Professional Documents

Culture Documents

3-Automobile - IJAuERD - Design and - P. Nagarjuna

Uploaded by

TJPRC PublicationsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3-Automobile - IJAuERD - Design and - P. Nagarjuna

Uploaded by

TJPRC PublicationsCopyright:

Available Formats

International Journal of Automobile Engineering Research and Development (IJAuERD ) ISSN 2277-4785 Vol.

2, Issue 2 Sep 2012 22-33 TJPRC Pvt. Ltd.,

DESIGN AND OPTIMIZATION OF SHEET METAL CONTROL ARM FOR INDEPENDENT SUSPENSION SYSTEM

1

P. NAGARJUNA, 2K. DEVAKI DEVI & 3V. SIVA SUBRAMANIAN

1,2

G Pulla Reddy Engineering College, Kurnool, Andhra Pradesh, India.

3

Satyam-Venture, Hyderabad, India.

ABSTRACT

Suspension system of an automobile plays an important role in ensuring the stability of the automobile. Although it has been achieved to a considerable extent, another major aspect of suspension system is passenger car is luxury. A lot of research is going on in this direction, which led to the development of independent suspension system. Control arm plays a major role in independent suspension system. It is generally made of forged steel which has considerable disadvantages such as weight, cost etc.The project involves the development of sheet metal control arm, which has many advantages over forged metal. The component has been modeled using the curves extracted from workspace available in PRO-E. This model is translated into STEP file, which is than retrieved in Unigraphics for analysis. The model is subjected to different load conditions and thus analyzed using Structures P.E solver. The stress and stiffness of the model is studied from the results obtained from analysis to verify the success of the design

INTRODUCTION CONTROL ARM

Control arm is the major part of the independent suspension system. It forms connection between the wheel hub and the automobile chassis [9]. The main functions of control arm are: To form a rigid connection between the chassis and wheel hub, to which wheel is attached. It allows the wheel, the required degrees of freedom for proper steering and suspension abilities. It supports the spring and dampers, which form the major components for shock absorbing. To do these functions properly the control arm needs to sufficiently strong. Depending upon the position of the control arm, there are mainly two types of control arms, upper and lower control arm. The springs are and shock absorbers are supported between these arms, which prevents lateral movement of

23

Design and Optimization of Sheet Metal Control Arm for Independent Suspension System

springs. Conventionally the control arms are manufactured by the process of forging the medium carbon steels, which are sufficiently strong as shown in figure.10. This forged component is bulky and heavier accounting for an increase in vehicle weight. Moreover, the process of forging the control arm is a costlier process as it involves use of complex dies .it also needs a proper care in heating process so as not to effect the strength of the component.

LOWER CONTROL ARM Fig.1 : A Suspension System With Ball Joint And Control

FORGING OPERATION

Forging is the operation where the metal is heated and then a force is applied to manipulate the metal in such way that the required final shape is obtained. This is the oldest of the metal working processes [10].

FORGING TYPES

Smith forging: this is the traditional forging operation done openly or in open dies by the village black smith or modern shop floor by manual hammering or by power hammers. Drop forging: This operation done in closed impression dies by means of the drop hammer .Here the force shaping the component is applied in a series of blows. Press forging: Similar to drop forging, the press forging is also done in closed impression dies with the exception that the forces is continuous squeezing type applied by the hydraulic presses. Machine forging: Unlike the drop or press forging where the material drawn out, in machine forging, the material is upset to get the desired shape. manufactured by drop forging process. The control arms are mostly

P. Nagarjuna, K. Devaki Devi & V. Siva Subramanian

24

ADVANTAGES

Uniformity of qualities for parts subjected to high stress and loads. Close tolerances Speed of production DISADVANTAGES High tool cost High tool maintenance No core holes Limitations in size and shape

SHEET METAL OPERATION

The sheet metal operation basically involves the process of press working consists of shearing and then plastically working the metal to the desired finished shape and the size through a few quick strokes under heavy loads [11].

PRESS TOOL OPERATIONS

Shearing Tension Compression Tension and compression shearing, blanking, piercing, trimming, shaving. stretch forming coining, sizing, ironing, hobbing drawing, spinning, bending, forming and embossing

ADVANTAGES

It is one the cheapest and fastest way of complete manufacture of a component.

DISADVANTAGES

Sheet metal operations are generally performed on the sheets of thickness less than 5mm.

DESIGN OF CONTROL ARM

DESIGN CONSIDERATIONS: Space Strength Weight

25

Design and Optimization of Sheet Metal Control Arm for Independent Suspension System

Manufacturing feasibility Cost

DESIGN PROCEDURE

The design is mainly based on the consideration like decrease of weight and cost etc. The existing forged component is heavy and its manufacturing is complex. So in order to make more reliable it is replaced by sheet metal component which is light and involves more simple operations. The workspace for the design is extracted from the existing forged model. The design and modeling is done using CAD softwarePRO-E.To obtains the workspace the curves are extracted from the extreme edges of the workspace model and copied to a new file as shown in figure 15. Modeling is done using surfaces. Design with surfaces is simpler and complex shapes can be modeled using operations like merging, trim etc. After the creation of the model using surfaces the surface is thicken to 3.5mm using solid protrusion. The rod and washer are designed as per required dimensions. A standard ball joint of suitable dimension is modeled. The thickness of the sheet metal component is 3.5mm. Practically the ball joint and the rod are attached to the sheet metal component using wields. Sheet metal component can be manufactured by making two bends along with form operation and one roll operation. The design is improvised based on the analysis results and a final model is developed.

Fig.2: Existing Forged Model

P. Nagarjuna, K. Devaki Devi & V. Siva Subramanian

26

FIG.3:SHEET METAL CONTROL ARM

MANUFACTURING PROCESS

1. A flat blank is created from the design. 2. The blank is then subjected to vertical draw.

Fig.4 :Vertical Draw 1. Flange inside operation is performed; it is done in 2 to 3 stage.

Fig.5: Flange Inside 2. 3. The sheet is rolled on to the back rod using rolling punches. It is also performed in stages. Finally, holes are pierced in the component. 2 to 3

27

Design and Optimization of Sheet Metal Control Arm for Independent Suspension System

ANALYSIS

The final model is exported by step translator to a step file. The created step file is imported into Unigraphics software and converted to Unigraphics part file. Environment Analysis Linearity Time dependency Solver MESHING The model is meshed with tetrahedral 10 elements. The element is defined by ten nodes having three degrees of freedom at each node, translation in the nodal x, y, and z direction. The element also has plasticity creep, swelling, stress stiffening, large deflections and large strain capabilities. : : : : : Structures P.E./Linear Statics Plus Structural Linearity: Steady-state Structures P.E.

8 9

10

7 2

6

FIG .6: Tetrahedral Element 5

Fig.7 : Meshed Component

P. Nagarjuna, K. Devaki Devi & V. Siva Subramanian

28

Fig.8 : Rigid Links In Hole At the ball joint hole a central node is created and rigid links are created connecting between the central node and nodes created on the hole during meshing of the component. This is to make nearest to practicality .The point loads are applied at that central node. Number of elements created = 28276 Number of nodes created =53272

The analysis is carried for three different load conditions.

LOADS AND BOUNDARY CONDITIONS

The Model has been analyzed for the following load cases.

INCIDENTAL LOAD CASE

These loads act on the vehicle when it is subjected to high and sudden decelerating forces. LOADS Load (N) Fx 10910 Fy 4350

All the loads were applied at the point D.

BOUNDARY CONDITIONS

z translation fixed for point D. x, y, z translations fixed for point E1. y, z translations fixed for point E2.

29

Design and Optimization of Sheet Metal Control Arm for Independent Suspension System

MAXIMUM LOAD CASE

These load conditions are observed during regular operations of the vehicle.

Loads Load (N) Fx 7880 All the loads were applied at the point D. Fy 5860

BOUNDARY CONDITIONS

z translation fixed for point D. x, y, z translation and rotations fixed for point E1. x, y, z translation and rotations fixed for point E2.

STIFFNESS CALCULATIONS

Loads

Load (N) Fx 1000

All the loads were applied at the point D.

Fy 1000

BOUNDARY CONDITIONS

z translation fixed for point D. x,y,z translations fixed for point E1. y,z translations fixed for point E2.

MATERIAL PROPERTIES

Modulus of Elasticity =210000 MPa Poissons ratio = 0.3 Steel (safe stress = 540 MPa) It is finally solved using structures P.E solver .The results obtained are retrieved through post processor section.

P. Nagarjuna, K. Devaki Devi & V. Siva Subramanian

30

Housing

Point D

Sheet metal

X Point E1

Point E2

Washer

Fig.9 : Points Where Loads And Boundary Conditions To Be Applied

Bar

RESULTS AND DISCUSSIONS

INCIDENTAL LOAD CASE: The maximum stress observed during this case is 513 MPa The yield strength of the material is 540 MPa It is observed that, the stress obtained is less than the yield strength of material .So the control arm withstands the incidental loads. MAXIMUM LOAD CASE: The maximum stress observed during this case is 466 MPa The yield strength of the material is 540 MPa It is observed that, the stress obtained is less than the yield strength of material .So the control arm withstands the maximum loads. STIFFNESS LOAD CASE: Stiffness calculations: Stiffness=force/maximum deflection Kx=1000/.1439=5263N/mm

31

Design and Optimization of Sheet Metal Control Arm for Independent Suspension System

Ky=1000/.02643=37835N/mm Direction Kx Ky Objective Stiffness N/mm 3000 24000 Obtained Stiffness N/mm 5263 37835

From the stiffness calculations it is observed that, the control arm satisfies the stiffness requirements in X and Y-directions.

Fig.10 : Incident Load Case

Fig .11: Maximum Load Condition

P. Nagarjuna, K. Devaki Devi & V. Siva Subramanian

32

Fig.12 : Displacement (-X) In Y Direction

Fig.13 : Displacement (Z) In X Direction

CONCLUSIONS

From the design and analysis data, it is observed that The weight of the component is decreased by 25% i.e. the weight of the forged model is 4.32 kg and the weight of the sheet metal model is 3.23kg. Ease of manufacturing. The sheet metal operations are simple and cheap when compared to the forged operations. Ball joints of different standards can be used by varying the size of the hole by changing the piercing tool. The cost of component is reduced to a considerable extent as the raw material used for sheet metal component is very cheap than that used for forged component.

33

Design and Optimization of Sheet Metal Control Arm for Independent Suspension System

The results obtained from analysis infer that the sheet metal component satisfies all the design considerations. The stresses obtained for different load conditions are within the limits. Stiffness is observed to be satisfactory.

Hence, sheet metal control arm is more beneficial than forged control arm.

REFERENCES

1. .R.B.Gupta, Automobile Engineering, Satya Prakash publications, 6th edition, 2003 2. 3. 4. 5. 6. 7. 8. 9. Herb Adams, Chassis Engineering, Berkley publishing group, Newyork, 1993. www.leafukcar.com Kirpal Singh, Automobile Engineering, Standarad publishers, vol 1, 1998. www.tetra.com www.ukcar.com K.K Jain, and R.B.Asthana, Automobile Engineering.Danpathrai publications. Heinz Heisler, Modern Automobile Engineering, McGraw Hill publishers, 2001. J.Reimpell, H.Stoll, J.W.Betzler, The Automotive Chassis, SAE International, 2nd edition, 2001. 10. P.N. Rao, Manufacturing TechnologyTATA McGraw Hill publishing company, 7th edition, 1987, pp 261-284. 11. Hajra Choudhury, Work Shop Technology, Media promoters and publishers, 10th edition, 2000, pp 608-620. 12. www.PTC.com , www.unigraphics.com, www.eds.com

You might also like

- Flame Retardant Textiles For Electric Arc Flash Hazards: A ReviewDocument18 pagesFlame Retardant Textiles For Electric Arc Flash Hazards: A ReviewTJPRC PublicationsNo ratings yet

- 2 44 1653632649 1ijprjun20221Document20 pages2 44 1653632649 1ijprjun20221TJPRC PublicationsNo ratings yet

- Baluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaDocument14 pagesBaluchari As The Cultural Icon of West Bengal: Reminding The Glorious Heritage of IndiaTJPRC PublicationsNo ratings yet

- 2 29 1645708157 2ijtftjun20222Document8 pages2 29 1645708157 2ijtftjun20222TJPRC PublicationsNo ratings yet

- Comparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanDocument8 pagesComparative Study of Original Paithani & Duplicate Paithani: Shubha MahajanTJPRC PublicationsNo ratings yet

- 2 51 1656420123 1ijmpsdec20221Document4 pages2 51 1656420123 1ijmpsdec20221TJPRC PublicationsNo ratings yet

- 2 52 1649841354 2ijpslirjun20222Document12 pages2 52 1649841354 2ijpslirjun20222TJPRC PublicationsNo ratings yet

- Development and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateDocument10 pagesDevelopment and Assessment of Appropriate Safety Playground Apparel For School Age Children in Rivers StateTJPRC PublicationsNo ratings yet

- 2 4 1644229496 Ijrrdjun20221Document10 pages2 4 1644229496 Ijrrdjun20221TJPRC PublicationsNo ratings yet

- 2 33 1641272961 1ijsmmrdjun20221Document16 pages2 33 1641272961 1ijsmmrdjun20221TJPRC PublicationsNo ratings yet

- Vitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019Document16 pagesVitamin D & Osteocalcin Levels in Children With Type 1 DM in Thi - Qar Province South of Iraq 2019TJPRC PublicationsNo ratings yet

- Self-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsDocument8 pagesSelf-Medication Prevalence and Related Factors Among Baccalaureate Nursing StudentsTJPRC PublicationsNo ratings yet

- Using Nanoclay To Manufacture Engineered Wood Products-A ReviewDocument14 pagesUsing Nanoclay To Manufacture Engineered Wood Products-A ReviewTJPRC PublicationsNo ratings yet

- 2 51 1651909513 9ijmpsjun202209Document8 pages2 51 1651909513 9ijmpsjun202209TJPRC PublicationsNo ratings yet

- 2 51 1647598330 5ijmpsjun202205Document10 pages2 51 1647598330 5ijmpsjun202205TJPRC PublicationsNo ratings yet

- An Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaDocument10 pagesAn Observational Study On-Management of Anemia in CKD Using Erythropoietin AlphaTJPRC PublicationsNo ratings yet

- Dr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahDocument12 pagesDr. Gollavilli Sirisha, Dr. M. Rajani Cartor & Dr. V. Venkata RamaiahTJPRC PublicationsNo ratings yet

- Covid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangDocument8 pagesCovid-19: The Indian Healthcare Perspective: Meghna Mishra, Dr. Mamta Bansal & Mandeep NarangTJPRC PublicationsNo ratings yet

- Effect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementDocument8 pagesEffect of Degassing Pressure Casting On Hardness, Density and Tear Strength of Silicone Rubber RTV 497 and RTV 00A With 30% Talc ReinforcementTJPRC PublicationsNo ratings yet

- A Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)Document8 pagesA Review of "Swarna Tantram"-A Textbook On Alchemy (Lohavedha)TJPRC PublicationsNo ratings yet

- Effectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewDocument14 pagesEffectiveness of Reflexology On Post-Operative Outcomes Among Patients Undergoing Cardiac Surgery: A Systematic ReviewTJPRC PublicationsNo ratings yet

- Analysis of Bolted-Flange Joint Using Finite Element MethodDocument12 pagesAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsNo ratings yet

- 2 67 1644220454 Ijmperdfeb202206Document9 pages2 67 1644220454 Ijmperdfeb202206TJPRC PublicationsNo ratings yet

- 2 67 1653022679 1ijmperdjun202201Document12 pages2 67 1653022679 1ijmperdjun202201TJPRC PublicationsNo ratings yet

- 2 67 1641277669 4ijmperdfeb202204Document10 pages2 67 1641277669 4ijmperdfeb202204TJPRC PublicationsNo ratings yet

- Numerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingDocument18 pagesNumerical Analysis of Intricate Aluminium Tube Al6061T4 Thickness Variation at Different Friction Coefficient and Internal Pressures During BendingTJPRC PublicationsNo ratings yet

- Next Generation'S Energy and Time Efficient Novel Pressure CookerDocument16 pagesNext Generation'S Energy and Time Efficient Novel Pressure CookerTJPRC PublicationsNo ratings yet

- 2 67 1645871199 9ijmperdfeb202209Document8 pages2 67 1645871199 9ijmperdfeb202209TJPRC PublicationsNo ratings yet

- Comparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsDocument22 pagesComparative Fe Analysis of Automotive Leaf Spring Using Composite MaterialsTJPRC PublicationsNo ratings yet

- 2 67 1640070534 2ijmperdfeb202202Document14 pages2 67 1640070534 2ijmperdfeb202202TJPRC PublicationsNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Composite Bridge Assessment To BD61.10Document5 pagesComposite Bridge Assessment To BD61.10stavros_stergNo ratings yet

- Chem 1 The Mole Practice QuizDocument4 pagesChem 1 The Mole Practice QuizDiyanaNadiahTojimanNo ratings yet

- Ficha Tecnica Acido SorbicoDocument1 pageFicha Tecnica Acido SorbicoCarlos SiuNo ratings yet

- Liquid Ferric Sulfate Product Data Sheet: DescriptionDocument1 pageLiquid Ferric Sulfate Product Data Sheet: DescriptionAnastasijaNo ratings yet

- Pipe and Equipment Install Manual (Pyrogel)Document4 pagesPipe and Equipment Install Manual (Pyrogel)EdinsonNo ratings yet

- Lab Report - Part A: Kanvasree Vuyyuru (C2084903)Document8 pagesLab Report - Part A: Kanvasree Vuyyuru (C2084903)suryaNo ratings yet

- SCL Instruction Manual R2 09 18 PDFDocument28 pagesSCL Instruction Manual R2 09 18 PDFCLAUDIONo ratings yet

- Report SedimentaryDocument6 pagesReport SedimentaryKerol Kerol KerolNo ratings yet

- Jitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetDocument23 pagesJitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetabhishekNo ratings yet

- Ibrahim Ahmadzai Syn CorrectedDocument10 pagesIbrahim Ahmadzai Syn CorrectedzahidNo ratings yet

- Roxas PWD BuildingDocument32 pagesRoxas PWD BuildingDennis SariegoNo ratings yet

- Rate-Determining Mechanisms For The Adsorption of Gold Di-Cyanide Onto Activated CarbonDocument10 pagesRate-Determining Mechanisms For The Adsorption of Gold Di-Cyanide Onto Activated CarbonInfernuzNo ratings yet

- Paint Chip AnalysisDocument11 pagesPaint Chip AnalysisIlyana ShalahudinNo ratings yet

- D 6641 - D 6641M - 01 - Rdy2ndevrdy2ndfn PDFDocument9 pagesD 6641 - D 6641M - 01 - Rdy2ndevrdy2ndfn PDFstaedtlerpNo ratings yet

- Jar Test Result ExcelDocument11 pagesJar Test Result ExcelMuhammad NuruddinNo ratings yet

- 157 - OreOre Deposit Geology (John Ridley, 2013)Document3 pages157 - OreOre Deposit Geology (John Ridley, 2013)hugoluis_hNo ratings yet

- The Behaviour of Organic Compounds in Sulphuric Acid PDFDocument27 pagesThe Behaviour of Organic Compounds in Sulphuric Acid PDFTazkiyatan IsriaNo ratings yet

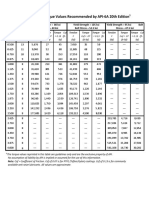

- Flange Bolting Torque Values API 6ADocument1 pageFlange Bolting Torque Values API 6Aparthameister100% (1)

- Blue FairwayDocument15 pagesBlue FairwayIsidro P. BuquironNo ratings yet

- Sources of Water On Concrete StrengthDocument5 pagesSources of Water On Concrete StrengthAmadu FarrowNo ratings yet

- BOQ - Secondary ContainmentDocument3 pagesBOQ - Secondary Containmentrehan7777No ratings yet

- 1 Memoriu Tehnic CS enDocument219 pages1 Memoriu Tehnic CS enIuly AnaNo ratings yet

- Civ E398 Mid 2 Fall 14Document10 pagesCiv E398 Mid 2 Fall 14Rajat GuptaNo ratings yet

- HWDP 6 5-8 - 8 1-2 OD X 4 1-2 ID PDFDocument2 pagesHWDP 6 5-8 - 8 1-2 OD X 4 1-2 ID PDFEdson Aguilar HerreraNo ratings yet

- Design of Well FoundationDocument31 pagesDesign of Well FoundationAshish Karki97% (32)

- Structural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersDocument3 pagesStructural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersBoby CuliusNo ratings yet

- Chapter 2Document9 pagesChapter 2Behar AbdurahemanNo ratings yet

- Asme Section IxDocument71 pagesAsme Section Ixranjitkumar1977100% (2)

- BW Cleaner+401 en 2022 GL 151 PreviewDocument2 pagesBW Cleaner+401 en 2022 GL 151 PreviewDeivid MiquelinoNo ratings yet

- Boeco Mantas de CalentamientoDocument2 pagesBoeco Mantas de CalentamientoJhon VallejoNo ratings yet