Professional Documents

Culture Documents

Effect of Blanching N Coating Wid Hydrocolloid On Reduction of Oil Uptake in French Fries

Uploaded by

swapoo_vanjiwaleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Blanching N Coating Wid Hydrocolloid On Reduction of Oil Uptake in French Fries

Uploaded by

swapoo_vanjiwaleCopyright:

Available Formats

International Food Research Journal 19(2): 697-699 (2012)

Effect of blanching and coating with hydrocolloids on reduction of oil uptake in french fries

Pahade, P. K. and *Sakhale, B. K.

1

Food Technology Division, Department of Chemical Technology, Dr. Babasaheb Ambedkar Marathwada University, Aurangabad, Maharashtra, India

Abstract: The French fries were prepared from potatoes after pretreating with water, CaCl2 and citric acid and then coating with different hydrocolloid solutions. It was observed that French fries pretreated with 0.5% aqueous solution of CaCl2 and coated with 1% aqueous solution of HPMC resulted better product in moisture retention and oil uptake than the French fries with other hydrocolloids (MC, guar gum and xanthan gum). However, the French fries pretreated with 1% aqueous solution of citric acid and coated with 1% aqueous solution of HPMC resulted in better sensory quality than the fries with other hydrocolloids. Keywords: Pretreatments, hydrocolloids, French fries, oil uptake, sensory parameters

Introduction French fries are a popular snack food made from potatoes. Potatoes are sliced to make sticks, deep fried in vegetable oil, seasoned and served with tomato chili sauce. The potato products such as French fries, chips, balls etc. are also fried products which absorb high amount of oil. These products though taste good, pose health problems due to high calorie and cholesterol intake. The people now become health cautious and demand for less dense and low calorie foods. Frying is a process of cooking and drying through contact with hot oil and it involves simultaneous heat and mass transfer. Deep fat frying of various kinds of foods coated with batter is a popular cooking procedure in many countries (Kimber and Holding, 1987), wherein the heat is transferred from oil to the product, water is evaporated and oil is absorbed. Crust formation and browning also take place giving the product an attractive golden appearance and crispy mouthfeel (Annapure et al., 1998).The amount of oil uptake is directly proportional to the amount of moisture lost (Gamble and Rice, 1988). The oil uptake and its distribution in the fried product is mainly near the surface i.e. crust (Varela, 1988) and fried potatoes absorb 15% oil during frying (Toma et al., 1986). To make such product more acceptable to the health cautious consumers, the oil uptake should be reduced either by use of fat replacers such as fat mimetics, low calorie fats and fat substitutes. Another approach is to use edible ingredients in the batter to improve coating performance and blending of cereals and legumes (Annapure et al., 1999). The hydrocolloids are widely used in many food formulations to improve quality attributes and

*Corresponding author. Email: bksakhale@gmail.com Tel: +91 240 2403308; Fax: +91 240 2400413

shelf-life (Saha and Bhattacharya, 2010). The use of hydrocolloids in the food industry has become very common in the last few decades. Various ingredients such as pectin, sodium alginate (Khalil 1999; Holikar et al., 2005), powdered cellulose (Mallikarjunan et al., 1997; Annapure et al., 1999; Sakhale et al., 2011) and corn zein (Feeney et al., 1993) were attempted. The objectives of present study was to know the effect of blanching and coating with edible agents such as hydroxypropyl methyl cellulose (HPMC), methyl cellulose (MC), guar gum and xanthan gum on moisture retention, oil uptake and sensory quality of French fries. Materials and Methods The fresh potato tubers (Solanum tuberosum L.) were washed, peeled with potato peeler and cut manually into 8 x 8 x 60 mm strips. The strips were divided into nine lots. The first lot was only water blanched at 850C for 6 min, drained and dried in a convection oven at 1500C for 3 min to reduce the surface moisture and treated as T0 (control). This treatment was not neither given chemical blanching treatment nor coated with any of the hydrocolloids used. The second, third, fourth and fifth lots each were blanched in 0.5% aqueous solution of CaCl2 and then coated with 1% aqueous solution each of HPMC, MC, guar gum, xanthan gum, respectively for 2 min, drained and then dried in convection drier as above. Similarly sixth, seventh, eighth and ninth lots of each were blanched in 1% aqueous solution of citric acid and then coated with 1% each of HPMC, MC, guar gum, xanthan gum, respectively for 2 min, drained and then dried in convection drier as above. Accordingly the lots were given the treatment number

All Rights Reserved

698

Pahade, P. K. and Sakhale, B. K.

from T0T8, respectively, as detail below. T0 (water blanching), T1, T2 ,T3 and T4 (blanching in 0.5% CaCl2 and coating with 1% each of HPMC, MC, guar gum and xanthan gum, respectively). T5, T6, T7 and T8 (blanching in 1.0% citric acid and coating with 1% each of HPMC, MC, guar gum and xanthan gum, respectively). The blanched and hydrocolloids treated samples were deep fried in a pan of three liter capacity in refined vegetable oil (1:6 strips: oil ratio). The oil was changed every after frying of each lot. The fried strips were allowed to cool at room temperature and analyzed for moisture retention and oil up take. The oil uptake was determined with Soxhlet extraction apparatus using petroleum ether (40-450C BP) and moisture was determined using Simadzu make MOC120 rapid moisture analyzer. The French fries were evaluated for sensory quality for appearance, color, taste, texture and overall acceptability by a semitrained panel of 10 judges on 9 point Hedonic scale (1- extremely dislike, 9- extremely like) (Amerine et al., 1965). The scores obtained for various quality parameters were recorded and average values of triplicate observations are reported. Results and Discussion Moisture loss and oil uptake The data on moisture and oil contents of French fries (Table 1) revealed that the product when pretreated with either 0.5% aqueous solution of CaCl2 or 1% aqueous solution of citric acid and coated with 1% aqueous solution of HPMC (T1, and T5 respectively) retained highest moisture (37.45 to 37.60% respectively) in the product. It is known that the HPMC forms a film on the product and decrease the tendency of the product to absorb the oil and lose moisture. The mass transfer ceases to occur. The oil content of French fries decreased considerably with pretreatments and addition of hydrocolloids, irrespective of the type of hydrocolloids as compared to control. In the present study this holds good and French fries retained more moisture and taken up less oil. The moisture retention of control (T0) was lowest (32.45%) than any of the other samples which indicated that it was only pretreated with hot water and not coated with any of the hydrocolloids and sufficient mass transfer might have occurred. The French fries when pretreated with either 0.5% aqueous solution of CaCl2 or 1% aqueous solution of citric acid and then coated with 1% MC, 1% guar gum or 1% xanthan gum solutions resulted in higher moisture retention and less oil uptake than the control one indicating thereby that mass transfer was also

less in these treatments (T2, T3, T4, T6, T7 and T8) than the To (control).

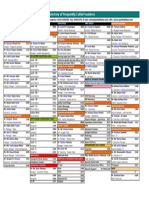

Table 1. Effect of pretreatments and coating of hydrocolloids on moisture content and oil uptake of French fries*

Moisture, % 32.45 37.45 35.51 34.37 33.17 37.60 36.12 33.68 33.02 34.821.15 Oil, % 26.4 14.0 18.6 21.4 24.8 16.4 19.4 23.6 25.4 21.110.43

Sample Treatments T0 (Control) T1 T2 T3 T4 T5 T6 T7 T8 Mean SD

*

% Reduction in oil uptake 46.9 29.5 18.9 6.1 37.8 26.5 10.6 3.8 15.430.81

Each value is the average of three determinations.

One of the most important properties of hydrocolloids is their ability to form films and sheets and act as a very effective barrier to oil and therefore used in number of food applications including adhesion, film forming, thermal gelling and non charring characteristics. The film forming characteristics of these hydrocolloids have prevented the absorption of oil and at the same time helped to retain the natural moisture of foods. This could be the reason of using these hydrocolloids in deep frying of fried products (Ang, 1993; Koelsch and Labuza, 1992; Mallikarjunan et al., 1997; Williams and Mittal, 1999; Sakhale et al., 2011). The reduction in oil uptake by French fries was lowest 46.9% and 37.8 % in T1 and T5 treatments respectively which might have been due to more film and sheet formation by HPMC which acted as effective barrier to oil. Khalil (1999) reported 40% reduction in oil uptake when he coated French fries with 0.5% calcium chloride and 5 % pectin. However, Sakhale et al. (2011) also reported the significant reduction in oil content in Samosa (8.56%) prepared with addition of xanthan gum at 1.5% level as compared to other hydrocolloids (HPMC, CMC, guar gum) and their concentration levels. Sensory quality Sensory quality is an important aspect in considering the overall acceptability of food product. Deep fat frying is widely used in industrial preparation of foods, because consumers prefer the taste, appearance, and texture of fried food products (Saguy and Pinthus, 1994). Effect of pretreatments and coating of hydrocolloids on sensory quality of French fries were studied and the scores obtained with respect to various sensory attributes are presented in Table 2. When pretreatments were given, the French

International Food Research Journal 19(2): 697-699

Food Chemistry or Food Hydrocolloids

699

fries might be hampered the taste, odor, mouth feel, color or aroma of the product. The blanching step previous to frying in potato chip processing improved the color and texture as reported earlier by Califano and Calvelo (1987). The appearance and color of French fries improved by pretreatment with either calcium chloride or citric acid and coating with HPMC. The overall acceptability was also improved in these treatments (T1 and T5) which could be probably because of improvement in other sensory quality parameters such as taste, texture, color and appearance. It is reported that hydrocolloids are used to improve the texture and moisture retention in cake batters and dough, to increase the volume and shelf life of cereal foods by limiting starch retrogradation, improve their eating quality and appearance (Kohajdova and Karovicova, 2009; Kotoki and Deka, 2010).

Table 2. Effect of pretreatments and coating of hydrocolloids on sensory quality of French fries*

Appearance 8 8 7 8 6 9 7 6 6 Color 7 8 7 7 6 8 7 7 6 Taste 8 7 8 6 6 7 7 7 6 Texture 7 8 7 7 6 8 7 8 6

Each value is the average of ten determinations.

Sample treatments T0 (Control) T1 T2 T3 T4 T5 T6 T7 T8

Overall acceptability 8 8 7 7 6 8 7 7 5

Conclusion Among all the hydrocolloids studied at different levels for preparation of French fries, it can be concluded that potato French fries pretreated with either 0.5% calcium chloride or 1% citric acid and coated with 1% HPMC were found better in both oil uptake and sensorial quality characteristics. Thus, French fries with reduced oil and low calorie content with better acceptance can be prepared in order to meet the demand of low fatty foods of health cautious consumers. References

Amerine, M.S., Pangborn, R.M. and Roessler, E.A. 1965. Principles of Sensory Evaluation of Foods. Academic Press, New York. Ang, J. F. 1993. Reduction of fat in fried batter coatings with powdered cellulose. Journal of the American Oil Chemists Society 70: 619-622. Annapure, U. S., Singhal, R. S. and Kulkarni, P. R. 1999. Screening of hydrocolloids for reduction in oil uptake of a model deep-fat fried product. Fett/Lipid 101: 217221. Annapure, U. S., Singhal, R. S. and Kulkarni, P. R. 1998. Studies on deep-fat fried snacks from some cereals and legumes. Journal of the Science of Food and

Agriculture 76: 377-382. Califano, A. N. and Calvelo, A. 1987. Adjustment of surface concentration of reducing sugars before frying of potato strips. Journal of Food Processing and Preservation 12: 1-9. Feeney, R.D., Haralampu, S.G. and Gross, A.T. 1993. Potato and other food products coated with edible oil barrier films. US Patent 5: 217-736. Gamble, M. H. and Rice, P. 1988. Effect of pre-frying drying on oil uptake and distribution in potato crisp manufacture. International Journal of Food Science and Technology 22: 535 -539. Holikar, M., Annapure, U.S., Singhal, R.S. and Kulkarni, P.R. 2005. Pectin and calcium chloride treatment for low-fat green gram splits. Journal of the Science of Food and Agriculture 85: 16771680. Khalil, A.H. 1999. Quality of French fried potatoes as influenced by coating with hydrocolloids. Food Chemistry 66: 201-208. Kimber, M.P. and Holding, S. 1987. Some Technological Aspects of Batter. In: 1st European Symposium on Savory Coatings, pp.85-89 London: Elsevier Applied Science Publishers LTD. Koelsch, C. Labuza 1992. Edible water vapor barriers: properties and promise. Trends in Food Science and Technology 5: 76-81. Kohajdova, Z. and Karovicova, J. 2009. Application of hydrocolloid as baking improvers. Chemical Papers 63: 26-38. Kotoki, D. and Deka, S.C. 2010. Baking loss of bread with special emphasis on increasing water holding capacity. Journal of Food Science and Technology 47: 128-131. Mallikarjunan, P., Chinnan, M.S. and Balsubramanium, V.M. 1997. Edible coatings for deep fat frying of starchy products. Journal of Food Science and Technology 30: 709 -714. Saguy, I.S. and Pinthus, E.J. 1994. Oil uptake during deep fat frying: Factors and Mechanisms. Food Technology 49 (4): 142-145,152. Saha Dipjyoti and Bhattacharya Suvendu 2010. Hydrocolloids as thickening and gelling agents in food: a critical review. Journal of Food Science and Technology 47: 587-597. Sakhale, B. K., Badgujar, J. B., Pawar, V. D. and Sananse S. L. 2011. Effect of hydrocolloids incorporation in casing of samosa on reduction of oil uptake. Journal of Food Science and Technology (Online) DOI: 10.1007/ s13197-011-0333-0. Varela, G. 1988. Current facts about the frying of foods. In: Valera, G., Bender, A.E. and Morten, J.D. (Ed). Principles, changes, new approaches, UK Pp-9-25. Williams, R. and Mittal, G. S. 1999. Low fat fried foods with edible coatings: modeling and simulation. Journal of Food Science 64: 317-322. Toma, R.B., Leung, H.K., Augstin, J. and Iritani, W.M. 1986. Quality of french potatoes as affected by surface freezing and specific gravity of raw potatoes. Journal of Food Science 51: 1213-1214.

International Food Research Journal 19(2): 697-699

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Alok ResumeDocument3 pagesAlok Resumealok choudharyNo ratings yet

- 01 - 01 - SK10 - JXNipponDocument1 page01 - 01 - SK10 - JXNipponredevils86No ratings yet

- Design and Built-A4Document2 pagesDesign and Built-A4farahazuraNo ratings yet

- BOF, LF & CasterDocument14 pagesBOF, LF & CastermaklesurrahmanNo ratings yet

- Merit of RatingDocument1 pageMerit of RatingRaidasNo ratings yet

- 50-Orthodontic Objectives in Orthognathic Surgery-State of The PDFDocument15 pages50-Orthodontic Objectives in Orthognathic Surgery-State of The PDFDeena A. AlshwairikhNo ratings yet

- Case Report on Right Knee FuruncleDocument47 pagesCase Report on Right Knee Furuncle馮宥忻No ratings yet

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 pageDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoNo ratings yet

- VIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhDocument3 pagesVIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhÝ Nguyễn NhưNo ratings yet

- Space Analysis in Orthodontic: University of GlasgowDocument16 pagesSpace Analysis in Orthodontic: University of GlasgowNizam Muhamad100% (1)

- Erapol EHP95ADocument2 pagesErapol EHP95AMohammad Doost MohammadiNo ratings yet

- Manual Masina de Spalat Slim SamsungDocument1,020 pagesManual Masina de Spalat Slim SamsungPerfectreviewNo ratings yet

- Spec BoilerDocument9 pagesSpec BoilerAchmad MakmuriNo ratings yet

- Siemens MV Gas Insulated Switch GearDocument14 pagesSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VNo ratings yet

- Quality ImprovementDocument3 pagesQuality ImprovementViky SinghNo ratings yet

- Hydrogeological Characterization of Karst Areas in NW VietnamDocument152 pagesHydrogeological Characterization of Karst Areas in NW VietnamCae Martins100% (1)

- XDocument266 pagesXTrần Thanh PhongNo ratings yet

- Ucg200 12Document3 pagesUcg200 12ArielNo ratings yet

- Válvulas Flomatic USADocument40 pagesVálvulas Flomatic USAEfrain DuarteNo ratings yet

- Interface GSKTMTRLBRCHR A4 Int 4webDocument7 pagesInterface GSKTMTRLBRCHR A4 Int 4webROGERIO GUILHERME DE OLIVEIRA MARQUESNo ratings yet

- Tugas B InggrisDocument9 pagesTugas B InggrisDellyna AlmaNo ratings yet

- Acc101Q7CE 5 3pp187 188 1Document3 pagesAcc101Q7CE 5 3pp187 188 1Haries Vi Traboc MicolobNo ratings yet

- Tutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)Document3 pagesTutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)NOR SYAZLIANA ROS AZAHARNo ratings yet

- The Secret of The House WTDocument22 pagesThe Secret of The House WTPetr -50% (2)

- Characteristics of Uveitis Presenting For The First Time in The Elderly Analysis of 91 Patients in A Tertiary CenterDocument9 pagesCharacteristics of Uveitis Presenting For The First Time in The Elderly Analysis of 91 Patients in A Tertiary CenterFrancescFranquesaNo ratings yet

- Neurons and Nerve Impulses: Nandika Arora and Risa Gaikwad (11 G2)Document17 pagesNeurons and Nerve Impulses: Nandika Arora and Risa Gaikwad (11 G2)RisaNo ratings yet

- Supply Chain Management of VodafoneDocument8 pagesSupply Chain Management of VodafoneAnamika MisraNo ratings yet

- Solcon Catalog WebDocument12 pagesSolcon Catalog Webquocviet612No ratings yet

- Speaking Coursebook C1.1Document80 pagesSpeaking Coursebook C1.1Yến VõNo ratings yet