Professional Documents

Culture Documents

Electrical Switchgear

Uploaded by

Khemraz RamduthOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Switchgear

Uploaded by

Khemraz RamduthCopyright:

Available Formats

Training in Switchgears, Circuit breakers and Transformers

1. Modern switchgear and protection coordination in MV and HV systems Examining switchgear components and challenges affecting us today Complying strictly with switchgear standards and legislation Reviewing the factors affecting the selection of switchgears for your operations Analysing the rating requirements for switchgear selection: - Load current - Interrupting current - Withstand - Fault-carrying capability Examining the nature of short circuit currents and the effect of rotating machines on the short circuit current. This is complimented by a description of the setting of protection relays - Coordination procedure - Relay settings - Types of faults - Nature of short circuit currents - Symmetrical & asymmetrical currents - Effect of rotating machines - Selection of relays - ANSI and BS 142 curves Practical Exercise: Ensuring environmental friendliness This practical exercise will allow participants the opportunity to an in-depth discussion based on trends and technology to improve their procedures, equipment and designs that are environmentally friendly. The aim of the exercise is to establish processes for enhanced environmental friendliness. 2. Analysing the impact of system components: Transformers and cables Developing an understanding of transformer classification Recognising the fundamentals of transformer construction Preparing vector and connection diagrams to understand and direct maintenance action Safeguarding your systems operations through stability and security of transformers and its use in electrical energy transfer Detecting problems in your current cooling techniques and overcoming the challenges Exploring new insulation materials available Choosing cooling equipment based on the transformer power rating Classifying your available cooling equipment to ensure optimal transformer cooling in respect to: - Natural - Forced air - Oil flow Exploring the types of cables and voltage to be used for optimum results: - PILC - XLPE - PVC Practical Exercise: Reviewing auxiliary equipment Participants should have an opportunity to brainstorm and discuss the role of auxiliary equipment essential to the successful operation of transformers. The discussion will be based on fans, gas relays, pumps and tap changer controls. The aim of the practical session is to allow participants to gain a deeper insight and supplement their discussion with additional information from your course facilitator

3. Embarking on the implementation of safety considerations and procedures Ensuring compliance to electrical safety standards and regulations stipulated Differentiating between old and new equipment in preventing accidents Identifying possible existing electrical hazards and taking proactive measures Ensuring sound risk assessments and audits to promote safety Benchmarking decisions based on effective fault studies Step and touch potentials Controlling internal arc hazards in switchgear Lightning protection 4. Evaluating effective and efficient techniques for monitoring and diagnostic testing Focusing on the purpose and application of switchgear and transformer maintenance Understanding the core components of inspection methodologies Communicating different testing techniques and procedures - Type tests - Routine tests - Special tests Highlighting advances and latest technology in diagnostic tools for test and audit processes Examining various complex field tests available - Oil screen testing - Moisture in oil testing - Gas in oil testing - Electrical testing - Thermography . 5. Modern maintenance principles: Challenging traditional approaches Maintenance of electrical equipment is usually considered a low priority by most management teams, who defer or ignore it until a failure occurs. The benefits of proactive maintenance programs together with the related problems of risk are briefly discussed showing the differences to low voltage switchgear which are mainly intended to be maintenance free devices. This session will cover: The purpose of maintenance and its evolution Reliability, availability and maintainability principles Testing paradigms 6. Designing a successful electrical maintenance programme Gaining insight into developing your maintenance programme and improving the existing plan Examining systems analysis as the initial step in establishing a maintenance plan Exploring systems parameters under normal and faulted conditions - Short circuits - Circuit breaker duty - Load flow - Motor starting and other dynamic conditions Selecting a type of maintenance strategy to base the maintenance programme on, by reviewing your own organisational maintenance needs in respect to production and equipment

Practical exercise: Data modelling and database design Participants should have an opportunity to discuss the management decisions that must be made in the operations and maintenance environment, and the information that is relevant to those decisions. The possible structures and implementation of databases that can assist with those decisions will be explored by the group. 7. Implementing and refining an electrical maintenance programme and ensuring successful execution Communicating to the team involved to capture the importance of effective maintenance and ensuring it is not a once-off routine Understanding some elementary change management principles The importance of systematic and thorough recruitment, skills development and performance management The value of well managed data, and the role of internal audits Failure investigations and maintenance programme refinements Case study: Switchgear failure investigation 8. Facilitating efforts to eliminate life-limiting factors Aging of switchgear and circuit breakers Overloading and other life limiting factors for transformers Pinpointing end of life indicators for switchgear and circuit breakers Life extension and asset replacement decisions lease write in BLOCK LETTERS

You might also like

- Technical Ratings To Facilitate The Selection of A LampDocument2 pagesTechnical Ratings To Facilitate The Selection of A LampKhemraz RamduthNo ratings yet

- Instal Cables & AccessoriesDocument5 pagesInstal Cables & AccessoriesKhemraz RamduthNo ratings yet

- Where To Place Recessed Lighting FixturesDocument1 pageWhere To Place Recessed Lighting FixturesKhemraz RamduthNo ratings yet

- Energy ManagementDocument11 pagesEnergy ManagementKhemraz RamduthNo ratings yet

- Test Instruments Installations:: For Electrical Accuracy and ConsistencyDocument12 pagesTest Instruments Installations:: For Electrical Accuracy and ConsistencydarkingNo ratings yet

- Apprenticeship TrainingDocument1 pageApprenticeship TrainingKhemraz RamduthNo ratings yet

- Instrumentation Training Tutorial Part3Document17 pagesInstrumentation Training Tutorial Part3Gary8100% (1)

- Certify Electrical InstallationDocument3 pagesCertify Electrical InstallationKhemraz RamduthNo ratings yet

- ESC Tips: Consumer Unit Replacement in Domestic PremisesDocument10 pagesESC Tips: Consumer Unit Replacement in Domestic PremisesSparks Electrical Wholesalers LtdNo ratings yet

- Electrical Installation GuideDocument259 pagesElectrical Installation GuideKhemraz RamduthNo ratings yet

- Test Instruments Installations:: For Electrical Accuracy and ConsistencyDocument12 pagesTest Instruments Installations:: For Electrical Accuracy and ConsistencydarkingNo ratings yet

- Motor Troubleshooting and MaintenanceDocument27 pagesMotor Troubleshooting and MaintenanceparabitoNo ratings yet

- Make Your Own Cat5Document8 pagesMake Your Own Cat5sudheerkvbNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 5STR 03T2040Document8 pages5STR 03T2040Vikas PatelNo ratings yet

- Introduction to AMOS - Basic building blocks and getting startedDocument1 pageIntroduction to AMOS - Basic building blocks and getting startedtomo100% (1)

- Mobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Document5 pagesMobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Nicolás Ilich SamusNo ratings yet

- Manual Erie 541NDocument43 pagesManual Erie 541NrichmondinnNo ratings yet

- Indoor Multi-Wall Path Loss Model at 1.93 GHZDocument6 pagesIndoor Multi-Wall Path Loss Model at 1.93 GHZadonniniNo ratings yet

- Astm c243 Withdrawn.31346Document4 pagesAstm c243 Withdrawn.31346SilvioCarrilloNo ratings yet

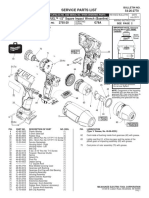

- 2755 22 (G78A) Milwaukee PBDocument2 pages2755 22 (G78A) Milwaukee PBZeckNo ratings yet

- Siebel Coding Best PracticeDocument15 pagesSiebel Coding Best PracticeYi WangNo ratings yet

- SEREP System Equivalent ReductionDocument2 pagesSEREP System Equivalent ReductiondogusNo ratings yet

- UML For Java ProgrammersDocument47 pagesUML For Java ProgrammersRajesh KumarNo ratings yet

- Continental Commercial Vehicle Load TablesDocument6 pagesContinental Commercial Vehicle Load TablesPatricio FNo ratings yet

- Acer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secDocument46 pagesAcer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secIhsan Yusoff IhsanNo ratings yet

- Solid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Document9 pagesSolid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Nikita GonnadeNo ratings yet

- DBMS Lab ExperimentsDocument45 pagesDBMS Lab ExperimentsMad Man100% (1)

- Detailed Analysis of Plane Table SurveyingDocument11 pagesDetailed Analysis of Plane Table SurveyingNirbhay SinghNo ratings yet

- Install and Configure SAPROUTER on IBM iDocument29 pagesInstall and Configure SAPROUTER on IBM iNelida PérezNo ratings yet

- CalibrationDocument7 pagesCalibrationstolen mechieducNo ratings yet

- ID-Operator Guide r2Document138 pagesID-Operator Guide r2Mahdi DehghankarNo ratings yet

- PSC Unit 4 PPT - Part 3Document35 pagesPSC Unit 4 PPT - Part 3Rino VidNo ratings yet

- ABC Vs Acb Phase Seq t60 Get-8431bDocument3 pagesABC Vs Acb Phase Seq t60 Get-8431bkcirrenwodNo ratings yet

- Productdatasheet en or 088423855cDocument1 pageProductdatasheet en or 088423855cpieroNo ratings yet

- SEP2 MeterViewDocument23 pagesSEP2 MeterViewmarcofffmota3196No ratings yet

- Lizmontagens Group ProfileDocument5 pagesLizmontagens Group ProfileRui Carlos Delgado Lopes AlvesNo ratings yet

- FiberHome Introduction (07.12.2015)Document13 pagesFiberHome Introduction (07.12.2015)Sandeep SheetalNo ratings yet

- Quantifying Life Safety Part II - Quantification of Fire Protection SystemsDocument6 pagesQuantifying Life Safety Part II - Quantification of Fire Protection SystemskusumawardatiNo ratings yet

- Equipment Schedule HVACDocument7 pagesEquipment Schedule HVACHussainShabbirNo ratings yet

- Lean & Environment ToolkitDocument96 pagesLean & Environment Toolkittinyplankton100% (7)

- The Autolisp TutorialsDocument285 pagesThe Autolisp Tutorialsmynareshk100% (7)

- Brockcommons Constructionoverview WebDocument28 pagesBrockcommons Constructionoverview WebcauecarromeuNo ratings yet

- IWA SG Global TrendsDocument113 pagesIWA SG Global Trendsandik_yNo ratings yet