBJIeHHlI npocroro

paapaoraa BbI1fHCJIeHHH conpOTHBJIeHHff

npH Typ6yJIeHTHOM nOTOKe B HeKpyrJIbIX KaHaJIaX, npH1feM npennorraraerca

TOJIbIW SHaHHe reOMeTpH1feCKOrO epaKTopa aaxoaa conpOTHBJIeHHff

naxnnapnoro nOTOKa. Ilpennaraesra MeTOp; pacsera rrponepen C MHOr01fHCJIeHHbIX

8KcnepHMeHTaJIbHbIX p;aHHbIX B rraroparypo OTHOCHTeJIbHO raxnx HeKpyrJIbIX KaHaJIOB,

KaK: ocrpoyrom.mrc TpeyrOJIbHHKH, 8Kcu;eHTpH1fHhIe KOJIhu;eBhIe aaaopsr H HY1fKHcrepaure

ClIIecTHyrOJIhHOil H xnanparno pemerrcoti B KpyrJIbIX rpyax H KaHaJIaX 1feThIpexyrOJIhHOrO

H lIIecTHyrOJIbHOrO Ce1feHHil. OKaShIBaeTCff, 1fTO uecs aacnepaaearam.au MaTepHaJI o-rem,

XOPOIIIO onHChIBaeTCH nyTeM aroro paapaoraaaoro

You might also like

- PressureDrop IJFMRDocument18 pagesPressureDrop IJFMRThinh Tran HungNo ratings yet

- Numerical Solutions of Viscous Flow Through A Pipe Orifice Al Low Reynolds NumbersDocument8 pagesNumerical Solutions of Viscous Flow Through A Pipe Orifice Al Low Reynolds NumbersozkeneNo ratings yet

- Flow Over A CylinderDocument14 pagesFlow Over A CylinderHariVathsalaNo ratings yet

- Pressure Drop in Laminar and Turbulent Flows in Circular PipeDocument17 pagesPressure Drop in Laminar and Turbulent Flows in Circular Pipegestapo85No ratings yet

- T 2Document31 pagesT 2Vinay Gupta100% (1)

- CFD Simulations of Lid Driven Cavity Flow at Moderate Reynolds NumberDocument14 pagesCFD Simulations of Lid Driven Cavity Flow at Moderate Reynolds NumberVivek JoshiNo ratings yet

- Crane J M Et Al - 2009 - Laminar Jet Discharged Into A Dead End TubeDocument21 pagesCrane J M Et Al - 2009 - Laminar Jet Discharged Into A Dead End TubejadamiatNo ratings yet

- Laminar Flow Friction and Heat Transfer Model for Non-Circular DuctsDocument9 pagesLaminar Flow Friction and Heat Transfer Model for Non-Circular DuctsmcalexanderNo ratings yet

- Numerical Simulation of Flow Past A Circular Cylinder With Varying Tunnel Height To Cylinder Diameter at Re 40Document7 pagesNumerical Simulation of Flow Past A Circular Cylinder With Varying Tunnel Height To Cylinder Diameter at Re 40International Journal of computational Engineering research (IJCER)No ratings yet

- Colebrook White. (1939)Document29 pagesColebrook White. (1939)carloscartasine100% (2)

- Aiaa 18973 703Document10 pagesAiaa 18973 703Pablo ApasionadoNo ratings yet

- Experimental and Analytical Evaluation of Ow in A Square-To-Square Wind Tunnel ContractionDocument16 pagesExperimental and Analytical Evaluation of Ow in A Square-To-Square Wind Tunnel ContractionDr-Manish SharmaNo ratings yet

- Kecman Bending Collapse of Rectangular and Square Section Tubes 1983 International Journal of Mechanical SciencesDocument14 pagesKecman Bending Collapse of Rectangular and Square Section Tubes 1983 International Journal of Mechanical SciencesNhật Vũ100% (2)

- Smee2010 3Document6 pagesSmee2010 3Anonymous 07A7rmhNo ratings yet

- Bell e Mehta 1988Document39 pagesBell e Mehta 1988Nelson LondoñoNo ratings yet

- Boundary Shear Stress in A Trapezoidal ChannelDocument9 pagesBoundary Shear Stress in A Trapezoidal Channeljavid_cenNo ratings yet

- Friction FactorDocument11 pagesFriction FactorshailiitbhuNo ratings yet

- The Effect of Convex Wall Curvature On The Structure of The Turbulent Boundary LayerDocument15 pagesThe Effect of Convex Wall Curvature On The Structure of The Turbulent Boundary LayerMandar MakwanaNo ratings yet

- Relaxation Behaviour of Lithium-Borosilicate GlassesDocument8 pagesRelaxation Behaviour of Lithium-Borosilicate GlassesInnovative Research PublicationsNo ratings yet

- Wind Tunnel Velocity Profiles Generated by Differentially-Spaced Flat PlatesDocument10 pagesWind Tunnel Velocity Profiles Generated by Differentially-Spaced Flat PlatesMario AlemanNo ratings yet

- Boundary Layer Analysis With Navier-Stokes Equation in 2D Channel FlowDocument5 pagesBoundary Layer Analysis With Navier-Stokes Equation in 2D Channel FlowDanielle HaysNo ratings yet

- Studies of Compression Corner Flowfields Using THREE Turbulent ModelsDocument7 pagesStudies of Compression Corner Flowfields Using THREE Turbulent Modelsarnalt_stalinNo ratings yet

- Determination of Line Tension From The Drop Size Dependence of Contact AnglesDocument12 pagesDetermination of Line Tension From The Drop Size Dependence of Contact AnglesrmvanginkelNo ratings yet

- Analytical Solutions For The Flow of Carreau and Cross Fluids in Circular Pipes and Thin SlitsDocument27 pagesAnalytical Solutions For The Flow of Carreau and Cross Fluids in Circular Pipes and Thin SlitsTaha SochiNo ratings yet

- 10.1515 - CPPM 2022 0056Document19 pages10.1515 - CPPM 2022 0056a.jasour97No ratings yet

- Important ThroughflowDocument14 pagesImportant ThroughflowkoolwaveoceanicNo ratings yet

- Wall EffectsDocument8 pagesWall Effectssubaachandran2429No ratings yet

- Numerical Prediction of Laminar F L o W and Heat Transfer Characteristics in A Tube Fitted With Regularly Spaced Twisted-Tape ElementsDocument9 pagesNumerical Prediction of Laminar F L o W and Heat Transfer Characteristics in A Tube Fitted With Regularly Spaced Twisted-Tape ElementschawarepNo ratings yet

- Attenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlDocument25 pagesAttenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlRehan NaseerNo ratings yet

- Walsh Effective PermeabilityDocument7 pagesWalsh Effective PermeabilityGlusmNo ratings yet

- Morgan 1974Document15 pagesMorgan 1974mintillaNo ratings yet

- Research 1 PDFDocument14 pagesResearch 1 PDFIan JamesNo ratings yet

- 2008 - Lister Et Al. - Shape and Stability of Axisymmetric Levitated Viscous Drops - Journal of Fluid MechanicsDocument19 pages2008 - Lister Et Al. - Shape and Stability of Axisymmetric Levitated Viscous Drops - Journal of Fluid MechanicsClaudio BiaginiNo ratings yet

- Static Resistance Bolted Circular Flange JointsDocument9 pagesStatic Resistance Bolted Circular Flange JointsBálint Vaszilievits-SömjénNo ratings yet

- Iraq University Engineering Report on Gas Pipeline Design FactorsDocument5 pagesIraq University Engineering Report on Gas Pipeline Design Factorsمحمد عبد الجبار كاظمNo ratings yet

- Hot Wire SynjetDocument8 pagesHot Wire SynjetDaniel SilvaNo ratings yet

- Turbulent Flow Through Pipes: Friction Factor and Velocity DistributionDocument17 pagesTurbulent Flow Through Pipes: Friction Factor and Velocity Distributiondurga345No ratings yet

- Quasi-3D Modelling of Two-Phase Slug Flow in PipesDocument12 pagesQuasi-3D Modelling of Two-Phase Slug Flow in PipeskumarNo ratings yet

- The Flow of Newtonian Fluids in Axisymmetric Corrugated TubesDocument17 pagesThe Flow of Newtonian Fluids in Axisymmetric Corrugated Tubesabcdefg43212004No ratings yet

- Numerical Investigation of Incompressible Flow Past Circular Tubes in Confined ChannelDocument14 pagesNumerical Investigation of Incompressible Flow Past Circular Tubes in Confined ChannelaadinathhariharNo ratings yet

- Direct Numerical Simulation of Turbulent in A Square Duct: Asmund Husert Sedat BiringenDocument31 pagesDirect Numerical Simulation of Turbulent in A Square Duct: Asmund Husert Sedat BiringenMaiman LatoNo ratings yet

- Mass Flow Rate Measurement of Gas/Liquid Two-Phase Flow in Horizontal Pipe Based On V-Cone Flow Meter and Adaptive Wavelet NetworkDocument6 pagesMass Flow Rate Measurement of Gas/Liquid Two-Phase Flow in Horizontal Pipe Based On V-Cone Flow Meter and Adaptive Wavelet NetworkFernando GuerreroNo ratings yet

- Calibrating The Discharge Coefficient of Semicircular Crested WeirDocument14 pagesCalibrating The Discharge Coefficient of Semicircular Crested Weirشيماء الهاشميNo ratings yet

- Numerical Modeling of Flow Over A Rectangular Broa PDFDocument12 pagesNumerical Modeling of Flow Over A Rectangular Broa PDFSawab MadeneNo ratings yet

- Impact of Pipes Networks Simplification On Water Hammer PhenomenonDocument18 pagesImpact of Pipes Networks Simplification On Water Hammer PhenomenonVelpandian ManiNo ratings yet

- Beggs and Brill MethodDocument25 pagesBeggs and Brill MethodHuy Lâm100% (2)

- Large Eddy Simulation of The Ow Past A Circular Cylinder at Re 3900Document16 pagesLarge Eddy Simulation of The Ow Past A Circular Cylinder at Re 3900samik4uNo ratings yet

- Achenbach Smooth - Rough CylinderDocument15 pagesAchenbach Smooth - Rough CylinderVivek KantiNo ratings yet

- Lee 2013 International Journal of Heat and Fluid FlowDocument13 pagesLee 2013 International Journal of Heat and Fluid FlowalexandreburanNo ratings yet

- Achenbach1972 PDFDocument11 pagesAchenbach1972 PDFdyabrudyNo ratings yet

- A Numerical Investigation of The Flow Structures and Losses For Turbulent Flow in 90° Elbow Bends. (Crawford N, Spence S, Et Al) (2008)Document18 pagesA Numerical Investigation of The Flow Structures and Losses For Turbulent Flow in 90° Elbow Bends. (Crawford N, Spence S, Et Al) (2008)Manuel AyalaNo ratings yet

- Numerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUDocument6 pagesNumerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUAzharuddin Ehtesham FarooquiNo ratings yet

- Karabelas - Liquid - Liquid Droplet Size Distribution PDFDocument11 pagesKarabelas - Liquid - Liquid Droplet Size Distribution PDFSwiftTGSolutionsNo ratings yet

- Pulsatil Flow in Curved PipesDocument28 pagesPulsatil Flow in Curved PipesAndrés Prada MoralesNo ratings yet

- European Scientific Journal Friction Coefficient FlowDocument16 pagesEuropean Scientific Journal Friction Coefficient FlowSafa BOUSSADANo ratings yet

- Developed Laminar Flow in Pipe Using Computational Fluid DynamicsDocument10 pagesDeveloped Laminar Flow in Pipe Using Computational Fluid Dynamicsyashsaini020No ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Fluid Dynamics in Complex Fractured-Porous SystemsFrom EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNo ratings yet

- A Method For Determining The Coefficient of Volume Thermal Expansion of Petroleum ParaffinsDocument11 pagesA Method For Determining The Coefficient of Volume Thermal Expansion of Petroleum Paraffinslimin zhangNo ratings yet

- Compressibility PDFDocument55 pagesCompressibility PDFShirdish PatilNo ratings yet

- Crude Oil Expansion Coefficient Third RhomaxDocument28 pagesCrude Oil Expansion Coefficient Third Rhomaxlimin zhangNo ratings yet

- AutoPIPE V8i Quick ReferenceDocument1 pageAutoPIPE V8i Quick ReferenceFabio MiguelNo ratings yet

- Abaqus Pipe Soil InteractionDocument5 pagesAbaqus Pipe Soil Interactionlimin zhang100% (1)

- Transient Cooling of Waxy Crude Oil in A Floating Roof TankDocument13 pagesTransient Cooling of Waxy Crude Oil in A Floating Roof Tanklimin zhangNo ratings yet

- 20120619-20 BanjacDocument24 pages20120619-20 BanjacsinhleprovietNo ratings yet

- Thermal Properties Gas To Liquid ProductsDocument12 pagesThermal Properties Gas To Liquid Productslimin zhangNo ratings yet

- 20120619-20 BanjacDocument24 pages20120619-20 BanjacsinhleprovietNo ratings yet

- Lube Tech093 ViscosityBlendingEquations - 2 PDFDocument4 pagesLube Tech093 ViscosityBlendingEquations - 2 PDFvivek20072008No ratings yet

- Welderqual Asme WPQ Asme IxDocument17 pagesWelderqual Asme WPQ Asme Ixnaveenbaskaran1989No ratings yet

- AutoPIPE vs Caesar user interface guideDocument7 pagesAutoPIPE vs Caesar user interface guidelimin zhangNo ratings yet

- Multiple Orifice Plates SpoolDocument2 pagesMultiple Orifice Plates Spoollimin zhangNo ratings yet

- Pipe Hanger Design-07Document84 pagesPipe Hanger Design-07mrvanlang100% (3)

- Making Pizza Dough Using Bread MakerDocument1 pageMaking Pizza Dough Using Bread Makerlimin zhangNo ratings yet

- Drip Pan Elbow - Kunkle PDFDocument2 pagesDrip Pan Elbow - Kunkle PDFlimin zhangNo ratings yet

- Casio Wave Acquture Watch qw5161 ManualDocument9 pagesCasio Wave Acquture Watch qw5161 Manuallimin zhangNo ratings yet

- Pipe Hanger Design-07Document84 pagesPipe Hanger Design-07mrvanlang100% (3)

- Asme 1Document3 pagesAsme 1Luis MarshNo ratings yet

- Multistage Restriction Orifice Assembly PDFDocument1 pageMultistage Restriction Orifice Assembly PDFlimin zhang100% (1)

- Victaulic Modeling by AutoPipe PDFDocument18 pagesVictaulic Modeling by AutoPipe PDFlimin zhangNo ratings yet

- Design of Structural Steel Pipe Racks PDFDocument12 pagesDesign of Structural Steel Pipe Racks PDFmobin1978100% (3)

- Victaulic I-100 Field Installation Handbook PDFDocument312 pagesVictaulic I-100 Field Installation Handbook PDFlimin zhang100% (1)

- Asme 1Document3 pagesAsme 1Luis MarshNo ratings yet

- Anchor Bolt DesignDocument26 pagesAnchor Bolt Designdwicahyo_as100% (1)

- Law Answer B PDFDocument13 pagesLaw Answer B PDFlimin zhang100% (1)

- Water Agencies Standards PDFDocument38 pagesWater Agencies Standards PDFlimin zhangNo ratings yet

- Law Answer A PDFDocument14 pagesLaw Answer A PDFlimin zhang100% (4)

- Law Question PDFDocument29 pagesLaw Question PDFlimin zhang70% (10)

- Pipe-Soil Interaction: Flexible and Rigid PipesDocument8 pagesPipe-Soil Interaction: Flexible and Rigid Pipesvmi_dude100% (2)

- Lewatit Monoplus TP 260: Product InformationDocument5 pagesLewatit Monoplus TP 260: Product InformationChang Chee HongNo ratings yet

- C 110Document41 pagesC 110Benhur K SamyNo ratings yet

- Earth Pressure Calculation Web PDFDocument273 pagesEarth Pressure Calculation Web PDFKumaranNo ratings yet

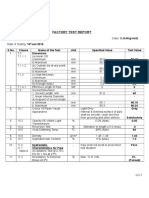

- FTRDocument1 pageFTRanon_127491670No ratings yet

- Light Fastness of Blue PigmentDocument7 pagesLight Fastness of Blue PigmentShaik DawoodNo ratings yet

- Air Separation Unit PDFDocument2 pagesAir Separation Unit PDFbodhi_cheNo ratings yet

- Chem 10Document5 pagesChem 10robert1789No ratings yet

- Freezing, Melting, and EvaporationDocument81 pagesFreezing, Melting, and EvaporationKris Paolo CamiasNo ratings yet

- Dapust 21Document5 pagesDapust 21Dewo BontangNo ratings yet

- 1 - Bhattiacademy - Com - Physics - 6. Azeem Acadmy (Objective) PDFDocument14 pages1 - Bhattiacademy - Com - Physics - 6. Azeem Acadmy (Objective) PDFAwaisNo ratings yet

- Natural Gas ProcessingDocument35 pagesNatural Gas ProcessingAleem AhmedNo ratings yet

- DSSC PresentationDocument50 pagesDSSC PresentationWisaruth MaethasithNo ratings yet

- GGR240L Use and Care ManualDocument2 pagesGGR240L Use and Care ManualBobDewilleNo ratings yet

- R&AC Assigment-cum-Turorial Questions - Unit-V - 2017Document6 pagesR&AC Assigment-cum-Turorial Questions - Unit-V - 2017sivakrishna100% (1)

- Lecture # 12Document11 pagesLecture # 12api-15026641100% (2)

- Hazardous Area Considerations for Diesel StorageDocument34 pagesHazardous Area Considerations for Diesel StorageSeun100% (1)

- Lecture 2 - Atoms, Molecules, and IonsDocument34 pagesLecture 2 - Atoms, Molecules, and Ionsapi-19824406100% (1)

- 2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Document14 pages2-Mathematical Modeling and Simulation of Hydrotreating Reactors Cocurrent Versus Countercurrent Operations - Art5Vicente SosaNo ratings yet

- Cooler Condenser Design for Vapor-Gas MixturesDocument1 pageCooler Condenser Design for Vapor-Gas MixturesNind's Chef0% (1)

- Is 4031 Part 4 - ConsistencyDocument4 pagesIs 4031 Part 4 - ConsistencyCrypto AbhishekNo ratings yet

- Thermoforming TroubleshootingDocument10 pagesThermoforming TroubleshootingdynafloNo ratings yet

- Ap41s 81 2009Document11 pagesAp41s 81 2009Anita VkNo ratings yet

- Specific HeatDocument2 pagesSpecific HeatVanessa Christonette SistosoNo ratings yet

- D473 - Sedimetnos Por ExtracciónDocument6 pagesD473 - Sedimetnos Por ExtracciónCarito LopezNo ratings yet

- Regents Chemistry Dynamic Equilibrium POGILDocument5 pagesRegents Chemistry Dynamic Equilibrium POGILEric RadulovichNo ratings yet

- Application & Analysis of Banana Stem Fibre Use As Construction MaterialDocument12 pagesApplication & Analysis of Banana Stem Fibre Use As Construction MaterialEditor IJTSRDNo ratings yet

- Important Notes On Ana Chem Lecture 1Document3 pagesImportant Notes On Ana Chem Lecture 1Eliza Loren PalleraNo ratings yet

- GTPL e BrochureDocument5 pagesGTPL e BrochuremishtinilNo ratings yet

- Physics of Aqueous Phase Evolution in Plutonic EnvironmentsDocument11 pagesPhysics of Aqueous Phase Evolution in Plutonic Environmentsjunior.geologia100% (1)

- Sci PPT Q1 WK2 Day 1-5Document44 pagesSci PPT Q1 WK2 Day 1-5Ruby Flor Dela Cruz100% (1)