Professional Documents

Culture Documents

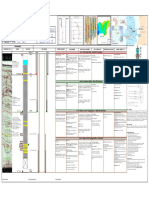

Relief Well Planning Checklist

Uploaded by

byedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Relief Well Planning Checklist

Uploaded by

byedCopyright:

Available Formats

OG-UK: Complexity assessment input data - checklist

Yes / No 1) Reservoir data estimated bottomhole pressure range; temperature profile; estimated reservoir fluid (i.e. gas, condensate, oil, or water); presence and concentration of H2S or CO2; estimated fluid PVT properties; and estimated worst case flow rates (from OPEP oil spill modelling analysis). 2) Well data well type (e.g. NPNT, HPHT, deepwater); planned casing setting depths and cement tops; planned casing weights and grades; wellhead details; drilling hazards from offset analysis; directional plan; close approach wells and collision risks; planned drilling fluid type and weight; estimated geological column pore pressure from seabed to total depth (TD); estimated formation type and strength from seabed to TD; planned completion details (including sandface completion type); and planned perforation intervals. 3) Additional well data: existing wells drilling hazards encountered when drilling the subject or offset wells; well integrity data; drilling and completion fluid types, weight and properties; completion details; and details of any fish, casing defects or sidetracks. 4) Well location - seabed & metocean related issue possible relief well seabed locations and minimum allowable distance from the blowout well; proximity to shipping lanes; proximity to existing infrastructure, including assets owned by others; proximity to shallow gas accumulations and subsurface hazards; and wind, wave, and metocean conditions. 5) Relief well directional plan potential intersect points with the blowout well; directional drilling complexity, including dogleg severity; and anti-collision considerations

6) Relief well design casing setting depths and sizes; mud weights and types; and potential drilling problems and mitigation strategies. 7) Equipment availability Rig availability - availablility of suitable relief well rigs? Rig status Casing availability - availability of csg sizes, weights, and grades? Wellhead availability - wellhead components readily available? Specialist equipment - e.g. ranging tools and pumping spreads?

Complexity Assessment - need to identify the degree of complexity assoc w/ relief well planning & execution Capable of natural flow: Reservoir formation fluids: Reservoir fluids contaminants: (H2S/CO2) Well locations: Weather: (potential weather impact & metocean conditions) Water depth: (Rig limitation) High bottomhole pressure and temperature: Offset well locations: (nearby wells - collision issues) Offset well analysis: (potential drilling related issues) Casing and wellhead design: (readily available?) Kill complexity: (pumping rate / properties of kill fluid / pumping arrangement)

Results of complexity assessment 1) Basic relief well - complexity associated with planning and / or executing relief well (Low to Medium) not necessary to generate a detailed relief well plan as long as:"- required long lead contigency equipment is in stock / readily sourced 2) Complex relief well - complexity associated with planning and / or executing relief well (High) necessary to generate a detailed relief well plan prior spud

Basic Relief Wells 1) Site survey Shallow seismic site survey at potential relief well location (for shallow gas identification) If jackup selected, need to consider jackup positioning site survey Seabed hazard & bathymetry survey during well rig mobilization period 2) Relief well seabed location selection Identify exclusion zone - based on current & wind patterns, volume & type of anticipated reservoir fluids Shallow gas hazards and bathymetry: - identify & avoid shallow gas hazard Seabed hazards and obstacles: - existing wells, manifolds, pipelines & other hazards Mooring plan: anchor location Gas hazard from blowout well: - to avoid high concentration of H2s / CO2 3) Intersection point a) Top of reservoir there's a drill string / Csg is across the intercept point most likely scenario for Completed wells If intersect point is opposite the casing, cemented section of casing should be selected b) deepest casing shoe there's a open hole and drill string is either out of hole or above csg shoe when blowout occurs ** for all relief wells, its essential that there's ferrous material (csg or drill string) at the intersection point 4) Relief well directional plan directional profile for relief well which demonstrate that it can reach the identified intersection point from 5) Relief well design High level of well design, identifying following issues:casing setting depths (csg string set directly above planned intersection point to reduce hole problems during csg sizes hole sizes wellhead size & rating Additional requirement for complex relief wells 1)Kill design Conduct blowout modelling scenario to determine the type of kill required. Conduct kill modelling (worst case a) identify the means for establishing communication between the relief and blowout well b) identify the necessary rig and pumping equipment requirements (pumping capacity & pressure rating, c) identify the volumes of kill fluids required at location, and means of storage and transfer (if required) d) conduct the relief well casing design and identify wellhead and casing material requirements 2) Seabed location selection a) Rig location - location of relief well rig will be outside of defined exclusion zones b) Re-spud location - respud location should be within the site survey boundries to allow quick access to c) ability to run & set anchors - ( if have to cross exclusion zone, consideration should be given or use

d) Suitablity for jackup rigs - if using jackup rig, should consider the aspects of positioning the rig at relief site. 3) Wellhead position uncertainty minimize the relative positional uncertainty between blowout wellhead and relief well wellhead 4) Relief well intersection strategy Planning & identification of search tool/instruments to be used for homing in on blowout well - magnetostatic search instruments (passive ranging) - electromegnetic search instruments (active ranging) Typical intersection plan is to make a pass-by of the target within 5 to 15m and at a relative angle between the Generally, the target should have casing or drillpipe extending for at least 300m below the crossover point Relief well directional plan should be design to:a) compatible with selected search tools b) allow ranging to be conducted at low relative angle between relief well & blowout well Once the well is intercepted, communication needs to be established with the blowout well. In open hole, this communication will most likely occur by means of a breakthrough when the well bores are between 0.2 and 1m apart. In this case, the communication link should establish itself very quickly. If communication is to a cased hole, the options available for establishing communication are perforating or The relief well plan should specify the preferred method for establishing communication. 5) Relief well directional plan Directional profile for relief well:a) identify the depth at which the wellbore interception should occur; b) maintain as simple a trajectory as possible, minimising dogleg severity; c) attempt to maintain inclination below 60o to allow the use of wireline ranging tools d) identify the desired approach angle and direction in converging to the target, taking into consideration e) kill point approach angle. 6) Borehole position uncertainty The relief well surveying programme must be designed to minimise survey inaccuracy and should, as a minimum, contain a combination of both measurement while drilling (MWD) and gyro surveys 7) Relief well drilling fluid selection selection of relief well mud systems should be based on the avoidance of hole problems and on ensuring 8) Hole size and casing design Design the kill casing string inner diameter to ensure that the kill fluids can be pumped at the required rate Consider at least one contingency intermediate casing string in the design, to ensure that the required kill Ensure the casing design allows for burst and collapse forces during kill pumping, well control or complete loss Ensure the casing design takes into account the impact of casing wear if multiple sidetracks are required prior High thermal loading due to pumping ambient temperature kill fluids at high rates should be included. The selected hole sizes should accommodate the required casing strings, while allowing full strength couplings

Equipment availability and supply 1) Relief well rig availability a) Rating of rig well control equipment: The rigs being considered for the relief well must have well control equipment suitable for the predicted pressures. b) Water depth: The rigs being considered for the relief well must be rated for the water depth at the relief well location c) Well location: Remote well locations will have an impact on the speed at which a suitable rig can be moved to the relief well location. d) Industry support: Access to a suitable rig from OCES 2011 participants may be considered. 2) Relief well long-lead equipment Long-lead equipment for relief well drilling includes the following key items: wellhead; conductor; and casing. Contingency stocking levels should be identified. These stocks may be held in either: operator controlled inventory; or vendor controlled inventories Means of gaining access to these items should be stated in the relief well plan. 3) Emergency well control equipment The specialist well control and relief well directional drilling contractors have an inventory of specialised tools and equipment ready for immediate mobilisation

Project plan and schedule Should include project schedule which identifies the critical time path from the start of the blowout to the completion of the blowout well kill As minimum: estimated time to source, mobilise, and locate a rig at the relief well site; personnel and equipment mobilisation; identification of the critical path activities to spud; and estimated time to drill the relief well, intercept the blowout well and complete the kill. Note: Reference to capping contingency plans may also be included in the project plan and schedule.

Relief well plan requirements

Specialist relief well planning contracts

The scope of services covered by these framework agreements may include, but not be limited to: 1) emergency response services involving all activities necessary to establish control over a blowout well; 2) well control management services involving the integration of the well control contractor into the blowout response team for effective and harmonised levels of communication and control; 3) routine engineering services and contingency planning; 4) training of personnel; 5) developing well intervention methods; 6) modelling the reservoir including inflow performance and kill rate requirements; 7) firefighting, including well capping, snubbing, freezing, hot tapping and valve drilling; 8) relief well planning and drilling; 9) pumping services; 10) environmental cleanup services.

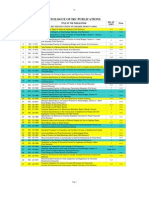

You might also like

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyFrom EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNo ratings yet

- Shallow Gas SummaryDocument4 pagesShallow Gas SummaryHerbertLansinkNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- 1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif SamiDocument17 pages1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif Samitashh raoNo ratings yet

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- Chapter F-4 Drilling FluidsDocument21 pagesChapter F-4 Drilling FluidsbjgunterjaredNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Drilling With Casing Promises Major BenefitsDocument12 pagesDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaNo ratings yet

- Heavy Weight Drill Pipe (HWDP)Document2 pagesHeavy Weight Drill Pipe (HWDP)km1790No ratings yet

- Drilling FluidsDocument19 pagesDrilling FluidsBenjamin HaganNo ratings yet

- Directional DrillingDocument66 pagesDirectional DrillingAjeet PriyanshaNo ratings yet

- Redback Operations ManualDocument11 pagesRedback Operations ManualDon BraithwaiteNo ratings yet

- Annular Pressure Loss AnalysisDocument26 pagesAnnular Pressure Loss AnalysisDhruv DasNo ratings yet

- 2 February - Onshore Vs Offshore DrillingDocument2 pages2 February - Onshore Vs Offshore DrillingHanly MauriceNo ratings yet

- Auto Fill Float Casing RunningDocument3 pagesAuto Fill Float Casing RunningtxcrudeNo ratings yet

- Spe 106346 MSDocument0 pagesSpe 106346 MSManthan MarvaniyaNo ratings yet

- StrongholdBarricade ProductsheetDocument1 pageStrongholdBarricade Productsheeteddy hariyadieNo ratings yet

- Drilling Fluids: Islamic Azad University Science and Research Branch Drilling DepartmentDocument26 pagesDrilling Fluids: Islamic Azad University Science and Research Branch Drilling Departmentali nahiNo ratings yet

- Tubing Convey PerforationDocument50 pagesTubing Convey PerforationRaed fouadNo ratings yet

- Stuck Pipe CourseDocument4 pagesStuck Pipe CourseAdama NdiayeNo ratings yet

- SPE-WVS-829: Evolving Technologies in The New Age of Horizontal Drilling in EcuadorDocument28 pagesSPE-WVS-829: Evolving Technologies in The New Age of Horizontal Drilling in Ecuadormiguel freitesNo ratings yet

- Freeing Stuck Pipe Probability and FishingDocument7 pagesFreeing Stuck Pipe Probability and Fishingvelayati_aNo ratings yet

- Stuck PipeDocument1 pageStuck Pipesaeed65No ratings yet

- AC-0021 Practical Assessment - Notice To AssessorsDocument1 pageAC-0021 Practical Assessment - Notice To AssessorsairlinemembershipNo ratings yet

- Casing Running and Drilling ToolsDocument33 pagesCasing Running and Drilling Toolsfffggg777No ratings yet

- Geothermal Well Design PDFDocument7 pagesGeothermal Well Design PDFLaurencius YanuarNo ratings yet

- Wa Asho Ver O Ope Ratio OnsDocument6 pagesWa Asho Ver O Ope Ratio OnsbilalpearltecNo ratings yet

- Analysis, Comparison and Application of CWD Against Conventional Drilling OperationsDocument104 pagesAnalysis, Comparison and Application of CWD Against Conventional Drilling Operationsprakharmathur14100% (1)

- Spe 196232 MSDocument18 pagesSpe 196232 MShijoetigreNo ratings yet

- DWOP CD Presentation PDFDocument20 pagesDWOP CD Presentation PDFkrishnsgkNo ratings yet

- Inspection Casing On Location Procedure22222222Document11 pagesInspection Casing On Location Procedure22222222hamdi hamdiNo ratings yet

- (J. A Short) Drilling A Source Book On Oil and Ga PDFDocument588 pages(J. A Short) Drilling A Source Book On Oil and Ga PDFZana QadirNo ratings yet

- Rilling Ngineering Course (2 Ed.)Document43 pagesRilling Ngineering Course (2 Ed.)MarcoNo ratings yet

- Depth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Document101 pagesDepth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Roger GuevaraNo ratings yet

- Qdoc - Tips New Iwcf ChapterDocument23 pagesQdoc - Tips New Iwcf ChapterlovekushNo ratings yet

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- Drill String ComponentsDocument17 pagesDrill String ComponentsMUHAMMED FUADNo ratings yet

- Fce 3000hp RigDocument6 pagesFce 3000hp RigTimothy PopikNo ratings yet

- Best Practice in Understanding and Managing Lost Circulation Challenges PDFDocument8 pagesBest Practice in Understanding and Managing Lost Circulation Challenges PDFnguyenhuutruong100No ratings yet

- Drill Pipe - API RP7GDocument4 pagesDrill Pipe - API RP7GHadi Faisal100% (2)

- UAS Drill String Design and Hole ProblemDocument37 pagesUAS Drill String Design and Hole Problemsbaluwel100% (1)

- Drilling ProblemsDocument14 pagesDrilling ProblemsRohith PgNo ratings yet

- Reaming While DrillingDocument26 pagesReaming While DrillingSuleiman BaruniNo ratings yet

- WFT Tubing Conveyed Perforating SystemsDocument8 pagesWFT Tubing Conveyed Perforating SystemsDenier RubianoNo ratings yet

- IADC WellCAP Well ControlDocument3 pagesIADC WellCAP Well ControlJorge ToalaNo ratings yet

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- IWCF Schedule of Fees 2019Document1 pageIWCF Schedule of Fees 2019mjm_1365No ratings yet

- Iadc Bit GradingDocument1 pageIadc Bit GradinganarkasisNo ratings yet

- Drilling Bit Introduction and Bit Selection (Part 2)Document32 pagesDrilling Bit Introduction and Bit Selection (Part 2)Ali AlakariNo ratings yet

- LTK 70 01 003Document2 pagesLTK 70 01 003romeoleonNo ratings yet

- Chapter 1+Casing+12Feb18Document47 pagesChapter 1+Casing+12Feb18Mohamad ZakwanNo ratings yet

- EXTENDED Well Control ChecklistDocument14 pagesEXTENDED Well Control ChecklistAdam InesNo ratings yet

- Centralizers & StopCollarsDocument19 pagesCentralizers & StopCollarsSaurabh Parihar100% (1)

- 1 API Introduction StandardsDocument29 pages1 API Introduction StandardsImam MalikNo ratings yet

- 01-Section 02 Drilling Fluids Functions PDFDocument11 pages01-Section 02 Drilling Fluids Functions PDFLazharNo ratings yet

- Lec 2 Intro To Drilling EngineeringDocument28 pagesLec 2 Intro To Drilling EngineeringRanaBarzamArshad100% (1)

- Drill String StandardsDocument27 pagesDrill String StandardsMuhammad Shahrukh100% (2)

- Core Drilling and Coring Tools: F Conventional Coring F Wireline (WL) - Coring F New Coring TechniqueDocument10 pagesCore Drilling and Coring Tools: F Conventional Coring F Wireline (WL) - Coring F New Coring TechniqueMarcos SobreiroNo ratings yet

- Global Syariah 03Document3 pagesGlobal Syariah 03byedNo ratings yet

- Erd Well SolutionsDocument2 pagesErd Well SolutionsbyedNo ratings yet

- (FINAL - ENG) YBMK - i-SINAR - 2021-02-11Document2 pages(FINAL - ENG) YBMK - i-SINAR - 2021-02-11byedNo ratings yet

- Trading Pulse - 19may20Document3 pagesTrading Pulse - 19may20byedNo ratings yet

- HIAPTEK - Technical View - 24 Dec 2020Document2 pagesHIAPTEK - Technical View - 24 Dec 2020byedNo ratings yet

- Workshop On Multilateral and Extended Reach WellsDocument49 pagesWorkshop On Multilateral and Extended Reach WellsbyedNo ratings yet

- Rock MechanicsDocument174 pagesRock Mechanicsbyed0% (1)

- Extended-Reach Drilling Exploration Strategy PDFDocument10 pagesExtended-Reach Drilling Exploration Strategy PDFbyedNo ratings yet

- Attachment E: Torque and Drag in ERD Wells: RotationDocument3 pagesAttachment E: Torque and Drag in ERD Wells: RotationbyedNo ratings yet

- Erd Well SolutionsDocument2 pagesErd Well SolutionsbyedNo ratings yet

- Bottom Hole CleaningDocument4 pagesBottom Hole CleaningtaruardsNo ratings yet

- Drill Bit SelectionDocument2 pagesDrill Bit SelectionbyedNo ratings yet

- Wellplan - Torque & DragDocument13 pagesWellplan - Torque & DragbyedNo ratings yet

- Wellplan Software: Key ValueDocument4 pagesWellplan Software: Key Valuebyed100% (1)

- CentralizerDocument3 pagesCentralizerbyedNo ratings yet

- Evaporator Pressure Regulating Valve SporlanDocument16 pagesEvaporator Pressure Regulating Valve SporlanSubramanian gokul100% (1)

- The Cognitive Science of Learning - Concepts and Strategies For The Educator and LearnerDocument14 pagesThe Cognitive Science of Learning - Concepts and Strategies For The Educator and LearnerNicholas BoonNo ratings yet

- Data Structures - Python 3.9.6 DocumentationDocument15 pagesData Structures - Python 3.9.6 DocumentationShahab-ud-din KhanNo ratings yet

- TN-B SC - NursingDocument106 pagesTN-B SC - NursingThanga SwamyNo ratings yet

- Week Logical FallaciesDocument79 pagesWeek Logical FallaciesSaqib AbbasNo ratings yet

- Answer: D: ExplanationDocument33 pagesAnswer: D: Explanationjaime costaNo ratings yet

- Micro Hydro BrochureDocument4 pagesMicro Hydro BrochureErlangga SatyawanNo ratings yet

- International Business Trade ReviewerDocument8 pagesInternational Business Trade ReviewerCoffee VanillaNo ratings yet

- Wap-3101 Um V1.0 PDFDocument34 pagesWap-3101 Um V1.0 PDFhtweakNo ratings yet

- FRIWO Product Catalog 12 2021 ENDocument150 pagesFRIWO Product Catalog 12 2021 ENyang liNo ratings yet

- IRC CodesDocument23 pagesIRC CodesabhijithavalNo ratings yet

- Ieo Sample Paper Class-5Document2 pagesIeo Sample Paper Class-5Dev AhanaNo ratings yet

- 2005 BHS YearbookDocument82 pages2005 BHS YearbookDallas County R-I SchoolsNo ratings yet

- The BoarderDocument3 pagesThe BoarderAnonymous iX6KV9LZzoNo ratings yet

- Instruction: Multiple Choice: Select The Letter of The Bet Answer. Write Your Answer in The Answer Sheet Provided For You. No ERASURES of Any KindDocument7 pagesInstruction: Multiple Choice: Select The Letter of The Bet Answer. Write Your Answer in The Answer Sheet Provided For You. No ERASURES of Any Kindmj Canilang100% (1)

- Philippine Urban TreesDocument83 pagesPhilippine Urban TreesKit LorenzNo ratings yet

- Chapter II Sample ThesisDocument13 pagesChapter II Sample ThesisAllen Bradley OngNo ratings yet

- À Bout de Souffle (Breathless) : Treatment by François TruffautDocument10 pagesÀ Bout de Souffle (Breathless) : Treatment by François TruffautAlex KahnNo ratings yet

- English Convents in ExileDocument6 pagesEnglish Convents in ExilePickering and ChattoNo ratings yet

- Post Purchase Cognitive DissonanceDocument18 pagesPost Purchase Cognitive DissonancePawan DihiyeNo ratings yet

- Generic List - MOH PHCs-March-2023Document11 pagesGeneric List - MOH PHCs-March-2023drabdulrabbNo ratings yet

- IO: Barriers To Entry and Exit in MarketsDocument4 pagesIO: Barriers To Entry and Exit in MarketsSamuel Liël OdiaNo ratings yet

- 2021 Moon Calendar-Cosmic RevolutionDocument47 pages2021 Moon Calendar-Cosmic RevolutionYahira NoeliNo ratings yet

- ThingworxDocument610 pagesThingworxSiriporn PansriNo ratings yet

- ST - Mother Theresa Engineering College: Course PlanDocument8 pagesST - Mother Theresa Engineering College: Course PlanAnonymous RJfsy8PtNo ratings yet

- Antiphon - Caritas - Habundat - in - Omnia - Hildegard Von BingenDocument3 pagesAntiphon - Caritas - Habundat - in - Omnia - Hildegard Von BingenGStarkNo ratings yet

- RET541 543ParlistENaDocument145 pagesRET541 543ParlistENaMatthew Mason100% (1)

- A Christmas Carol ScriptDocument95 pagesA Christmas Carol ScriptBrian O'BrienNo ratings yet

- 211 ThermoDynamics ThermoDynamicsDocument5 pages211 ThermoDynamics ThermoDynamicsmozam haqNo ratings yet

- Syllabuses MSC (Eng) 2014-15Document78 pagesSyllabuses MSC (Eng) 2014-15kelvinaaaNo ratings yet