Professional Documents

Culture Documents

Line Sizing and Pressure Drop Calculations for Sanstar Bio-Polymers Ltd Steam Lines

Uploaded by

santosh_rajuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Line Sizing and Pressure Drop Calculations for Sanstar Bio-Polymers Ltd Steam Lines

Uploaded by

santosh_rajuCopyright:

Available Formats

Sanstar Bio-Polymers Ltd

Line sizing calculations

Design Calculations for Line sizing and pressure drop for Steam Turbine and Process steam lines

Prepared by Forbes Marshall Pvt. Ltd

Page 1

Sanstar Bio-Polymers Ltd

Line sizing calculations

Contents

1. Steam Turbine Line Design Calculations: ............................................................................................ 3 1.1 1.2 HP steam line thickness calculation from boiler outlet to turbine inlet: ................................ 3 Line sizing and pressure drop calculation: .............................................................................. 4

2. Process steam pressure drop calculations:......................................................................................... 5 2.1 Pressure drop calculations for external lines................................................................................ 5 2.2 Pressure drop calculation for MP and LP steam lines inside the process block: .......................... 8 3. Break-up of Piping BOQ: ................................................................................................................... 10 Option 1: ........................................................................................................................................... 10 Option 2: ........................................................................................................................................... 10 Process block distribution lines: ....................................................................................................... 11

Prepared by Forbes Marshall Pvt. Ltd

Page 2

Sanstar Bio-Polymers Ltd

Line sizing calculations

1. Steam Turbine Line Design Calculations:

1.1 HP steam line thickness calculation from boiler outlet to turbine inlet:

Steam line from Power boiler outlet to the turbine inlet is a High pressure critical line, for which thickness calculations are required to be dons as ASME B31.1, calculation sheet is given below.

Pipe size Working Pressure 1.0Pipe Material= 2.0Type/Class of Pipe= 3.0Operating Temperature=495 deg c 4.0O.D. of Pipe( D )= 5.0Schdule of pipe selected= 6.0Designated Thickness as per Sch.No. less 12.5 % thickness mill under tolerance DESIGN DATA: *Min.Tensile strength at room Temp(R).= Therefore,R/2.7 *Yield Point(Et) = Et/R20 ratio at 500 deg c Et Therefore,Et/1.5 Formula: allowable working Pr. W= 60000 22222.222 0.23 13800.000 9200.000 2fe(t-C) D-t+C Allowable Working Pr.in Kg/Cm2 = Actual Working Pressure in Kg/cm2 g= 76.30284028 68 in psi in psi 200 NB 68 kg/cm2 g Working Temp.above 495 degC(925 degF)

A335 P11 Seamless 925 8.625 Sch 100 0.594 0.51975 in Inch in Deg.F in INCH.

in psi in psi in psi

Prepared by Forbes Marshall Pvt. Ltd

Page 3

Sanstar Bio-Polymers Ltd

Line sizing calculations

1.2 Line sizing and pressure drop calculation:

Line sizing from boiler outlet to turbine inlet is as given below: 8inch line 100SCH 68 barg 490 degC 35000 kg/h 202.72 mm 53 m 4 1 1 8 188.45 m

Steam Pressure Steam Temperature Req'd capacity Pipe size Pipe length No. of gate valves No. of strainers No. of lift check valves No of 90o elbows Equivalent pipe length

Results Pressure at end of pipe 67.68 bar Upstream velocity 11.42 m/s Downstream velocity 11.48 m/s

Prepared by Forbes Marshall Pvt. Ltd

Page 4

Sanstar Bio-Polymers Ltd

Line sizing calculations

2. Process steam pressure drop calculations:

Pressure drop and line sizing is done for two options viz. 1)Single extraction turbine, and 2)Extraction cum back pressure turbine. Pressure drop calculations for the external lines would vary for each of the case whereas pressure drop for internal lines will remain the same. Therefore Calculations are worked out separately for external lines and internal lines i.e. MP and LP steam lines from turbine house to process block, and Steam distribution from process headers to individual equipment which are the internal lines.

2.1 Pressure drop calculations for external lines

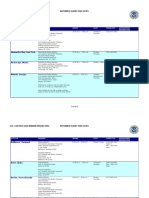

Option 1: Below given is the pressure drop calculation for external lines and internal lines considering Extraction cum back pressure turbine with extraction at 10.5barg and backpressure at 4.5barg pressures. a. Pressure drop calculation across MP steam line from turbine house to Process header: Inlet Pressure Barg Flow TPH Size From 10 25 250NB Turbine MP header 9.61 18 200NB Starch Block Steam Header (Dryer section) 4 16 1.8 14.4 140 154.4 185.28 8 24 72 86.4 271.68 0.39 28 9.22

To Starch Block Expansion loops 7 No of bends 28 Loop vertical length 2.5 Total length for exp. Loops 35 Actual Pipe length 238 Total pipe length 273 20% margin 327.6 Additional bends 4 total bends 32 Eq length 120 20% margin 144 Total eq length 471.6 Pr drop 0.39 Velocity (m/s) 25 Pressure at end point 9.61

Prepared by Forbes Marshall Pvt. Ltd

Page 5

Sanstar Bio-Polymers Ltd

Line sizing calculations

b. Pressure drop calculations across LP steam line from LP header in Turbine house to LP header at the process block: Pressure Barg Flow TPH Size From To Expansion loops No of bends Loop vertical length Exp. Loop vertical length Actual Pipe length Total pipe length 20% margin Additional bends total bends Eq length 20% margin Total eq length Pr drop Velocity (m/s) Pressure at end point 4.5 10 250NB Turbine DSH/ LP header in Turbine house LP header in Process 9 36 2.5 45 308 353 423.6 6 42 157.5 189 612.6 0.17 18 4.33

Prepared by Forbes Marshall Pvt. Ltd

Page 6

Sanstar Bio-Polymers Ltd

Line sizing calculations

Option 2: Below given are the pressure drop calculations for main lines considering single extraction turbine with extraction at 10.5barg pressure a. Pressure drop calculation across MP steam line from turbine house to steam header at the process block: Pressure Barg Flow TPH Size From To Expansion loops No of bends Loop vertical length Exp. Loop vertical length Actual Pipe length Total pipe length 20% margin Additional bends total bends Eq length 20% margin Total eq length Round off length Pr drop Velocity (m/s) Pressure at end point 10 35 300NB Turbine DSH Starch Block 7 28 3 42 238 280 336 4 32 144 172.8 508.8 510 0.32 24 9.68 9.68 28 250NB Starch Block Inlet of 4.5barg PRS 2 8 2.5 10 70 80 96 6 14 52.5 63 159 160 0.17 29 9.51 9.51 18 200NB Inlet of 4.5barg PRS Steam Header (Dryer section) 2 8 1.8 7.2 70 77.2 92.64 2 10 30 36 128.64 130 0.19 27 9.32

Prepared by Forbes Marshall Pvt. Ltd

Page 7

Sanstar Bio-Polymers Ltd

Line sizing calculations

2.2 Pressure drop calculation for MP and LP steam lines inside the process block:

a. Pressure drop calculations for MP steam lines Pressure Barg 9.32 Flow TPH 1.2 Size From To Final evaporators Expansion loops 2 No of bends 8 Loop vertical length 1 Exp. Loop vertical length 4 Actual Pipe length 78 Total pipe length 82 20% margin 98.4 Additional bends 4 total bends 12 Eq length 12 20% factor 14.4 Total eq length 112.8 Round off length 115 Pr drop 0.3 Velocity (m/s) 19 Pressure at end point 9.02 9.2 21 0.12 70 65.52 10.8 9 6 2 54.72 45.6 43 2.6 1.3 4 1 Jet cooker 65NB Steam Header (Dryer section) 100NB Steam Header (Dryer section) 3.1 9.32

Prepared by Forbes Marshall Pvt. Ltd

Page 8

Sanstar Bio-Polymers Ltd

Line sizing calculations

b. Pressure drop calculations for LP steam lines inside process block Pressure Barg Flow TPH Size 4.33 0.2 40NB LP header in Process DMH dryers 4 16 0.8 6.4 146 152.4 182.88 3 19 0.6 11.4 13.68 196.56 215 0.4 17 3.93 4.33 1.2 80NB LP header in Process Near dryers header 1 4 1.2 2.4 58 60.4 72.48 2 6 1.2 7.2 8.64 81.12 90 0.14 21 4.19 4.19 1 65NB Near dryers header Steeping section 2 8 1 4 76 80 96 3 11 1 11 13.2 109.2 110 0.4 31 3.79 4.19 1 80NB Near dryers header Steeping section 2 8 1.2 4.8 76 80.8 96.96 3 11 1.2 13.2 15.84 112.8 115 0.13 18 4.06 4.33 1.4 80NB LP header in Process Hydrocyclo ne 2 8 1.2 4.8 74 78.8 94.56 3 11 1.2 13.2 15.84 110.4 115 0.27 28 4.06

From

To Expansion loops No of bends Loop vertical length Exp. Loop vertical length Actual Pipe length Total pipe length 20% margin Additional bends total bends Eq length per bend (mtr) Eq length 20% factor Total eq length Round off length Pr drop Velocity (m/s) Pressure at end point

Prepared by Forbes Marshall Pvt. Ltd

Page 9

Sanstar Bio-Polymers Ltd

Line sizing calculations

3. Break-up of Piping BOQ:

Option 1:

Descripton Boiler to turbine inlet Boiler to bypass pRS inlet bypass Prs O/L to DSH I/L Turbine exhaust to DSH I/L MP DSH Outlet to MP header MP header to LP PRS I/L Size Pressure 200NB 68 200NB 68 300NB 10.5 250NB 10.5 250NB 10.5 150NB 10.5 Flow 35 35 35 25 35 10 Sch 100 100 40 40 40 40 Material Pipe length Bends P11 46 8 P11 23 8 CS 23 8 P11 23 8 CS 5 3 CS 10 3

Turbine exhaust to DSH I/L to LP header LP header(turbine) to LP header (process) MP Header (turbine) to Starch Block Starch block to MP header(Process) MP header(turbine) LP header(turbine)

250NB 250NB 250NB 200NB 350NB 300NB

4.5 4.5 10.5 10.5 10.5 4.5

10 10 25 17.5

40 40 40 40 40 40

CS CS CS CS CS CS

23 423.6 327.6 185.28 5 5

8 42 32 24

Option 2:

Descripton Boiler to turbine inlet Boiler to bypass pRS inlet bypass Prs O/L to DSH I/L Turbine exhaust to DSH I/L DSH O/L to DA I/L Main line to LP PRS DSH O/L to Process(Starch block) Starch Block to MP header Size 200NB 200Nb 300NB 300NB 100NB 150NB 300NB 250NB Pressure 68 68 10.5 10.5 10.5 10.5 10.5 10.5 Flow 35 35 35 35 5 10 35 28 Sch 100 100 40 40 40 40 40 40 Material P11 P11 CS CS CS CS CS CS Pipe length 46 23 23 23 37 10 336 96 Bends 8 8 8 8 8 3 32 14

Prepared by Forbes Marshall Pvt. Ltd

Page 10

Sanstar Bio-Polymers Ltd

Line sizing calculations

Process block distribution lines:

LP Lines - header to equipment I/L Process LP hdr to Hydro cyclone 80NB 4.5 Process LP Hdr to LG evaporator 100NB 4.5 Process LP Hdr to DMH and DAH evaporator 40NB 4.5 Process LP Hdr to LG batch evap 40NB 4.5 Process LP hdr to DMH dryers HDR 40NB 4.5 DMH HDR to I/L 25NB 4.5 Process LP hdr to Near MP Hdr 80NB 4.5 LP line near MP Hdr to Steeping tanks LP line near MP Hdr to 2.5barg PRS I/L 2.5barg PRS O/L to Saccfn. HDR HDR to sacrfn. Tanks I/L 80NB 40NB 40NB 25NB** 20NB** 1.4 4.7 1.6 0.6 0.2 0.1 1.2 40 40 40 40 40 40 40 CS 95 11 CS 14 4 CS 28 8 CS 14 4 CS 183 19 CS 30 6 CS 72 6 97 11 15 3 5 3 75 9 30 30

4.5 1 40 CS 4.5 0.2 40 CS 2.5 0.2 40 CS 2.5 40 CS 2.5 40 CS

MP lines - Header to equipment I/L MP header to Final evaporators 65NB 10.5 1.2 40 CS MP header to Jet Cooker 100NB 10.5 3.1 40 CS MP header to rotary dryers I/L 80NB 10.5 40 CS

98 12 55 6 25 15

LP header(Evaporator) LP header(DMH)

LP headers 300NB 50NB MP headers 250NB 80NB 150NB

4.5 4.5

40 CS 40 CS

7 5

MP header(Dryer section) MP header(Final evap) MP header(Starch dryers)

10.5 10.5 10.5

40 CS 40 CS 40 CS

7 5 5

------

Prepared by Forbes Marshall Pvt. Ltd

Page 11

You might also like

- CW Pump CalculationDocument22 pagesCW Pump Calculationzamijaka100% (1)

- Cooling TowerDocument27 pagesCooling Towerjogedhayal100% (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line Sizingemmanuilmoulos6339100% (1)

- Cooling Tower-CalculatorDocument7 pagesCooling Tower-CalculatorparykoochakNo ratings yet

- Surface CondenserDocument33 pagesSurface CondensershivvaramNo ratings yet

- Distillation DesignDocument1 pageDistillation DesignvicopipNo ratings yet

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- CBE 417 FlashDrumSizing WankatDocument7 pagesCBE 417 FlashDrumSizing WankatRahmansyah GaekNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetsyamsudin200683% (6)

- Condensate Line SizingDocument2 pagesCondensate Line SizingWade ColemanNo ratings yet

- Pump Sizing Calculation SheetDocument7 pagesPump Sizing Calculation Sheetvofaith100% (2)

- Pump CalculationsDocument20 pagesPump CalculationsPRATIK P. BHOIR50% (2)

- Design of Cooling TowerDocument17 pagesDesign of Cooling TowerMohan VarkeyNo ratings yet

- PUMP SIZING SPREADSHEET FOR KEROSENE TRANSFERDocument30 pagesPUMP SIZING SPREADSHEET FOR KEROSENE TRANSFEREbby Onyekwe100% (1)

- BoilerCalcSteamPropDocument4 pagesBoilerCalcSteamPropMarc EdwardsNo ratings yet

- Chimney Sizing PDFDocument13 pagesChimney Sizing PDFtitieNo ratings yet

- Piping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsDocument17 pagesPiping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsDhanny Miharja100% (1)

- Sizing StrainerDocument8 pagesSizing Strainerchadvillela0% (1)

- Assessment of CompresorsDocument14 pagesAssessment of CompresorsranveerNo ratings yet

- Pressure Drop CalculationsDocument4 pagesPressure Drop CalculationsOmprakaash Mokide100% (1)

- @S V All FansDocument19 pages@S V All Fanshasanadel88No ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Pump Design WorksheetDocument3 pagesPump Design Worksheetejzuppelli8036100% (8)

- Pump Head Calculation for DIC R&D Condenser Water SystemDocument1 pagePump Head Calculation for DIC R&D Condenser Water SystemMFaiz RHamiraNo ratings yet

- Pump SizingDocument4 pagesPump SizingNikunj100% (5)

- Pump Branch DesignDocument7 pagesPump Branch DesignMarcelo PerettiNo ratings yet

- Pump Desing SpreadsheetDocument10 pagesPump Desing SpreadsheetAnonymous a4Jwz14WNo ratings yet

- FAD CALCULATION FOR AIR DELIVERYDocument4 pagesFAD CALCULATION FOR AIR DELIVERYAnonymous JZK84WzfKNo ratings yet

- Thermal 3TPH 12Kg FO Fired Boiler R0Document6 pagesThermal 3TPH 12Kg FO Fired Boiler R09913489806No ratings yet

- Design Calculations - Insulation Thickness REV-1Document4 pagesDesign Calculations - Insulation Thickness REV-1delMAK100% (1)

- Cooling Tower Calculation DESIGNDocument6 pagesCooling Tower Calculation DESIGNThakur Chandra Partap singh100% (1)

- Chilled Water PumpsDocument6 pagesChilled Water PumpsNghiaNo ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- Expansion Tank SizingDocument36 pagesExpansion Tank SizingEngFaisal AlraiNo ratings yet

- Agricultural Bank Chilled Water Pumps Head Loss CalculationDocument6 pagesAgricultural Bank Chilled Water Pumps Head Loss CalculationMohammed Hassan Mohiuddin Khan67% (3)

- Heat Exchanger Design CalculationsDocument6 pagesHeat Exchanger Design CalculationsryanarthurNo ratings yet

- Duct Static Pressure Loss CalculationDocument8 pagesDuct Static Pressure Loss CalculationYe Thiha Min100% (2)

- Air Receiver SizingDocument3 pagesAir Receiver Sizingmazumdar_satyajit100% (2)

- Ejector BasicsDocument2 pagesEjector Basicsa234f56No ratings yet

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- Pressure Drop CalculationDocument6 pagesPressure Drop CalculationNaveen Pete100% (1)

- Calculating Centrifugal Chiller Condenser LoadsDocument49 pagesCalculating Centrifugal Chiller Condenser Loadseka resmana100% (1)

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- Sizing Calculation of General Service PumpsDocument193 pagesSizing Calculation of General Service Pumpsmkha87No ratings yet

- Technical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Document7 pagesTechnical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Chakravarthy BharathNo ratings yet

- Axial Piston Pumps: Series Pvplus - Design Series 47 Variable DisplacementDocument72 pagesAxial Piston Pumps: Series Pvplus - Design Series 47 Variable DisplacementJhonata CavalcanteNo ratings yet

- DESIGN of Pump Head-KiratpuraDocument18 pagesDESIGN of Pump Head-KiratpuraJacob B Chacko100% (1)

- Duct & Vent EngineeringDocument70 pagesDuct & Vent Engineeringtop20202080% (5)

- Drilling Engineering FormulasDocument102 pagesDrilling Engineering FormulasJose Flores Hernandez100% (1)

- Drilling Formulas Calculation Sheet Verson 1.3Document186 pagesDrilling Formulas Calculation Sheet Verson 1.3Sarhad Ahmed100% (1)

- Hydraulics worksheet Rev (2) optimizedLength10570 ft450 ft180 ft150 ftDocument9 pagesHydraulics worksheet Rev (2) optimizedLength10570 ft450 ft180 ft150 ftShivaram SuppiahNo ratings yet

- WP ValveDocument7 pagesWP ValveHamed ArianNo ratings yet

- HSN 7461-70Document11 pagesHSN 7461-70codymasterNo ratings yet

- MSG30-3245 UkDocument68 pagesMSG30-3245 Ukoperacion hydratekNo ratings yet

- 22 1739 04 - 02012010XXDocument16 pages22 1739 04 - 02012010XXMartinez MarNo ratings yet

- Boilers Chimney Draft and Breeching CalculationDocument15 pagesBoilers Chimney Draft and Breeching Calculationjoabjim8392No ratings yet

- Pump CalculationDocument20 pagesPump Calculationcoolsummer1112143100% (1)

- Mud Tool KitDocument52 pagesMud Tool KitChris RoarkNo ratings yet

- Continuum Mechanics in MathematicaDocument1 pageContinuum Mechanics in Mathematicasantosh_rajuNo ratings yet

- Soln 1Document1 pageSoln 1santosh_rajuNo ratings yet

- Continuum MechanicsDocument3 pagesContinuum Mechanicssantosh_rajuNo ratings yet

- Class3 PDFDocument4 pagesClass3 PDFVishnu SamyNo ratings yet

- Excerpts From CraigDocument37 pagesExcerpts From Craigsantosh_rajuNo ratings yet

- Raju HW1Document11 pagesRaju HW1santosh_rajuNo ratings yet

- Class4 SructureDocument6 pagesClass4 Sructuresantosh_rajuNo ratings yet

- Class 1Document4 pagesClass 1santosh_rajuNo ratings yet

- Class Xii - Differntiation & Integration Formulae.Document1 pageClass Xii - Differntiation & Integration Formulae.Mandeep Singh Plaha59% (22)

- Wind Power CalcDocument4 pagesWind Power Calcsantosh_rajuNo ratings yet

- Notes on Fourier SeriesDocument20 pagesNotes on Fourier SeriesSiva GuruNo ratings yet

- Integral FormulasDocument7 pagesIntegral Formulassantosh_rajuNo ratings yet

- Fourier ConvergenceDocument5 pagesFourier Convergencesantosh_rajuNo ratings yet

- Chapter 13 M-FilesDocument30 pagesChapter 13 M-Filessantosh_rajuNo ratings yet

- Integral FormulasDocument7 pagesIntegral Formulassantosh_rajuNo ratings yet

- JNTU Old Question Papers 2007Document8 pagesJNTU Old Question Papers 2007Srinivasa Rao GNo ratings yet

- Boiler Water TreatmentDocument73 pagesBoiler Water Treatmentsantosh_rajuNo ratings yet

- 25 Lessons Jack Welch Ten3 Mini CourseDocument49 pages25 Lessons Jack Welch Ten3 Mini Coursesantosh_rajuNo ratings yet

- Deferred Inspection SitesDocument15 pagesDeferred Inspection Sitessantosh_rajuNo ratings yet

- Santosh Raju: Search Plan Enroll My Academics My Class Schedule Add Drop SwapDocument1 pageSantosh Raju: Search Plan Enroll My Academics My Class Schedule Add Drop Swapsantosh_rajuNo ratings yet

- Wind PotentialDocument10 pagesWind Potentialsantosh_rajuNo ratings yet

- MArket AnalysisDocument5 pagesMArket Analysissantosh_rajuNo ratings yet

- Ingersoll-Watches 2011Document36 pagesIngersoll-Watches 2011Ingersoll WatchesNo ratings yet

- Restraint PDFDocument119 pagesRestraint PDFErkki IsokangasNo ratings yet

- Electrical Wiring Components and AccessoriesDocument14 pagesElectrical Wiring Components and AccessoriesHarshit SaraswatNo ratings yet

- 3.0L Duramax LM2 Diesel I-6 Specs (2020 Silverado - Sierra 1500) PDFDocument2 pages3.0L Duramax LM2 Diesel I-6 Specs (2020 Silverado - Sierra 1500) PDFSyedNo ratings yet

- Fact Sheet - VolvoDocument2 pagesFact Sheet - VolvoMihai AncutaNo ratings yet

- GA 250 Manual UpdateDocument3 pagesGA 250 Manual UpdateEyver SubiaNo ratings yet

- BDocument78 pagesBMarcel Vicencio100% (1)

- PC138US-8: Hydraulic ExcavatorDocument28 pagesPC138US-8: Hydraulic ExcavatorHitri Pepe100% (1)

- 2008-2009 GM Magna Transfer Case Detailed Info, Bulletin # 1226Document10 pages2008-2009 GM Magna Transfer Case Detailed Info, Bulletin # 1226davidNo ratings yet

- Spec Sheet Dl08 Ind 1Document8 pagesSpec Sheet Dl08 Ind 1Văn Tuấn Nguyễn100% (1)

- Mitsui-Man B&W Me-B Engines InstructionDocument520 pagesMitsui-Man B&W Me-B Engines InstructionGamalMahran100% (4)

- Polaris Predator 90 Owners ManualDocument153 pagesPolaris Predator 90 Owners Manualmilkman951No ratings yet

- Automation Objective QuestionsDocument10 pagesAutomation Objective QuestionsSrinivasaReddyM100% (2)

- DTC Control of BLAC and BLDC Motors For Pure Electric VehiclesDocument10 pagesDTC Control of BLAC and BLDC Motors For Pure Electric VehiclesSidahmed LarbaouiNo ratings yet

- MOTOMAN Mantaince ManualDocument99 pagesMOTOMAN Mantaince ManualschrienerNo ratings yet

- Subaru and Mitsubishi Parts SheetDocument51 pagesSubaru and Mitsubishi Parts SheetConsuelo AriasNo ratings yet

- 458CHP OverhaulDocument45 pages458CHP OverhaulKtkPowder100% (3)

- Section 4 Brake System: Group 1 Structure and FunctionDocument22 pagesSection 4 Brake System: Group 1 Structure and FunctionREMZONANo ratings yet

- Proposed Ductline Layout: Feu DilimanDocument7 pagesProposed Ductline Layout: Feu DilimanKenth GavNo ratings yet

- Actuator Torque Ratings: Series A / B / C / S / HPDocument88 pagesActuator Torque Ratings: Series A / B / C / S / HPSreekanthNo ratings yet

- PM Check Sheet (PC1250-8,8R)Document2 pagesPM Check Sheet (PC1250-8,8R)Naughty VongNo ratings yet

- Mecanica Chery Modelo CheryDocument80 pagesMecanica Chery Modelo CheryjcarlosahuatltNo ratings yet

- SG SM SH07 12APG Uk PDFDocument46 pagesSG SM SH07 12APG Uk PDFMihaela CaciumarciucNo ratings yet

- Upra Teks Prosedur How To UseDocument3 pagesUpra Teks Prosedur How To UseAdinda SyifaNo ratings yet

- Difference Between Otto Cycle and Diesel Cycle (Notes & PDF)Document5 pagesDifference Between Otto Cycle and Diesel Cycle (Notes & PDF)tarek nadeNo ratings yet

- SfuDocument1 pageSfuNaza PalomoNo ratings yet

- HMTDocument25 pagesHMTRaj PanditNo ratings yet

- Engine Performance Data at 1800 RPM: QSX 1 Cummins IncDocument3 pagesEngine Performance Data at 1800 RPM: QSX 1 Cummins IncHernan Peñafiel ReaNo ratings yet

- Heavy Duty Truck Cooling System Design Using Co-SimulationDocument8 pagesHeavy Duty Truck Cooling System Design Using Co-Simulationwen liuNo ratings yet

- Code of Practice For Installation and Maintenance of Induction MotorsDocument37 pagesCode of Practice For Installation and Maintenance of Induction MotorsHimansu Sekhar JenaNo ratings yet