Professional Documents

Culture Documents

Welding Procedure

Uploaded by

dương_thành_28Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure

Uploaded by

dương_thành_28Copyright:

Available Formats

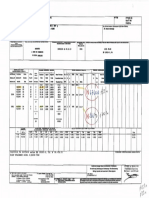

Project :

Thu Duc B.O.O Water Treatment Plant ( 300.000 m 3/ day ).

Package II:

Treated Water Transmission Pile Line ( 05-Line-D1200 & 06-Line-D900)

WELDING PROCEDURE BMC

No. 1 Items Description Operation 1. Preparation materials (Welding electrode) 2. Preparation of machines and instruments (Welding machine, generator, grinder): Type, condition, safety, fuel, 3. Preparation Welder : All welder have been approved to weld for construction must satisfy all the followings: - To get certificate with grade 6G or 5/7 or equivalent - To pass the welding test at site with welding sample inspected by ultra-sonic test * After welding one actual pipe joint at site, the joint tested by magnetic test with result is good, the welder become official welder for construction a). Pre-welding on the ground 4-a. Preparation storage-yard enough long pipe 5-a. Putting pipes onto the supporting racks 6-a. Fitting two pipe pieces into each other 7-a. Adjusting the clearance between external pipe and internal pipe of joint equally 8-a. Welding inside joint by electric arc welding machine + Welding first time with heigh and width of weld about 5mm, then grinding and leaning weld surface + Welding second time covering the first time and fill full the weld (see drawing) 9-a. Welding outside joint by electric arc welding machine + Welding first time with height and width of weld about 5mm, then grinding and leaning weld surface + Welding second time covering the first time with Total heigh and width of weld about 10mm, then grinding and leaning weld surface + Welding third time covering the second time and fill full the weld (see drawing) 10-a. Conduct air tightness test at every joint. * Magnetic particle test shall be applied at : + the first welded joint which had been done by a new welder

Welding joints a). Pre-welding on the ground b). Welding in trench bottom

Doc: working procedure-BMC/Dam

page 1/7

+ one welded joint for every 20 joints done by the same welder or as reasonably directed by the Employer's Representative to confirm the quality of the welds b). Welding in trench bottom 4-b. Fitting current pipe pieces into the previous one 5-b. Welding inside joint by electric arc welding machine (procedure as similar as item 5.8-a above) 6-b. Welding outside joint by electic arc welding machine (procedure as similar as item 5.9-a above) 7-b. Conduct air tightness test at every joint * Magnetic particle test like as above item 10-a Remarks: * Welding direction: around cycle of pipe from lowest point to highest point * Welding qualification by: + Weld-line dimemtion is fill full + Weld surface is neat, steady, clean and no any crack + No leakage during air testing 2 Testing welding joints 1. Air testing 1. Preparation of instrument (Air compressor, pressure-gauge, driller, tapper, grinder) 2. Making a hole with dia 10-15mm on the bell of pipe by drilling and tapping 3. Painting soap around of weldding cycle 4. Pressing air with 40psi into the connection between double welding, maintaining for 10 minutes 5. Marking any leaks indicateed by escaping bubbles 6. Grinding at leakage weld and re-welding again 7. Closing the hole for testing by welding

Doc: working procedure-BMC/Dam

page 2/7

Project :

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ).

Package II:

Treated Water Transmission Pile Line ( 05-Line-D1200 & 06-Line-D900)

PROCEDURE FOR SHORING BMC

No. 1 Items Prepairation of sheet piles

From station ..+.m to station ...+

Specification - Length: - Length: m, Qty = m, Qty = ps ps Check Sign/Date

Prepairation of instrument

- Manufacturer: - Power: - Quantity:

Marking pile line

- Length: - By:

Shoring and driving piles

- Length: - Length:

m, Qty = m, Qty =

ps ps m

Checking pile lines

- Total length : - Number of line : - Distance line1 to line 2: - Distance line2 to line 3:

m m

* Remarks:

BMC Sign/name

HYUNDAI MOBIS Sign/name

SAMPLES Material Project Package II Filling sand

To Symbol

Hyundai Mobis MS-FS-1/1

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II

To

Hyundai Mobis MS-ST 0/4-1/1

Stone Aggregate size 0-4mm Symbol

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II Formwork

To Symbol

Hyundai Mobis MS-FW 0.2x1m-1/1

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II Water Stop

To Symbol

Hyundai Mobis MS-WS150-1/3

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II Water Stop

To Symbol

Hyundai Mobis MS-WS200-2/3

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II Water Stop

To Symbol

Hyundai Mobis MS-WS250-3/3

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II Polyetylen fabric

To Symbol

Hyundai Mobis MS-PF-1/2

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II Polyetylen fabric

To Symbol

Hyundai Mobis MS-PF-2/2

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

SAMPLES Material Project Package II

To

Hyundai Mobis MS-FC-1/1

Fabric cable for handling pipeSymbol

Thu Duc B.O.O Water Treatment Plant ( 300.000 m3/ day ). Treated Water Transmission Pile Line ( D1200 & D900 )

Subcontractor BUILDING MATERIALS AND CONSTRUCTION COMPANY (BMC) Date ././2006

Page No : 1

MEETING MINUTES

Project :Thu Duc B.O.O Water Treatment Plant ( 300.000 m3 / day ). Start ..

No 01.

Package II: Treated Water Transmission Pile Line ( D1200 & D900 Pipe Line ) Date : March 03.2006 Place : Site office Finish ..

ATTENDERS : HYUNDAI MOBIS 1 2 3 4 5 6 Mr CHO PAN SIK Mr BUI DUC NGHIA Mr NGUYEN THANH MINH Mr NGUYEN XUAN KHOAT Mr NGUYEN DANG KHOA Position Site Manager Safety officer Site Engineer Surveyor Site Engineer BMC Mr VO MINH THANH Mr BUI DINH DAM Mr Mr Position

No

1 Weekly meeting at 9:30 on Friday.

Item

Action

2 3 4

Daily report should be fill in and submit everyday . Submit schedule and weekly schedule Submit detail method statements for pipe line

5 6 7

Submit schedule & method statement for Phu My Hung Co. (delay) Manpower List and Organization Chart , Welder List and Civil . Materials(sand, stone,rebar, ready mix concrete , water stop, geotextile,) Submit ( samples , catalogue , supplyer , mill certificate, Test result , Trial mix , .)

8 9

Preparation machinery and equipment, .. Arrangement storage-yard to stockpile suitable materials and another place to disposal surplus, unsuitable materials .

10

Safety :

Page No :

MEETING MINUTES

No Item

No . Action

HYUNDAI MOBIS

Sign/name

BMC

Sign/name

You might also like

- Asim CVDocument2 pagesAsim CVShahzeb HassanNo ratings yet

- Operation and Maintenance Considerations For Oil and Gas SeparatorsDocument2 pagesOperation and Maintenance Considerations For Oil and Gas SeparatorsJatin RamboNo ratings yet

- Product Selection Guide: Tube & Clamp ScaffoldDocument10 pagesProduct Selection Guide: Tube & Clamp ScaffoldGanesh Eshwar100% (1)

- Material Certificate Plate 16mmDocument1 pageMaterial Certificate Plate 16mmAdeoyeNo ratings yet

- Scffold & Lifitng Supervisor & Safety InspectorDocument9 pagesScffold & Lifitng Supervisor & Safety InspectorMuhamedragabNo ratings yet

- Insulation ProcedureDocument3 pagesInsulation ProcedurejunidomarNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Welding Procedure Specification - Tie - inDocument3 pagesWelding Procedure Specification - Tie - indndudcNo ratings yet

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Control of Welding Consumables ProcedureDocument16 pagesControl of Welding Consumables Procedureimran100% (1)

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Rp-205 Crane Operation, Maintenance and TestingDocument30 pagesRp-205 Crane Operation, Maintenance and TestingWilman Barrera Grados100% (1)

- 03-Procedure For WeldingDocument8 pages03-Procedure For WeldingAyush AgarwalNo ratings yet

- Webbing Sling - SWLDocument4 pagesWebbing Sling - SWLChandrasekhar SonarNo ratings yet

- S-AAA-ELMS-CRANE (Rev.0-2015)Document7 pagesS-AAA-ELMS-CRANE (Rev.0-2015)Swathish SivaprasadNo ratings yet

- Universal Beams PDFDocument2 pagesUniversal Beams PDFbrodieNo ratings yet

- Hse Standards ScaffoldsDocument7 pagesHse Standards ScaffoldsBALAJINo ratings yet

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanNo ratings yet

- How To Write A Welding Procedure SpecificationDocument14 pagesHow To Write A Welding Procedure Specificationnizam1372100% (2)

- Form Inspection Premob - Quarterly (1) - 2Document26 pagesForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniNo ratings yet

- Welding Procedure Preparation1Document6 pagesWelding Procedure Preparation1Rajeshwar KumdaleNo ratings yet

- EotDocument16 pagesEotMayuresh GoregaonkarNo ratings yet

- Inspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsDocument1 pageInspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsmukeshayoorNo ratings yet

- Fall ArrestersDocument1 pageFall ArrestersTrust EmmaNo ratings yet

- Weld Repair ProcedureDocument15 pagesWeld Repair Proceduremohd as shahiddin jafriNo ratings yet

- Daily report for Smiths Detection Malaysia upgrading worksDocument2 pagesDaily report for Smiths Detection Malaysia upgrading worksMustaffa HoodMus100% (1)

- Butterfly Valve Installation GuideDocument3 pagesButterfly Valve Installation GuideVasile PopescuNo ratings yet

- Horizontal Life Line Inspection FormDocument1 pageHorizontal Life Line Inspection FormSelva GanapathiNo ratings yet

- Welder, Welding Operator Qualification Test ReportDocument2 pagesWelder, Welding Operator Qualification Test Reportkarthik sundaramNo ratings yet

- Scaffold Classes and Duties CalsDocument20 pagesScaffold Classes and Duties CalsMohideenAlhaseb100% (1)

- QCP 040 QCP CrmsDocument7 pagesQCP 040 QCP Crmsarockiyathass100% (1)

- Welding Welding Procedure Qualification PDFDocument38 pagesWelding Welding Procedure Qualification PDFpratap biswas100% (1)

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Document255 pagesD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Welding Safety ChecklistDocument2 pagesWelding Safety ChecklistSaid Elsamna100% (1)

- Ladders Inspection Register: Location: TSM ARABIADocument4 pagesLadders Inspection Register: Location: TSM ARABIAmuhammad imtiazNo ratings yet

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- SOP - 03C Rev 1 Weld Shop PDFDocument9 pagesSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- WELDING PROCEDURE SPECIFICATIONSDocument2 pagesWELDING PROCEDURE SPECIFICATIONSnidhinchandranvsNo ratings yet

- Indra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)Document57 pagesIndra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)med chabaneNo ratings yet

- Load Testing of Static Modular Aluminium ScaffoldDocument33 pagesLoad Testing of Static Modular Aluminium ScaffoldReda ElawadyNo ratings yet

- TCVN Water PipeDocument43 pagesTCVN Water PipeTuan DangNo ratings yet

- Welding Inspection and TestingDocument14 pagesWelding Inspection and TestingMyst VernNo ratings yet

- Welding SafetyDocument58 pagesWelding SafetyAntonio Jose De Jesus100% (1)

- Fire Safety Checklist for Saudi Aramco CampsDocument5 pagesFire Safety Checklist for Saudi Aramco CampsHaleem Ur Rashid BangashNo ratings yet

- Welding OperationDocument13 pagesWelding OperationAshwani DograNo ratings yet

- Flame Straightening S355Document9 pagesFlame Straightening S355Anonymous oI04sS100% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- How to select the right welding electrodeDocument6 pagesHow to select the right welding electrodeRobert DelafosseNo ratings yet

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- Welding Workshop ManualDocument16 pagesWelding Workshop ManualMuhammad FarooqNo ratings yet

- WeldingDocument13 pagesWeldingAna Hidayah SyuhadaNo ratings yet

- API6D Ball Valves Inspection and Test ProceduresDocument5 pagesAPI6D Ball Valves Inspection and Test ProceduresChi Cha100% (2)

- List of Qualified Welder Summary BLCPDocument2 pagesList of Qualified Welder Summary BLCPpstechnical_43312697No ratings yet

- Code 1 WPS Rev 0 PDFDocument18 pagesCode 1 WPS Rev 0 PDFEarl HarbertNo ratings yet

- Basic Data of Works For Inspection of (V&e)Document4 pagesBasic Data of Works For Inspection of (V&e)Rajesh BabuNo ratings yet

- SECTION 02200 EarthworksDocument8 pagesSECTION 02200 EarthworksStraus WaseemNo ratings yet

- Trac Doc Tuyen Kenh 1Document1 pageTrac Doc Tuyen Kenh 1dương_thành_28No ratings yet

- Asce Manuals 0108Document4 pagesAsce Manuals 0108dương_thành_28No ratings yet

- B012Document1 pageB012dương_thành_28No ratings yet

- Detailed Design: Date DescriptionDocument1 pageDetailed Design: Date Descriptiondương_thành_28No ratings yet

- CV CommentDocument1 pageCV Commentdương_thành_28No ratings yet

- Published Standards for Water SystemsDocument7 pagesPublished Standards for Water Systemsdương_thành_28No ratings yet

- Published Standards for Water SystemsDocument7 pagesPublished Standards for Water Systemsdương_thành_28No ratings yet

- Detailed Design: Date DescriptionDocument1 pageDetailed Design: Date Descriptiondương_thành_28No ratings yet

- Published Standards for Water SystemsDocument7 pagesPublished Standards for Water Systemsdương_thành_28No ratings yet

- Job Applycation 1Document6 pagesJob Applycation 1dương_thành_28No ratings yet

- DienDong-MAT BANG VI TRI HO KHOAN - PHUONG AN CUOI-Layout1 PDFDocument1 pageDienDong-MAT BANG VI TRI HO KHOAN - PHUONG AN CUOI-Layout1 PDFdương_thành_28No ratings yet

- Data Recovery Suite PDFDocument2 pagesData Recovery Suite PDFdương_thành_28No ratings yet

- CN 00 3 Docn 18 3Document2 pagesCN 00 3 Docn 18 3dương_thành_28No ratings yet

- Waste Stabilization Ponds and Constructed Wetlands Design ManualDocument59 pagesWaste Stabilization Ponds and Constructed Wetlands Design ManualRaluca IustinaNo ratings yet

- PIPELINE TESTING PROCEDURESDocument5 pagesPIPELINE TESTING PROCEDURESdương_thành_28No ratings yet

- BS 1387/1985 Standard for Black and Galvanized Steel TubesDocument2 pagesBS 1387/1985 Standard for Black and Galvanized Steel TubesmullanjiNo ratings yet

- Published Standards for Water SystemsDocument7 pagesPublished Standards for Water Systemsdương_thành_28No ratings yet

- Netter Vibration KnockersDocument4 pagesNetter Vibration KnockersCojuhari SergiuNo ratings yet

- Screw JackDocument1 pageScrew Jackhola100% (1)

- Steel Sheds IntroductionDocument9 pagesSteel Sheds IntroductionMaqsood100% (1)

- Urban architecture interior design solutionsDocument1 pageUrban architecture interior design solutionsMadhav RathiNo ratings yet

- PK CmuDocument53 pagesPK CmuSuriansyah RudiNo ratings yet

- ARAMCO DrawingDocument1 pageARAMCO DrawingLainhatanhNo ratings yet

- Aerial Ropeways: Transport via Overhead CablesDocument43 pagesAerial Ropeways: Transport via Overhead CablesAnshul yadavNo ratings yet

- RF Joints Manual enDocument75 pagesRF Joints Manual enVladimir Jerson Alferez VargasNo ratings yet

- Bearing Reference Guide - Setscrew Ball Bearings DimensionsDocument2 pagesBearing Reference Guide - Setscrew Ball Bearings DimensionsjaviervbNo ratings yet

- To: MR.: Masaaki KusunokiDocument33 pagesTo: MR.: Masaaki KusunokiWnava Cris100% (1)

- Rigid Pavement Design: A.K.A NAASRA (National Association of Australian State Road Authorities), 1979Document46 pagesRigid Pavement Design: A.K.A NAASRA (National Association of Australian State Road Authorities), 1979Leejieun BusinessNo ratings yet

- Mesri2009 - Obituary Ralph B. Peck, 1912-2008Document3 pagesMesri2009 - Obituary Ralph B. Peck, 1912-2008Santiago OsorioNo ratings yet

- Mini ProjectDocument42 pagesMini ProjectVamshi ChinthalaNo ratings yet

- Full Thesis PDFDocument89 pagesFull Thesis PDFKaushiki KambojNo ratings yet

- Ten Storey Construction MethodologyDocument18 pagesTen Storey Construction MethodologyeteureNo ratings yet

- Wall - Penstock - 200x200 1200x1200Document2 pagesWall - Penstock - 200x200 1200x1200Mohamed RamadanNo ratings yet

- Overstrength and Redundancy FactorDocument3 pagesOverstrength and Redundancy FactorJordi FranchNo ratings yet

- Geotechnical Aspects of Storage Tank Foundation Types: February 2017Document8 pagesGeotechnical Aspects of Storage Tank Foundation Types: February 2017Pecel LeleNo ratings yet

- Approved Steel Plate and Sheet SuppliersDocument93 pagesApproved Steel Plate and Sheet Supplierszakir84md3639No ratings yet

- Extracts of SS636Document2 pagesExtracts of SS636alvinchuanNo ratings yet

- Analysis and Design of Elevated Intze Watertank and Its Comparative Study in Different Wind Zones - Using SAP2000Document12 pagesAnalysis and Design of Elevated Intze Watertank and Its Comparative Study in Different Wind Zones - Using SAP2000IJSTENo ratings yet

- Part 1: The Contract Period'Document37 pagesPart 1: The Contract Period'ameliaNo ratings yet

- Hollow Bar ChartDocument1 pageHollow Bar Charthornet121No ratings yet

- NR.473-GQ1 Replace Roof, CasingDocument8 pagesNR.473-GQ1 Replace Roof, CasingSafrin SangiaNo ratings yet

- IstanbulDocument10 pagesIstanbullsmnklcNo ratings yet

- Sor 16-17 PDFDocument524 pagesSor 16-17 PDFRamuCivilNo ratings yet

- HVAC System Design and Installation ProceduresDocument24 pagesHVAC System Design and Installation ProceduresMiguelAzucena100% (5)

- ICBT Campus in Oman ConstractiongDocument20 pagesICBT Campus in Oman ConstractiongNilan GamageNo ratings yet

- Bolt Anchor FAZ II07302015 173728Document9 pagesBolt Anchor FAZ II07302015 173728Kliment RistevskiNo ratings yet

- HILTI DTA Hilt PDFDocument9 pagesHILTI DTA Hilt PDFDesta Sandi Putra PrabowoNo ratings yet