Professional Documents

Culture Documents

Wps For Smaw06-001 (Pipe 6g CS)

Uploaded by

walitedisonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps For Smaw06-001 (Pipe 6g CS)

Uploaded by

walitedisonCopyright:

Available Formats

CONSOLIDATED TRAINING SYSTEMS, INC.

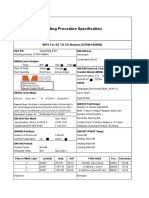

WELDING PROCEDURE SPECIFICATION (WPS) WPS NO WELDING PROCESS MANUAL OR MACHINE POSITION OF WELDING FILLER METAL SPECIFICATION FILLER METAL CLASIFICATION TRADE/ BRAND NAME BASE METAL GROUP SPECIFICATION THICKNESS RANGE BASE METAL Groove 3mm to 23mm 25mm and above Fillet Fillet FLOWRATE MULTIPASS SINGLE DC DCSP & DCRP UPHILL STRING & WEAVE See Note on p.2 See Note on p.2 Wire Brushing, Minor Grinding at every weld restart Gas cut, Machined bevel ends 4 equidistant Tack welds. Removed as weld progressses See JOINT DETAIL @ p2 BACKING NONE POSTHEAT N/A ALL ALL N/A PIPE D RANGE Groove FLUX/SHIELDING GAS SINGLE OR MULTIPASS SINGLE OR MULTIPLE ARC WELDING CURRENT POLARITY WELDING PROGRESSION WELDING TECHNIQUE PRE HEAT TEMP INTERPASS TEMP CLEANING METHODS BASE METAL PREPARATION JOINT ALIGNMENT JOINT DESIGN W01 P1 Gr1 to P1-Gr2 HL-045 B E 42-4 B42 H5 UNITOR LH 314 N CTWP-06-001 111 SMAW MANUAL 6G BASIC AWS E 7018 F NO A NO 4 1

Low carbon,unalloyed steels, low alloyed steels,

inccluding fine-grade structural steels

WELDING PROCEDURE WELD PASS ROOT HOT FILL CAPPING CAPPING CAPPING WELD PROCESS SMAW SMAW SMAW SMAW SMAW SMAW FILLER METAL CLASS E-7018 E-7018 E-7018 E-7018 E-7018 E-7018 DIA 2.5mm 2.5mm 3.2mm 3.2mm 3.2mm 3.2mm CURRENT POLARITY DCSP DCRP DCRP DCRP DCRP DCRP AMPS RANGE 75-85 95-140 95-140 95-125 95-125 95-125 RANGE 12-16 22-28 22-27 22-28 22-28 22-28 RANGE 3-5 IPM 4-7 IPM 3-6 IPM 3-6 IPM 3-6 IPM 3-6 IPM VOLT TRAVEL SPEED

WPS NO

CTWP-06-001

REV

CONTRACTOR

Consolidated Training Systems Inc

Page 1

WPS FOR SMAW06-001(PIPE 6G CS)

CONSOLIDATED TRAINING SYSTEMS, INC.

WELDING PROCEDURE SPECIFICATION (WPS)

Bevel JOINT DETAILS A) Root Gap 2.5mm - 3.0mm B) Root Face 1.0mm - 1.5mm C) Bevel 35 -37.5 angle

Bevel

Thickness

D)Thickness 11mm Root Face Root Gap

Root pass Hot pass 45 Fill pass Cap 3 Cap 1 Cap 3 2 nd pass

6G Position

PreHeat Temperatures A) Up to 3/4" B) Over 3/4" thru 1 1/2" C) Over 1 1/2" thru 2 1/2" D) Over 2 1/2" 50 f Min 150 F Min 225 F Min 300 F Min

Interpass Temperatures =500 F Min

WPS NO

CTWP-06-001

REV

CONTRACTOR Consolidated Training Systems Inc

CONSOLIDATED TRAINING SYSTEMS, INC.

PROCEDURE QUALIFICATION RECORD (PQR) WPS NO WELDING PROCESS MANUAL OR MACHINE POSITION OF WELDING FILLER METAL SPECIFICATION FILLER METAL CLASIFICATION TRADE/ BRAND NAME BASE METAL GROUP SPECIFICATION THICKNESS RANGE BASE METAL PIPE D.Range FLUX/SHIELDING GAS SINGLE OR MULTIPASS SINGLE OR MULTIPLE ARC WELDING CURRENT POLARITY WELDING PROGRESSION WELDING TECHNIQUE PRE HEAT TEMP INTERPASS TEMP CLEANING METHODS BASE METAL PREPARATION JOINT ALIGNMENT JOINT DESIGN RECORD ACTUAL VALUES RECORD ACTUAL VALUES Wire Brushing, Minor Grinding at every weld restart Gas cut, Machined bevel ends 4 equidistant Tack welds. Removed as weld progressses See JOINT DETAILS/ BACKING Groove RECORD ACTUAL VALUES Groove RECORD ACTUAL VALUES Fillet Fillet FLOWRATE RECORD ACTUAL VALUES RECORD ACTUAL VALUES RECORD ACTUAL VALUES RECORD ACTUAL VALUES RECORD ACTUAL VALUES RECORD ACTUAL VALUES POSTHEAT N/A W01 Low carbon,unalloyed steels, low alloyed steels, inccluding fine-grade structural steels HL-045 B E 42-4 B42 H5 UNITOR LH 314 N CTWP-06-001 111 PQR NO SMAW MANUAL 6G BASIC AWS E 7018 F NO A NO 4 1 CTQR-06-001

WELDING PROCEDURE WELD PASS WELD PROCESS FILLER METAL CLASS DIA POLARITY CURRENT AMPS RANGE RECORD ACTUAL VALUES RECORD ACTUAL VALUES RECORD ACTUAL VALUES RECORD ACTUAL VALUES RECORD ACTUAL VALUES RANGE RANGE VOLT TRAVEL SPEED

WPS NO

CTWP-06-001

REV

CONTRACTOR Consolidated Training Systems Inc

TRAVEL SPEED

CONSOLIDATED TRAINING SYSTEMS, INC.

PROCEDURE QUALIFICATION RECORD (PQR) WPS NO CTWP-06-001 PQR NO CTQR-06-001

TENSILE TEST RESULT

SPECIMEN ID T1 T2

WIDTH mm

THICKNESS mm

AREA sq mm

YIELD LOAD

STRESS

ULTIMATE LOAD

STRESS

ELONGATION %

GUIDED BEND TEST RESULT

IDENTIFICATION

ROOT 1 ROOT 2 FACE 1 FACE 2

RESULT

IDENTIFICATION

SIDE 1 SIDE 2

IMPACT TOUGHNESS TEST (CHARPY)

FILLET WELD TEST

SPECIMEN ID T1 T2

SIZE mm

NOTCH LOCATION

TEST TEMP(C)

IMPACT VALUES

RESULT SATISFACTORY PENETRATION INTO PARENT METAL MACRO RESULTS

YES YES

HARDNESS TEST RESULT (CHARPY)

(see attached result)

PARENT METAL WELD METAL HAZ

AVE AVE AVE

HI HI HI

LOW LOW LOW

WELDERS NAME

Test Conducted By

LAB TEST NO

FAILURE LOCATION

RESULT

LLET WELD TEST

NO NO

LAB TEST NO

You might also like

- Welding Qusetion and AnswersDocument9 pagesWelding Qusetion and AnswersSunil100% (1)

- Larsen & Toubro underground piping inspection planDocument4 pagesLarsen & Toubro underground piping inspection planBhavani PrasadNo ratings yet

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionDocument5 pagesPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- Saudi Aramco Welding Consumables ChecklistDocument5 pagesSaudi Aramco Welding Consumables ChecklistAnsuman KalidasNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- Mahle Air Filter Clearner Assy For ELGIDocument7 pagesMahle Air Filter Clearner Assy For ELGISurajPandey0% (1)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Manufacturing Process of Piston Rings and Cylinder LinersDocument26 pagesManufacturing Process of Piston Rings and Cylinder Linersanish jain100% (6)

- Hydrostatic Test Procedure PDFDocument2 pagesHydrostatic Test Procedure PDFLuis Pullas86% (43)

- Inspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDocument9 pagesInspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDelta akathehuskyNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- MATERIAL SUBMITTAL FOR PLASTER & BLOCK ACCESSORIESDocument106 pagesMATERIAL SUBMITTAL FOR PLASTER & BLOCK ACCESSORIESJason RazatlabNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Sae Ams 5387Document8 pagesSae Ams 5387desingbuschprojectsNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Limit GaugesDocument68 pagesLimit Gaugesaneesh19inNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Project quality control form QCF307Document1 pageProject quality control form QCF307minhnnNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationGodwin A.udo-akanNo ratings yet

- Welder Visual Inspection ReportsDocument24 pagesWelder Visual Inspection ReportsKyNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Glossary of Furnace TermsDocument7 pagesGlossary of Furnace TermsMohsin Raza MaitlaNo ratings yet

- ASME BPVC.IX performance thickness limitsDocument1 pageASME BPVC.IX performance thickness limitskumar100% (2)

- Installation of Tripper Gallery PWIDocument14 pagesInstallation of Tripper Gallery PWIwalitedisonNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- Ayari Maher: Qualified Welder I.D.CardDocument10 pagesAyari Maher: Qualified Welder I.D.CardZouhair BenmabroukNo ratings yet

- WPS for SS to CS WeldingDocument1 pageWPS for SS to CS WeldingLipika GayenNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Wps Pip Gtaw - ArabianDocument1 pageWps Pip Gtaw - ArabianIshack MohammedNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- QC FORMDocument3 pagesQC FORMRicardo LourençoNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Welder Qualification Register 01Document3 pagesWelder Qualification Register 01Andrei UrsacheNo ratings yet

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Document2 pagesSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Welder qualification test recordDocument3 pagesWelder qualification test recordTuTuy AnNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- Inspection Report - ValvesDocument2 pagesInspection Report - ValvesJaspal KaurNo ratings yet

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocument2 pagesFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- Valve List Test LimitDocument37 pagesValve List Test LimitwalitedisonNo ratings yet

- Senior Welding InspectorDocument1 pageSenior Welding InspectorwalitedisonNo ratings yet

- Boiler and Piping ToolsDocument4 pagesBoiler and Piping ToolswalitedisonNo ratings yet

- List of Inspection Report For Turnover Package For WWTDocument1 pageList of Inspection Report For Turnover Package For WWTwalitedisonNo ratings yet

- T0rque Value of A193 B7Document2 pagesT0rque Value of A193 B7walitedisonNo ratings yet

- Final Alignment Monitoring ReportDocument2 pagesFinal Alignment Monitoring ReportwalitedisonNo ratings yet

- Yuhan Welder List - Nov.22017Document1 pageYuhan Welder List - Nov.22017walitedisonNo ratings yet

- Gag For Pressure Safety Valve JimCaseyDocument1 pageGag For Pressure Safety Valve JimCaseywalitedisonNo ratings yet

- Final Alignment Monitoring ReportDocument2 pagesFinal Alignment Monitoring ReportwalitedisonNo ratings yet

- T0rque Value of A193 B7Document2 pagesT0rque Value of A193 B7walitedisonNo ratings yet

- Yuhan Welder List - Nov.22017 PDFDocument2 pagesYuhan Welder List - Nov.22017 PDFwalitedisonNo ratings yet

- Woolim Welder List - Oct.302017Document1 pageWoolim Welder List - Oct.302017walitedisonNo ratings yet

- Yuhan Welder List - Nov.22017Document2 pagesYuhan Welder List - Nov.22017walitedisonNo ratings yet

- Yuhan Welder List - Oct.312017Document3 pagesYuhan Welder List - Oct.312017walitedisonNo ratings yet

- Review of Radiographic Examination ReportDocument1 pageReview of Radiographic Examination ReportwalitedisonNo ratings yet

- AGP Welder List - Nov.032017Document7 pagesAGP Welder List - Nov.032017walitedisonNo ratings yet

- Welding Properties and Chemical Composition SelectionDocument84 pagesWelding Properties and Chemical Composition SelectionwalitedisonNo ratings yet

- NDT TrainingDocument1 pageNDT TrainingwalitedisonNo ratings yet

- Tension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMDocument4 pagesTension Test Plate: G-Gage Length W-Width 200 0.25 MM 40 +3 - 6 MMwalitedisonNo ratings yet

- Steel Material Thickness RequestDocument1 pageSteel Material Thickness RequestwalitedisonNo ratings yet

- B31.1 Nde RequirementsDocument1 pageB31.1 Nde RequirementswalitedisonNo ratings yet

- Ut Formate1Document187 pagesUt Formate1walitedisonNo ratings yet

- Xwell StickerDocument1 pageXwell StickerwalitedisonNo ratings yet

- Correct Welding of Main Steam LineDocument2 pagesCorrect Welding of Main Steam LinewalitedisonNo ratings yet

- Xwell StickerDocument1 pageXwell StickerwalitedisonNo ratings yet

- Equipment Inventory SummaryDocument16 pagesEquipment Inventory SummarywalitedisonNo ratings yet

- NDT Advantage and DisadvantageDocument4 pagesNDT Advantage and DisadvantagewalitedisonNo ratings yet

- Review of Radiographic Examination ReportDocument1 pageReview of Radiographic Examination ReportwalitedisonNo ratings yet

- Vol 1 PDFDocument2 pagesVol 1 PDFأبومحمدالزياتNo ratings yet

- Bt2-Module 4Document26 pagesBt2-Module 4Oira, Maica ShaneNo ratings yet

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaNo ratings yet

- Welder Qualification Radiography Acceptance CriteriaDocument2 pagesWelder Qualification Radiography Acceptance CriteriaKamalnath KpNo ratings yet

- To Study The Mechanical Properties of Mild Steel After Heat Treatment ProcessesDocument58 pagesTo Study The Mechanical Properties of Mild Steel After Heat Treatment ProcessesRISHAVNo ratings yet

- Aws Er70sDocument4 pagesAws Er70smanofNo ratings yet

- Quench Towers Monroe EnvironmentalDocument2 pagesQuench Towers Monroe EnvironmentalmalikaNo ratings yet

- AkzoNobel - QN102QF - Interpon ACE 2000Document3 pagesAkzoNobel - QN102QF - Interpon ACE 2000Eslam FaroukNo ratings yet

- Mastertop 1120tDocument3 pagesMastertop 1120themajsuryaNo ratings yet

- Guide Lines For Discontinued ProductsDocument6 pagesGuide Lines For Discontinued ProductsJodyNo ratings yet

- LEVAPOR - IFAS Upgrade of Activated Sludge ProcessDocument1 pageLEVAPOR - IFAS Upgrade of Activated Sludge ProcessAmit ChristianNo ratings yet

- 1 - CBT Welding NDT 26 02 2020 - Ans and ExplanetionDocument27 pages1 - CBT Welding NDT 26 02 2020 - Ans and ExplanetionAMALENDU PAULNo ratings yet

- 3M ASD Catalogue 2011Document93 pages3M ASD Catalogue 2011burraganeshNo ratings yet

- Customer: Camfil Farr Air Filtration (I) LTD Project: RINL - VIZAG Product: Air Filter System For Turbo Blower Camfil Drg. No.: 604631Document4 pagesCustomer: Camfil Farr Air Filtration (I) LTD Project: RINL - VIZAG Product: Air Filter System For Turbo Blower Camfil Drg. No.: 604631Trilok Singh TakuliNo ratings yet

- AFCONA-3570 chemical composition and propertiesDocument1 pageAFCONA-3570 chemical composition and propertiesSantosh RajNo ratings yet

- Powercrete R-65/F1: Product Data SheetDocument2 pagesPowercrete R-65/F1: Product Data SheetFernando Ytozu TairaNo ratings yet

- Practical 4 WeldingDocument7 pagesPractical 4 WeldingSyamira ZakariaNo ratings yet

- C0832332 PDFDocument10 pagesC0832332 PDFrahil_sangNo ratings yet

- 5 6Y-3607 - Valve GP Controll 1 380358 10/mar/21 22-Mar-21 SGP, 4daysDocument2 pages5 6Y-3607 - Valve GP Controll 1 380358 10/mar/21 22-Mar-21 SGP, 4daysmahmuda levianiNo ratings yet

- PWII 350 Profile Wrapping Application HeadDocument2 pagesPWII 350 Profile Wrapping Application HeadNordson Adhesive Dispensing SystemsNo ratings yet

- Product Elastakote Oct18Document1 pageProduct Elastakote Oct18DWI RAHMASARI FATMAWATINo ratings yet

- Solderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MDocument1 pageSolderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MBernardo LeorNo ratings yet

- Lime Kiln Gasification General - 2012Document18 pagesLime Kiln Gasification General - 2012DiogoNo ratings yet