Professional Documents

Culture Documents

Flight: Plywood

Uploaded by

seafire47Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flight: Plywood

Uploaded by

seafire47Copyright:

Available Formats

JANUARY

24TH, 1946

FLIGHT

87

limb being riveted between the alloy sheets of the web, which overlap the edge of the plywood for this purpose. The top boom is of spruce, glued and screwed like the main spar. Number six rib's are a scaled-down version of the number ones. Numbers two, five, seven and eleven rite are each built up from plywood sheet screwed and glued to spruce frames. Two and five carry pick-up fittings for the tank doors, while seven and eleven have metal flanges. Metal-clad The engine ribs, numbers three and four, are alloy/ply/ alloy sandwiches rather similar to the fuselage ribs but having " T " section extrusions for both top and bottom booms. The top skin is glued, to the top booms after a thin veneer has been Eeduxed to them. With the exception of number fifteen, which is an all-metal pressing, the remaining ribs are built up with single plywood webs j r screwed and glued to spruce booms.

>

An example of inter-rib strengthening members in the wing for attachment of drop tanks or R.P. gear.

PLYWOOD

VENEER REDUXED " DURAL

VENEER SEDUXED TO DURAL. EXTRUSION:

VFNEER REDUXED TO DURAL PRESSING

^PLYWOOD

PLYWOOD

N0I5 RIB

NO.I RIB

NO 5 RI8

Details of rib construction can be followed in conjunction with the illustration on the facing page. To ensure a smooth surface and torsional stiffness in the wing, the leading edges are of all-metal construction. Exrept for their attachment by Reduxing to the top of the front spar they are quite conventional. The attachment and construction of the all-metal flap and aileron shrouds is similar to that of the leading edge. Six main bolts and fittings attach the wing to the fuselage and, like the Mosquito, the Hornet has a balsa-ply sandwich fuselage made in halves split vertically. Small differences are the use of a thinner balsa core to the sandwich, which saves about one-third of balsa weight, and the use of duralumin strengthening plates on the fuselage walls for the attachment of equipment and the like. On the Mosquito, plastic plates or attachment ferrules are generally used, and bolt holes are necessarily wide apart to prevent splitting. By the use of Redux bonding, small metal plates can be substituted for the plastic ones with considerable advantage. On the underside of the fuselage just aft of the rear spar is a hatch giving access to equipment and control cables. The Tail The tailplant- is of conventional two-spar all-metal construction, with ribs from the rubber press. By virtue of its attachment it is adjustable for rigging, two turnbuckletype fittings being incorporated. Later marks of Hornet have two extra ribs in the tailplane, with a corresponding increase in span. This modification followed the adoption of '' down and i n ' ' airscrew rotation and to some extent offsets the de-stabilisiiig eftect of this arrangement. The area of the horn balances was also slightly increased. The tail fin is of all-metal construction and does not call for any special attention. The addition of a fairly long shallow dorsal fairing up to the fin is now under consideration. All elevator and 1 udder control mechanisms on the Hornet are placed behind the fin and are exposed for inspection when the tail cone is removed. Both frame and covering of the main controls are metal, and in each case they are noticeably flat-sided, no doubt to obviate any tendency towards reversal at high altitudes.

Engines.

PRINCIPAL DATA AND PERFORMANCE FIGURES R.R. Merlins 130 (R.H. port) 131 (L.H. starboard). 45ft.

'."screws. D.H. Narrow, 4-blade, 12ft. diameter. Wing span ,, area ,, loading Length

Heighttail up . tpeed.

tail dowr ... Tail span range climb Operational ceiling Type Fighter Photographic Reconnaissance : .

...

...

' ...

...

44.5ft. 37ft 16ft. 2in. 14ft. 2in.

j . ft.

Condition Short-range Long-range Short-range Long-range

I8fr Urn. 473 m.p.h. 12,000ft. 2,900 miles. 4,000ft. >in. to 15,000fc. 35,OOOft. Total fuel Weight capacity gal. Ib. 16,100 20,900 15,900 20,200 358 928 418 928

You might also like

- PH - Almond & Garlic Crusted Chicken With Cherry Tomato SaladDocument2 pagesPH - Almond & Garlic Crusted Chicken With Cherry Tomato Saladseafire47No ratings yet

- Flight.: Final Gliding Contest ResultsDocument1 pageFlight.: Final Gliding Contest Resultsseafire47No ratings yet

- PH - Carolina's Chorizo Carbonara With Garden SaladDocument2 pagesPH - Carolina's Chorizo Carbonara With Garden Saladseafire47No ratings yet

- Gtsac : Flight Engineering SectionDocument1 pageGtsac : Flight Engineering Sectionseafire47100% (1)

- Shor BRQS.: of RochesterDocument1 pageShor BRQS.: of Rochesterseafire47No ratings yet

- Commercial Aviation and Airlines Updates in 1935Document1 pageCommercial Aviation and Airlines Updates in 1935seafire47No ratings yet

- East To West Record: 13% HOURSDocument1 pageEast To West Record: 13% HOURSseafire47No ratings yet

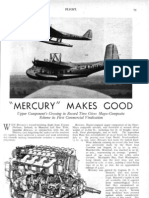

- "Mercury" Makes GoodDocument1 page"Mercury" Makes Goodseafire47No ratings yet

- Short S.20 Mercury SDocument3 pagesShort S.20 Mercury Sseafire47No ratings yet

- 598 Flight.: DECEMBER I 6, 1937Document1 page598 Flight.: DECEMBER I 6, 1937seafire47No ratings yet

- 1938 - 2869Document1 page1938 - 2869seafire47No ratings yet

- Second Parting: Short-Mayo Compo-Site Separated "In Public"Document1 pageSecond Parting: Short-Mayo Compo-Site Separated "In Public"seafire47No ratings yet

- 4 Worlds FairDocument5 pages4 Worlds Fairseafire47No ratings yet

- 1937 - 3487Document1 page1937 - 3487seafire47No ratings yet

- Percival Q4,6 1937 - 3486Document1 pagePercival Q4,6 1937 - 3486seafire47No ratings yet

- 8 Ross RS1 93Document4 pages8 Ross RS1 93seafire47No ratings yet

- 74-A-23 Se5a F938Document4 pages74-A-23 Se5a F938seafire47No ratings yet

- 95 Sample ArticleDocument5 pages95 Sample Articleseafire47No ratings yet

- 1937 - 3485Document1 page1937 - 3485seafire47No ratings yet

- 203 Sample ArticleDocument8 pages203 Sample Articleseafire47No ratings yet

- 7 Moundsville Lone Eagle 94Document9 pages7 Moundsville Lone Eagle 94seafire47No ratings yet

- Wright Flyer 1903 EngineDocument3 pagesWright Flyer 1903 Engineseafire47No ratings yet

- F4u 4Document8 pagesF4u 4seafire47100% (1)

- Chance Vought F4u CorsairDocument6 pagesChance Vought F4u Corsairseafire47100% (3)

- SB2U VindicatorDocument11 pagesSB2U Vindicatorseafire47100% (1)

- Splash 1Document4 pagesSplash 1seafire47100% (1)

- Raid On Regensburg2Document8 pagesRaid On Regensburg2seafire47100% (1)

- VS-10001 GA 02 F4U-1 CorsairDocument0 pagesVS-10001 GA 02 F4U-1 Corsairseafire47No ratings yet

- Designation OF USA AIRCRAFTDocument9 pagesDesignation OF USA AIRCRAFTseafire47No ratings yet

- b47 v3Document4 pagesb47 v3seafire47100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cheryl reyes-ACTIVITYDocument4 pagesCheryl reyes-ACTIVITYCheryl ReyesNo ratings yet

- Geberit Bathroom Collection BrochureDocument125 pagesGeberit Bathroom Collection BrochureThanhNo ratings yet

- Building Resilient Teams Workbook FINALDocument16 pagesBuilding Resilient Teams Workbook FINALКремена П.No ratings yet

- 2 Oieyqhwgfdewio 9 D 328 eDocument1 page2 Oieyqhwgfdewio 9 D 328 euihgfhjjhghNo ratings yet

- Circular Motion and InertiaDocument2 pagesCircular Motion and InertiaAnthony QuanNo ratings yet

- Abis For GSM TelecommunicationsDocument2 pagesAbis For GSM TelecommunicationsUmar Abbas BabarNo ratings yet

- ECC-Map: A Resilient Wear-Leveled Memory-Device Architecture With Low Mapping OverheadDocument12 pagesECC-Map: A Resilient Wear-Leveled Memory-Device Architecture With Low Mapping OverheadSudip DasNo ratings yet

- Notes On Module 3 PDFDocument2 pagesNotes On Module 3 PDFabby jacksonNo ratings yet

- Subchapter M Alternate Fuel Systems and ControlsDocument10 pagesSubchapter M Alternate Fuel Systems and Controlsbilly dillpickerNo ratings yet

- Heat Load Calculation : J.IlangumaranDocument70 pagesHeat Load Calculation : J.Ilangumaranapi-25999517No ratings yet

- Information Technology Standards GuidelinesDocument2 pagesInformation Technology Standards GuidelinesmanjarimaranNo ratings yet

- Rating: Interpretive Guides For Behavioural Interview SDocument8 pagesRating: Interpretive Guides For Behavioural Interview SMaestro MertzNo ratings yet

- Signed Off - Introduction To Philosophy12 - q1 - m2 - Methods of Philosophizing - v3Document25 pagesSigned Off - Introduction To Philosophy12 - q1 - m2 - Methods of Philosophizing - v3Benjamin Fernandez Jr.No ratings yet

- WelcomeDocument10 pagesWelcomeappp2711No ratings yet

- BP Energol-ThbDocument2 pagesBP Energol-ThbRajesh BNo ratings yet

- Allen Fisher PoemsDocument28 pagesAllen Fisher PoemsArkava DasNo ratings yet

- Design of Rapid Sand Filter - PDFDocument3 pagesDesign of Rapid Sand Filter - PDFNIKHIL BANDWAL100% (1)

- Alan Maley Poster 2Document1 pageAlan Maley Poster 2Cory KobyNo ratings yet

- Top 20 Automation Testing Interview Questions and AnswersDocument36 pagesTop 20 Automation Testing Interview Questions and AnswersBilal Achernan100% (1)

- BSS Steel Guide CataloguesDocument52 pagesBSS Steel Guide Cataloguessaber66No ratings yet

- LVL Hip Rafter DesignDocument5 pagesLVL Hip Rafter DesignDavid Shanks 1No ratings yet

- Yashica IP PracticalDocument51 pagesYashica IP Practicalreetapgupta78No ratings yet

- Chapter 1 StratManDocument32 pagesChapter 1 StratManRujean Salar AltejarNo ratings yet

- 7 - EST 1 - October 2021 - Session TestDocument5 pages7 - EST 1 - October 2021 - Session Testyasser AnwarNo ratings yet

- TDS - Penguard Primer - Issued.26.11.2010Document4 pagesTDS - Penguard Primer - Issued.26.11.2010vitharvanNo ratings yet

- Chapter 2 - PlanningDocument31 pagesChapter 2 - PlanningAlwiCheIsmailNo ratings yet

- Project ProposalDocument2 pagesProject ProposalTanya Naman SarafNo ratings yet

- Microbiologically Influenced Corrosion (Mic)Document2 pagesMicrobiologically Influenced Corrosion (Mic)MohamedNo ratings yet

- En 13364 - 2001Document2 pagesEn 13364 - 2001Letícia Valdo0% (1)

- Detector Geam SpartDocument16 pagesDetector Geam SpartGabrielNo ratings yet