Professional Documents

Culture Documents

sm8 117

Uploaded by

Sadie HnatowOriginal Description:

Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

sm8 117

Uploaded by

Sadie HnatowCopyright:

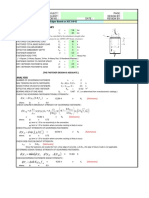

PROBLEM 8.117 KNOWN: Diameters and length of three microchannels machined in a copper block.

Inlet temperature of water flowing through the channels, copper block temperature, pressure difference from inlet to outlet of the channels. FIND: (a) Mass flow rate and outlet temperature in each channel, (b) Average flow rate through

each channel and average, mixed temperature of water collected from all three channels, (c) Comparison between average flow rates and average heat transfer rates based upon experiment to that calculated based upon a single microchannel diameter of 50 m.

SCHEMATIC:

Tcu = 310 K Copper block

. m1 Water Tm,i = 300 K

. m2

. m3

L = 20 mm p = 2.5x106 Pa

D1 = 45 m D2 = 50 m D3 = 55 m

ASSUMPTIONS: (1) Constant properties and steady-state conditions, (2) Incompressible

liquid and negligible viscous dissipation, (3) Negligible microscale or nanoscale effects, (4) Negligible entrance or exit losses in the microchannels, (5) Fully developed flow for purposes of calculating the mass flow rate in each channel, (6) Isothermal copper block.

PROPERTIES: Table A.6, water: ( Tm = 305 K): k = 0.620 W/mK, cp = 4178 J/kgK, = 769

10-6 Ns/m2, = 7.728 10-7 m2/s, Pr = 5.2, = 995 kg/m3.

ANALYSIS: (a) For the D = 50 m channel, from Equation 8.22a,

p = fu 2 L / 2D = f 995kg / m3 u 2 20 103 m /(2 50 106 m) m m where the friction factor may be evaluated using the Petukhov expression, f = (0.790lnReD-1.64)-2 The Reynolds number may be expressed as

Re D = u m D u m 50 106 m = 7.728 107 m 2 / s (3) Continued

(1)

(2)

PROBLEM 8.117 (Cont.)

Simultaneous solution of Equations (1) through (3) yields, for the D = 50 m channel, ReD = 845, um = 13.06 m/s. The mass flow rate is

& m = u m D 2 / 4 = 995kg / m3 13.06m / s (50 106 m) 2 / 4 = 2.55 105 kg / s

<

The thermal entrance length is xfd,t = 0.05ReDPrD = 0.05 845 5.2 50 10-6 m = 11.0 10-3 m = 11.0 mm. From the Hausen correlation,

Nu D = 3.66 + Hence,

h=

0.0668 (50 106 m / 20 103 m) 845 5.2 1 + 0.04 (50 106 m / 20 103 m) 845 5.2

2/3

= 4.27

Nu D k 4.27 0.62W / m K = = 5.29 104 W / m 2 K 6 D 50 10 m

From Equation 8.42,

PL Tm (x = L) = Ts Ts Tm,i exp mc p & h

50 106 m = 310K [310K 300K ] exp 5.29 104 W / m 2 K 2.55 105 kg / s 4178J / kg K = 307.9K = 34.9C = Tm,o

Results for the three different channels are shown in the table below.

D = 45 m (case 1) ReD um (m/s) 690 11.85 1.88 10-5 8.1 4.12 D = 50 m (case 2) 845 13.06 2.55 10-5 11.0 4.27

5.29 104 307.9

< <

D = 55 m (case 3) 1012 14.23 3.36 10-5 14.5 4.44

5.01 104 307.1 Continued

& m (kg/s)

xfd,t (mm)

Nu D

h(W / m 2 K) 5.68 104 Tm,o (K) 308.7

PROBLEM 8.117 (Cont.)

(b) The average mass flow rate is

& & & & m = (m1 + m 2 + m3 ) / 3 = (1.88 105 + 2.55 105 + 3.36 105 )kg / s / 3 = 2.60 105 kg / s

(c) The average, mixed outlet temperature is

<

& & & & & & Tm,o = (m1Tm,o,1 + m 2 Tm,o,2 + m3Tm,o,3 ) /(m1 + m 2 + m3 ) = (1.88 105 kg / s 308.7K + 2.55 105 kg / s 307.9K + 3.36 105 kg / s 307.1K) (1.88 105 + 2.55 105 + 3.36 105 )kg / s = 307.7K

(d) Equation 8.42 may be re-arranged to

Ts Tm,o ln PL Ts Tm,L 2.60 105 kg / s 4178J / kg K 310 307.7 2 ln = = 50,800W / m K 50 106 m 20 103 m 310 300

h=

& mc p

Thus, the inferred value of the mass flow rate is 2% greater than the predicted value for a 50 m diameter channel. The inferred value of the convection coefficient (50,800 W/m2K) is 4% less than the predicted value for a 50 m diameter channel. The experimenter must carefully assess his or her claims since the differences are small and might be attributed to variations in the channel dimensions that occur during their manufacture.

COMMENTS: (1) Experimentation at the microscale is challenging. Misinterpretation of the experimental results might occur unless the experimental system is designed very carefully. For example, the diameters of the channels might need to be measured after their manufacture. (2) When boring holes, the hole diameter is always greater than the diameter of the tool. If the experimentalist assumes that the actual hole size is the same as the tool size, what (inappropriate) conclusions might he or she make regarding possible microscale fluid flow and heat transfer effects when analyzing the measured results?

You might also like

- ForScribd Difussion ProbsetDocument25 pagesForScribd Difussion Probsetmendoza21203831mNo ratings yet

- Solution Ch8Document15 pagesSolution Ch8Anonymous ou6LhnW6qv100% (2)

- 5) Problems (Ch. 3)Document26 pages5) Problems (Ch. 3)Arham AmjadNo ratings yet

- Met 02023 Material Science IDocument13 pagesMet 02023 Material Science IlallyprabhNo ratings yet

- PED Term PaperDocument13 pagesPED Term PaperUtsav PatelNo ratings yet

- Heat Transfer UNIT-8 Heat Exchangers:: Problem 50Document8 pagesHeat Transfer UNIT-8 Heat Exchangers:: Problem 50Miguel Angel Carranza OlveraNo ratings yet

- Chapter 7 SolutionsDocument21 pagesChapter 7 SolutionsARSYIAN RIZKI PRATAMANo ratings yet

- Heat Exchanger - Effectiveness - NTU MethodDocument15 pagesHeat Exchanger - Effectiveness - NTU MethodhendiyrNo ratings yet

- Banco de TubosDocument9 pagesBanco de TubosArturo Arévalo FloresNo ratings yet

- MATERIAL Mechanical DesignDocument11 pagesMATERIAL Mechanical DesignanisNo ratings yet

- Process Design of CondenserDocument5 pagesProcess Design of CondenserVivek VĩvĕNo ratings yet

- sm1 36Document1 pagesm1 36awoods12835No ratings yet

- Example-1: Soil Mechanics-I Examples On Chapter-3Document16 pagesExample-1: Soil Mechanics-I Examples On Chapter-3LemiNo ratings yet

- Ejercicios Resueltos de Transferencia de CalorDocument10 pagesEjercicios Resueltos de Transferencia de CalordeibissotoNo ratings yet

- MATERIAL Mechanical DesignDocument13 pagesMATERIAL Mechanical DesignSchaieraNo ratings yet

- Gambar Skema HE: Example 12.1Document5 pagesGambar Skema HE: Example 12.1FarisNo ratings yet

- Solutions Asgn-1,2 2Document4 pagesSolutions Asgn-1,2 2razakhanNo ratings yet

- Perancangan Alat ProsesDocument3 pagesPerancangan Alat ProsesIndra watiNo ratings yet

- Sol HW9Document6 pagesSol HW9Jao Wei KuangNo ratings yet

- Ch10waste WaterDocument29 pagesCh10waste WaterAljebre Mohmed67% (3)

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Solution For Assignment1Document13 pagesSolution For Assignment1hamadamjad047No ratings yet

- Fluid Mechanics d203 ReseniDocument90 pagesFluid Mechanics d203 ReseniDennys Fabricio Ramirez100% (1)

- Diffusion and Conduction Problem SolvingDocument8 pagesDiffusion and Conduction Problem Solvingmendoza21203831mNo ratings yet

- CHE4162 Particle Technology November 2010 Exam SolutionsDocument14 pagesCHE4162 Particle Technology November 2010 Exam SolutionsPa1 Kumar MNo ratings yet

- HW 7Document15 pagesHW 7r8chel100% (4)

- Shell Tube Design ReactorDocument9 pagesShell Tube Design ReactorSanjeevNo ratings yet

- Solutions To CL 444 Tests Test 1Document10 pagesSolutions To CL 444 Tests Test 1Sumit VermaNo ratings yet

- Experiment Simulation Exercise Report No. 1Document9 pagesExperiment Simulation Exercise Report No. 1Thalia RodriguezNo ratings yet

- The Health Physics Solution Manual (246-280)Document35 pagesThe Health Physics Solution Manual (246-280)omarNo ratings yet

- LE2 Review PDFDocument2 pagesLE2 Review PDFJulian de LaraNo ratings yet

- 25 - Tutorial 5Document16 pages25 - Tutorial 5Mihir KordeNo ratings yet

- ME3122E - Tutorial Solution 3Document8 pagesME3122E - Tutorial Solution 3LinShaodun100% (3)

- Lecture 5Document39 pagesLecture 5Dany LoboNo ratings yet

- Delhi Technological University: Heat and Mass Transfer (ME-302) Group: M4Document190 pagesDelhi Technological University: Heat and Mass Transfer (ME-302) Group: M4Subhash SharmaNo ratings yet

- Heat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Document15 pagesHeat Exchangers: The Effectiveness - NTU Method: Sections 11.4 Through 11.7Joli SmithNo ratings yet

- Transfer Matrix Method For Dual Chamber by MihaiDocument7 pagesTransfer Matrix Method For Dual Chamber by MihaiaruatscribdNo ratings yet

- Chemical Engineering DepartmentDocument18 pagesChemical Engineering Departmentiffat100% (1)

- Gas LooplinestptDocument64 pagesGas Looplinestptniyo7No ratings yet

- Example CoagulFloccu1Document3 pagesExample CoagulFloccu1Adarsh Agrawal100% (3)

- Module 8: Solved ProblemsDocument11 pagesModule 8: Solved ProblemscaptainhassNo ratings yet

- Solutions To Chapter27Document18 pagesSolutions To Chapter27AladdinSultanAlTamimiNo ratings yet

- Saet 1 BDocument9 pagesSaet 1 BnaefmubarakNo ratings yet

- Ejercicios Calor ExamenDocument4 pagesEjercicios Calor ExamenAlexander Yauri Gomez50% (2)

- Answer Bfc10403-Sem1.20142015Document15 pagesAnswer Bfc10403-Sem1.20142015Syihabuddin Yusoff100% (3)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Chapter 8 - TutorialDocument4 pagesChapter 8 - TutorialDavidNo ratings yet

- Transfderencia de CalorDocument1 pageTransfderencia de CalorDavid Cj AcNo ratings yet

- Problem 8.3: u p f L 2D Δ = P pV p D 4 u = Δ = Δ &Document14 pagesProblem 8.3: u p f L 2D Δ = P pV p D 4 u = Δ = Δ &Siva PrasadNo ratings yet

- A House Built On A Riverside...Document8 pagesA House Built On A Riverside...ErsanİmamoğullarıNo ratings yet

- Dyn AssignmentDocument8 pagesDyn AssignmentTekle AschuNo ratings yet

- Solved Example of CH-3Document13 pagesSolved Example of CH-3Abubeker AreboNo ratings yet

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MNo ratings yet

- Assignment 2 SolDocument9 pagesAssignment 2 SolNickshan NahenthiramNo ratings yet

- Laporan FIlter PressDocument10 pagesLaporan FIlter PressDwizky WijayaNo ratings yet

- Problem 7.2Document6 pagesProblem 7.2Yufandi FandyNo ratings yet

- Final Compilation of Assing 3 - Vignes ShanmuganathanDocument28 pagesFinal Compilation of Assing 3 - Vignes ShanmuganathanlibbissujessyNo ratings yet

- Electrochemical Processes in Biological SystemsFrom EverandElectrochemical Processes in Biological SystemsAndrzej LewenstamNo ratings yet

- sm9 012Document2 pagessm9 012Sadie HnatowNo ratings yet

- CH 14Document82 pagesCH 14Sadie Hnatow75% (4)

- CH 14Document82 pagesCH 14Sadie Hnatow75% (4)

- sm9 010Document1 pagesm9 010Sadie HnatowNo ratings yet

- sm9 009Document1 pagesm9 009Sadie HnatowNo ratings yet

- sm9 011Document1 pagesm9 011Sadie HnatowNo ratings yet

- sm9 008Document1 pagesm9 008Sadie HnatowNo ratings yet

- sm9 001Document1 pagesm9 001Sadie HnatowNo ratings yet

- sm8 123Document1 pagesm8 123Sadie HnatowNo ratings yet

- sm9 006Document1 pagesm9 006Sadie HnatowNo ratings yet

- sm9 004Document1 pagesm9 004Sadie HnatowNo ratings yet

- sm9 003Document1 pagesm9 003Sadie HnatowNo ratings yet

- sm9 005Document1 pagesm9 005Sadie HnatowNo ratings yet

- sm9 007Document1 pagesm9 007Sadie HnatowNo ratings yet

- sm9 002Document1 pagesm9 002Sadie HnatowNo ratings yet

- sm8 129Document2 pagessm8 129Sadie HnatowNo ratings yet

- sm8 128Document1 pagesm8 128Sadie HnatowNo ratings yet

- sm8 125Document1 pagesm8 125Sadie HnatowNo ratings yet

- sm8 127Document2 pagessm8 127Sadie HnatowNo ratings yet

- sm8 122Document3 pagessm8 122Sadie HnatowNo ratings yet

- sm8 124Document2 pagessm8 124Sadie HnatowNo ratings yet

- sm8 126Document1 pagesm8 126Sadie HnatowNo ratings yet

- sm8 121Document1 pagesm8 121Sadie HnatowNo ratings yet

- sm8 116Document2 pagessm8 116Sadie HnatowNo ratings yet

- sm8 114Document2 pagessm8 114Sadie HnatowNo ratings yet

- sm8 120Document1 pagesm8 120Sadie HnatowNo ratings yet

- sm8 119Document1 pagesm8 119Sadie HnatowNo ratings yet

- sm8 118Document1 pagesm8 118Sadie HnatowNo ratings yet

- sm8 115Document3 pagessm8 115Sadie HnatowNo ratings yet

- Photolysis Study by FtirDocument8 pagesPhotolysis Study by FtirrakibhossainNo ratings yet

- 2SV888 DatasheetDocument4 pages2SV888 DatasheetsegalignoNo ratings yet

- Catalyst (DMC Type)Document3 pagesCatalyst (DMC Type)Visarut RujirawanichNo ratings yet

- Atoms Pyq 2023Document10 pagesAtoms Pyq 2023SREE GANESHNo ratings yet

- 1525950185module-2 Unit5 COM-IDocument8 pages1525950185module-2 Unit5 COM-ISimranNo ratings yet

- Irf 9520 NDocument9 pagesIrf 9520 NislaNo ratings yet

- Mech-Project Report of VwatDocument50 pagesMech-Project Report of VwatOscar Reyes RodríguezNo ratings yet

- Paper-2: Cumulative Test-1 (Ct-1)Document44 pagesPaper-2: Cumulative Test-1 (Ct-1)vikram2002No ratings yet

- Pile Testing PresentationDocument59 pagesPile Testing PresentationAHMAD YAGHI75% (4)

- Emulsions - Formation, Stability, Industrial Applications PDFDocument243 pagesEmulsions - Formation, Stability, Industrial Applications PDFsandy44 wankhade100% (4)

- 1 - General Chemistry (MANOR 2017)Document13 pages1 - General Chemistry (MANOR 2017)Michaela Berndt100% (1)

- KTR Rotex GS KaplinDocument26 pagesKTR Rotex GS KaplinrudyNo ratings yet

- Single Tension Fastener Away From Edges Based On ACI 318-02Document2 pagesSingle Tension Fastener Away From Edges Based On ACI 318-02civixxNo ratings yet

- Physics NotesDocument10 pagesPhysics NotesWavyBaconNo ratings yet

- Crushed Ore Agglomeration and Its Control For Heap Leach OperationsDocument18 pagesCrushed Ore Agglomeration and Its Control For Heap Leach Operationsmehra222100% (3)

- StoichiometryDocument5 pagesStoichiometryMiek67% (3)

- 4 Space Time SymmetriesDocument46 pages4 Space Time Symmetriesmcb0431703No ratings yet

- 14 Transformer PhasorsDocument13 pages14 Transformer PhasorsShahnawaz AhmadNo ratings yet

- Chemical Basis of LifeDocument9 pagesChemical Basis of LifeRem AlbarnNo ratings yet

- Crane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005Document38 pagesCrane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005yercNo ratings yet

- PDC Lecture Notes 7 - Stability of Closed-Loop Systems 2018Document56 pagesPDC Lecture Notes 7 - Stability of Closed-Loop Systems 2018R-A PascualNo ratings yet

- Es TG Module 2 Climate RevisedDocument23 pagesEs TG Module 2 Climate RevisedNikkieIrisAlbañoNovesNo ratings yet

- Atomic Model WorksheetDocument2 pagesAtomic Model WorksheetTelle Telle100% (1)

- Irradiation Effects in A Highly Irradiated Cold Worked Stainless SteelDocument11 pagesIrradiation Effects in A Highly Irradiated Cold Worked Stainless SteelW.t. HanNo ratings yet

- Lecture 3Document32 pagesLecture 3Quang TrườngNo ratings yet

- Cah2 + 2 H2O - 2 H2 + Ca (Oh) 2: Sig FigDocument4 pagesCah2 + 2 H2O - 2 H2 + Ca (Oh) 2: Sig FigDennis KimNo ratings yet

- Chemistry Final Exam Review KEY: Practice ProblemsDocument7 pagesChemistry Final Exam Review KEY: Practice ProblemsZetrix JensenNo ratings yet

- Kinetics of Catalytic Reactions: (Ch.5 Adsorption and Desorption Process)Document16 pagesKinetics of Catalytic Reactions: (Ch.5 Adsorption and Desorption Process)comeon2amNo ratings yet

- Molecular Weight & Polymer Solutions: Chemical and Bioengineering Konkuk UniversityDocument35 pagesMolecular Weight & Polymer Solutions: Chemical and Bioengineering Konkuk UniversityArraafi FadhillahNo ratings yet

- Sensors & Instrumentation Notes Unit-02Document47 pagesSensors & Instrumentation Notes Unit-02shivangi sharmaNo ratings yet