Professional Documents

Culture Documents

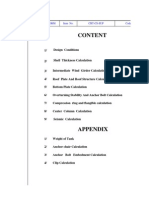

Storage Tank Calculation

Uploaded by

Chaitanya Sai TOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storage Tank Calculation

Uploaded by

Chaitanya Sai TCopyright:

Available Formats

Design Code

API 650 Eleventh Editions June 2007

References

Appendix B Appendix E Formulae for Stress And Strain Tank Data Sheet

Rules followed for designing

All components are designed with API 650 June 2007 edition Shell are designed as per one foot method Wind force and moment are calculated as per API 650 Seismic force and moment are calculated as per API 650

CALCULATION 1. DESIGN DATA TO BE COLLECTED AS PER DATA SHEET 2. MATERIAL OF CONSTRUCTION

Materials are selected for the following Shell/Bottom/Roof Plate Roof Structure/Curb Angle Nozzles Flanges Bolting For Nozzles Bolting for Structures

Wind Girder Plate specification and Minimum Yield strength, Minimum Tensile Strength and Product Design Stress are selected from Table 5.6.2 for the shell plates.

3. SHELL DESIGN CALCULATION

Allowable Stress for Shell in Design Condition

Sd = 2/3*Ys*Fy Sd = 2/5*UTS sterength Sd = Table 5.2

where

Ys = Min. yield stress Fy = Yield stress reduction factor UTS= Ultimate tensile

Three values of Sd are got and the least value is taken as Sd Allowable Stress For Shell in Hydrostatic Test Condition St = 3/4*Ys*Fy St = 3/7*UTS St = Table 5.2 Three values of St are got and the least value is taken as St

4. Shell Thickness Calculation One foot Method

The 1-foot method calculates the thicknesses required at design points 0.3 m (1 ft) above the bottom of each shell course. This method shall not be used for tanks larger than 60 m (200 ft) in diameter.

td =

4.9 x D x (H - 0.3) x G ---------------------------------- + C.A. Sd 4.9 x D x (H - 0.3) -----------------------------St

tt =

Where, td = Design Shell Thickness in mm tt = Hydrostatic Test Shell Thickness in mm H = Design Liquid Height as per Cl. 5.6.3.2 Minimum required shell thickness is selected from the table 5.6.1.1 Thickness of each shell course is calculated using above formulae. The thickness calculated must be greater than minimum thickness taken from the table 5.6.3.2 Thickness of each shell course is tabulated.

5. ANNULAR PLATE

Radial Width of annular plate

Annular bottom plates shall have a radial width that provides at least 600 mm Therefore min required radial width = +Bottom plate Projection outside the shell

Thickness+ Lap of bottom plate (Refer 5.5.2) Check for min. width of Annular Plate In SI units:

Where tb = thickness of the annular plate (see 5.5.3), in mm, H = maximum design liquid level (see 5.6.3.2), in m, G = design specific gravity of the liquid to be stored.

Thickness of annular plate

Minimum thickness of the bottom plate is 6mm as per 5.4.1 (Excluding the corrosion allowance) Hydrostatic test stress in the lowest course Sth is calculated. As per Sth value thickness of the annular plate is checked with Table 5.1

6. Bottom Plate

As per API 650 5.4.1, the minimum required thickness shall be 6 mm + C.A.

All rectangular and sketch plates shall have a minimum nominal width of 1800 mm (72 in.) Tank bottoms requiring sloping shall have a minimum slope of 1:120 upwards toward center of the tank.

7. Design of Roof Plate Thickness:

As per API 650 5.10.2.2, the minimum nominal thickness shall be 5 mm + C.A. Roof Slope / Angle 1 : 100

8. Sizing of Top Curb Angle

As per API 650 5.1.5.9.e, min. curb angle of size is L 76 X 76 X 6.4 THK.

9. Top Wind girder

The Top Wind Girder is provided at: 1100 mm From Top Curb Angle as per 5.9.4 As per API 650, 3.9.6 the required min. section modulus is,

H2 = Height of Tank Shell Vz=Design wind velocity

C = A(1)*Y(1) + A(2)*Y(2) + A(3)*Y(3) -----------------------------------------------A(1)+A(2)+A(3) I= BD^3 ------12 +AY^2

Z =I/Ymax Zprovided > Zreqd.

10. Intermediate Wind Girder

Transformed width of each shell stake is given by

Where, Wtr = transposed width of each shell course, mm (in.), W = actual width of each shell course, mm (in.), tuniform = as ordered thickness, unless otherwise specified, of the top shell course, mm (in.),

tactual = as ordered thickness, unless otherwise specified, of the shell course for which the transposed width is being calculated, mm (in.). The values are tabulated as follows

The Cumm Wtr gives the Transformed Width Htr

As per API 650 5.9.7.1, the maximum height of the unstiffened shell H1 is

If Htr > H1 then intermediate wind girder must be provided The section modulus of the intermediate wind girder shall be based on the properties of the attached members and may include a portion of the tank shell for a distance above and below the attachment to the shell, in mm (in.) In SI units

11. WEIGHT CALCULATION

Calculate Weight for each and every part of the tank

12. WIND ANALYSIS

Basic Wind Pressure on cylinder (Pcy) = P*Hc Basic Wind Pressure on roof (Pr) =P*Hc Hc = (v/160) ^2 (The value of P is given below) (Refer 5.2.1 The design wind pressure shall be 0.86 kPa (V/190)^2, ([18lbf/ft2][V/120]^2) on vertical projected areas of cylindrical surfaces and 1.44 kPa (V/190)^2, ([30lbf/ft2][V/120]^2) uplift on horizontal projected areas of conical or doubly curved surfaces, where V is the 3-sec gust windspeed.) Wind load on cylinder section Wind load on the roof section (Fcyl) =Dw *H*Pcy (Fr) =Ac*pr

Where Dw = effective tank diameter H = height of the tank Ac =Effective cone area Resultant wind load F =Fcyl+Fc Resultant Moment M = F*Z + Fr*(H+Hd/3)

Hd=Dome height Effective wind load on tank Fe =1.1*F Effective wind moment on the base Me=1.1*M

13. Check For Over Turning Due To Wind

Overturning wind moment = Me

Wt of shell + wt of roof +wt of plate =W1 Force due to internal pressure =W2 Wt available to resist uplift (W) = W1-W2 Two third of the dead load resisting moment= 2/3 * (W*D/2)

14. CALCULATION FOR SESMIC MOMENT FOR OPERATING CONDITION

Find form factor (K) from Fig E-4 Find effective mass of the contents from Fig E-2 (W1/Wt and W2/Wt) Find effective centroid of seismic force from Fig E-3 (X1/H and X2/H) Over turning at the base of the tank

15. CHECK FOR OVERTURNING DUE TO SESMIC MOMENT

Max weight of the tank content resisting overturning moment is Wl = 99*tb*(Fby*G*H) How ever overturning moment Wl should not exceed 196GHD Where tb= Thickness of the bottom plate Fby= Yield Strength of the bottom plate

You might also like

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- Storage Tank Design Calculations for Hydrogen PeroxideDocument12 pagesStorage Tank Design Calculations for Hydrogen Peroxidechompink6900No ratings yet

- Maximum PressureDocument83 pagesMaximum Pressureanhhung80No ratings yet

- API Standard 650 Storage Tank Data SheetDocument3 pagesAPI Standard 650 Storage Tank Data SheetLuis JaraNo ratings yet

- Ldo Storage Tank Calculation 170Document6 pagesLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- AMETank Product BrochureDocument6 pagesAMETank Product BrochureSYedZYnAleNo ratings yet

- TK-500MB - DB - Rev. 00Document173 pagesTK-500MB - DB - Rev. 00Daniel GómezNo ratings yet

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarNo ratings yet

- Thickness Cal. Fo DM Water Storage Tank-API 650Document15 pagesThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Ldo Storage Tank Calculation 170Document12 pagesLdo Storage Tank Calculation 170Alvin SmithNo ratings yet

- Storage Vessel DesignDocument4 pagesStorage Vessel DesignArpit ThumarNo ratings yet

- Autopipe Vessel Guide 1-5Document5 pagesAutopipe Vessel Guide 1-5fiuto_rights_1404802No ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Tank Stability 10.0: Shell Dimension, NewDocument4 pagesTank Stability 10.0: Shell Dimension, NewjonedNo ratings yet

- 620Document33 pages620ccricaNo ratings yet

- Teto Api620Document3 pagesTeto Api620viniciuskurtNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- API 650 Water Storage Tank - Xls 36Document71 pagesAPI 650 Water Storage Tank - Xls 36rudi 01No ratings yet

- Calculation StandardsDocument40 pagesCalculation Standardsraghav abudhabiNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelineschrisevabNo ratings yet

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Document1 pageShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNo ratings yet

- Mechanical Engineer CV for Oil & Gas rolesDocument4 pagesMechanical Engineer CV for Oil & Gas rolesKarthik AnandanNo ratings yet

- 06745JS2 (7) - Strength Calculations of Module4 (IBR)Document23 pages06745JS2 (7) - Strength Calculations of Module4 (IBR)Pratik Ray Chaudhury100% (3)

- Stack SpecDocument10 pagesStack SpecHoney TiwariNo ratings yet

- API 650 Steel Tank Design GuideDocument18 pagesAPI 650 Steel Tank Design GuideJoshue AdeleNo ratings yet

- AES Floating HeadDocument8 pagesAES Floating HeadArjun Singh AroraNo ratings yet

- Filter Vessel Calculations Per As Me Viii 1Document40 pagesFilter Vessel Calculations Per As Me Viii 1Anonymous J1vjrU2No ratings yet

- Tank Manual CalculationsDocument19 pagesTank Manual Calculationsbhavanamadhuri itapuNo ratings yet

- Nozzle Loads As Per Shell DEPDocument4 pagesNozzle Loads As Per Shell DEPSarfaraz KhanNo ratings yet

- Ldo Storage Tank CalculationDocument7 pagesLdo Storage Tank CalculationchetanmaleNo ratings yet

- Hemispherical HeadDocument5 pagesHemispherical HeadPuRuiSen HelathchemicalNo ratings yet

- Design of Reinforced Concrete RING BEAM FOUNDATIONDocument2 pagesDesign of Reinforced Concrete RING BEAM FOUNDATIONnirmal suthar100% (1)

- Design of Base RingDocument1 pageDesign of Base RingMohammed Faizal Nv100% (1)

- Double Deck - Floating RoofDocument7 pagesDouble Deck - Floating RoofDhia SlamaNo ratings yet

- AWS A5.12: Material Safety Data Sheet (MSDS)Document3 pagesAWS A5.12: Material Safety Data Sheet (MSDS)Mani VannanNo ratings yet

- Chapter 3: Tank DesignDocument4 pagesChapter 3: Tank Designevrim77No ratings yet

- Application For The Static Equipment Design EngineerDocument3 pagesApplication For The Static Equipment Design EngineerTejas ShahNo ratings yet

- Shell and Tube Heat ExchangerDocument1 pageShell and Tube Heat ExchangerNurulHiNo ratings yet

- Fdocuments - in API 650 Storage TanksDocument15 pagesFdocuments - in API 650 Storage TanksRAHUL THAKORNo ratings yet

- Amp RevaDocument6 pagesAmp RevajavilapiedraNo ratings yet

- Condensate Storage Tank Design OverviewDocument44 pagesCondensate Storage Tank Design OverviewkpsahuNo ratings yet

- API 650 Design TanksDocument39 pagesAPI 650 Design TanksAhmedAli25% (4)

- Nozzle Load & Saddle CalculationDocument26 pagesNozzle Load & Saddle CalculationSACHIN PATEL100% (1)

- Pa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyDocument33 pagesPa5 MC SH 01 c14 003 - 00 - Calculation For Platform Beam of ChimneyHmilkNo ratings yet

- Add any change made in the sheet with new revision NoDocument16 pagesAdd any change made in the sheet with new revision Nochenfs27531No ratings yet

- Nozzle Reinf Calc (Rough)Document12 pagesNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- Pressure Vessel Design CalculationsDocument2 pagesPressure Vessel Design CalculationsMohan VarkeyNo ratings yet

- Storage Tank Calculation 3 PDF FreeDocument10 pagesStorage Tank Calculation 3 PDF Freealilou2013No ratings yet

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- TDI13 Storage Tank Design As Per IS803 and API650Document36 pagesTDI13 Storage Tank Design As Per IS803 and API650Faizal Sattu100% (3)

- TDI13 Storage Tank Design As Per IS803 and API650Document36 pagesTDI13 Storage Tank Design As Per IS803 and API650zefiloNo ratings yet

- Design Tanks Menurut API 650Document80 pagesDesign Tanks Menurut API 650irbar.darmansyah.alwiNo ratings yet

- API-650 Design Procedure ExampleDocument21 pagesAPI-650 Design Procedure Examplegdwvcd92% (13)

- Design As Per APIDocument82 pagesDesign As Per APINeeraj BhallaNo ratings yet

- Design Calculation R1 PDFDocument14 pagesDesign Calculation R1 PDFJagankumarNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- VpCI-649 BDDocument2 pagesVpCI-649 BDChaitanya Sai TNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- CTW Quotation No - GHCS220915002Document1 pageCTW Quotation No - GHCS220915002Chaitanya Sai TNo ratings yet

- Classic MinutesDocument1 pageClassic MinutesChaitanya Sai TNo ratings yet

- Kian Huat Metal Catalogue PlatesDocument4 pagesKian Huat Metal Catalogue PlatesChaitanya Sai TNo ratings yet

- Kia Sonet ConfiguratorDocument1 pageKia Sonet ConfiguratorChaitanya Sai TNo ratings yet

- MMcineplexesDocument1 pageMMcineplexesChaitanya Sai TNo ratings yet

- ThinkPad X1 Carbon Gen 10Document6 pagesThinkPad X1 Carbon Gen 10Chaitanya Sai TNo ratings yet

- Material P-Number - Chai (Rev3)Document3 pagesMaterial P-Number - Chai (Rev3)Chaitanya Sai TNo ratings yet

- Tank Cycling ScheduleDocument1 pageTank Cycling ScheduleChaitanya Sai TNo ratings yet

- PlanDocument1 pagePlanChaitanya Sai TNo ratings yet

- Cutting ModelDocument1 pageCutting ModelChaitanya Sai TNo ratings yet

- Material P NumberDocument11 pagesMaterial P NumberChaitanya Sai TNo ratings yet

- Cheras 2020 PDFDocument1 pageCheras 2020 PDFChaitanya Sai TNo ratings yet

- Conceptual Engineering: Project Activities ListDocument2 pagesConceptual Engineering: Project Activities ListChaitanya Sai TNo ratings yet

- Advanced Exchange TermsDocument1 pageAdvanced Exchange TermsChaitanya Sai TNo ratings yet

- Nozzle and Manhole Weight ChartDocument3 pagesNozzle and Manhole Weight ChartChaitanya Sai TNo ratings yet

- 2020 P Number EbookDocument9 pages2020 P Number EbookChaitanya Sai TNo ratings yet

- Asme Vert FilterDocument27 pagesAsme Vert FilterChaitanya Sai TNo ratings yet

- Beam LiftingDocument11 pagesBeam LiftingChaitanya Sai TNo ratings yet

- Cheras 2020 PDFDocument1 pageCheras 2020 PDFChaitanya Sai TNo ratings yet

- On-X® Mitral Heart ValveDocument20 pagesOn-X® Mitral Heart ValveChaitanya Sai TNo ratings yet

- SI Nozzle Qty SIZE (Inch) LENGTH (MM) Weight (KG) Thickness (MM) Volume (M)Document5 pagesSI Nozzle Qty SIZE (Inch) LENGTH (MM) Weight (KG) Thickness (MM) Volume (M)Chaitanya Sai TNo ratings yet

- The Basics of API 650 Standard for Storage TanksDocument52 pagesThe Basics of API 650 Standard for Storage Tanksferdad79% (19)

- Roof Cutting Plan 1 PDFDocument1 pageRoof Cutting Plan 1 PDFChaitanya Sai TNo ratings yet

- Warfarin INR Antibx InteractionDocument3 pagesWarfarin INR Antibx InteractionSheila UlinaNo ratings yet

- Warfarin INR Antibx InteractionDocument4 pagesWarfarin INR Antibx InteractionChaitanya Sai TNo ratings yet

- Hanger SizingDocument26 pagesHanger SizingBùi Văn HợpNo ratings yet

- Bills of Material: Rev. Date Description by CHK'D Reviewed ClientDocument5 pagesBills of Material: Rev. Date Description by CHK'D Reviewed ClientChaitanya Sai TNo ratings yet

- Performance LogDocument1 pagePerformance LogChaitanya Sai TNo ratings yet

- DNS Mapping and Name ResolutionDocument5 pagesDNS Mapping and Name ResolutionAmit Rashmi SharmaNo ratings yet

- The Space of Reflection: Thirdness and Triadic Relationships in Family TherapyDocument19 pagesThe Space of Reflection: Thirdness and Triadic Relationships in Family TherapyTasos TravasarosNo ratings yet

- Business Policy FormulationDocument21 pagesBusiness Policy FormulationWachee Mbugua50% (2)

- 202002Document32 pages202002Shyam SundarNo ratings yet

- Course Outline Physics EducationDocument3 pagesCourse Outline Physics EducationTrisna HawuNo ratings yet

- Sakolsky Ron Seizing AirwavesDocument219 pagesSakolsky Ron Seizing AirwavesPalin WonNo ratings yet

- News CorpDocument17 pagesNews CorpIshita SharmaNo ratings yet

- Portal ScienceDocument5 pagesPortal ScienceiuhalsdjvauhNo ratings yet

- Rhodes Solutions Ch4Document19 pagesRhodes Solutions Ch4Joson Chai100% (4)

- AREVA Directional Over Current Relay MiCOM P12x en TechDataDocument28 pagesAREVA Directional Over Current Relay MiCOM P12x en TechDatadeccanelecNo ratings yet

- Level 1:: Advanced Financial Modeler (Afm)Document23 pagesLevel 1:: Advanced Financial Modeler (Afm)munaftNo ratings yet

- Elderly Suicide FactsDocument2 pagesElderly Suicide FactsThe News-HeraldNo ratings yet

- Ardipithecus Ramidus Is A Hominin Species Dating To Between 4.5 and 4.2 Million Years AgoDocument5 pagesArdipithecus Ramidus Is A Hominin Species Dating To Between 4.5 and 4.2 Million Years AgoBianca IrimieNo ratings yet

- Audience AnalysisDocument7 pagesAudience AnalysisSHAHKOT GRIDNo ratings yet

- Developing The Marketing Mix: Notre Dame of Jaro IncDocument3 pagesDeveloping The Marketing Mix: Notre Dame of Jaro IncVia Terrado CañedaNo ratings yet

- Unit 3 Activity 1-1597187907Document3 pagesUnit 3 Activity 1-1597187907Bryan SaltosNo ratings yet

- Registration details of employees and business ownersDocument61 pagesRegistration details of employees and business ownersEMAMNNo ratings yet

- 04-DDD.Assignment 2 frontsheet 2018-2019-đã chuyển đổi PDFDocument21 pages04-DDD.Assignment 2 frontsheet 2018-2019-đã chuyển đổi PDFl1111c1anh-5No ratings yet

- 2009 IBP ElectionsDocument77 pages2009 IBP ElectionsBaldovino VenturesNo ratings yet

- Paul Smith - Discerning The SubjectDocument226 pagesPaul Smith - Discerning The SubjectdisconnectaNo ratings yet

- Ice Task 2Document2 pagesIce Task 2nenelindelwa274No ratings yet

- Essay A Level Drama and Theatee Studies A LevelDocument2 pagesEssay A Level Drama and Theatee Studies A LevelSofia NietoNo ratings yet

- 1402 2046Document11 pages1402 2046Luca PilottiNo ratings yet

- Veerabhadra Swamy MantrasDocument6 pagesVeerabhadra Swamy Mantrasगणेश पराजुलीNo ratings yet

- The ADDIE Instructional Design ModelDocument2 pagesThe ADDIE Instructional Design ModelChristopher Pappas100% (1)

- Course Outline IST110Document4 pagesCourse Outline IST110zaotrNo ratings yet

- Importance of SimilesDocument10 pagesImportance of Similesnabeelajaved0% (1)

- MOTOR INSURANCE TITLEDocument5 pagesMOTOR INSURANCE TITLEVara PrasadNo ratings yet

- Review Unit 10 Test CHP 17Document13 pagesReview Unit 10 Test CHP 17TechnoKittyKittyNo ratings yet

- CPARDocument22 pagesCPARAngelo Christian MandarNo ratings yet