Professional Documents

Culture Documents

Engineered Compounding Solutions: BUSS Kneader Technology

Uploaded by

Chinmoy DholeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineered Compounding Solutions: BUSS Kneader Technology

Uploaded by

Chinmoy DholeCopyright:

Available Formats

BUSS Kneader Technology Engineered Compounding Solutions

BUSS KNEADER TECHNOLOGY

APPLICATIONS

02 03

High-end systems for value added Compounds

BUSS Kneader systems set the standard, in particular for demanding heat- and shear-sensitive applications.

Medical grade PVC

Carbon black masterbatch

BUSS Kneader systems, with their unique operating principle, are well proven as first-class machines with excellent references in the plastics, aluminium, chemical and food industries. The polyvalent BUSS Kneader technology is ideal for continuous processes requiring:

> > > > > > >

Calender feeding

> > >

PVC ( rigid, flexible, transparent or filled ) PP, PET TPE

Masterbatches

> > >

mixing fusing plasticizing homogenizing dispersing degassing reacting

Carbon black Filler Additives

Coatings, thermosets

> > > >

Thanks to their process versatility BUSS Kneaders have an extremely successful track record in various industrial applications: Cable compounds

> > > > > > > >

Powder coatings Toners Epoxy moulding compounds Thermosets

Foodstuffs

> > >

Halogen-free flame retardant ( HFFR ) Semiconductives PVC flexible XLPE, peroxide crosslinkable Silane crosslinkable (Sioplas) Telecommunication, foamable Black jacketing Elastomerics

Gum base Chewing gum Chewy sweets

Specialities

> > > > > > > > > > >

PVC pelletizing

> > > > >

Flexible PVC Rigid PVC PVC alloys Chlorinated PVC Wood Plastic Composites

Biopolymers Magnetoplastics Conductive compounds Fluoro polymers Thermoplastic elastomers High-performance plastics Crosslinkable compounds Reactive extrusion Nano composites Anode paste Fluorine chemicals

BUSS KNEADER SERIES

04 05

Success through flexibility

A maximum degree of efficiency in an extremely wide spectrum of applications from anode pastes to thermoplastics, thermosets to elastomers.

MX 105-15F

quantec 96-10C

The BUSS Kneader is a highly versatile compounding system capable of the most demanding mixing tasks. The latest generation of BUSS Kneaders, quantec and MX, represent highly developed machine concepts based on the proven reciprocating screw working principle. quantec Series

> > >

MKS Series

> > >

Thermosets and magnetoplastics EMC (epoxy molding compounds) High-performance plastics

PCS/TCS Series

> >

Powder Coatings Toners

PVC compounds XLPE, peroxide crosslinkable Calender feeding (films, sheets)

LR Series

> > >

MX Series

> > > > >

Foodstuffs Reaction processes Special applications

Cable compounds Semi conductives Flame retardant Masterbatches Silane crosslinkable (Sioplas)

KX Series

>

Anode paste

K_FE Series

>

Fluorine chemicals

TECHNOLOGY

06 07

Great in detail, perfect all-round

Modular construction. Easy to open processing section. Easy cleaning between formulation changes.

MX 105 Process section

Polymers, additives intake Melting, homogenizing Split feeding fillers Mixing, homogenizing Degassing Pressure build-up Screening Pelletizing

Process zones cable compounds set-up

Basic machine design MKS

Machine concept The basic construction of all BUSS Kneader series is similar. The process section and the drive unit are mounted on a compact, integrated base frame. All models feature a temperature-controlled oscillating mixing and kneading screw. The split barrel enables wide opening for easy access. Optimized processing zones Within the processing section several functional regions can be identified. Each of these zones has been integrally evaluated and optimized using mathematical models, and confirmed by laboratory trials and field experience. Polymers, additives and fillers feeding Specific feed devices allow all kinds of bulk solids to be handled and fed at optimal rates. Liquid components are injected directly into the melt through hollow kneading teeth. Melting with dissipative energy input The energy required for melting is dissipated almost entirely by the mixing and kneading screw as shear energy. Split feeding fillers A second feed section, optimized for fillers, is equipped with a rear vent in the barrel. This allows entrained air to naturally escape and higher filler levels and output ratios to be achieved.

Downstream homogenizing with minimal energy input When the remaining fillers are added to the now molten material, the resultant cooling of the melt contributes significantly to keeping the stock temperature low. Following this is a further homogenizing section without any more significant energy input. For particularly critical compounding requirements, another mixing and homogenizing zone can be added. Degassing and transfer to a pressurizing module The final zone of the kneader processing section has a degassing port for removing volatiles and moisture from the melt before it is transferred to the pressurizing module. Pressure build-up for filtration and pelletizing A single-screw discharge extruder or a gear pump, mounted directly to the kneader, efficiently builds up the pressure required for melt filtration and pelletizing. If a discharge extruder is used, it is equipped with an additional venting/degassing port. The two-stage arrangement of BUSS Kneader systems enables independent optimization of the processing and pressurizing sections. This ensures optimal adaptation to the application requirements. Both hot and cold pelletizing systems are available, according to requirements.

TECHNOLOGY

08 09

BUSS Kneader operating principle

Oscillating screw shaft, extremely short processing length, controlled temperature profile.

quantec 96 Process section

max.

Drag flow

s

min.

Screw flight

Kneading bolt n1 = stationary Screw rotation Pressurized flow

Stroke

n2 = turning Product flow similar to roll nip

BUSS Kneader working principle

Advanced 4-flight screw geometry

The BUSS Kneader is a unique compounding extruder. Its distinguishing feature is a special operating principle whereby the screw shaft oscillates axially once per revolution. The characteristic kneading flights of the reciprocating mixing and kneading screw interact in conjunction with each of the stationary kneading teeth in the barrel. This allows for an extremely short processing length. Oscillating screw shaft The oscillating screw shaft ensures simultaneous intensive material exchange in an axial direction by multiple splitting, folding and reorientation of the product. This results in an excellent distributive mixing effect and hence optimal distribution of the raw materials. This is particularly effective when significant differences exist between melt viscosities and melting ranges of the components of the formulation, when liquid components have to be incorporated or high proportions of fibres or fillers need to be added.

Optimal mixing effect The dispersive mixing effect avoids product damaging pressure peaks and high radial pressures. Stress relief is achieved in the matrix after each shear cycle by distribution to neighbouring channels before renewed splitting, folding and reorientation during the next shear cycle. This results in a number of advantages such as:

> > > > > >

Extremely short processing length Uniform shearing effect without temperature peaks Significantly lower product temperatures Precise temperature control Narrow residence time distribution Excellent self-cleaning

OPTIONS

10 11

Increased flexibility with engineered processing options

Specific product input, individual product output the right option for every processing requirement.

BUSS offers a range of technical options tailored to suit the specific task and the associated processing requirements. These options include

>

>

Vertical inlet screw consisting of conveying screw with drive unit, intake guide, lifting and swivelling system fitted to the base frame. Suitable for feeding pellets, chips, powders and fibres.

Injection nozzle with locking pin for attachment to kneader barrel. Suitable for injection of liquid components via a drilled kneading pin with retractable needle valve to prevent back flow of polymer. Vacuum dome with inspection glass for connection to vacuum system.

>

Die plate with cutter

Die face pelletizing system

Intermittent cutting device

>

Vertical connecting tube for cascade configuration between kneader barrel and discharge extruder. Includes vacuum connection and inspection glass. Discharge extruder, linked with connecting tube, consisting of single screw, temperaturecontrolled discharge extruder, barrel temperature controlled by means of heat transfer fluid, base frame with gear reducer and drive unit. Cascade design is specially suitable for production of PVC or elastomers. Discharge extruder, flange-mounted at right angles to kneader barrel, consisting of single screw barrel, temperature controlled by means of heat transfer fluid or electric heating, base frame with gear reducer and drive unit, movable on rails. Especially suitable for production of flame retardants. Discharge pump, flange-mounted to kneader barrel, consisting of gear pump, electrically heated or temperature controlled using heat transfer fluid. Base frame with gear box and drive unit, mounted on movable cart. Especially suitable for low viscosity melts in combination with a screen changer. Screen changer, flange-mounted to discharge pump or discharge extruder. Used according to specific application. Die face pelletizing system, flange-mounted to discharge extruder or melt pump, consisting of heatable die head with die plate, pelletizer cutting assembly and knife motor, pellet collector casing with air, air / water vapour or water connection. Especially suitable for PVC, elastomers, cable compounds and other highly viscous melts or highly filled formulations.

>

>

Underwater pelletizing system, moveable unit, flange-mounted to discharge pump or discharge extruder, consisting of die plate with cutting device and water transport system. Especially suitable for low viscosity and sticky melts. Strand pelletizer system, consisting of a strand die head flange-mounted to discharge extruder or discharge pump, water bath and strand pelletizer. Especially suitable for low viscosity melts. Intermittent cutting device, forms uniformly shaped product pieces from the Kneader. It ensures uniform cutting speeds for both high and low throughputs and helps to ensure smooth control of the filling operation of the calender roller gap, which in turn leads to a better film quality. Pellet cooling and conveying system, cooling and / or drying units for each pelletizing system. Comprising a pellet conveyor, cooling or drying system to suit each process. The pellets are either cooled and /or dried with hot air in a centrifugal chamber, or quenched with water and cooled and / or dried with a centrifugal drier.

>

>

>

>

>

>

>

CONTROLS

12 13

Optimal operation with the right control system

Control systems to meet specific requirements.

BUSS Standard Control

BUSS Basic Control

BUSS Process Control

Flexible choice BUSS offers as many as three different applicationoriented control systems: BUSS Basic Control A simple and self-explanatory control system with all essential functions and information. Based on a state-of-the-art 5.7 TFT touch screen. BUSS Basic Control (BBC) is the perfect user interface for stand-alone machinery. BUSS Standard Control Originally designed for standard use in the plastics industry, BUSS Standard Control (BSC) with its 12 TFT panel and membrane keypad (shortstroke buttons for fast operation) has become increasingly popular for other applications as well. BSC offers all the flexibility required for customized design of production line control systems. BUSS Process Control For complete installations and even entire production plants requiring extensive data transfer and backup, with expandable workstation-based visualization. BUSS Process Control (BPC) is a scaleable concept incorporating extensive trending and archiving options. Almost all known communication interfaces are adaptable to this expandable control system.

Maximal automation All three control concepts are equipped with the latest components available world wide, making updates in response to technical advances and production situations possible at any time. Control components by Siemens and others are used mainly to guarantee both maximum automation know-how and access to services provided by a technology leader. The outstanding competence of BUSS Control engineers, ISO-9001 certified project management as well as an in-house testing laboratory, are further significant advantages from which users may benefit ensuring a maximum degree of process and investment security.

TECHNICAL DATA

14 15

Technical data

Screw diameter

Process length

Max. screw speed [rpm] 750 750 750 750 750 750 750

Max. drive power [kW] 40 55 140 200 350 450 710 unfilled [kg/h] 140 200 280 400 600 900 1200 1700 1800 2600 2800 4000 4600 6500

PVC pelletizing filled [kg/h] 180 250 350 500 700 1000 1400 2000 2100 3000 3500 5000 5600 8000

PVC calendering Films, Sheets [kg/h] * 600 1800 900 2800 1300 4100

Cable compounds XLPE (peroxide) [kg/h] 70 100 140 200 200 300 400 600 700 1000 1100 1500 1400 2000 HFFR [kg/h] Semiconductives [kg/h)

[mm] quantec 40 EV quantec 50 EV quantec 67 EV quantec 80 EV quantec 96 EV quantec 110 EV quantec 129 EV 44 55 72 86 105 121 142

L/D 10 or 15 10 or 15 10 or 15 10 or 15 10 or 15 10 or 15 10 or 15

MX 34 MX 58 MX 80 MX 105 MX 125 MX 140

34 58 80 105 125 140

15 or 22 15 or 22 15 or 22 15 or 22 15 or 22 15 or 22

750 750 750 750 750 750

13 70 140 350 630 980

40 50 180 250 400 600 1000 1400 1800 2500 2500 3500

40 50 180 250 500 650 1000 1400 1800 2500 2500 3500

MKS 30 MKS 55 MKS 70 MKS 100 MKS 140 MKS 200

30 55 70 100 140 200

8 or 20 8 or 20 8 or 20 8 or 20 8 or 20 8 or 20

500 650 650 500 500 500

7.5 65 160 260 650 1200

500 2000 1000 4000

PCS/TCS 30 PLK/MDK 46 PCS/TCS 70 PCS/TCS 100

30 46 70 100

11 or 17 11 or 17 11 or 17 11 or 17

500 600 650 500

5.5 22.5 65 110

LR 100 LR 200 LR 300 LR 400

100 200 300 400

7 or 19 7 or 19 7 or 19 7 or 19

300 250 150 120

50 200 400 500

KX 540 DT KX 650 DT KX 750 DT

540 650 750

9.5 9.5 9.5

75 75 75

400 600 900

K 400 FE K 550 FE

400 550

10 10

30 30

50 150

* Throughput range 1:3

MKS screw section Black masterbatch Silane crosslinkable [kg/h] Powder coatings Toners Thermosets Chewy sweets [kg/h] Chewing gum [kg/h]

LR inlet screw Anode paste Fluorine chemicals

Food applications Gum base [kg/h] Chocolate products [kg/h]

[kg/h]

[kg/h]

[kg/h]

[kg/h]

[t/h]

[t/h]

30 40 180 250 500 650 1100 1500 1800 2600 2500 3600

40 60 250 350 600 850 1300 1900 2200 3200 3200 4500

5 15 50 100 100 200 200 400 400 1000 800 2000

0.3 40 50 450 100 700 300 1500

5 15 30 150 50 300 100 600

24 30 150 190 450 560 960 1200

140 200 700 1200 1600 3300 3000 7000

220 280 1100 1400 2800 3500

320 400 1600 2000 4100 5100 8000 10000

20 40 35 60 54 90

8 12 15 23

WWW.BUSSCORP.COM

Buss AG Hohenrainstrasse 10 4133 Pratteln Switzerland Phone +41 61 825 66 00 Fax +41 61 825 68 58 info@busscorp.com www.busscorp.com Buss, Inc. USA 455 Kehoe Boulevard, Suite 109 Carol Stream, IL 60188 USA Phone +1 630 933 9100 Fax +1 630 933 0400 info.us@busscorp.com www.busscorp.com Buss Japan Ltd. Wakura Building 702, 1-5, Fukagawa 1 chome Koto-ku, Tokyo 135-0033 Japan Phone +81 3 5646 7611 Fax +81 3 5646 7612 info.jp@busscorp.com www.busscorp.com

Buss Asia Pacific Pte. Ltd. 190 Middle Road #20-01 Fortune Centre Singapore 188979 Phone +65 6837 3768 Fax +65 6837 3769 info.sg@busscorp.com www.busscorp.com Buss AG Shanghai Representative Office Room 904, Evergo Plaza 1325 Middle Huaihai Road Xuhui District, Shanghai 200031 PRC Phone +86 21 64339233 Fax +86 21 64332793 info.cn@busscorp.com www.busscorp.com Buss UK Ltd. Unit T, The Holt St Pauls Trading Estate Huddersfield Road, Stalybridge Cheshire SK15 3DN, England Phone +44 161 338 33 33 Fax +44 161 338 33 33 info.uk@busscorp.com www.busscorp.com

Buss Service-Hotline +41 61 821 00 00

34EN / 06-10-10 / concept by www.stier.ch

You might also like

- CIT PVC ProcessingDocument45 pagesCIT PVC ProcessingThao Nguyen Van100% (1)

- Plastics Additives InfoDocument58 pagesPlastics Additives InfoFranzMigNo ratings yet

- First Internal Question & Answer For Plastic ProcessingDocument17 pagesFirst Internal Question & Answer For Plastic ProcessingSupreeth PremkumarNo ratings yet

- Pelletizing Process PDFDocument8 pagesPelletizing Process PDFAbdulhakeemSolimanNo ratings yet

- Dynasylan For Mineral Fillers and Pigments enDocument28 pagesDynasylan For Mineral Fillers and Pigments enForeverNo ratings yet

- SAN & ABS Polymers GuideDocument9 pagesSAN & ABS Polymers GuideSdkmega HhNo ratings yet

- The Essential Ingredients in A PVC Formulation AreDocument7 pagesThe Essential Ingredients in A PVC Formulation AreRicky DavisNo ratings yet

- Compounding Additives: in This ChapterDocument17 pagesCompounding Additives: in This Chaptermonalihania100% (1)

- EP2566920A2 - Super-Soft Thermoplastic Elastomers - Google Patents PDFDocument20 pagesEP2566920A2 - Super-Soft Thermoplastic Elastomers - Google Patents PDFSimas ServutasNo ratings yet

- PVC PLasticisersDocument2 pagesPVC PLasticisersKrishna PrasadNo ratings yet

- The Pultrusion Process PDFDocument2 pagesThe Pultrusion Process PDFSan SvsNo ratings yet

- Additives: Fully CompoundedDocument4 pagesAdditives: Fully CompoundedVy ThoaiNo ratings yet

- Flame and Smoke in Vinyl Chloride Polymers  " Commercial Usage and Current DevelopmentsDocument25 pagesFlame and Smoke in Vinyl Chloride Polymers  " Commercial Usage and Current Developmentsabilio_j_vieiraNo ratings yet

- Additives and CompoundingDocument117 pagesAdditives and CompoundingShubham ChaudharyNo ratings yet

- BoPET Applications 2016Document32 pagesBoPET Applications 2016SHRIPAD AMATENo ratings yet

- AdditivesDocument62 pagesAdditivesMohsin Alam100% (1)

- Plastics AdditivesDocument95 pagesPlastics AdditivesJose Castro100% (1)

- A Guide To Thermoplastic Polyurethanes (TPU)Document26 pagesA Guide To Thermoplastic Polyurethanes (TPU)camb1967No ratings yet

- Final1 Additive StandardsDocument16 pagesFinal1 Additive StandardsmohammedNo ratings yet

- Lecture - 15 Additives and CompoundingDocument34 pagesLecture - 15 Additives and CompoundingK.Raghavendra100% (1)

- Technology of PVC Compounding and Its ApplicationsDocument21 pagesTechnology of PVC Compounding and Its ApplicationsBibhu Ranjan Bihari100% (1)

- AdditivesDocument148 pagesAdditivesAkash Yadav100% (2)

- Baerlocher PVC Stabilisers Asian Technical Seminar 2013Document37 pagesBaerlocher PVC Stabilisers Asian Technical Seminar 2013Jen Chavez100% (1)

- PVC Technology: Chapter 11Document80 pagesPVC Technology: Chapter 11Andri0% (1)

- Compounding World June2012Document58 pagesCompounding World June2012Clint FosterNo ratings yet

- 1304 SSchoenfeld Kiev Sofia Applications enDocument55 pages1304 SSchoenfeld Kiev Sofia Applications enHiếu Mai ĐứcNo ratings yet

- Seminar-2 Rubber Compression MoldingDocument11 pagesSeminar-2 Rubber Compression MoldingSwapnil Ahire50% (2)

- Unit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentDocument13 pagesUnit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentSaisurendra VeerlaNo ratings yet

- TPU Drying GuideDocument16 pagesTPU Drying GuideBang QuachNo ratings yet

- InTech Thermoplastic ElastomersDocument19 pagesInTech Thermoplastic ElastomersRajeev Singh BaisNo ratings yet

- Extrusion Coating Substrates GuideDocument17 pagesExtrusion Coating Substrates GuidecehigueraNo ratings yet

- Solvent Cast Technology - A Versatile ToolDocument14 pagesSolvent Cast Technology - A Versatile ToolsggdgdNo ratings yet

- De AssignmentDocument9 pagesDe AssignmentManish MohapatraNo ratings yet

- CompoundingDocument39 pagesCompoundingratanjeet pratap singhNo ratings yet

- Thermal Stabilizers For PVC A ReviewDocument8 pagesThermal Stabilizers For PVC A ReviewDarshan ShahNo ratings yet

- Compounding of PlasticsDocument3 pagesCompounding of PlasticsslchemNo ratings yet

- PlasticizersDocument19 pagesPlasticizersPathik ShahNo ratings yet

- Sb2o3 Ath PVCDocument6 pagesSb2o3 Ath PVCnilayNo ratings yet

- Guide To Resin SystemsDocument9 pagesGuide To Resin SystemsDaud Simon A100% (1)

- RIGID PVC EXTRUSION Sigle Vs Twin Screw ExtrudersDocument3 pagesRIGID PVC EXTRUSION Sigle Vs Twin Screw ExtrudersJuan David Melián Cruz100% (1)

- BlendsDocument106 pagesBlendsAnish Kumar100% (1)

- Polymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic ResinsDocument27 pagesPolymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic Resinsgidlavinay100% (1)

- Desiccant MasterbatchDocument1 pageDesiccant MasterbatchNguyen Xuan GiangNo ratings yet

- Polymer Additives: Fillers & ReinforcementsDocument5 pagesPolymer Additives: Fillers & ReinforcementsHina IbrahimNo ratings yet

- Twin ExtruderDocument20 pagesTwin ExtruderSalem GarrabNo ratings yet

- PVC Technology: Chapter 4Document37 pagesPVC Technology: Chapter 4AndriNo ratings yet

- Effect of Stabilizers On Properties of PVC (Polymer) 1Document52 pagesEffect of Stabilizers On Properties of PVC (Polymer) 1DIPAK VINAYAK SHIRBHATE100% (5)

- BASF - Masterbatch Conference Teheran FinalDocument25 pagesBASF - Masterbatch Conference Teheran Finaljaviera1983No ratings yet

- Basics of Polymers Fabrication and Processing TechnologyDocument108 pagesBasics of Polymers Fabrication and Processing TechnologyneftNo ratings yet

- Reactive ExtrusionDocument19 pagesReactive ExtrusionEetu SatosalmiNo ratings yet

- 19.02.additives For PlasticsDocument61 pages19.02.additives For Plasticsjraman24No ratings yet

- Micro Molding Vacuum Venting BenefitsDocument21 pagesMicro Molding Vacuum Venting BenefitsvenkithankamNo ratings yet

- Purging and Cleaning Screws and Barrels for Plastics ProductionDocument6 pagesPurging and Cleaning Screws and Barrels for Plastics ProductionRodolfoAntonioLeónCárdenasNo ratings yet

- Brochure Carbon Additives For PolymersDocument24 pagesBrochure Carbon Additives For PolymersTUNGNo ratings yet

- PC Makrolon 2405 - 2407 - 2456-DatasheetDocument4 pagesPC Makrolon 2405 - 2407 - 2456-DatasheetNhox Xu0% (1)

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975From EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovRating: 5 out of 5 stars5/5 (1)

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- Coatings and InksDocument50 pagesCoatings and InksAndrew KellyNo ratings yet

- CNT From Waste PlasticDocument7 pagesCNT From Waste PlasticChinmoy DholeNo ratings yet

- To Control Stability and Compatibility of Pigment PastesDocument3 pagesTo Control Stability and Compatibility of Pigment PastesChinmoy DholeNo ratings yet

- Offset Ink Good 2Document34 pagesOffset Ink Good 2Chinmoy DholeNo ratings yet

- Black Pearls® 5160 Specialty Carbon BlackDocument3 pagesBlack Pearls® 5160 Specialty Carbon BlackChinmoy DholeNo ratings yet

- Borchi Gen 0851 Product Page ArticleDocument4 pagesBorchi Gen 0851 Product Page ArticleChinmoy DholeNo ratings yet

- CB MFG ProcessDocument35 pagesCB MFG ProcessChinmoy DholeNo ratings yet

- 01 KuttlerDocument81 pages01 KuttlerAhmad Ma'rupNo ratings yet

- Inks For Printing On Plastic FilmsDocument8 pagesInks For Printing On Plastic FilmsLucas Del PretteNo ratings yet

- TDS Byk-C 8013 enDocument2 pagesTDS Byk-C 8013 enChinmoy DholeNo ratings yet

- Carbon Black Production Analyzing and CharacterizationDocument86 pagesCarbon Black Production Analyzing and CharacterizationabdulqadirNo ratings yet

- Paraloid™ Dm-55: Solid Grade Thermoplastic Acrylic ResinDocument5 pagesParaloid™ Dm-55: Solid Grade Thermoplastic Acrylic ResinChinmoy DholeNo ratings yet

- Carbon-Black-Orion ListDocument4 pagesCarbon-Black-Orion ListChinmoy DholeNo ratings yet

- Brochure Specialty Carbon Blacks For Plastic Film and Sheet ApplicationsDocument12 pagesBrochure Specialty Carbon Blacks For Plastic Film and Sheet ApplicationsXuan Giang NguyenNo ratings yet

- Gasification Cabot PatentDocument19 pagesGasification Cabot PatentChinmoy DholeNo ratings yet

- Binders For Industrial SpreadsDocument17 pagesBinders For Industrial SpreadsnatashayukafastianaNo ratings yet

- B Mr. Prashant Agarwal WazirDocument20 pagesB Mr. Prashant Agarwal WazirChinmoy DholeNo ratings yet

- TSE of CNT in PP - Process ConditionsDocument8 pagesTSE of CNT in PP - Process ConditionsChinmoy DholeNo ratings yet

- Entrepreneur Magazine-April 2013 PDFDocument128 pagesEntrepreneur Magazine-April 2013 PDFChinmoy DholeNo ratings yet

- Clariant Antistatic AgentsDocument20 pagesClariant Antistatic AgentsJose Bustos100% (1)

- Offset Ink Very GoodDocument99 pagesOffset Ink Very GoodChinmoy DholeNo ratings yet

- Offset Ink Good 2Document34 pagesOffset Ink Good 2Chinmoy DholeNo ratings yet

- D Mr. Steve Jenkins PCIDocument22 pagesD Mr. Steve Jenkins PCIChinmoy DholeNo ratings yet

- Plastics ProcessingDocument5 pagesPlastics ProcessingChinmoy DholeNo ratings yet

- 30 Seconds That Can Change Your Life: A Decision-Making Guide For Those Who Refuse To Be MediocreDocument155 pages30 Seconds That Can Change Your Life: A Decision-Making Guide For Those Who Refuse To Be Mediocrehenry95366No ratings yet

- Mental StrengthDocument9 pagesMental StrengthChinmoy DholeNo ratings yet

- 44 Ways To KickDocument8 pages44 Ways To KickChinmoy DholeNo ratings yet

- Engineering Plastics: Product Guide For Design EngineersDocument88 pagesEngineering Plastics: Product Guide For Design Engineersrossifam777No ratings yet

- Best Business BooksDocument40 pagesBest Business BooksChinmoy DholeNo ratings yet

- Additive MasterbatchesDocument4 pagesAdditive MasterbatchesChinmoy DholeNo ratings yet

- Hit-Re 500 With Hit-V Has RodsDocument3 pagesHit-Re 500 With Hit-V Has RodsMKNo ratings yet

- Manual Servicio SubaruDocument5,963 pagesManual Servicio SubaruCristian Mauricio Alarcon RojasNo ratings yet

- CUCM Intracluster Port Usage GuideDocument3 pagesCUCM Intracluster Port Usage GuideAbhinayMylavarapuNo ratings yet

- Velp ZX3 Vortex PDFDocument5 pagesVelp ZX3 Vortex PDFarodassanchez0% (1)

- Instructions pour pied SeniorDocument52 pagesInstructions pour pied SeniorPriyanka PatilNo ratings yet

- Coco Press KitDocument55 pagesCoco Press KitPaula RiddenNo ratings yet

- Engine & Transmission ToolsDocument45 pagesEngine & Transmission Toolsabduallah muhammad100% (1)

- DiodeDocument22 pagesDiodeSaurabh Mittal100% (1)

- Lithography GuideDocument29 pagesLithography GuidezanibtahiraNo ratings yet

- Catálogo King LaiDocument144 pagesCatálogo King LaiJason Salas FloresNo ratings yet

- Support Orca3D HelpDocument281 pagesSupport Orca3D Helplavrik100% (1)

- Dewatering SystemDocument124 pagesDewatering SystemSpyros NannosNo ratings yet

- Foxpro For O LevelDocument3 pagesFoxpro For O LevelShiv PathakNo ratings yet

- Mixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Document84 pagesMixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Masayu MYusoffNo ratings yet

- SHB 2503-3703 en 1000081433Document192 pagesSHB 2503-3703 en 1000081433Alberto100% (1)

- QUS 303 CONSTRUCTION ECONOMICSDocument21 pagesQUS 303 CONSTRUCTION ECONOMICSjudexnams1on1No ratings yet

- Achievements Under EpiraDocument6 pagesAchievements Under EpiraLyn Dela Cruz DumoNo ratings yet

- GD&T Training Levels and ServicesDocument1 pageGD&T Training Levels and ServicesdramiltNo ratings yet

- Micron Ezeprox Access Control KeypadDocument4 pagesMicron Ezeprox Access Control KeypadThuy VuNo ratings yet

- Studio GPGL LogDocument5 pagesStudio GPGL LogCarlos Julian LemusNo ratings yet

- Alketerge EDocument4 pagesAlketerge EYohanes OktavianusNo ratings yet

- P1 Conservation and Dissipation of Energy Student Book AnswersDocument11 pagesP1 Conservation and Dissipation of Energy Student Book AnswersjoeNo ratings yet

- Solar TrackerDocument13 pagesSolar TrackerMuthuRajNo ratings yet

- Correlation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaDocument5 pagesCorrelation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaShakeel AhmadNo ratings yet

- Duet CE-3301 Geotechnical Engineering - IDocument37 pagesDuet CE-3301 Geotechnical Engineering - IShekh Muhsen Uddin AhmedNo ratings yet

- DR System ConciseDocument37 pagesDR System ConciseJiten KarmakarNo ratings yet

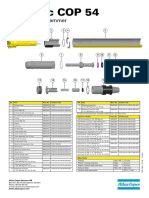

- 9853 1239 01 - COP 54 Service Poster - LOWDocument1 page9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasNo ratings yet

- Sad Thesis Guidelines FinalsDocument13 pagesSad Thesis Guidelines FinalsJes RamosNo ratings yet

- GOT2000 - UserManual Monitor - SH 081196 I PDFDocument614 pagesGOT2000 - UserManual Monitor - SH 081196 I PDFFanny Achmad Hindrarta KusumaNo ratings yet

- Brochure 45 AntasariDocument11 pagesBrochure 45 AntasariFisio Terapi100% (1)