Professional Documents

Culture Documents

Screen Openings For Y-Strainers

Uploaded by

boom10Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screen Openings For Y-Strainers

Uploaded by

boom10Copyright:

Available Formats

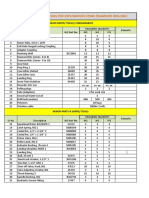

Engineering Data Screen Openings for Y-Strainers

Factors To Consider

Purpose

If the basket strainer is being used for protection rather than direct filtration,IFCs standard screens will suffice in most applications.

Filtration Level

Service

With services that require extremely sturdy screens, such as high pressure/ temperature applications or services with high viscosities, IFC recommends that perforated screens without mesh liners be used. If mesh is required to obtain a certain level of filtration, then IFC recommends a trapped perf./mesh/perf. combination. Screen Types/Dimensions

When choosing a perf. or a mesh/perf. combination attention should be given to ensure overstraining does not occur.As a general rule the specified level of filtration should be no smaller than half the size of the particle to be removed. If too fine a filtration is specified the pressure drop through the strainer will increase very rapidly, possibly causing damage to the basket.

0.027 Dia. - 23% O.A.

Notes: 1. Screen openings other than those shown above are readily available. IFC inventories various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2 Dia. 2. Screens are available in a wide range of materials. IFC inventories various screen material in carbon steel, stainless steel (304, 316), alloy 20, monel 400, hastalloy C and titanium grade 2. 3. Custom manufactured screens are available upon request. Please consult factory.

Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

100 Mesh - 30% O.A. 0.006 Openings

Dia. - 50% O.A.

Dia. - 37% O.A.

Dia. - 36% O.A.

Dia. - 40% O.A.

20 Mesh - 49% O.A. 0.035 Openings

30 Mesh - 45% O.A. 0.022 Openings

40 Mesh - 41% O.A. 0.016 Openings

60 Mesh - 38% O.A. 0.010 Openings

80 Mesh - 36% O.A. 0.008 Openings

Dia. - 58% O.A

Dia. - 40% O.A.

3/ 16

5/ 32

Dia. - 40% O.A.

3/ 32

Dia. - 39% O.A

1/ 16

3/ 64

1/ 32

1/ 4

1/ 8

20

Engineering Data Y-Strainer Pressure Drop Liquids

Y-Strainer Pressure Drop Liquids (Sizes

10

1/

- 11/ 2 ) FIGURE 1

PRESSURE DROP (PSID)

/4

1 /4

3 /8

1 /2

3 /4

11

0.1 0.1

10

11

/2

100

FLOW RATE (GPM)

Y-Strainer Pressure Drop Liquids (Sizes 2 - 16 )

10

FIGURE 2

PRESSURE DROP (PSID)

/2

10

12 14

21

0.1 10

100

1000

16

10000

FLOW RATE (GPM)

Notes: 1. Pressure drop curves are based on water flow with standard screens. See page 22 for correction factors to be used with other fluids and/or screen openings.

21

Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

Engineering Data Screen Correction Factor Chart

For Non-Standard and Mesh Lined Screens *Multiply values obtained from figure 1 thru 4 by the appropriate values shown below Size R ange 60%

1/ 1 4 - 1 /2

Chart # 1 Mesh lined standard screens % Screen Material Open Area 50% 40% 30%

1.05 1.05 1.05 1.05 1.2 1.2

SCREEN OPENINGS Perforated Plate % Screen Material Open Area 50% 40% 30% 20%

0.55 0.8 0.7 1 1 1.4 1.15 2.15

0.45 0.65

2 - 16

Notes: 1. See page 20 for % Open Areas of IFC inventoried perforated plate. 2. Standard screens for sizes 1/4 to 11/2 is approximately a 30% open area screen media. 3. Standard screens for sizes 2 and larger is approximately a 40% open area screen media.

Example:

Strainer Size: 11/4 1/ Perf. Filtration: 100 Mesh lined 32 Flow rate: 30 GPM Service: Water

A) Using figure 1 the pressure drop is determined to be 1.0 psid with IFCs standard screen. B) Looking at page 20 we find that the % Open area of 100 mesh is 30%. C) Using chart 1 we read the correction factor to be 1.2 for 100 mesh lined 1/32 perf. D) Total pressure drop equals 1.0 x 1.2 = 1.2 psid clean.

Viscosity and Density Correction Factor Chart * For use see instructions below. Chart # 2

Size R ange

1/ 4

Chart # 3

Viscosity Body Loss Screen Loss Factor Cp Factor Perf alone 20 Mesh 30, 40, Mesh 60 to 300 Mesh (BF) (PF) Lined (MF) Lined (MF) Lined (MF)

Component Factor (CF)

- 11/2

0.25 0.35

10 25 100 200

1 1.2 1.6 2.2

1.15 1.25 1.4 1.5

1.3 2 3 4.5

1.4 2.2 4 7

1.5 2.5 6.5 11.5 25 50 100

2 - 16

How to Use:

1) Using figures 1 or 2 determine the

2)

3) 4) 5) 6) 7) 8)

500 4.4 1.6 10 15 pressure drop (P1) through the strainer with water flow and standard screens. 1000 8 1.7 15 30 If non-standard screens (i.e. 40 mesh, 2000 15.2 1.9 30 60 etc.) are being used apply factors in Chart #1 to determine corrected pressure drop (P2). Multiply P1 or P2 (is used) by the specific gravity of the fluid actually flowing through the strainer to get P3. Using Chart #2 multiply P3 by the appropriate Component Factor (CF) to get P4. Let P5 = P3 - P4. Multiply P4 by the appropriate Body Loss Factor (BF) in Chart #3 to get P6. Multiply P5 by the appropriate Screen Loss factor (PF or MF) in Chart #3 to get P7. Total pressure drop P8 = P6 + P7.

Example:

Strainer Size: 11/4 1/ Perf. Filtration: 100 Mesh lined 32 Flow rate: 30 GPM Specific Gravity: 1 Viscosity: 25 cP

A) As shown in the above example, the corrected pressure drop (P2) = 1.2 psid B) Since S.G. = 1, P3 = P2 = 1.2 psid C) Using Chart #2 P4 = 0.25 x P3 = 0.30 psid D) P5 = 1.2 - 0.3 = 0.90 psid E) Using Chart #3 P6 = 0.3 x 1.2 = 0.36 psid F) Again using Chart #3 P7 = 0.9 x 2.5 = 2.25 psid G) Total pressure drop P8 = 0.36 + 2.25 = 2.61 psid

Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

22

Engineering Data Y-Strainer Pressure Drop Saturated Steam (Sizes 1/ 4 - 11/ 2 )

Y-Strainer Pressure Drop Saturated Steam (Sizes FIGURE 3

10000

1/ 4

- 11/ 2 )

INLET PRESSURE (PSIG)

600 400 200 160 120 80 10 20 40

STEAM FLOW (Lbs/hr) PRESSURE DROP (PSID)

1000

100

3 /8

1 /4

1 /2

/4

11

0.1

Notes: 1. Pressure drop curve is based on saturated steam flow with standard screens. See page 20 for correction factors to be used with other fluids and/or screen openings. 2. Chart can be used for air and gas by using the following formula:

Qs = 0.138Qg

(460+t) s.g.

DP <1.0 P2

FOR NON-CRITICAL FLOW

where;

Qs Qg t s.g. DP P2 = = = = = = Equivalent Steam Flow, lbs./hr. Air or gas flow, SCFM. Temperature, F. Specific gravity (s.g. = 1 for air.) Pressure Drop, psid Outlet Pressure

Example:

Service: Pressure: Steam Flow: Size: Saturated Steam Flow 400 psig 1000 Lbs/hr 11/4

Locate steam flow Follow horizontal line to required pressure. Follow vertical line downwards to required strainer size. Follow horizontal line to read pressure drop. Pressure drop equals 0.8 psid.

23

Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

11

10

3 /4

/2

Engineering Data Y-Strainer Pressure Drop Saturated Steam (Sizes 2 to 16 )

Y-Strainer Pressure Drop Saturated Steam (Sizes 2 - 16 ) FIGURE 4

1000000

INLET PRESSURE (PSIG)

600 400 200 160 120 80 40 20 10

21 / 3 2 2 4

STEAM FLOW (Lbs/hr) PRESSURE DROP (PSID)

100000

10000

1000

100

10

0.1

Notes: 1. Pressure drop curve is based on saturated steam flow with standard screens. See page 22 for correction factors to be used with other screen openings. 2. Chart can be used for air and gas by using the following formula:

Qs = 0.138Qg

(460+t) s.g.

DP <1.0 P2

FOR NON-CRITICAL FLOW

where;

Qs Qg t s.g. DP P2 = = = = = = Equivalent Steam Flow, lbs./hr. Air or gas flow, SCFM. Temperature, F. Specific gravity (s.g. = 1 for air.) Pressure Drop, psid Outlet Pressure

Example:

Service: Pressure: Steam Flow: Size: Saturated Steam Flow 400 psig 90,000 Lbs/hr 8

Locate steam flow Follow horizontal line to required pressure. Follow vertical line downwards to required strainer size. Follow horizontal line to read pressure drop. Pressure drop equals 2.0 psid.

10 12 14 16

5 6

Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

24

Engineering Data Correction Factors For Clogged Screens

Correction Factors For Clogged Screens * Multiply values obtained from figures 1 thru 4 and Charts #1, #2 and #3 (if used) by the appropriate values shown below Chart # 4 R atio of Free Screen Area to Pipe Area % Clogged 10:1 8:1 6:1 4:1 3:1 2:1 1:1

10% 20% 30% 40% 50% 60% 70% 80% 90% 2.3 1.1 3.45 1.75 6 1.15 1.75 3.6 13.5 1.25 1.8 2.95 6.25 24 1.15 1.4 1.8 2.5 3.7 6.4 14 55 3.15 3.9 5 6.65 9.45 14.5 26 58 -

Notes: 1. See page 27 for the Ratio of Free Area to Pipe Area for IFC Y-Strainers equipped with standard screens. 2. For screens other than IFCs standard use the following formula to calculate the Ratio Free Area to Pipe Area.

R = Ag x OA 100Ap

Example # 1:

Strainer Size: IFC Series: Filtration: Flow rate: Service: % Clogged: 4 Y150F 1/ Perf. 8 300 GPM Water 60%

where;

R Ag OA Ap = = = = Ratio Free Area to Pipe Area Gross screen area, sq. in. (See page 27) Open area of screen media, % (See page 20, i.e. 1/8 perf. = 40%) Nominal area of pipe fitting, sq. in. (See page 27)

A) Using Figure #1 the pressure drop is determined to be 1.1 psid with IFCs standard screen. B) Looking at page 27 the Ratio of Free Area to Pipe Area for a 4 IFC series Y150F strainer is equal to 2.72:1 (3:1 approx.). C) Using Chart #4 we read the correction factor to be 1.80 at 60% clogged. D) Total pressure drop equals 1.1 x 1.8 = 1.98 psid when 60% clogged.

Example # 2:

Strainer Size: IFC Series: Filtration: Flow rate: Service: % Clogged: 12 Y300F 3/ Perf. 16 2000 GPM Water 70% A) Using Figure #1 the pressure drop is determined to be 0.54 psid with IFCs standard screen. B) Looking at page 20 we find that the % Open area (OA) of 3/16 Perf. is 50%. C) Using Chart #1 we read the correction factor to be 0.8 for 3/16 Perf. D) Total clean pressure drop equals 0.54 x 0.8 = 0.43 psid. E) Since a non-standard screen is being used we must calculate the Ratio Free Area to Pipe Area using the above formula. F) Looking at page 27 we find AG = 753.12 in2,Ap = 113.10 in2. G) The Ratio Free Area to Pipe Area is calculated as 3.33:1. (3:1 approx.) H) Using Chart #4 we read the correction factor to be 2.95 at 70% clogged. I) Total pressure drop equals 0.43 x 2.95 = 1.27 psid when 70% clogged.

25

Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

You might also like

- VDO Instrument Manual TU00-0755-00000002Document273 pagesVDO Instrument Manual TU00-0755-00000002boom10100% (1)

- Section 06 - Hole CleaningDocument81 pagesSection 06 - Hole CleaningRicardo Villar100% (2)

- Material Equivalent TableDocument8 pagesMaterial Equivalent Tableprashantpan1776% (21)

- Flat To Steep Curve - Orifice Plate at Pump DischargeDocument1 pageFlat To Steep Curve - Orifice Plate at Pump Dischargeorchids28No ratings yet

- ResourcesFrictionLossData PDFDocument4 pagesResourcesFrictionLossData PDFEduardo MirandaNo ratings yet

- Comparison Carrier vs. McQuayDocument2 pagesComparison Carrier vs. McQuayPradeep SukumaranNo ratings yet

- Lewa Poster LMV 322Document1 pageLewa Poster LMV 322boom10No ratings yet

- Williams Material Suffix Common Designation Astm Casting Specification Service RecommendationsDocument2 pagesWilliams Material Suffix Common Designation Astm Casting Specification Service Recommendationsboom10No ratings yet

- Flexible ConnectionsDocument118 pagesFlexible ConnectionsMuzaffarNo ratings yet

- Duct Construction Schedule & References PDFDocument8 pagesDuct Construction Schedule & References PDFEslam ElsayedNo ratings yet

- Controlling Ejector Performance with Steam Bleed ControlDocument9 pagesControlling Ejector Performance with Steam Bleed ControlCan YıldırımNo ratings yet

- BOSS™ Pressurisation Units and Expansion Vessels PDFDocument16 pagesBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASNo ratings yet

- Growing Power of Social MediaDocument13 pagesGrowing Power of Social MediaKiran HanifNo ratings yet

- Curtiss SO3C-1 Seamew Recon PlaneDocument11 pagesCurtiss SO3C-1 Seamew Recon PlaneAdrian Rosero Bautista100% (1)

- Building MaterialsDocument13 pagesBuilding MaterialsPriyanka BasuNo ratings yet

- Flexibox Serie RDocument5 pagesFlexibox Serie Rboom10No ratings yet

- Flexibox Serie RDocument5 pagesFlexibox Serie Rboom10No ratings yet

- Hydroheater Auto Manual VersionDocument45 pagesHydroheater Auto Manual VersionVishal Nawalgaria100% (3)

- Calculate Strainer Pressure DropDocument11 pagesCalculate Strainer Pressure DropBIDDU GHOSHNo ratings yet

- Pipe WorkDocument12 pagesPipe WorkSudheepNo ratings yet

- PHE-Plate Heat Exchanger SpecificationDocument2 pagesPHE-Plate Heat Exchanger SpecificationPaulusIwanNo ratings yet

- Strainer Sizing GuideDocument20 pagesStrainer Sizing Guidealiscribd46No ratings yet

- Liquid Ring Compressor System PrincipleDocument3 pagesLiquid Ring Compressor System Principleboom1067% (3)

- B A S Ket Strainer Pressure Drop-LiquidsDocument4 pagesB A S Ket Strainer Pressure Drop-LiquidsguillemaraNo ratings yet

- Collaborative Cyber Threat Intelligence Detecting and Responding To Advanced Cyber Attacks at The National LevelDocument566 pagesCollaborative Cyber Threat Intelligence Detecting and Responding To Advanced Cyber Attacks at The National Levelanon_760702463No ratings yet

- Pressure Volume Calculator 02Document6 pagesPressure Volume Calculator 02Jenny Cecilia Ureña ZuriNo ratings yet

- Questions STPDocument22 pagesQuestions STPRabindra SinghNo ratings yet

- Climatic Constants Using ASHRAE CD Ver 6.0 PDFDocument99 pagesClimatic Constants Using ASHRAE CD Ver 6.0 PDFmohdNo ratings yet

- NSB Liquid Ring CompressorDocument8 pagesNSB Liquid Ring Compressorboom10100% (1)

- Product-Data-Sheet-Catalog-12 - (Two Phase Control Valve Sizing Calculation Fisher)Document41 pagesProduct-Data-Sheet-Catalog-12 - (Two Phase Control Valve Sizing Calculation Fisher)reninbabaski100% (1)

- Spirax Sarco - PRODUCT HANDBOOK AUGUST 2017 PDFDocument1,900 pagesSpirax Sarco - PRODUCT HANDBOOK AUGUST 2017 PDFboom1086% (7)

- Analytics For Sustainable BusinessDocument6 pagesAnalytics For Sustainable BusinessDeloitte AnalyticsNo ratings yet

- Copper Wire and Cable: From Wikipedia, The Free EncyclopediaDocument16 pagesCopper Wire and Cable: From Wikipedia, The Free Encyclopediatanwar_anuj1990No ratings yet

- Easyheat s27 - 02 SarcoDocument8 pagesEasyheat s27 - 02 SarcoMarcelo ResckNo ratings yet

- Slope Drainage PipingDocument1 pageSlope Drainage PipingRyan CarterNo ratings yet

- 9.line Size & Wall ThicknessDocument48 pages9.line Size & Wall ThicknessClark PlúaNo ratings yet

- Data Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG ODocument4 pagesData Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG Ogabriel riveroNo ratings yet

- MVAC Duct Pressure Drop (Reference Summary)Document19 pagesMVAC Duct Pressure Drop (Reference Summary)Cheng Chun TingNo ratings yet

- GM Construction Leads Rs 8140 Crore PCII C2C3 Recovery ProjectDocument24 pagesGM Construction Leads Rs 8140 Crore PCII C2C3 Recovery ProjectAnuj GuptaNo ratings yet

- Installation & Maintenance Manual for Hisaka Plate Heat ExchangerDocument48 pagesInstallation & Maintenance Manual for Hisaka Plate Heat Exchangercengiz kutukcuNo ratings yet

- Ecodial Advance Calcualtion IndiaDocument16 pagesEcodial Advance Calcualtion IndiaJosé Mendes da Silva100% (1)

- AF Range BrochureDocument27 pagesAF Range Brochureboom10100% (1)

- Fire Fighting Pumps and Packages for all StandardsDocument6 pagesFire Fighting Pumps and Packages for all StandardsAddeNifiraNo ratings yet

- Centrifugal Pump Troubleshooting ChecklistDocument8 pagesCentrifugal Pump Troubleshooting Checklistab_s5036No ratings yet

- Submersible Borehole Pumps - 50 HZDocument118 pagesSubmersible Borehole Pumps - 50 HZanirbanpwd76No ratings yet

- Booster Pump-TechPart - 2of2 BDocument71 pagesBooster Pump-TechPart - 2of2 BKatie RamirezNo ratings yet

- ASME B31.9 Building Services Piping Code (2011) ComplianceDocument3 pagesASME B31.9 Building Services Piping Code (2011) ComplianceАнж БжлNo ratings yet

- KP KPV Internet 74005Document60 pagesKP KPV Internet 74005Udomsin WutigulpakdeeNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Grundfosliterature 1563Document60 pagesGrundfosliterature 1563Montoya SantiagoNo ratings yet

- Woods Silencer Catalogue and Technical DataDocument12 pagesWoods Silencer Catalogue and Technical DataJagatjeet MaanNo ratings yet

- Forbes Marshall Consultancy specifications for compressed air accessoriesDocument2 pagesForbes Marshall Consultancy specifications for compressed air accessoriessppatilNo ratings yet

- Rosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionDocument24 pagesRosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionJames ThomasNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- Hunter GP100 08-2003 PDFDocument1 pageHunter GP100 08-2003 PDFaymanmkNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Designing Airflow Systems: A Guide to BasicsDocument40 pagesDesigning Airflow Systems: A Guide to BasicsKagitha TirumalaNo ratings yet

- Concentric EccentricDocument4 pagesConcentric EccentricGabbar SinghNo ratings yet

- TrapDocument4 pagesTrapdcsamaraweeraNo ratings yet

- General-Service Packaged Air Compressors and ReceiversDocument11 pagesGeneral-Service Packaged Air Compressors and ReceiversElie HajjNo ratings yet

- 25hp 4p 284tpa Wpi Bf37 AuDocument15 pages25hp 4p 284tpa Wpi Bf37 Aurhusseinpos4765No ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Nozzle Load - PumpDocument1 pageNozzle Load - Pumpduf fu0% (1)

- E-1 Deluge ValveDocument10 pagesE-1 Deluge ValveTracy SankarNo ratings yet

- PVC Pipe (SCH.40, SCH.80, and SCH.120) CondensedDocument7 pagesPVC Pipe (SCH.40, SCH.80, and SCH.120) CondensedAhmed ZakiNo ratings yet

- Pumpapi675presentation 150805065440 Lva1 App6891 PDFDocument42 pagesPumpapi675presentation 150805065440 Lva1 App6891 PDFsanthoshkumarplNo ratings yet

- Vertical Turbine Pump Installation GuideDocument70 pagesVertical Turbine Pump Installation Guideagmibrahim5055No ratings yet

- Process Industry Basket StrainersDocument27 pagesProcess Industry Basket StrainersmartinnovelNo ratings yet

- Tuttle and Bailey CircularDocument2 pagesTuttle and Bailey CircularTalha BaigNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Liquid Overfeed Systems by R. P. ParanjpeyDocument15 pagesLiquid Overfeed Systems by R. P. Paranjpeyurp30234No ratings yet

- Sand Filter Design GuideDocument2 pagesSand Filter Design Guideoanzar100% (1)

- Static Mixers Waste & WaterDocument3 pagesStatic Mixers Waste & WaterIsmael KhalilNo ratings yet

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFDocument1 pagePages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafNo ratings yet

- p21 006 P 02 (Support Load Data)Document3 pagesp21 006 P 02 (Support Load Data)Trishul Nath PallayNo ratings yet

- Fire Hydrant Valve Bs 5041: SpecificationDocument2 pagesFire Hydrant Valve Bs 5041: Specificationirrosel4650No ratings yet

- 4 Allowable Leakage Rate For Standard InstallationsDocument2 pages4 Allowable Leakage Rate For Standard InstallationsGdfsndh GfdvhjzdNo ratings yet

- Fabrication Strainers Mesh SizingDocument6 pagesFabrication Strainers Mesh SizingArun GuptaNo ratings yet

- DEPA Air Operated Diaphragm PumpsDocument6 pagesDEPA Air Operated Diaphragm Pumpsboom10No ratings yet

- SKF Belt Tension TesterDocument1 pageSKF Belt Tension Testerboom10No ratings yet

- Shore Hardness Scale Cross Reference ChartDocument1 pageShore Hardness Scale Cross Reference Chartboom10No ratings yet

- SHURflo 5904XXX Ficha Despiece enDocument2 pagesSHURflo 5904XXX Ficha Despiece enboom10No ratings yet

- 10 Steps GuideDocument14 pages10 Steps GuideUmair Haqqan AminurrahmanNo ratings yet

- Manual - Coupling - Flexibox TSK and TSB Flexible Couplings (From v425)Document6 pagesManual - Coupling - Flexibox TSK and TSB Flexible Couplings (From v425)anrava100% (1)

- Valve Selection GuidelinesDocument6 pagesValve Selection Guidelinesboom10No ratings yet

- DHP-306AV A1 Manual v1.00 (WW)Document17 pagesDHP-306AV A1 Manual v1.00 (WW)Lip Eang ZhaoNo ratings yet

- Dieselfacts 2006 2Document16 pagesDieselfacts 2006 2boom10No ratings yet

- Marine and Rail Lubricants: Engine OilsDocument10 pagesMarine and Rail Lubricants: Engine Oilsboom10No ratings yet

- Wider Choise in Fuel ConsumptionDocument3 pagesWider Choise in Fuel Consumptionboom10No ratings yet

- 0111 Tension Load Cell Datasheet enDocument2 pages0111 Tension Load Cell Datasheet enJosipaNo ratings yet

- ASHIDA Product CatalogueDocument4 pagesASHIDA Product Cataloguerahulyadav2121545No ratings yet

- Valvula Relief Pruebas y Ajustes 325blDocument9 pagesValvula Relief Pruebas y Ajustes 325blcristian chuquicondor torresNo ratings yet

- Airfoil Surface Pressure and Wake Velocity ExperimentDocument24 pagesAirfoil Surface Pressure and Wake Velocity ExperimentAh WenNo ratings yet

- Intelligent Network: © Bharat Sanchar Nigam LimitedDocument50 pagesIntelligent Network: © Bharat Sanchar Nigam LimitedshridonNo ratings yet

- TRINITY GCSL S2707 Quick Reference: J22 Front Panel ConnectorDocument1 pageTRINITY GCSL S2707 Quick Reference: J22 Front Panel Connectorrick krossNo ratings yet

- Minimum drilling supplies stockDocument3 pagesMinimum drilling supplies stockAsif KhanzadaNo ratings yet

- UnlversDocument55 pagesUnlversCan AcarNo ratings yet

- Training Nathpa Jhakri SJVNLDocument53 pagesTraining Nathpa Jhakri SJVNLParas Thakur100% (3)

- User Manual SR 9797HDDocument47 pagesUser Manual SR 9797HDnavamivbNo ratings yet

- Philips DoseRight 2.0 CT Dose ControlDocument4 pagesPhilips DoseRight 2.0 CT Dose Controlsombrero61No ratings yet

- RO-BL-005-Mech-XII-2022 Desmi Pump Hose Radiator Clamp Hose Rubber Gasket Air Filter Dust Strip Curtain Spark LighterDocument2 pagesRO-BL-005-Mech-XII-2022 Desmi Pump Hose Radiator Clamp Hose Rubber Gasket Air Filter Dust Strip Curtain Spark LighterIlyas Rangga RamadhanNo ratings yet

- Assignment Fall2018Document2 pagesAssignment Fall2018Frans LoekitoNo ratings yet

- A Real-Time Face Recognition System Using Eigenfaces: Daniel GeorgescuDocument12 pagesA Real-Time Face Recognition System Using Eigenfaces: Daniel GeorgescuAlex SisuNo ratings yet

- SD Card Formatter 5.0 User's Manual: June 30, 2017Document11 pagesSD Card Formatter 5.0 User's Manual: June 30, 2017Everton Klinger Sousa SilvaNo ratings yet

- Iwss 31 Win en AgDocument237 pagesIwss 31 Win en AgmarimiteNo ratings yet

- A Homemade Edison Tinfoil PhonographDocument32 pagesA Homemade Edison Tinfoil PhonographGabriel MedinaNo ratings yet

- Piper Archer II Checklist GuideDocument8 pagesPiper Archer II Checklist GuideJosías GenemNo ratings yet

- Network Layer Packet Tracer LabDocument3 pagesNetwork Layer Packet Tracer LabSendy Trias NugrahaNo ratings yet

- Thyristor Controlled Reactor: Circuit DiagramDocument4 pagesThyristor Controlled Reactor: Circuit DiagramSpk SudhinNo ratings yet

- IssabelPBX AdministrationDocument9 pagesIssabelPBX AdministrationDaniel VieceliNo ratings yet