Professional Documents

Culture Documents

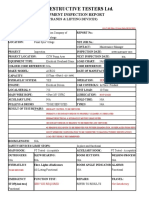

Evaluation Sheet - Mechanical

Uploaded by

dhanu_lagwankarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaluation Sheet - Mechanical

Uploaded by

dhanu_lagwankarCopyright:

Available Formats

Name of Employee : Designation : Designer

Sr No. A A

Name of the activity

Description (knowledge)

Technical Skills Primary + Secondary Job Responsibilities Please contribute your views for Points A by selecting any of the options

0 = Not Applicable requirement 1 = Basic knowledge 2 = Working knowledge and ability to meet 3 = Detailed knowledge 4 = Good experience and ability to train others 5 = Expert

A.1. Primary Job Responsibilities HVAC 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Cleanroom HVAC Specification Air classification scheme HVAC basic design data Basis of design for HVAC Air flow and control diagram Air flow and control diagram Functional description document AHU and room grouping scheme layout AHU and room grouping scheme sheet HVAC supply and return air equipment per room HVAC equipment arrangement sheet Differerent equipment GA drawings BOQ Room pressurization scheme sheet (Mention Room pessurization scheme Values) heat load estimation Load & Air flow calculations Air flow calculations Trane trace 700 fluency Duct design HVAC duct drawing Duct drawing Electrical Calculations for HVAC Electrical load calculations equipment AHU layout HVAC supply and return air equipment per room HVAC equipment arrangement layout Auxilliary equipment layout Room pressurization scheme layout Room pressurization scheme LAF specification LAF unit Control and wiring diagram Electrical Drawings for HVAC SLD for AHU control panels

21

Vendor drawings approval

Approving shop drawings submitted by vendors

Piping & packaged utility equipment 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Preparation of piping & utility basis of design. Also preparing any specialised BOD for other Piping & utility BOD applications like tank farms, instrumentation, Stress analysis. PROCESS FLOW DIAGRAM To work on Autocad. (PFD) To have Basic Knowledge of PFD for utilities To work on Autocad. UTILITY/ PIPING P & ID'S To have Basic Knowledge of P&ID for utilities Dimentional standards for pipes. Pressure and temperature ratings for different piping Pipe selection materials. Piping MOC & type selection as To select appropriate MOC for distribution based on process and utility requirements. per process To work on different type of component used in component selection as per utilities. On different components used like process pump, vent filter, steam trap etc. To work on different type of selection of Instrument selection instrument for utilities. To have knowledge of selection of valves for Valve selection utilities. pressure drop calculation for pumps. Pump Head calculation To work on Pipe sizing for utilities Pipe sizing calculation On hydraulic weight calculation for Piping. Hyderaulic weight calculation To work on production processes, cleaning requirements & Utility requirements of equipments & processes. . UTILITY CAPACITY STUDY Study of production planning & On Quantities of utilities required for different manufacturing process Utility generation Equipment Knowledge of capacity analysis, Equipment sizing selection & sizing Pumps Pump capacity calculation and pump selection To have understanding on utility requirement in Utility room book each operation Making Bill of quantities for utilities COMPONENT LISTS To work on piping & accesories Data Sheets PIPING Class (DS) To work on components like tanks,filters, heat exchangers,steam traps,pump,safety valves, Data Sheet control valves, strainers etc. VALVE LIST AND SPECIFICATIONS PIPING EXECUTION SPECIFICATIONS To work on different types of selection of valves like gate,globe,ball,butterfly,plug etc for utilities. Making utility piping execution specification.

15 16 17 18 19 20 21

22 23

24 25

PIPING EXECUTION SPECIFICATIONS EQUIPMENT SPECIFICATIONS

26

LAYOUTS

To work on welding,errection & installation procedures. utility equipment like Boiler, Air compressor, N2 generator, HW generator etc.& Distribution systems for all utilities Study of layout for making utility room book, pipe routing etc. Pipe routing layouts Piping isometrics Approving shop drawings submitted by vendors Preparation of hookup drawings for instruments Identification of critical lines, providing suitable piping supports or making suitable changes in the piping after stress analysis Proficiency in Caesar II Awareness and proficiency in all design standards for piping and mechanical engineering like ASME, API, ANSI and ASTM Approving shop drawings submitted by vendors

27 28

Vendor drawings approval Hookup diagrams

29

Stress Analysis

30 31

Design codes and standards Vendor drawings approval

Process and Industrial Equipment 1 PROCESS FLOW DIAGRAM 2 (PFD) 3 4 5 6 7 8 9 10 11 12 13 PROCESS DESCRIPTION CAPACITY & CYCLE TIME ANALYSIS PROCESS AND UTILITY EQUIPMENT LIST COMPONENT LISTS EQUIPMENT SPECIFICATIONS LAYOUTS VALIDATION, COORDINATION VALIDATION PLANS/REPORTS FOR DIFFERENT SYSTEMS

To work on Autocad. To have Basic Knowledge of PFD for manufacturing process. To work on Autocad. To have Basic Knowledge of P&ID for manufacturing process. To work on various industrial process requirements Knowledge of different processes, time taken in each processes etc Equipment size selection, Vendor for that equipment, tentative power requirement. Making Bill of quantity. Making & TS for process and industrial equipment Study of layout for making equipment list, GA drawing checking etc. Preaperation of validation documents & coordination between client & vendor Knowledge of validation

Process P & ID'S

14 15 16

WRITING VALIDATION PROGRAMS, DQ,IQ,OQ,PQ DQ,IQ,OQ,PQ REPORTS Vendor drawings approval

Knowledge of DQ,IQ,OQ,PQ Knowledge of DQ,IQ,OQ,PQ Approving shop drawings submitted by vendors

Layouts 1 Room layout of industrial 2 facilities. 3 4 5 6 Plot plan layout Men & material movement layout Civil/Drain layout Equipment layout

To work on autocad To have detail understanding about industrial facilities' layout To have understanding about varios utility equipment and develop an entire plot plan. To identify the work flow of Industrial process and design the layout of the facitlity accordingly. To generate drain routing and other plumbing layouts. To work on function of various process and industrial equipment and position them as per the process requirement

Others 1 PROJECT MANAGEMENT 2 PROJECT MANAGEMENT 3 4 5 6 7 8 9 10 TENDERING

To work in a project team as per requirement. Time management Preperation of document list. Planning of work.

11 12 13 14

Making & study of tender documents for HVAC low side and high side, piping, Utility equipment Preparing MOM for meeting Project Meeting Making reports for project i.e. on level of PROJECT SECRETARY WORK completion, Pending work, priority of work, resource management. Attending trainings, give training to juniors PROJECT TRAINING Making documents as per quality attributes QUALITY CONTROL To implement project & quality plan. To study URS & make conceptual engineering DESIGN CRITERIA AND documents on basis of design criteria as per PLANT DESCRIPTION international Codes, guidelines & GEP Making & checking discipline plan and man hour estimation requirement for activities of TIME SCHEDULE Mechanical stream. Making & checking costing for Mechanical COST BREAKDOWN stream Attending & conducting meetings for PROJECT MEETINGS interdepartment work, with clients & vendors. Preaparing / Identifing training needs. PROJECT TRAINING

15 16 17

Checking quality of documents prepared. Quality Control PROJECT AND QUALITY PLAN To study & prepare project & quality plan Awareness about qualification requirement of PROJECT QUALIFICATION pharma facility. Awareness about DR, PLAN IQ,OQ,PQ & validation documents.

Interpersonal Relationship Please contribute your views for Points B by selecting any of the options 1 = Poor 2 = Average 3 = Good / Ability to Guide Others 4 = Very Good B 5 = Excellent B.1 Interpersonal Follow Code of Ethics set by SSOE 1 Integrity / Business Ethics Achieving qualitative & quantitative goals / targets set by SSOE for the growth of the 2 Achieving Goals / Targets organisation Attire 3 Flexibility 4 Communication 5 Demonstrates Professionalism Courteous 6 Persuasive 7 Availability to others 8 Ability to plan sub tasks very well based on an 9 Time Management / Planning activity allocated Ability to work as a Part of a team 10 Team Building 11 12 13 B.2. 14 B.3. 15 Creativity & Innovation Participation in improvement and making suggestions Other Assignments Ability to work on new assignments / initiatives over and above regular work responsibilities On Job Knowledge Sharing Under Pressure Motivation Impart job knowledge with other team members Ability to work under pressure and withstand stress Ability to Motivate others in all the situations

Level 4

Skills Actual required by Skills of the the engineer engineer / / designer designer

ting any of the options

rking knowledge and ability to meet experience and ability to train others

0 0 4 0 4 0 0 0 0 0 0 0 0 4 4 0 0 4 4 4 0 4 4

4 4 0 4 4

0 0

0 0 0 0 0 0

0 0 0 0 0 0

0 0

0 4 4 4 0 4

0 0

0 0

4 4 4 4

0 0 0 0 0 0

0 0 0

4 4 4

4 4

4 4 0

0 0

0 4 0 0

0 0 0 0

0 0

ting any of the options uide Others 4 = Very Good

5 5 5 5 5 5 5 5 5 5 5 5

Designer 4 Designer 1 Designer 2 Designer 3 Designer 4 Designer 5 Engineer 1 Engineer 2 Engineer 3 Engineer 4 Engineer 5 Master Engineer Team leader Section Manager 1 2 3 4 5 1 2 3 4 5 5 5 5 0 Basic knowledge Working knowledge and ability to meet requirement Detailed knowledge Good experience and ability to train others Expert

Engineer Designer Master Engineer Team Leader Section Manager

1 2 3 4 5 0

meet requirement

You might also like

- Piping ResponsibilitiesDocument14 pagesPiping Responsibilitiesshivabtowin3301No ratings yet

- X-Matrix - Reference MetronixDocument1 pageX-Matrix - Reference MetronixRenz PerezNo ratings yet

- 2 Months Lookahead Plan & Major Material RequirmentsDocument110 pages2 Months Lookahead Plan & Major Material RequirmentsshankarswaminathanNo ratings yet

- Pump Performance DataDocument3 pagesPump Performance DataJiJO J JOSENo ratings yet

- Mechanical Design Report - EX-3340 - R00Document75 pagesMechanical Design Report - EX-3340 - R00Aditya JainNo ratings yet

- AHU New CostingDocument48 pagesAHU New Costingmohammed RizwanNo ratings yet

- Heat Exchanger CostingDocument4 pagesHeat Exchanger Costingjrmkum0% (1)

- Eco Solutions - Saving Resources, Creating ValueDocument17 pagesEco Solutions - Saving Resources, Creating ValueChayon MondalNo ratings yet

- Cost Estimation and Weight Calculation for Vessel DimensionsDocument46 pagesCost Estimation and Weight Calculation for Vessel Dimensionsshankarbt83No ratings yet

- Discipline ITTODocument65 pagesDiscipline ITTOumeshchandra yadavNo ratings yet

- 3119-Gear Box Data Sheet Rev.01Document4 pages3119-Gear Box Data Sheet Rev.01SAHTEESHKUMARNo ratings yet

- Al PSW FormatDocument2 pagesAl PSW Formatabhayjha1988No ratings yet

- LT 2021-6847 (Equipment Inspection Report - Crane & Lifting Devices)Document4 pagesLT 2021-6847 (Equipment Inspection Report - Crane & Lifting Devices)michaelNo ratings yet

- Technical Data: 150x125 CNHA 5 18.5Document5 pagesTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىNo ratings yet

- Greenheck Relief DamperDocument2 pagesGreenheck Relief DamperguythaiNo ratings yet

- Material Comparison ListDocument1 pageMaterial Comparison Listdarren84No ratings yet

- API Tank Data SheetDocument1 pageAPI Tank Data SheetAtomic JNo ratings yet

- Gear Pump Design SheetDocument3 pagesGear Pump Design SheetJagankumarNo ratings yet

- AES Floating HeadDocument8 pagesAES Floating HeadArjun Singh AroraNo ratings yet

- Tank Design and DetailingDocument17 pagesTank Design and DetailingFuatNo ratings yet

- Overall Mechanical Discipline Checklist With Lessons Learned Added 7-19-2012Document5 pagesOverall Mechanical Discipline Checklist With Lessons Learned Added 7-19-2012dhanu_lagwankarNo ratings yet

- Design Philosophy - StaticDocument61 pagesDesign Philosophy - StaticDarshan PanchalNo ratings yet

- Piping FabricationDocument36 pagesPiping Fabricationmurali100% (1)

- Oriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesDocument18 pagesOriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesTejas ShahNo ratings yet

- BOQ Ductile IronDocument2 pagesBOQ Ductile IronAshraf SalehNo ratings yet

- Document List DrawingDocument13 pagesDocument List Drawingzat572000No ratings yet

- Template in Excel For PE's (By CPDEP)Document36 pagesTemplate in Excel For PE's (By CPDEP)BibizhanKadyrberliNo ratings yet

- 7-13-0001 Rev 6Document1 page7-13-0001 Rev 6cynideNo ratings yet

- BN MLS 21 PTSC 307526Document1 pageBN MLS 21 PTSC 307526mailmaverick8167No ratings yet

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- NSDL Project Technical Data Sheet for 541-Ton Air-Cooled ChillerDocument3 pagesNSDL Project Technical Data Sheet for 541-Ton Air-Cooled ChillerVenu GopalNo ratings yet

- Austempered Ductile Iron (Adi)Document26 pagesAustempered Ductile Iron (Adi)bvphimanshuNo ratings yet

- Gewan Island Project Mechanical Submittal Log-Sheet: Total 47Document5 pagesGewan Island Project Mechanical Submittal Log-Sheet: Total 47Anand TVNo ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- Automatic Coke Drum Unheading System Rate BoQDocument8 pagesAutomatic Coke Drum Unheading System Rate BoQAnonymous fLgaidVBhzNo ratings yet

- Fire Extinguishers and Safety Equipment MTODocument2 pagesFire Extinguishers and Safety Equipment MTOMohamed RizkNo ratings yet

- Weight of Piping MaterialDocument9 pagesWeight of Piping Materialilayarasan100% (1)

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- RFI Fabrication Rev. 03Document22 pagesRFI Fabrication Rev. 03AdewaleNo ratings yet

- Pressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)Document6 pagesPressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)KOMATSU SHOVELNo ratings yet

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenNo ratings yet

- TBE Pumps CP 16Document21 pagesTBE Pumps CP 16ivomNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Cost Working of Mechanical Press: Description General Formula CostDocument4 pagesCost Working of Mechanical Press: Description General Formula Costazadsingh1No ratings yet

- PipingDocument7 pagesPipingfarhanyazdaniNo ratings yet

- Pipe Data Calculator: ANSI B 36.1 Nominal Bore & ScheduleDocument2 pagesPipe Data Calculator: ANSI B 36.1 Nominal Bore & ScheduleAmrit Singh KalsiNo ratings yet

- Temporary Slip Blind Thickness Calculation ChartDocument3 pagesTemporary Slip Blind Thickness Calculation ChartthmaraishriNo ratings yet

- API 650 Storage Tank Data Sheet March 2017Document3 pagesAPI 650 Storage Tank Data Sheet March 2017Nasi GorengNo ratings yet

- Piping For PDFDocument1 pagePiping For PDFSumañ DašNo ratings yet

- Lifting Pump PDSDocument3 pagesLifting Pump PDSsunii19847908No ratings yet

- Weld Map of Well 32 FLDocument13 pagesWeld Map of Well 32 FLArfanAliNo ratings yet

- Deliverables and Estimated Man-Hours: Detail DesignDocument10 pagesDeliverables and Estimated Man-Hours: Detail DesignkingNo ratings yet

- Basic valve datasheets for inquiryDocument21 pagesBasic valve datasheets for inquirymainur mechanical engineerNo ratings yet

- Material Submittal Log Sheet - MechanicalDocument2 pagesMaterial Submittal Log Sheet - MechanicalElla CelineNo ratings yet

- Guideline storage handling acidsDocument12 pagesGuideline storage handling acidsR k MishraNo ratings yet

- THK Pressure Calculations For Internal DimensionsDocument2 pagesTHK Pressure Calculations For Internal DimensionsConstrsupervisNo ratings yet

- Design of Pressure Vessel NewDocument200 pagesDesign of Pressure Vessel NewneelNo ratings yet

- Heat Treating Industry Processes EquipmentDocument75 pagesHeat Treating Industry Processes EquipmentAhmed Shaban Kotb100% (1)

- Mathcad - C02-C1Document5 pagesMathcad - C02-C1Krish ChandNo ratings yet

- Mechanical Engineer Resume SEODocument2 pagesMechanical Engineer Resume SEOManoj KumarNo ratings yet

- Structural Integrity Assessment Report PDocument126 pagesStructural Integrity Assessment Report Pdhanu_lagwankarNo ratings yet

- Tech Specs For Nitrogen GeneratorDocument5 pagesTech Specs For Nitrogen Generatordhanu_lagwankarNo ratings yet

- Risk Management in Sterile EnvironmentsDocument30 pagesRisk Management in Sterile Environmentsdhanu_lagwankarNo ratings yet

- Scope Statement Structure PaintDocument4 pagesScope Statement Structure Paintdhanu_lagwankarNo ratings yet

- Installation, Operation, and Maintenance Manual: Sample ValvesDocument11 pagesInstallation, Operation, and Maintenance Manual: Sample Valvesdhanu_lagwankarNo ratings yet

- Understanding Valves and Their Role in Mechanical IntegrityDocument13 pagesUnderstanding Valves and Their Role in Mechanical Integritydhanu_lagwankarNo ratings yet

- Automatically Controlled Air Cooled Condenser With Backlit Displays Dramatically Reduces Testing TimesDocument6 pagesAutomatically Controlled Air Cooled Condenser With Backlit Displays Dramatically Reduces Testing Timesdhanu_lagwankarNo ratings yet

- Boiler Capcity-F&A 100 Deg CDocument3 pagesBoiler Capcity-F&A 100 Deg CAgeng Firstyan BagaskoroNo ratings yet

- PortfolioDocument2 pagesPortfoliodhanu_lagwankarNo ratings yet

- Rooftop Pipe Support EBookDocument22 pagesRooftop Pipe Support EBookdhanu_lagwankarNo ratings yet

- ELmach QuoteDocument2 pagesELmach Quotedhanu_lagwankarNo ratings yet

- Care That Inspires Innovation: Cipla Limited Annual Report 2021-22Document392 pagesCare That Inspires Innovation: Cipla Limited Annual Report 2021-22dhanu_lagwankarNo ratings yet

- MAHAVIR - 24 (21) ValveDocument3 pagesMAHAVIR - 24 (21) Valvedhanu_lagwankarNo ratings yet

- Articulo Concept SelectionDocument14 pagesArticulo Concept Selectiondhanu_lagwankarNo ratings yet

- FAT-Compounding Isolator 100 L Compounding VesselDocument33 pagesFAT-Compounding Isolator 100 L Compounding Vesseldhanu_lagwankarNo ratings yet

- OQ COMPOUNDING 100 Ltrs ISOLATORDocument28 pagesOQ COMPOUNDING 100 Ltrs ISOLATORdhanu_lagwankarNo ratings yet

- DQ - CRAB For Lyo LoadingDocument30 pagesDQ - CRAB For Lyo Loadingdhanu_lagwankarNo ratings yet

- WBSDocument287 pagesWBSdhanu_lagwankarNo ratings yet

- Ampoule Labelling Machine User Requirement SpecificationsDocument15 pagesAmpoule Labelling Machine User Requirement Specificationsdhanu_lagwankarNo ratings yet

- Impact AssessmentDocument18 pagesImpact Assessmentdhanu_lagwankarNo ratings yet

- Way To Select An ACDocument1 pageWay To Select An ACdhanu_lagwankarNo ratings yet

- Analysis For Boiler and Pre-Treatment SystemDocument2 pagesAnalysis For Boiler and Pre-Treatment Systemdhanu_lagwankarNo ratings yet

- Pid Legend PDFDocument1 pagePid Legend PDFSocMed Dtk UI0% (1)

- Conceptual Design Deliverables Latest Rev2Document14 pagesConceptual Design Deliverables Latest Rev2dhanu_lagwankarNo ratings yet

- Factories Act 1948Document68 pagesFactories Act 1948Sreelakshmi KambapuNo ratings yet

- Risk Engineering Position Paper 01 Atmospheric Storage Tanks 2015Document28 pagesRisk Engineering Position Paper 01 Atmospheric Storage Tanks 2015SardeniantoNo ratings yet

- Dokumen - Tips Building Projects Pdri Automated Excel Spreadsheet WeightedDocument6 pagesDokumen - Tips Building Projects Pdri Automated Excel Spreadsheet Weighteddhanu_lagwankarNo ratings yet

- 12C 004 01 Asset Tag and Equipment Label Guidance 7.0 RedactedDocument20 pages12C 004 01 Asset Tag and Equipment Label Guidance 7.0 Redacteddhanu_lagwankarNo ratings yet

- Glenmark Sustainability Report FY 2020 21Document126 pagesGlenmark Sustainability Report FY 2020 21dhanu_lagwankarNo ratings yet

- TMS1647 Plant and Equipment Tag Numbering Rev06Document17 pagesTMS1647 Plant and Equipment Tag Numbering Rev06abdelhalimNo ratings yet

- Indigo Assessment - Cynthia Nieto VargasDocument14 pagesIndigo Assessment - Cynthia Nieto Vargasapi-506651646No ratings yet

- IPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldDocument13 pagesIPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldJean Carlos100% (1)

- Assessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryDocument38 pagesAssessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryAbhishek Kumar0% (1)

- Plasmon CD-R ReviewDocument11 pagesPlasmon CD-R Reviewgrudva2No ratings yet

- Transient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationDocument5 pagesTransient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationSwati kNo ratings yet

- Squeeze Cementing TechniquesDocument22 pagesSqueeze Cementing TechniquesDoni KurniawanNo ratings yet

- Documentation For: Bank - MasterDocument6 pagesDocumentation For: Bank - MastervijucoolNo ratings yet

- Robohawks Team HandbookDocument11 pagesRobohawks Team Handbookapi-376756259No ratings yet

- MCP HistoryDocument18 pagesMCP HistoryStanciu VladNo ratings yet

- Grade CalculatorDocument1 pageGrade CalculatorKHENN ALDIANONo ratings yet

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDocument7 pagesMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94No ratings yet

- Operating Manual Parts List: 1000Vmc (Siemens)Document226 pagesOperating Manual Parts List: 1000Vmc (Siemens)apodshNo ratings yet

- Applications: H D P TDocument2 pagesApplications: H D P TEnrique MurgiaNo ratings yet

- Maintenance & Trouble Shooting of Voith CouplingDocument20 pagesMaintenance & Trouble Shooting of Voith Couplingsen_subhasis_58100% (1)

- Civil-Vii-Air Pollution and Control (10cv765) - Question PaperDocument4 pagesCivil-Vii-Air Pollution and Control (10cv765) - Question PaperSathya MurthyNo ratings yet

- Compressors & Compressed Gas Audit ChecklistDocument3 pagesCompressors & Compressed Gas Audit ChecklistPerwez21100% (1)

- HVDC Grid Feasibility StudyDocument189 pagesHVDC Grid Feasibility StudyDeoudrafNo ratings yet

- Tivizen Iplug Greek GuideDocument13 pagesTivizen Iplug Greek GuideDenexoNo ratings yet

- Q7 Running GearDocument54 pagesQ7 Running GearJoseph MorantNo ratings yet

- Haffmans DPT: Dew Point TesterDocument2 pagesHaffmans DPT: Dew Point TesterLaura Elianne QuirogaNo ratings yet

- EE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Document5 pagesEE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Kulanthaivelu RamaswamyNo ratings yet

- Finite Element Analysis of The In-Service-Welding of T Joint Pipe ConnectionDocument12 pagesFinite Element Analysis of The In-Service-Welding of T Joint Pipe ConnectionMohamed SamyNo ratings yet

- Cable Memebres ProfiledirectoryDocument5 pagesCable Memebres ProfiledirectoryMigration Solution100% (1)

- Operating Procedure ERLDCDocument154 pagesOperating Procedure ERLDCbramhanand vermaNo ratings yet

- L Uk SulphDocument24 pagesL Uk SulphypyeeNo ratings yet

- Autocad 2010 Tutorial Series Autocad Mechanical 2010 Tutorial SeriesDocument4 pagesAutocad 2010 Tutorial Series Autocad Mechanical 2010 Tutorial Seriesbdi_roNo ratings yet

- Direct Stiffness Method for Truss AnalysisDocument28 pagesDirect Stiffness Method for Truss Analysisgilberthufana446877No ratings yet

- Contact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentDocument8 pagesContact-Molded Reinforced Thermosetting Plastic (RTP) Laminates For Corrosion-Resistant EquipmentQUALITY MAYURNo ratings yet

- BYG Опросный лист на режущую кромкуDocument51 pagesBYG Опросный лист на режущую кромкуMMM-MMMNo ratings yet

- DB2 WebSphere BestPracticeDocument53 pagesDB2 WebSphere BestPracticeSpeedyKazamaNo ratings yet